Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chevrolet

Caricato da

AminadavCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chevrolet

Caricato da

AminadavCopyright:

Formati disponibili

TABLE OF CONTENTS

SPECIAL FEATURES OF THE SYSTEM I

REMOVING / REFITTING SYSTEM COMPONENTS II

2 py

01 o

/2 C

02 nce

APPENDICES III

va

Ad

Produced and published by:

Delphi France SAS

Diesel Aftermarket

12 - 14 Boulevard de l’industrie Tel: (+33) (0) 2 54 55 39 39

41042 Blois Cedex Fax: (+33) (0) 2 54 55 39 12

France http://www.delphi.com/am

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 i

I SPECIAL FEATURES OF THE SYSTEM

TABLE OF CONTENTS

1. CHEVROLET Z20D Z22D ENGINE SPECIFICATIONS

1.1 Z20D/Z22D Engine Specifications................................................................................................................................1-1

2. PARTS SUPPLIED BY DELPHI

2.1 High pressure pump ....................................................................................................................................................2-3

2.1.1 DFP3.2 high pressure pump........................................................................................................................2-3

2.1.2 Inlet metering valve (IMV)...........................................................................................................................2-4

2.1.3 HP outlet........................................................................................................................................................2-4

2.1.4 Pressure limiter............................................................................................................................................2-5

2.1.5 LP unions......................................................................................................................................................2-5

2.1.6 Venturi...........................................................................................................................................................2-6

2.2 Rail .................................................................................................................................................................................2-7

2.2.1 Tubular rail....................................................................................................................................................2-7

2.2.2 Rail pressure sensor (HPS)..........................................................................................................................2-8

2.3 Injectors..........................................................................................................................................................................2-8

2.4 DCU..............................................................................................................................................................................2-10

2 py

3. PARTS NOT SUPPLIED BY DELPHI

3.1 HP pipes.......................................................................................................................................................................3-11

01 o

3.2 Filter..............................................................................................................................................................................3-11

/2 C

3.2.1 Diesel filter..................................................................................................................................................3-12

3.2.2 Fuel temperature sensor............................................................................................................................3-12

02 nce

3.2.3 Water detector............................................................................................................................................3-12

3.2.4 Heater..........................................................................................................................................................3-13

3.3 Electric Priming Pump................................................................................................................................................3-13

4. SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

va

4.1 Fuel Supply/Air Supply...............................................................................................................................................4-15

4.2 Electrical supply..........................................................................................................................................................4-16

4.2.1 Switch on DCU...........................................................................................................................................4-16

Ad

4.2.2 Sensor supply.............................................................................................................................................4-17

4.3 The Immobiliser..........................................................................................................................................................4-17

4.3.1 Function......................................................................................................................................................4-17

4.3.2 Communication between the immobiliser and the DCU........................................................................4-17

4.3.3 Functional description...............................................................................................................................4-18

4.3.4 Replacing the DCU.....................................................................................................................................4-18

4.3.5 Synchronising the DCU and the immobiliser..........................................................................................4-18

4.3.6 Reading immobiliser faults.......................................................................................................................4-18

4.4 Diagnostics..................................................................................................................................................................4-19

4.4.1 Diagnostic communication........................................................................................................................4-19

4.4.2 Diagnostic socket.......................................................................................................................................4-19

4.5 Dashboard warning LEDs...........................................................................................................................................4-20

4.5.1 Description..................................................................................................................................................4-20

4.5.2 The fault LED..............................................................................................................................................4-20

4.5.3 Preheating LED...........................................................................................................................................4-21

4.5.4 Immobiliser light........................................................................................................................................4-21

4.5.5 Presence of water in the diesel filter LED.................................................................................................4-21

4.6 DCU Inputs/Outputs....................................................................................................................................................4-23

© Delphi

ii DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

TABLE OF CONTENTS

4.7 Pre-post heating..........................................................................................................................................................4-26

4.7.1 Function......................................................................................................................................................4-26

4.7.2 Control circuit.............................................................................................................................................4-26

4.7.3 Preheating...................................................................................................................................................4-26

4.7.4 Postheating.................................................................................................................................................4-26

4.7.5 Diagnostics.................................................................................................................................................4-27

4.8 Engine cooling.............................................................................................................................................................4-27

4.8.1 Function......................................................................................................................................................4-27

4.8.2 Control circuit.............................................................................................................................................4-27

4.8.3 Control strategy..........................................................................................................................................4-28

4.9 Particle filter.................................................................................................................................................................4-28

4.9.1 Particle filter................................................................................................................................................4-28

4.9.2 Particle filter differential pressure sensor................................................................................................4-29

4.10 EGR management.......................................................................................................................................................4-29

4.10.1 Principle......................................................................................................................................................4-29

2 py

4.10.2 Function......................................................................................................................................................4-29

4.10.3 EGR setting.................................................................................................................................................4-30

4.10.4 EGR valve....................................................................................................................................................4-30

4.10.5

01 o

Throttle Valve.............................................................................................................................................4-31

/2 C

4.10.6 Swirl valve..................................................................................................................................................4-31

4.10.7 EGR Cooler Bypass....................................................................................................................................4-32

4.10.8 Air flowmeter..............................................................................................................................................4-32

02 nce

4.11 Air conditioning (AC) checks......................................................................................................................................4-32

4.11.1 Function......................................................................................................................................................4-32

4.11.2 Components...............................................................................................................................................4-32

4.11.3 Compressor control circuit........................................................................................................................4-33

va

4.11.4 Compressor activation...............................................................................................................................4-34

4.11.5 Air conditioning request............................................................................................................................4-34

Ad

4.12 The water heaters........................................................................................................................................................4-34

4.12.1 Function......................................................................................................................................................4-34

4.12.2 Control circuit.............................................................................................................................................4-34

4.12.3 Control strategy..........................................................................................................................................4-35

4.13 The CAN.......................................................................................................................................................................4-35

4.13.1 Function......................................................................................................................................................4-35

4.13.2 Description..................................................................................................................................................4-35

4.13.3 Fault type....................................................................................................................................................4-36

4.14 Camshaft sensor..........................................................................................................................................................4-37

4.15 Crankshaft sensor........................................................................................................................................................4-37

4.16 Accelerometer sensor.................................................................................................................................................4-37

4.17 Pedal sensor Double track..........................................................................................................................................4-39

4.17.1 Function......................................................................................................................................................4-39

4.17.2 Measuring circuit........................................................................................................................................4-39

4.17.3 Pedal position calculation..........................................................................................................................4-40

4.18 Vehicle Cruise Control / Speed Limiter......................................................................................................................4-40

4.18.1 Function......................................................................................................................................................4-40

4.18.2 Control circuit.............................................................................................................................................4-40

4.18.3 Control strategy..........................................................................................................................................4-40

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 iii

I SPECIAL FEATURES OF THE SYSTEM

TABLE OF CONTENTS

4.19 Clutch switches............................................................................................................................................................4-42

4.19.1 Function......................................................................................................................................................4-42

4.20 Brake pedal switch(es)................................................................................................................................................4-42

4.20.1 Function......................................................................................................................................................4-42

4.20.2 Description..................................................................................................................................................4-42

4.21 Turbocharging Pressure Control................................................................................................................................4-43

4.21.1 VGT boost pressure control......................................................................................................................4-43

4.22 Temperature sensors..................................................................................................................................................4-44

4.22.1 Coolant temperature..................................................................................................................................4-44

4.22.2 Fuel temperature........................................................................................................................................4-45

4.22.3 Boost air temperature................................................................................................................................4-45

4.22.4 Pre - VGT exhaust gas temperature..........................................................................................................4-46

4.22.5 Pre - catalyser exhaust gas temperature..................................................................................................4-46

4.22.6 Pre - DPF exhaust gas temperature..........................................................................................................4-47

4.23 Oxygen probe..............................................................................................................................................................4-47

2 py

4.23.1 Oxygen probe.............................................................................................................................................4-47

4.23.2 Oxygen probe heater.................................................................................................................................4-47

5. COMPONENT PLACEMENT

01 o

5.1 Component location ...................................................................................................................................................5-49

/2 C

5.1.1 Engine compartment.................................................................................................................................5-49

5.1.2 Passenger compartment ...........................................................................................................................5-50

02 nce

va

Ad

© Delphi

iv DDNX384(EN) - Issue 1 of 12/2011

REMOVING / REFITTING SYSTEM COMPONENTS II

TABLE OF CONTENTS

6. SUMMARIES

6.1 Cleanliness conditions................................................................................................................................................6-51

6.2 Plugs and Caps............................................................................................................................................................6-52

6.3 Fuel Filter.....................................................................................................................................................................6-53

6.4 Rail/Injector high pressure pipe.................................................................................................................................6-54

6.5 Injector.........................................................................................................................................................................6-55

6.6 Rail................................................................................................................................................................................6-57

6.7 Pump/Rail high pressure pipe....................................................................................................................................6-58

6.8 High pressure pump...................................................................................................................................................6-59

6.9 Venturi..........................................................................................................................................................................6-61

6.10 Inlet metering valve (IMV)..........................................................................................................................................6-62

6.11 Fuel temperature sensor.............................................................................................................................................6-64

6.12 DCU..............................................................................................................................................................................6-65

6.13 Torque settings............................................................................................................................................................6-66

6.14 Schedule......................................................................................................................................................................6-67

2 py

7. PRELIMINARY OPERATIONS

8. REMOVING/REFITTING THE FUEL FILTER

01 o

8.1 Removing the filter......................................................................................................................................................8-71

/2 C

8.1.1 SUV..............................................................................................................................................................8-71

8.1.2 Saloon/PCV.................................................................................................................................................8-72

02 nce

8.2 Preparing the filter......................................................................................................................................................8-72

8.3 Refitting the filter.........................................................................................................................................................8-72

9. REMOVING/REFITTING THE RAIL/INJECTOR HIGH PRESSURE PIPES

9.1 Removing the rail/Injector high pressure pipe ........................................................................................................9-73

va

9.2 Preparing the rail/Injector high pressure pipe .........................................................................................................9-74

9.3 Refitting the rail/Injector high pressure pipe............................................................................................................9-74

Ad

10. REMOVING / REFITTING AN INJECTOR

10.1 Removing the injector...............................................................................................................................................10-75

10.2 Preparing an injector.................................................................................................................................................10-76

10.3 Refitting the injector..................................................................................................................................................10-77

11. REMOVING / REFITTING RAIL

11.1 Removing the rail......................................................................................................................................................11-79

11.2 Preparing the Rail......................................................................................................................................................11-80

11.3 Refitting the Rail........................................................................................................................................................11-80

12. REMOVING/REFITTING THE HIGH PRESSURE PUMP AND ASSOCIATED COMPONENTS

12.1 Removing/Refitting the HP pump/Rail HP pipe.......................................................................................................12-81

12.1.1 Removing the pump/rail HP pipe ...........................................................................................................12-81

12.1.2 Preparing the pump/rail HP pipe.............................................................................................................12-82

12.1.3 Refitting the pump/rail HP pipe...............................................................................................................12-82

12.2 Removing/Refitting the Venturi................................................................................................................................12-82

12.3 Removing/Refitting the IMV.....................................................................................................................................12-82

12.3.1 Removing the IMV....................................................................................................................................12-83

12.3.2 Preparing the IMV....................................................................................................................................12-84

12.3.3 Refitting the IMV.......................................................................................................................................12-84

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 v

II REMOVING / REFITTING SYSTEM COMPONENTS

TABLE OF CONTENTS

12.4 Removing/Refitting the fuel temperature sensor...................................................................................................12-85

12.4.1 Removing the fuel temperature sensor..................................................................................................12-85

12.4.2 Preparing the fuel temperature sensor..................................................................................................12-85

12.4.3 Refitting the fuel temperature sensor.....................................................................................................12-85

12.5 Removing/refitting the High Pressure Pump. ........................................................................................................12-87

12.5.1 Removing the HP pump...........................................................................................................................12-87

12.5.2 Preparing the HP pump ..........................................................................................................................12-90

12.5.3 Refitting the HP pump..............................................................................................................................12-90

13. REMOVING/REFITTING THE DCU

13.1 Removing the DCU....................................................................................................................................................13-93

13.2 Preparing the DCU....................................................................................................................................................13-93

13.3 REFITTING THE DCU.................................................................................................................................................13-94

2 py

01 o

/2 C

02 nce

va

Ad

© Delphi

vi DDNX384(EN) - Issue 1 of 12/2011

APPENDICES III

TABLE OF CONTENTS

14. REFERENCE VALUES

14.1 Reference values.......................................................................................................................................................14-95

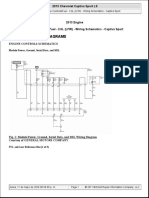

15. WIRING DIAGRAM

15.1 Wiring diagram........................................................................................................................................................15-101

15.1.1 Wiring diagram - 96 pin connector.......................................................................................................15-101

15.1.2 Wiring diagram - 58 pin connector.......................................................................................................15-102

16. TOOLING

16.1 Tooling required......................................................................................................................................................16-103

16.1.1 Special tooling........................................................................................................................................16-103

16.1.2 Standard tooling.....................................................................................................................................16-103

16.1.3 Consumables summary.........................................................................................................................16-105

16.1.4 Repair harness range.............................................................................................................................16-105

17. ABBREVIATIONS

17.1 Abbreviations/Descriptions....................................................................................................................................17-107

2 py

01 o

/2 C

02 nce

va

Ad

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 vii

III APPENDICES

TABLE OF CONTENTS

2 py

01 o

/2 C

02 nce

va

Ad

© Delphi

viii DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

CHEVROLET Z20D Z22D ENGINE SPECIFICATIONS

This manual presents the specific features of the Common Rail injection system fitted on the Z20D and Z22D engines

fitted to CHEVROLET vehicles and all information relating to fault finding.

The DELPHI Common Rail injection system is described in the Common Rail Manual "Operating Principles" binder :

DDGX200B".

1.1 Z20D/Z22D Engine Specifications

2 py

01 o

/2 C

02 nce

va

CAPTIVA Z22D Euro V

Ad

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 1-1

I SPECIAL FEATURES OF THE SYSTEM

CHEVROLET Z20D Z22D ENGINE SPECIFICATIONS

2 py

01 o

/2 C

CRUZE Z20D Euro V / ORLANDO Z20D Euro V

02 nce

Z20D Z22D

Layout 4 in-line cylinders with direct injection

va

Layout Transverse

Cubic capacity 1,998 cm3 2,231 cm3

Ad

Bore x stroke 86 x 86 mm 86 x 96 mm

Number of valves 4

per cylinder

Timing Two overhead camshafts driven by a chain

Inlet air cooling Air/Air exchanger

Turbocharging By variable geometry turbocharger

Maximum power 130(bhp) at 3800 163(bhp) at 3800 rpm 163(bhp) at 3800 rpm 184(bhp) at 3800 rpm

rpm

Maximum torque 315 Nm at 2750 rpm 360 Nm at 2750 rpm 360 Nm at 2750 rpm 400 Nm at 2750 rpm

Maximum no load 4800 rpm

engine speed

Compression ratio 16.3

© Delphi

1-2 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS SUPPLIED BY DELPHI

DELPHI supplies the following original fitment parts:

• The HP pump with a filling actuator(IMV), a venturi and a pressure limiter.

• A tubular rail with a rail pressure sensor.

• Four injectors.

• A DCU.

2.1 High pressure pump

Operation:

The fuel sent to the pump is controlled by a filling actuator known as the Inlet Metering Valve (IMV). High pressure is

generated by a DFP3.2 type HP pump. The pressure is then stored in a rail and sent to the injectors via HP pipes.

The filling actuator (IMV) is fed by an electric priming pump in the fuel tank.

A venturi incorporated in the pump body regulates the vacuum in the injector return circuit.

The integrated high pressure pump :

2 py

• A pressure stage managed by an IMV.

• A pressure limiter

• A venturi.

01 o

/2 C

2.1.1 DFP3.2 high pressure pump

02 nce

The pump has the following inlets/outlets :

• Fuel inlet.

• High pressure outlet (rail supply).

• Low pressure outlet (fuel return).

va

Specifications :

High pressure pump

Ad

• Pumping chamber : 0.97 cm3/pump

revolution.

• High pressure regulation by the IMV.

• Integrated pressure limiter (see paragraph

on Pressure limiter).

• Oldham coupling.

• Drive ratio 1/2.

• Maximum speed 2700 rpm (peaks to 3500

rpm).

• External temperature range : -30°C to +120°C.

The high pressure fuel generated by the HP pump is stored in the tubular injection rail and redistributed via HP

pipes to the injectors.

It is driven via an Oldham coupling on the pump drive shaft.

The pressure can be checked using the H3PI kit YDT278, YDT410 and the HP-T kit YDT465.

CAUTION

For all operations, all openings must be plugged using clean plugs from the dispenser YDT480.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 2-3

I SPECIAL FEATURES OF THE SYSTEM

PARTS SUPPLIED BY DELPHI

2.1.2 Inlet metering valve (IMV)

The IMV regulates the quantity of fuel delivered to

the HP pump pumping elements to control the

pressure in the rail.

Specifications :

• Supply voltage : +Vbat.

• Control signal : PWM between 300 Hz and

2000 Hz depending on rpm.

• Nominal control current : between 0 and 1.3

A.

• Maximum current : 1.6 A.

• Resistance : 5.3 Ω at 20 .

It is located on the pump. Diagnostics can be carried

out with the kit YDT330B.

2 py

The pressure can be checked using the H3PI kit

YDT278, YDT410 and the HP-T kit YDT465.

2.1.3 HP outlet

01 o

/2 C

The pump has a high pressure connector to connect

it to the rail via a 1/4 inch (6.35 mm external) HP pipe.

02 nce

HP outlet diameter : M14 x 1.5 mm.

It is fitted in the main housing.

CAUTION

va

This part should only be manipulated in accordance

with the relevant safety, cleanliness and torque

recommendations (see specific operations).

Ad

A counter torque is required for all tightening/

slackening operations on the HP tube.

This part does not require any network intervention.

© Delphi

2-4 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS SUPPLIED BY DELPHI

2.1.4 Pressure limiter

This unit mechanically limits the pressure to 2150

bar +/- 100 bar.

It discharges the pressure on an ad hoc basis if

IMV regulation is no longer active or if discharge via

the injectors is not being managed.

The fuel is returned to the tank via the LP backleak

circuit.

This component does not require any network

intervention.

2 py

2.1.5 LP unions

01 o

The pump has several LP connectors (screwed into the main housing) :

• An inlet feed from the electric priming pump.

/2 C

• A return for the fuel returning to the tank.

Z20D engine

02 nce

• The inlet diameter is 9.89 mm. It is straight

with respect to the pump body.

• The return diameter is 8 mm.

va

These are quickfit type connectors with flexible

plastic locking tabs.

These parts do not require any network

Ad

intervention.

Z22D engine

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 2-5

I SPECIAL FEATURES OF THE SYSTEM

PARTS SUPPLIED BY DELPHI

• The inlet diameter is 7.89 mm. It is elbowed

with respect to the pump body.

• The return diameter is 8 mm.

These parts do not require any network

intervention.

These are quickfit type connectors with metal

2 py

locking tabs (4). These connectors can be

disconnected with the YDT597 tool.

01 o

/2 C

02 nce

va

Ad

2.1.6 Venturi

It is integral with the pump body.

The venturi creates a vacuum in the injector return

circuit. It reduces any variation in flow to injectors

(stroke to stroke).

The injector return is connected to the venturi

double canal system.

© Delphi

2-6 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS SUPPLIED BY DELPHI

2.2 Rail

The rail is a high pressure accumulator. It is supplied by the HP pump and functions as a high pressure reserve for the

injectors.

It is made up of the following elements :

• A tubular body.

• A rail pressure sensor (HPS)

• A pump inlet.

• 4 injector outlets with integral jets.

The jets help absorb the pressure waves to limit instability. They cannot be removed from the rail body.

2.2.1 Tubular rail

Specifications :

• Dry weight : 1.185 kg.

• Volume : 17.5 cm3.

2 py

• Maximum operating pressure 2200 bar.

• Burst pressure > 7000 Bar.

01 o

/2 C

02 nce

va

CAUTION

For all operations, all openings must be plugged using clean plugs from the dispenser YDT480.

Ad

CAUTION

When the engine is stopped, fuel is still pressurised in the rail. It is vital to wait before working on the system.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 2-7

I SPECIAL FEATURES OF THE SYSTEM

PARTS SUPPLIED BY DELPHI

2.2.2 Rail pressure sensor (HPS)

The HP sensor transmits the rail pressure value to

the DCU. This value is used to calculate the flow and

injection advance.

It consists of a membrane that deforms due to the

fuel pressure. The deformation is converted into an

electrical value representing the rail pressure level.

It supplies a voltage proportional to the fuel

pressure.

CAUTION

It is not permitted to remove it as there is a risk of

contaminating the system.

Specifications :

2 py

• Supply voltage : 5 V ±0.1 V.

• Measurement range : from 0 to 1800 bar.

• Maximum pressure : 2300 bar.

01 o

• Sensor type : KOSTAL

/2 C

It is located on the end of the rail. Diagnostics can

be carried out with the kit YDT330C.

02 nce

2.3 Injectors

The injector is a DFI1.5 type and conforms to Euro V standards.

va

Ad

© Delphi

2-8 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS SUPPLIED BY DELPHI

The DFI1.5 incorporates several design changes :

• The valve and adaptor plate are combined in a

single unit.

• There is a radial inlet.

• The individual calibration uses a 20 alphanumeric

C3I.

Specifications :

Injector :

• Opening controlled by electric pulse.

• Peak pull current : 22 A min to 24 A max.

• Peak holding current: 6 A min to 8 A max.

• Pull duration : approximately 260 μs (indicative

value for a battery voltage of 12 V).

• Resistance : between 0.155 Ω and 0.185 Ω at 20 .

2 py

• Multiple injection possible: separate pilot, close

pilot, main, close post and separate post.

• Maximum pressure : 1800 bar.

• Number of holes : 8.

01 o

/2 C

• Vacuum : 300 mbar.

• Sealing washer : a copper washer is fitted between

the cylinder head and the injector contact face.

02 nce

- Z20D : thickness 3 mm.

- Z22D : thickness 2 mm.

They are located in the cylinder head wells with a specific position for the correct orientation of the injection jets and are

va

supplied with fuel by the HP pipes.

Electrical supply is ensured by a connector (2 pin) locked

to the injector body. Each injector has its own connector.

Ad

Diagnostics can be carried out using the YDT479 kit.

For ease of assembly in the body plant, the n°4 injector

is connected to the main engine harness via a sub-

harness.

No fuel can be injected if the DCU is off or if a control

wire is cut.

CAUTION

During an operation, the connections and surrounding area must be protected from fuel spills. All openings to be plugged

using clean plugs from the dispenser (YDT480) .

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 2-9

I SPECIAL FEATURES OF THE SYSTEM

PARTS SUPPLIED BY DELPHI

2.4 DCU

The DCU is a DCM3.7 type. It manages the engine by

applying various strategies depending on running

conditions (idle, full load...).

Main characteristics are:

• Normal operating voltage: from 10V to 16V.

• 96 way connector.

• 58 way connector.

• Motorola 32 bit microprocessor.

The DCU controls the following functions :

• Voltage supply.

• Immobiliser.

• Pre-post heating.

• Engine cooling.

2 py

• EGR. DCU DCM3.7 - 154 pins

• Air conditioning cut-out.

• Water heater control.

01 o

/2 C

• Boost pressure control

• Cruise control.

02 nce

• The fuel flow and the advance.

• System diagnostics.

It is fitted vertically next to the battery. It can be connected using the kit YDT374 (YDT375 + YDT376) with the kit

YDT175 (terminal box) to gain access to the DCU pins.

va

Ad

© Delphi

2-10 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS NOT SUPPLIED BY DELPHI

DELPHI does not supply the following original fitment parts:

• The HP pipes.

• The fuel filter.

3.1 HP pipes

The DELPHI injection systems for the GMDAT

applications Z20D and Z22D have 5 HP pipes. Each

injector has a specific HP pipe.

Pump/Rail pipe

• It feeds high pressure fuel from the pump to the

rail.

- Internal diameter : 3 mm.

- External diameter : 6.35 mm.

2 py

- Length : 295.1 ± 0.5 mm.

- Maximum operating pressure : 1800 bar.

- Max peak pressure : 2100 bar.

Rail / injector pipes

01 o

/2 C

• They distribute fuel from the rail to the injectors.

- Internal diameter : 3 mm.

- External diameter : 6.35 mm.

02 nce

- Length : 190.6 ± 0.5 mm.

- Maximum operating pressure : 1800 bar.

- Max peak pressure : 2100 bar.

va

CAUTION

Ad

Operations on the HP pipes must follow the safety and cleanliness instructions and the correct sequence(see specific

operations). For all operations, all openings must be plugged using clean plugs from the dispenser YDT480.

3.2 Filter

The DELPHI injection system for the GMDAT

applications Z20D and Z22D are fitted with a fuel filter.

There are 2 versions depending on the engine type.

For the 2 applications Z20D and Z22D, the filter

integrates :

• A fuel temperature sensor.

• A water detector.

• A heater.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 3-11

I SPECIAL FEATURES OF THE SYSTEM

PARTS NOT SUPPLIED BY DELPHI

3.2.1 Diesel filter

The filter is located under the vehicle on the right hand side near the rear wheel.

Specifications :

• Filtration efficiency:

> 4 μm 84.26 %.

> 5 μm 96.47 %.

> 6 μm 99.92 %.

> 10 μm 99.99 %.

> 20 μm 99.99 %.

> 30 μm 100 %.

3.2.2 Fuel temperature sensor

The diesel temperature sensor is in the HP pump

low pressure circuit. It is used in the injection

2 py

control strategy to apply corrections for fuel

temperature. It is also used to protect the system in

cases of excessively high fuel temperatures.

01 o

This is a combination sensor with the fuel heater on

/2 C

the filter.

Specifications :

02 nce

• Supply voltage : +5 V ±0.25 V.

• Thermistor type : negative temperature

coefficient (resistance decreases as

temperature increases).

va

• Resistance : 2.057 kΩ at 25 °C.

• Measurement range : -30 to +110 .

• Equivalent impedance range : 26.114 kΩ at 144

Ad

Ω.

The sensor can be electrically checked with the

YDT538C kit.

3.2.3 Water detector

It is integral with the filter and protects the injection

system by detecting the presence of water in the

fuel.

Specifications :

• Detection level: 170 ml.

• Maximum current : less than 200 mA.

The sensor can be electrically checked with the

YDT529C kit.

© Delphi

3-12 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

PARTS NOT SUPPLIED BY DELPHI

3.2.4 Heater

It is integral with the filter and can heat the fuel to

the correct operating temperature for the injection

system.

The heater control is integrated with the

combination temperature sensor on the filter.

Specifications :

• Z20D heater : 210W.

• Z22D heater : 250W.

• Maximum current : 21 A.

The sensor can be electrically checked with the

YDT538C kit.

2 py

3.3 Electric Priming Pump

The system includes an external priming pump. It is located in the tank and supplies the HP pump.

01 o

It has an integrated regulator to maintain the fuel pressure at the correct level for the engine speed.

/2 C

Specifications :

• Z20D : Bosch.

02 nce

• Z22D : Kafus.

• Fuel flow : 215 l/h at 380 kPa under 12 V.

va

Ad

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 3-13

I SPECIAL FEATURES OF THE SYSTEM

PARTS NOT SUPPLIED BY DELPHI

2 py

01 o

/2 C

02 nce

va

Ad

© Delphi

3-14 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.1 Fuel Supply/Air Supply

ENGINE LAYOUT Z20D 2.0l – Z22D 2.2l Euro V

HPS

T2 P2

Inlet air duct

Rail

Swirl valve

EGR

IMV

HP pump

Injectors Venturi

Preheating Filter +

Exchanger

EGR cooler

Heater

1 Fuel T˚

2

Oil pump 4

3 Tank

2 py

Electric priming

pump

Cool air

6 5

Exhaust gas

Oil

01 o Bypass

Heating radiator

Coolan (pneumatic)

/2 C

t oil

Diesel Thermostat

unit

Radiator

T3

02 nce

Water pump Expansion tank

M

T1 AMF

va

T5

O2 T4

VGT

Ad

1

Air filter

CATA DPF EXHAUST GAS

OUTLET

FRESH AIR P4

INLET

SENSORS & ACTUATORS

T1 Inlet air temperature 1 Accelerometer sensor (x2) Throttle Valve

T2 Boost air temperature. 2 Camshaft sensor

AMF Air flowmeter

T3 PreVGT Temperature 3 Crankshaft sensor

DPF Particle filter

T4 Temperature upstream of catalyser 4 Oil level sensor

VGT

T5 Pre-DPF Temperature 5 Variable Geometry Turbo with :

Coolant temperature sensor

pneumatic actuator position sensor

P2 Boost air pressure

6 Oil pressure sensor

P4 Particle filter differential pressure sensor

O2 Oxygen probe

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-15

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.2 Electrical supply

4.2.1 Switch on DCU

When the ignition signal goes to terminal 19 in the 58 pin connector, the DCU controls the supply relay by earthing

terminal 45 (58 pin connector). If the relay is stuck, the following components are supplied by Pbatt (+12 V protected

by the fuse and the main relay) :

• The injection DCU.

• Inlet metering valve (IMV)

• The EGR solenoid valve.

• The VGT solenoid valve.

• The oxygen probe and its heater.

• The air flowmeter.

The DCU is supplied :

• When the ignition is switched on.

2 py

• Before and after starting.

• When the engine is running.

• During and just after engine stop in order to carry out key-off tests, memory write, programming and engine

fan cooling.

01 o

/2 C

02 nce

Main supply relay T87

F1

Pbatt

201

F4 Pbatt

203

va

Pbatt

205

T15

F2 245

Ignition key 219

Ad

Starter relay

DCU

211

IGN_2

Accessory

F3 Vehicle

012 wake

electrical 212

Key switch system

+

Battery 12V

-

Earth

202

Earth

204

Earth

206

1xx = Engine connector 96 way

2xx = Vehicle connector 58 way

© Delphi

4-16 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

CAUTION

Before disconnecting the DCU or any other electronic component of the common rail system (valves, sensors,

injectors), wait for the end of the power latch phase (approximately 10 seconds).

4.2.2 Sensor supply

The DCU generates three independent 5 Volt supplies (Vreft 1, Vref 2 and Vref 3) for all the system sensors.

These 3 supplies are protected against short circuits to earth and Vbatt as well as overloads.

Sensor supply allocation

• Vref1 :

- Engine speed sensor (maximum consumption: 15 mA).

- Cam sensor (maximum consumption : 15 mA).

- Rail pressure sensor (maximum consumption: 10 mA).

- N°1 pedal position sensor (maximum consumption : 5 mA).

• Vref2 :

2 py

- Inlet pressure sensor (maximum consumption: 12.5 mA).

- Brake circuit pressure sensor (maximum consumption 15 mA).

01 o

- Swirl position sensor (maximum consumption 15 mA).

- Coolant pressure sensor (maximum consumption: 7 mA).

/2 C

- Particle filter differential pressure sensor (maximum consumption 10 mA).

- N°2 pedal position sensor (maximum consumption : 5mA).

02 nce

- Vehicle speed sensor/TOSS (Transmission Output Shaft Speed) (maximum consumption : 15 mA).

• Vref3 :

- VGT position sensor (maximum consumption 15 mA).

- Air flap valve position sensor (maximum consumption 15 mA).

va

- EGR position sensor (maximum consumption: 15 mA).

- Clutch and brake pedal position sensor (maximum consumption : 5 mA).

Ad

- AT neutral position sensor (maximum consumption: 15 mA).

- ECO Mode control (maximum consumption : 15mA).

- Oil pressure sensor (maximum consumption: 12 mA).

4.3 The Immobiliser

4.3.1 Function

The engine immobiliser increases vehicle protection in the event of an attempted theft. It prevents fuel injection

control using the DCU.

4.3.2 Communication between the immobiliser and the DCU

The system uses a master-slave relationship. The DCU is the master control and always initiates any

communication.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-17

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.3.3 Functional description

Injection authorisation/prevention immobilisation has several steps :

• Step n°1 : The DCU generates a random code and sends it to the immobiliser.

• Step n°2 : The DCU and the immobiliser calculate the unlocking code from the random code.

• Step n°3 : The immobiliser sends the unlocking code to the DCU.

• Step n°4 : The DCU compares the unlocking code which it has calculated with the code received from the

immobiliser. If the two codes match, the engine may be started.

If the two codes are different, steps 1, 2 and 3 are repeated. If the two codes do not correspond after several

attempts, the immobiliser stays locked and will prevent the engine from starting.

Note:

- If the immobiliser does not respond to the DCU and the vehicle configuration is "without immobiliser", the

engine may be started.

- If the immobiliser does not respond to the DCU and the vehicle configuration is "with immobiliser", the

engine may not be started.

2 py

- The engine cannot be started if the coded key is not identified correctly or if the key transponder does not

communicate with the immobiliser.

01 o

/2 C

4.3.4 Replacing the DCU

The DCU may only be replaced by the vehicle manufacturer's network so that the new DCU may be matched,

02 nce

coded and programmed.

Note:

Access to these services is restricted by a coded program protected by the vehicle manufacturer and

which is therefore not available.

va

These services can therefore only be executed by the manufacturer's diagnostic tool.

Ad

4.3.5 Synchronising the DCU and the immobiliser.

Synchronising consists of matching the injection DCU and the immobiliser. It must be performed when replacing

a DCU or the immobiliser to activate the engine immobiliser.

Note:

Synchronisation is a service linked to the immobiliser. This service is secure and can only be

accessed via the vehicle manufacturer's diagnostic tool.

4.3.6 Reading immobiliser faults

The injection DCU can store faults linked to the immobiliser:

List of possible faults:

• No response.

• Incorrect response.

• Functions not activated.

• NVM fault.

• General fault.

© Delphi

4-18 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.4 Diagnostics

4.4.1 Diagnostic communication

Diagnosis of the injection system is performed via the CAN link in the DCU. This link connects terminals 47

and 48 of the 58 pin DCU connector to terminals 14 and 6 of the vehicle OBD socket.

Diagnostics are performed by the UDS communication protocol.

4.4.2 Diagnostic socket.

These vehicles are fitted with a 16 pin OBD socket. Communication between DIAMAND and the DCU is via the

"standard" YDT452 cable.

Diagnostic socket pin allocation

Diagnostic socket type Pin no. Description

1 positive IGN

2 py

4 and 5 Earth

01 o 6 CAN H

14 CAN L

/2 C

16 positive batt

02 nce

For this application, it is located :

• Under the dashboard on the driver side (LHD or RHD).

va

Ad

CAPTIVA diagnostic socket location.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-19

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

ORLANDO diagnostic socket location.

2 py

01 o

/2 C

02 nce

va

Ad

CRUZE diagnostic socket location.

4.5 Dashboard warning LEDs

4.5.1 Description

The following instrument panel warning LEDs are managed by the DCU via the CAN :

• Fault light.

• Preheating light.

• Immobiliser light.

• The fuel filter LED (water present in the fuel).

• Cruise control light.

• DPF clogged LED.

4.5.2 The fault LED

This indicates a fault in the injection system which requires immediate attention in the Aftermarket network.

© Delphi

4-20 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

Engine status Light status(Normal system operation) Light status(Permanent serious fault at

key on)

Pre-start Permanently on(illumination time limited to 2 Permanently on

s.)

Starting and engine running Off Permanently on when limp home mode is

active

4.5.3 Preheating LED

It indicates the preheater plug activation to aid combustion during the starting phase. When the preheating LED

is on continuously, it indicates the preheating phase.

When the LED goes out, the preheating phase has finished and the driver may start the engine.

Engine status Light status(Normal system operation) LED status(fault detected by the pre-post

heating unit)

2 py

Pre-start Permanently on (time on is a function of the Off

01 o coolant temperature, the battery voltage and

the atmospheric pressure and is limited to 60

s)

/2 C

Starting and engine running Off Off

02 nce

4.5.4 Immobiliser light

This indicates the operating status of the engine immobiliser system.

va

LED status Possible indications

Light permanently on Communication running between the DCU and the immobiliser unit.

Ad

DCU and immobiliser unit not synchronised.

Light off Communication established. Engine authorised to start.

Immobiliser unit not connected.

Engine stopped.

Immobiliser not installed.

Light flashing (2Hz) Fault detected on the engine immobiliser system.

Communication error between the DCU and the immobiliser unit.

Pairing invalid.

Key recognition or programming problem.

4.5.5 Presence of water in the diesel filter LED

This informs the driver that there is water in the diesel fuel filter.

Engine status Light status(Normal system operation) Light status(if water is detected in diesel

fuel filter)

Pre-start Permanently on(illumination time limited to 15 Permanently on

s.)

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-21

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

Engine status Light status(Normal system operation) Light status(if water is detected in diesel

fuel filter)

Starting and engine running Off Permanently on

Synchronised Permanently on Permanently on

2 py

01 o

/2 C

02 nce

va

Ad

© Delphi

4-22 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.6 DCU Inputs/Outputs

5 6 46

73 96 58

33

49 72 45

3 4

20

25 48 32

1 2 7

1 24 19

96 pin connector (identified 1xx on the wiring diagram)

2 py

Pins Role Pins Role

1 Not used 01 o 2 Not used

3 Injector control cylinder - 4 - HSD 4 Air Temperature sensor (analogue)

/2 C

5 Pre-DPF temperature sensor signal 6 Pre - VGT temperature sensor signal

7 Exhaust gas temperature signal before the catalytic 8 Particle filter differential pressure sensor signal

02 nce

converter

9 Coolant temperature signal 10 Fuel temperature signal

11 VGT position signal 12 Boost pressure sensor signal

va

13 Brake circuit pressure signal 14 Swirl position signal

15 Flap valve position analogue signal (Throttle) 16 EGR valve position signal

Ad

17 Clutch or brake pedal position signal 18 Not used

19 Rail pressure sensor earth 20 Gearbox neutral position sensor earth

21 Brake circuit pressure sensor earth 22 Pre-DPF temperature sensor earth

23 Pre - VGT temperature sensor earth 24 Temperature sensor pre-catalyser earth.

25 Injector control cylinder 4 - LSD 26 Injector control cylinder 1 - LSD

27 Injector control cylinder - 1 - HSD 28 Accelerometer n°1 sensor shield

29 Accelerometer n°2 sensor shield 30 Accelerometer n°1 Sensor Earth

31 Accelerometer n°1 Sensor Signal 32 Accelerometer n°2 sensor signal

33 Accelerometer n°2 sensor Earth 34 Boost air temperature signal

35 Rail pressure sensor signal 36 Not used

37 Oil pressure sensor supply 38 Rail pressure sensor supply (Vref1)

39 Crank sensor supply (Vref1) 40 Camshaft sensor supply (Vref1)

41 Boost pressure sensor supply (Vref2) 42 Brake circuit pressure sensor supply

43 Swirl valve supply (Vref2) 44 DPF differential pressure sensor earth

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-23

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

Pins Role Pins Role

45 Coolant temperature sensor earth 46 Fuel temperature sensor earth

47 Camshaft sensor earth 48 VGT position sensor earth

49 Not used 50 Injector control cylinder - 2 - HSD

51 Injector control cylinder - 3 - HSD 52 Gearbox neutral position switch (AutoTrans)

53 Gearbox position sensor signal 54 Oxygen probe compensation resistance

55 Oxygen probe pump current 56 Oxygen probe nernst voltage

57 Oxygen probe virtual earth 58 Air flowmeter signal (frequency)

59 Camshaft sensor signal 60 Crank sensor signal

61 VGT supply (Vref3) 62 Gearbox position sensor supply (Vref3)

63 Flap valve position sensor (Throttle - Vref3) 64 EGR valve position supply (Vref3)

65 ECO Mode supply 66 DPF differential pressure sensor supply (Vref2)

2 py

67 Turbo pressure sensor earth 01 o 68 Temperature sensor earth

69 Swirl valve position sensor earth 70 Flap valve position sensor earth (Throttle)

/2 C

71 Air temperature sensor earth (Air flow sensor) 72 EGR valve position sensor earth

73 Not used 74 Injector control cylinder 2 - LSD

02 nce

75 Injector control cylinder 3 - LSD 76 Air flowmeter supply (if not supplied by Pbatt)

77 Inlet metering valve control (PWM) 78 Brake pedal signal (Normally open)

79 Alternator control signal 80 Alternator load signal

va

81 Not used 82 Oxygen probe heater control

83 Flap valve negative control (Throttle) 84 Flap valve positive control (Throttle)

Ad

85 Fan n°1 control / Fan controller 86 EGR valve cooler bypass control

87 Crank sensor earth 88 VGT control (PWM)

89 Swirl valve control 90 EGR valve positive control

91 EGR valve negative control 92 Not used

93 Not used 94 ECO mode

95 Water in the fuel detector 96 Oil pressure sensor

58 pin connector pin allocation (identified 2xx on the wiring diagram)

Pins Role Pins Role

1 Protected DCU supply Pbatt 2 DCU earth

3 Protected DCU supply Pbatt 4 DCU earth

5 Protected DCU supply Pbatt 6 DCU earth

7 Priming pump control HSD 8 Coolant pressure sensor signal

9 Fuel level sensor n°1 signal 10 Vehicle Speed Sensor / TOSS (transmission drive shaft

speed) sensor

© Delphi

4-24 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

Pins Role Pins Role

11 Starter relay control HSD 12 Ancillary control data

13 Signal from (Track 2) accelerator pedal sensor 14 Earth (Track 2) accelerator pedal sensor

15 Temperature sensor signal 16 Reverse gear switch signal

17 Pre-post heating unit diagnostic 18 Clutch pedal sensor signal - disengaged position

(Normally open)

19 Ignition key signal 20 Coolant pressure sensor earth

21 Vehicle speed sensor earth 22 AC refrigerant pressure sensor supply (Vref2)

23 Clutch / brake pedal position sensor supply (Vref3) 24 Accelerator pedal sensor track 1 supply (Vref1)

25 Signal from (Track 1) accelerator pedal sensor 26 Earth (Track 1) accelerator pedal sensor

27 Vehicle speed / TOSS sensor signal 28 Oil level sensor (frequency)

29 Accelerator pedal sensor track 2 supply (Vref1) 30 Brake pedal switch + brake LED signal(Normally closed)

2 py

31 Not used 32 Clutch pedal switch signal (Normally open)

33 Fuel level sensor n°1 earth 34 Clutch / brake pedal position sensor earth

01 o

35 Fuel level sensor n°2 signal 36 Fan n°2 control

/2 C

37 Auxiliary heater relay control 38 Water heater control n°1

39 Fuel level sensor n°2 earth 40 Water heater sensor control

02 nce

41 Air conditioning relay control 42 Fan n°3 control

43 Oil vapour heater relay control 44 Not used

45 Main DUC supply 46 Pre-heater unit control

va

47 CAN Low 48 CAN High

Ad

49 Oil pump control 50 Fuel heater relay control

51 Water pump control Version 2012 52 Oil pressure sensor earth Version 2012

53 Not used 54 Not used

55 MIL LED 56 Water heater n°2 and n°3 control

57 Flowmeter switch LSD 58 Not used

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-25

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.7 Pre-post heating

4.7.1 Function

The preheater plugs are located next to each

injector to heat the air around the injector nozzle.

They are controlled by the pre-post heating unit

next to the battery.

This heating is necessary to ensure that the diesel

fuel ignites when the temperature is low.

Preheating is used in the engine starting phase

(minimum time to reach idle) and may continue if

the external temperature is very low (post heating).

Preheating time is therefore a function of the

external temperature and the engine coolant

temperature.

The unit is located either in front of the battery

2 py

(Z20D) or behind it (Z22D).

01 o

4.7.2 Control circuit

/2 C

The supply to the plugs is controlled by the injection DCU via the pre-post heating unit. The command is only

authorised when the supply voltage is less than 18 V to avoid damaging the preheating plugs with excess voltage.

02 nce

Specifications :

• Nominal plug supply voltage 4.4 V ±0.1 V.

• Operating temperature range: -40°C to 105°C (ambient temperature).

• Time taken to reach 1000°C : 3 s.

va

• Temperature after 60 s (nominal voltage) : Between 950 and 1050 .

• Nominal current after 60 s : minimum 5.2 A and maximum 8.2 A.

Ad

• Voltage profile : 11 V ± 0.1 V for 1.9 s then 4.4V ± 0.1 V for 58.1s.

4.7.3 Preheating

The preheating phase begins as soon as the ignition is switched on. It involves:

• Illumination of the preheating LED.

• Supplying the preheating plugs.

The duration of preheating is determined according to the engine coolant temperature:

Engine coolant temperature (°C)

–35 –25 –20 –10 0 10 20 30

Preheating duration (s)

31 22 19 17 14 0 0 0

4.7.4 Postheating

Postheating is when the heater plugs are supplied after starting the engine when the outside temperature is too

low. The preheating light is not on during postheating. The duration of preheating is determined according to the

engine coolant temperature:

© Delphi

4-26 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

Engine coolant temperature (°C)

–30 –20 –10 0 20 30 40 60

Postheating duration (s)

115 80 30 19 11 11 0 0

However, the supply to the plugs may be interrupted momentarily, depending on the torque demand.

• If the request exceeds an upper threshold, the plugs are not supplied.

• If it falls below a lower threshold, they are supplied.

4.7.5 Diagnostics

The pre-postheating unit (PPH unit) has a diagnostic function which can detect :

• Short circuits and open circuits on the plug supply.

• Pre-post heating unit supply faults

• Communication faults with DCU.

2 py

• Internal faults (PPH unit).

• Faults linked to pre-post heater unit temperature.

01 o

After key on, the DCU asks the unit for diagnostic information. The DCU generates a fault code specific to each

/2 C

type of fault.

02 nce

4.8 Engine cooling

4.8.1 Function

The DCU controls the engine cooling fan units during and after engine operation. To do this, the system takes

va

into account the coolant temperature and aircon cooling requirements.

4.8.2 Control circuit

Ad

The Z20D and Z22D engines are fitted with 3 fan units. They are controlled by the DCU as follows :

• Fan n°1 : PWM signal or control relay (depending on vehicle specification).

• Fan n°2 : Control relay.

• Fan n°3 : Control relay.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-27

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.8.3 Control strategy

The fan strategy and speed control depend on :

• The engine status (running, stopped).

• Coolant temperature.

• Engine oil temperature.

• Gearbox oil temperature.

• Refrigerant pressure measurement (AC).

• Particle filter regeneration.

4.9 Particle filter

4.9.1 Particle filter

A) Principle

2 py

The particle filter is able to satisfy current anti-pollution standards. It is located downstream of the catalytic

converter, but upstream of the exhaust silencer. This system enables - under certain conditions - the burning of

any soot particles in the exhaust gases that have been stopped by the filter. This combustion takes place at very

01 o

high temperature (approximately 650°C) and destroys most of the particles that passed through the catalytic

converter.

/2 C

B) Activation

The strategy is able to activate regeneration under three different sets of conditions:

02 nce

• When the pressure difference between particle filter entry and exit shows that the filter is heavily loaded

• When the previous regeneration cycle took place 1000 km ago

• When the agent launches the routine with the diagnostic tool

• When several regeneration attempts have failed.

va

Other conditions must also be satisfied to ensure satisfactory regeneration:

• Catalytic converter temperature greater than 315°C.

Ad

• Filter temperature greater than 650 .

C) Strategy

In order to generate the high temperature needed for particle filter regeneration, the strategy can :

• Increase the amount of fuel injected

• Add two post-injections

• Under-set the main injection

• Reduce turbo pressure (in relation to the required normal operating pressure)

• Close the flap valve for mow torque settings (town/traffic jam running).

© Delphi

4-28 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.9.2 Particle filter differential pressure sensor

The sensor measures the difference in exhaust gas

pressure throughout the assembly (Catalyser /

Particle Filter). This data is required to manage the

DPF regeneration schedule to avoid clogging.

Specifications :

• Power supply : +5 V ±0.25 V.

• Maximum current : 10 mA.

• Accuracy : ± 3 kPa.

• Measurable vacuum level : -20 kPa to 120 kPa.

• Operating temperature : -40 to +140 .

It is located. Diagnostics can be carried out with the

kit YDT559B.

2 py

4.10 EGR management

01 o

/2 C

4.10.1 Principle

The exhaust gas recirculation system (EGR) is used

02 nce

to divert part of the exhaust gases to the engine's

air inlet in order to reduce the excess air and the

temperature in the combustion chamber. This

device therefore provides a significant reduction in

va

nitrogen oxide emissions from the exhaust.

Ad

4.10.2 Function

The EGR valve is directly controlled by the DCU. The EGR valve control signal is determined depending on the

EGR setting and the air flow measured by the flowmeter. The position is copied to the DCU.

EGR regulation is activated if the following conditions are met:

• Engine running.

• Sufficient torque requested.

• Idle duration less than 1 seconds.

• Engine speed between 0 and 2600 rpm.

• Coolant temperature between 0 and 100 °C.

• Atmospheric pressure greater than 920 mbar.

• Vehicle speed less than 100 km/h.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-29

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.10.3 EGR setting

The EGR setting is calculated from a main "engine speed / indicated torque" map. It is adjusted as a function of:

• Coolant temperature

• Inlet air temperature.

• Atmospheric pressure.

• Turbo pressure loop difference.

The EGR setting directly indicates the fresh air flow which should be allowed and is measured by the flowmeter.

It increases with engine speed and torque and is therefore inversely proportional to the volume of exhaust gas.

4.10.4 EGR valve

It is located in the exhaust gas return to the inlet

circuit. The valve allows the quantity of exhaust gas

sent to the inlet to be regulated.

• Power supply : + Vbatt.

2 py

• Response time (position 10% to 90% / position

90% to 10%) : 120 ms (opening) / 90 ms

01 o

(closing).

• Maximum operating temperature : +550°C

/2 C

(Exhaust gas)..

• Electric stops : 0.9 V ± 0.1 to +3 V.

02 nce

• Mechanical stops : 0 mm (closed position) to

8 mm (open position).

• Maximum current : 8.7 A.

• Motor coil resistance : 1.45 to 3.45 Ω

va

(depending on the position).

It is located next to the flowmeter in front of the air

hose. Diagnostics can be carried out with the kit

Ad

YDT529D.

Note:

The EGR flap remains completely open in the full load and high engine speed zones.

© Delphi

4-30 DDNX384(EN) - Issue 1 of 12/2011

SPECIAL FEATURES OF THE SYSTEM I

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.10.5 Throttle Valve

It is located in the inlet air circuit. Closing this flap

decreases the amount of fresh air entering the

engine and consequently increases the EGR rate

when recycling is operational.

Diagnostics can be carried out with the kit

YDT710C.

• Supply voltage: 12 V.

• Normal operating voltage : 9 V to 17 V.

• Operating temperature : ±40 to +125

• Response times : 70 ms maximum (position

10% to 90%).

• Motor resistance : 1.9 Ω ± 10%.

The flap stops are as follows :

2 py

• Electrical : 4.5 V ± 0.147 to 0.790 V ± 0.152.

• Mechanical : 4 deg ± 0.25 to 93 deg ± 1.

4.10.6 Swirl valve

01 o

/2 C

It is located in the inlet air circuit. This creates a

vortex effect in the air entering each cylinder. The

02 nce

fuel/air mix is therefore more regular improving

combustion.

It is managed by a PWM signal to the pneumatic

swirl control solenoid.

va

The swirl control (2 way solenoid valve) diagnostics

can be carried out using the kit YDT246B and the

copy signal (3 way) with the kit YDT559B.

Ad

• Supply (position sensor) 5 V ± 0.25.

• Operating range: 0 to 100%

• Operating temperature : -40 to 140 .

• Frequency range (PWM) : 150 to 350 Hz

• Solenoid vacuum : -900 mbar ±10.

• Motor coil resistance : 15.5 Ω ± 10%.

• Position sensor resistance 20 Ω

• Position sensor resolution 5 mV.

© Delphi

DDNX384(EN) - Issue 1 of 12/2011 4-31

I SPECIAL FEATURES OF THE SYSTEM

SPECIAL FEATURES OF THE COMMON RAIL SYSTEM

4.10.7 EGR Cooler Bypass

It cools the exhaust gases sent to the EGR valve.

The flap is controlled pneumatically. The exhaust

gases are cooled when the valve is open;

conversely, when the valve is closed, the gases are

sent directly to the inlet. The valve operation period

is limited to the vehicle starting phase.

It is controlled by a PWM signal sent to a pneumatic

solenoid valve.

• EGR gas temperature - inlet : 480 .

• Gas temperature - outlet : 155 .

Diagnostics can be carried out with the kit

YDT521B.

2 py

4.10.8 Air flowmeter

01 o

The flowmeter informs the DCU of the mass of cool

inlet air to allow the EGR flow and rate to be

/2 C

calculated in real time.

The flowmeter is a frequency type, it uses a hot-wire

02 nce

cell. The electronics measure the frequency at

which the detection cell cools in contact with the air.

The greater the cell cooling, the higher the air flow.

The frequency sent to the DCU is representative of

the quantity of air flowing in.

va

It is located after the air filter. Electrical diagnostics

can be carried out using the kit YDT574C for the

Z20D.

Ad

4.11 Air conditioning (AC) checks

4.11.1 Function

The air conditioning cools the passenger compartment by circulating a refrigerant through a heat exchanger