Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Astm B733 97 PDF

Caricato da

Jesus VelizTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Astm B733 97 PDF

Caricato da

Jesus VelizCopyright:

Formati disponibili

ASTM B733

ADOPTION NOTICE

custodians: Adopting Activity:

h y " R Air Force - 11

Navy - AS (Proj No. MFFP-0565)

Air Force - 11

Review activity:

Air Force- 99

AREA MFFP

AMSC NIA

DISTRJBUTION STATEMENTA. Approved for public release; distribution is unlimited.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

S T D - A S T M B733-ENGL 3777 W 0757530 Ob04732 T A U m

4Tb Designation: B 733 97 - AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken. PA 19428

Repmted from lhe Amua1 Book of ASTM StardardS. Copyright ASTM

Standard Specification for

Autocatalytic (Electroless) Nickel-Phosphorus Coatings on

Metal'

1. scope contents greater than I 1.2 76 P are not considered to be

t. 1 Thisspecificationcoversrequirementsforauto- ferromagnetic.

catalytic(electroless)nickel-phosphoruscoatingsapplied 1.10 The values stated in SI units are to be regarded as

from aqueous solutionsto metallic products for engineering standard.

(functional) uses. l . 1 1 The following precautionary statement pertains only

1.2 Thecoatingsarealloysofnickel and phosphorus to the test method portion, Section 9, of this specification.

producedbyautocatalyticchemicalreductionwith h m This stan&ud does not purport to address all of the safety

phosphite. Because the deposited nickel alloy iscatalyst

a for comem, if any, associated with its use. It is the responsi-

the reaction, the processis self-sustaining. The chemical and bility of the user of this standard to establish appropriate

physical propertiesof the depositvaryprimarilywithits safety and health practices and determine the applicability of

phosphoruscontentandsubsequentheattreatment.The regulatoty limitations priorto use.

chemical makeup ofthe plating solution andthe use of the

solution can affect the porosity and corrosion resistance of

the deposit. For more details, see ASTM STP 265 (1)2 and 2. R e f e r e d Docoments

Refs (2) (3) (4) and (5) also refer to Figs. X 1.I,X 1.2, and 2.1 ASTM Standardr:

X 1.3 in the Appendixof Guide B 656. B 368 Test Method for Copper-Accelerated Acetic Acid-

1.3 Thecoatingsaregenerallydepositedfromacidic Salt Spray (Fog) Testing (CAS Testing)3

solutions operatingat elevated temperatures. B 374 Terminology Relatingto Electroplating3

1.4 The process produces coatings of uniform thickness B 380 Test Method ofCorrosion by the Corrodkote

on irregularlyshaped parts, provided the plating solution P r d d

circulates freely over their surfaces. B 487 Test Method for Measurementof Metal and Oxide

1.5 The coatings havemultifunctional properties, such as Coating Thicknessesby Microscopical Examinationof a

hardness, heat hardenability, abrasion, wear and corrosion Cross W o n 3

resistance, magnetics, electrical conductivity provide dif€u- B 499 Test Method for Measurement of Coating Thick-

sion barrier, and solderability. They are also used for the nesses by the Magnetic M e t h d Nonmagnetic Coatings

salvage of worn or mismachined parts. on Magnetic Basis Metals3

1.6 The low phosphorus (2 to 4 % P) coatings are

microcrystalline and possess high as-plated hardness (620to B 504 Test MethodforMeasurementofThicknessof

750 HK 100). Thesecoatings are used inapplications Metallic Coatings by the CoulometricMethod3

B 537 Practice for Rating of Electroplated Panels Sub

requiring abrasion andwear resistance.

1.7 Lowerphosphorusdepositsintherange between 1 jeCtea to Atmospheric Expos&

and 3 % phosphorus are also microcrystalline. These coat- B 567 Method for Measurement of Coating Thickness by

ings are used in electronicapplicationspro,yidingsolder- the Beta Backscam Method3

ability,bondability,increasedelectricalconductivity, and B 568 Method for Measurement of CoatingThicknes by

resistance to strong alkali solutions. X-Ray Spectrometry3

1.8 The medium phosphorous coatings ( 5 to 9 96 P) are B 571 Test Methods for Adhesion of Metallic Coatings3

most widely used to meet the general purpose requirements B 578 Test Method for Microhardness of Electroplated

of wear and corrosion resistance. Coatings3

1.9 The high phosphorous (more than 10 % P) coatings B 602Test Method for Attribute Sampling of Metallic and

have superior salt-spray and acid resistance in a wide range Inorganic Coating?

of applications. They are used on beryllium and titanium B 656 Guide for Autocataytic Nickel-Phosphorus Deposi-

partsfor low stressproperties.Coatings with phosphorus tion on Metals for Engineering U&

B 667 Practice for Construction and Use of a Prok for

Measuring Electrical Contact Resistance4

'This specitication is under (he jurisdiction of ASIM Cornmittee Bo8 an B 678 Test Method for Solderability of MetalliGCoated

Metal Powders and Metal Po& Products and is tbe. direct responsibility of Products3

Subcommittee B08.08 on Eoginmiug coatingr

Current edition approved July IO, 1997. Published October 1997. origioauy

-

published as B 733 - 84. Last previous edition B 733 90(1994).

The boldface n u m b m given in parentheses refer to a List of references at the A d Book ofASTM &anh&, Vd 0205.

end of the text A d Bod ofAS7" &anh&, Vol 03.W.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

B 697 Guide for Selection of Sampling Plans for Inspec- the coating must protect fiom corrosion or w ea

r

, or both,

tion of ElectrodepositedMetallic

and

Inorganic and that are esential to the performance.

Coatings3 3.2 Other D&itiom-Terminology B 374 defines most

B 762 MethodforVariableSamplingofMetallicand of the technical terms used in this specification.

Inorganic Coatings3

B 849 Specification for Pre-Treatmentof Iron or Steel for

Reducing the Risk of Hydrogen Embrittlement3 4. contingchapifuction

B 850 Specification for Post-CoatingTreatments of 4.1 The cuating dadication system provides for a

Iron or SteelforReducing the Risk ofHydrogen scheme to select an elechroless nickelcoatingto meet specific

Embrittlement3 performance requkments based on alloycomposition,

B 851 Specification for AutomatedControlledShot thickness and hardness.

PeeningofMetallicArticles Prior to Nickel, Auto- 4.1.1 TYPE describes the general composition of the

catalytic Nickel, Chromium, orAs A Final F e h 3 deposit with respectto the phosphorus content and is divided

D 1 193 Specification for Reagent W a t d into five categories which establish deposit properties (see

D 2670 Method for Measuring Wear Roperties of Fluid Table 1).

Lubricants (Falex Method)'

D 27 14 Method forCalibration and Operation of an Alpha . . 1-h" to the pmckion of some phosphorus analysismethods

NOTE

a&v1at~mof0.5%hpbeendesigecdintothisdarrificetionscbane.

L F W - 1 Friction and Wear Testing Machin&

D 395 1 practice for Commercial Packaging7 Roundingoftktcatresultsduttothe~ofthclimitspmrideJ

foran~limaofCSand9.5%~~.ForQCampk.~

D 4060 Test Method for Abrasion Resistance of organic withatestresultfar~of9.71wouldhaveaclasgificatiollof

Coatings by the Taber A b d TYPE V, stt Appeaaix 4, M o y TYPES.

E 60 Practice for PhotometricMethods for Chemical

Analysis of Metalsg 4.2 Service Condition Based on Thickness:

E 156 TestMethodfor Determination of Phospho- 4.2.1 service condition n u m b are based on the severity

NS inHigh-Phosphorus Brazing Alloys (Photometric of the exposure in which the coating is intended to perform

Method)Io and minimum coating thickness to provide satisfi&%ory

E 352 Test Methods for ChemicalAnalysis of Tool Steels performance (seeTable 2).

and Other Similar Medium-and High-Alloy Steel' 4.2.2 SC0 Minimum Service, 0.1 pm-This is defined by

F 519 Test MethodforMechanicalHydrogenEmbrit- a minimum coating thickness to provide specific material

tlement I properties and extend the life of a part or its finction.

G5 Practice for Standard Reference Method for Making Applications include requirementsfordiffusion barrier,

PotentiostaticandPotentiodynamicAnodicPolariza- undercoat, electrical conductivity and wear and c o d o n

tion Measurementst2 protection in specialized environments.

G 31 Practice for LaboratoryImmersionCorrosion 4.2.3 SC1 Light Mice, 5 pm-This is debed by a

Testing of Metals12 minimum coating thickness Of 5 pm for extending the life of

G 59 Practice for Conducting Potentiodynamic Polariza- the part. Typical environments includelight-load lubricated

tion Resistance Measurements12 w e ar

, indoor c o d o n protection to prevent rusting, and for

G 85 Practice for Modified Salt Spray(Fog) Testing'' soldering and mild abrasive wear.

2.2 Military Standards: 4.2.4 SC2 Mild Mice, 13 pm-This is defined by mild

MLR-81841 Rotary Flap Peening of Metal P a d 3 c o d o n and wear environments. It is &am&xid by

"S13165 Shot Peeningof Metal Parts13 industrial atmosphere exposureon steel substrates in dry or

"STLl-109 Sampling procedures and Tables for In- oiled environments

spection by Attribute" 4.2.5 SC3 Moderate Service, 25 Pm-This is defined by

2.3 I S 0 Stanaízrds: moderate environments such as non marine outdoor expo-

IS0 4527 Autocatalytc Nickel-Wosphorus Coatings- sure,alkaIi salts at elevated temperature,and moderate wear.

Specification and Test Meth0dd4 4.2.6 X 4 Severe Service, 75 pm-This is defined by a

very aggnssive environment. Typical environments would

3. Termindlagy indude acid solutions, elevated t empemm and pressme,

3.1 DeJirrition: hydrogen diide and carbon dioNde oil service, high-

3. l. 1 significant su$bces-those substrate surfaces which temperam chloride systems, very severe w e ar

, and marine

immersioa

'AlFmdLkddASTM&&dS,Vd 11.01. Nars2-"Ihe~oftherutocoEllytic~caatingdb

6A d Lkd t$ASTM s*abnrdr,Vd 05.02 pendstoa~cxtcotontbesurhabishofthearridetobepletal

A d Bod t$ASl"JzcAdrudr,Vd 09.02.

8AnnurrlBoakt$~~,VdOaOl.

A d Ba& t$ASl" Vd 03.05. TABLE1

10 Dircantinuad;IDC 1992 A d Bad:dASZ44J1.nBardr.Vd 03.05. TLP.

II A d Bodr 4.U"- Vd 15.03. I N

o

-*

-

12 A

I3Avühbkh-

. .

d Bodr #ASTMJhndmdr. Vd 03.02.

Ilmmmts(3rQa65~4*4

I 1 (D3

ln 2104

7 O O ~ A v e , p b i l d d p b t P A19111-~Atta:NpoDs N 510s

~4Avühbk6romrlmaicrn~SMdPd,lP.ttmtE,11W.~nd~.13tb V 10"

Flow,NewYork+NY10036.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

B 733

TABLE2 senicecondilions 5.1.1 Title, ASTM designation number, and year of issue

Coating TNdrnert Requirrnnents of this specification.

Minmuncoating 5. I .2 Classification of the deposit by type, seMce condi-

secvicecondipbn Thidcness v m. (m) tion, class, (see4.1, 4.2 and 4.3).

specificetan

5.1.3 Specify maximum dimensionand tolerance require-

Sc0 Mr

iLnrn- 0.1 o.-( 1 ments, if any.

SC1 Light service 5 ~.oO02 ( 1

SC2 hwservice 13 o.O@x ( 1 5.1.4 Peening, if required (see6.5).

Sc3 Modmatesenice 25 0.001 ( ) 5.1.5 Stress relief heat treatment before plating, (see 6.3).

Sc4 severeservice 75 0.m ( ) 5.1.6 Hydrogen Embrittlement Relief after plathg, (see

6.6).

5.1.7 Sisnificant surfaces and surfices not to be plated

must be indicated on drawings or sample.

and how it was pretreated. Rough, non uniform wrfàces require thicker 5.1.8 Supplementalor Special Government Requirements

coatings than smooth surfaces to achieve maximum corrosion such as, specific phosphorus content,abrasion wear or

and minimum porosity. corrosion resistaace of the coatin& solderability, contact

resistance and packagingselectedfirom Supplemental Re-

4.3 Post Heul Treatment Class-The nickel-phosphorus quirements.

coatings shall be classified by heat treatment after plating to 5.1.9 Requirement for a vacuum, inert or reducing a t m e

increase coating adhesion and or hardness (seeTable 3). sphere for heat treatment above 26032 to prevent surface.

4.3.1 Class I-"deposited, no heat treatment. oxidation of the mating (see S3).

4.3.2 Class 2-Heat treatment at 260 to 400°C to produce 5. l. 10 Test methods for coating adhesion, composition,

a minimum hardness of 850 HKIOO. thickness, porosity, wear and corrosionresistance, if re-

4.3.3 Class 3-Heat treatment at 180 to 200°C for 2 to 4 quired, selected from those found in W o n s 9 and Supple-

h to improve coating adhesion on steel and to provide for mental Requirements.

hydrogen embrittlement relief (see 6.9). 5. l . 1 1 Requirements for sampling (seeSection 8).

4.3.4 Class 4-Heat treatment at 120 to 130°C for at least

1 h to increaseadhesion ofheat-treatable(age-hardened) N m 4" purchasa should furnish separate test specimens or

coupons of the basis metal for test purposes to be plated concurrently

aluminum alloys and carburizedsteel (see Note 3). with the articIes to be plated (see 8.4).

4.3.5 Class 5-Heat treatment at 140 to 150°C for at least

1 h to improve coating adhesion for aluminum, non age- 6. Materials and Mandacture

hardened aluminum alloys, copper, copperalloys and beryl- 6.1 Substrate-Defects in the surface of the basis metal

lium. such as scratches, porosity, pits,inclusions, roll and die

4.3.6 Class 6-Heat treatment at 300 to 320°C for at least

marks, laps, cracks, bum, cold shuts, and roughness may

1 h to improve coating adhesionfor titanium alloys.

advemly affect the appearance and performanœ of the

N m 3-Heat-treatablealuminum alloys such as Type 7075 can deposit, despite the observanœ of the best plating practice.

undergo microstructural changes and lose strength when heated to over Any such d e f m on signifïc8nt surfaces shall be brought to

130'C. the attention of the purchaser before plating. The producer

shall not be responsible for coatings defects resulting h m

5. Ordering Information s u r f a conditions of the metal, ifthese conditions have been

brought to the attention of the purchaser.

5.1 The following information shall be supplied by the 6.2 Pretreuttment"parts to be autocatalytic nickel plated

purchaser in either the purchase order or the

on engineering may be pmtreated in accordancewithGuide B656. A

drawing of the part to be plated: suitable method shall activate the surface and remove oxide

and foreign materials, which may cause poor adhesion and

TABLE 3 ClassilicaiionoiPostHeatTreabnent coating porosity.

CLASS oescription

CC)

Tm@) N m 5-Heat treatment of the base material may effect its metal-

lurgical pro

p ex t

e

i An example is leaded steel which may exhibit liquid

1 No Heat Treatment, As Plated or solid embritUement after heat treatment. Careful selection of the pre

2 IieatTrearmentforMaXinun

Hardness

and post heat treatmeatsare recommended.

TYPE I 260 20 6.3 Stress Reli&

285 16

320 8 6.3.1 Pretreatntent of Iron und Steelfor Reducing the Risk

400 1 of Hydrogen Embrittlement-Parts that are made of steel

NP€II 350t0380 1 with ultimatetensilestrength of greater than IO00 Mpa

TYPE 111 36ot0390 1

(hardness of 31 HRC or greater), that have been machined,

TYPE IV 366to400 1

TYPE V 375 to 400 1 ground, coldformed,or cold straightened subsequent to heat

3 HvaogenEmbrittlementand 18oto200 2to4 treatment, shall require stress relief heat treatment when

Adhes*n on steel specified by the purchaser, the tensile strengthto be supplied

4 A&esim.carbwidsteeland 120to130 1-6

" egA

by the purchaser, Specification B 849 may be consulted for a

5 AdhesbnmBerycunand 140 to 150 lto2 list of premtments that are widely used.

Aluminum 6.3.2 Peening-Peening prior to plating may be required

6 AdhesanOnTrtaniun 300-320 I 4

on high-st~~ngth steel parts to induce residual compressive

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

~~

S T D - A S T M B733-ENGL L777 D 0757530 Ob07735 7 9 T

@ B733

stresses in the sudace, which can reduœ loss offatigue 6.8.2 See Appendixes 3 and 4 and Guide B656 Fgs

strength and improvestress corrosion resistance after plating, X1.2 and X1.3.

(See Supplementary Requirements). 6.8.3 A heat treatment at 260’C for greater than 20 h

6.3.3 Steel parts which are designedfor unlimited life sho~dbeusedtoreduœthelossofsurfacehardn~and

underdynamicloads shall be shot peened or rotary flap strength of some ferrous basis metals. Avoid rapid heating

peened. and cooling of plated pouts.Suffiicient time must be allowed

for large parts to reach oven temperature.

N m bcontroUed shot peening is the ppefkred method because

thereare~~’swh~~taryOappeeningisaoteffectimSeeSl11. NOIE7-Th~~oftinact0reachmaximumhardaessvarieswah

tbCphosphanucontentOftllCdeposit.Highpbogpbanrs~tS~~

6.3.3.1 Unless otherwise specitïed, the shot peening shall mquireb~timcorahigbertem~orboth.Iadividualalloys

be accomplished on all s u r k a for which the coating is should be tested for maximum hardness attainaMe, especially for

required and all immediateadjacent surfàces whenthey COIlditi~Of”andloaggtima.

~8-rncrtorreducingatmosphereor~umsufficientt0

contain notches, fillets, or other abrupt changes of section ~toxidpoionisrrawmendedforheattreatmentrbovc26oxDo

size where stresses will be concentrated. notusegasam~hydrogenwithhigh~stedparts

6.4 Racking-Parts should be positioned so as to mini-

&trapping of hydrogen gas in cavities and holes, allowing

free circulation of solutionoverall surfaces to obtain 7. Requirements

uniform coating thickness. The location ofrack or wire 7.1 fiocm-Tbe coating shall be produced h m an

marks in the coating shall be agreed upon betwen the aqueous solution through chemical reduction reaction.

producer and purchaser. 7.2 AcxqMam? Requiren?ents”These requirements are

6.5 Plating Process: placed on each lot or batch and can be evaluated by testing

6.5.1 To obtainconsistent coating properties, the bath the plated part.

must be monitored periodically for pH, temperature, nickel 7.2.1 Appearance:

and hypophosphite. Replenishments to the plating solution 7.2.1.1 The coating surface shall have a d o r m , metallic

should be as frequent as required to maintain the concentra- appearanœ withoutvisible d e f a such as blisters, pits,

tion of the nickel and hypophosphite between90 and 100 % pimples, and m ks (see9.2).

of set point. The use of a statistical regimento establish the 7.2.1.2 Imperféctions that arise from surface conditions of

control limits and frequency of analysis may be employed to the substrate which the producer is unable to remove using

ensure quality deposits are produced. conventional pretreatmenttechniques and thatpersist in the

6.5.2 Mechanical movement of parts and agitation of the coating shall not be cause for rejection (see 6.1). Also,

bath is recommended to increase coating smoothness and discoloration due to heat treatment shall not be cause for

uniformity and prevent pittingor StreaLing due tohydrogen rejection unless special heat treatment atmosphere is speci-

bubbles. fied (see5.9).

6.6 Post Coating Treatment for Iron and Steel for Re- 7.2.2 Thkksts-The thickness of the coating shall ex-

ducing the Risk of Hydrogen Embrittlement-Parts that are ceed the minimum requirements in Table 2 as specified by

made of steel with ultimate tensile strengths of 10oO Mpa the servíœ condition agreed to prior to plating (see 9.3).

(hardness of 3 I HRC or -ter), as well as surface hardened Aftercoatingandifspecified,thepartshallnotexceed

p a r t s y shall require post coatinghydrogenembrittlement maximum dimension on signiscant surface (see5.3).

relíefbakingwhen specified by the purchaser, the tensile NOIE9--The~oftbecoatingcannotbecontrolledinMind

strength to be supplied by the purchaser. SpecificationB 850 orsmalldiameterdeepholcsorwheresolutioncirculationisrcstricted

may be consulted for a list of post treatments that are widely

used. 7.2.3 Adhesion-The coating shall have sufficient adhe

6.6.I Heat treatment shall be p e r f i i e d preferably within sion to the hasis metal to pas the specified adhesion test (see

1 h but not morethan 3 h of platingon plated after plating of 9.4 and Test Methods B 571).

steel parts to reduœ the risk of hydrogen embrittlement. In 7.2.4 PorositpThe coatings shall be essentiauy porefree

all cases, the durationof the heat treatment shall commence when tested Bccording to one ofthe methods of 9.6. The test

from the time at which the whole of each part attains the method, the duration of the test, and number of allowable

specified temperature. spots per unit axa shall be specified (see5.10 and 9.6).

6.6.2 High-strength steelpartswith actual t e d e strengths 7.3 Qual@cation Requirements-These requirements m

greater than loo0 MPa (correspondinghardness values 300 placed on the deposit and process and are performed on

HV10,303 HB or 31 HRC) and s d k e hardened parts shall specimens to qualï@ the deposit and plating process Tbe

be pn>cessed after coating in accordance with speciscation tests for these qualification requirementsshall be performed

B 850. monthly or more kquentIy.

6.7 Heat Treatment After Plating to Improve Adhesion- 7.3.1 Conrparition-Tm II, m,IV, V deposits shall be

To improve the adhesion of the coating to various substrats, analyzed far alloy composition by testing for phosphorus(see

the heat treatments in Table 3 should be performed as soon 9.1). The weight percent of phosphorus shall be in the range

as practical &el plating (see 4.3). designated by type dassitication (see4.1).

6.8 Heat Treatment ABer Plating to Increase Hurdms: 7.3.2 Mb-me microhardnesp of Class 2 de-

6.8.1 To increase the hardness of the coating a heat posits shall be determined by Test Method B 578 (KMIOP).

treatment of over 260.C is requid. Table 3 describes the ForClass2~themim~nessshalleq~orexceed

heat tnatment for maximumhardness. a minimum of 850 (HK100 (or equivalent Vickers) (see4.3

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

and 9.5).The conversion of Vickers to Knoop using Tables tion, emission or X-ray fluorescence spectrometry.

E 140 is not recommended. N m 12"Inductively coupled plasma techniques can determine the

7.3.3 Hydrogen Embrittlement-The process used to de- alloy to within 0.5 Om.The foUowing analysis wavelength lines have bee0

posit a coating ontohigh strength steels shallbe evaluated for ued with minimum interfaence to determine thealloy.

hydrogen embrittlement by Test Method F 5 19. Ni 216.10 nm Cd 214.44 nm Fe 23820 nm

P 215.40 nm CD 238.34 nm Pb 283.30 nm

8. Sampling P 213.62 nm Cr 284.32 om Sn 198.94 nm

Al 202.55 nm Cu 324.75 nm Zn 206.20 om

8.1 Thepurchaserandproducer are urged to employ 9.2 Appearance-Examine the coating visually for com-

statisticalprocesscontrol in thecoatingprocess.F'roperly pliance withthe requirements of 7.2.l.

performed this will ensure m t e d products of satisfactory 9.3 Thickness:

quality and w lireduce the amount of acceptance inspection.

8.1.1 Sampling plans can only screen out unsatisfactory N m 13-Eddy-cummt type instruments give enatic measurements

due to variations in conductivity of the coatings withchanges in

productswithout assurance thatnone ofthem will be phosphorus content.

accepted. (7)

8.2 Thesamplingplan used for theinspection of a 9.3.I Microscopicd Method-Measum the coating thick-

quantity of coated parts (lot) shall be Test Method B 602 ness of a cross section accordingto Test Method B 487.

unless otherwise specified by purchaser in the purchase order N m 14-To protect the edges, electroplate the specimens with a

or contract (see 5.1 1 and S.1 1.1). minimum of 5 pm of nicket or copper prior to c~(lsssectioning.

NOTE IO-Usually, when a collection of coated parts (the inspection 9.3.2 Magnetic Induction Instrument Method-Test

lot 8.2) is examined for compliance with the requirements placedthe on Methad B 499 is applicable to magnetic substrates plated

parts a relativelysmall number of parts, thesample, is selected at with autocatalytic nickel deposits,that contain morethan 11

random and inspected.The inspection lot is then clasifted as compIying

or not complying with the requirements based on the results of the

mass 96 phosphorus (not ferromagnetic) and that have not

inspection sample.The size of the sample andthe criteria of compliance been heat-treated The instrument shall be calibrated with

are determined by the application of statistics. The procedure is known deposits plated in the same solution under the same condi-

as sampling inspection. Three standads Test Method B 602, Guide tions on magnetic steel.

B 697, and Test Method B 762 contain sampling plansthat are designed 9.3.3 Beta Backscatrm Method-Test Method B 567 is

for the sampling inspectionof coatings. only applicableto coatings on aluminum, beryllium,magne-

Test Method B 602 contains four sampling plans, three for use with

tests that are nondestructiveandonefor use with tests that are sium, and titanium. The instrument mustbe calibrated with

destructive. Thepurchaserand prcduœr may on the plants) to be standards having the same compositionas the coating.

used. If they do not,Test Method B 602 identifig the plan to be used. N m 15-The density of the coating varies with its mass 56

Guide B 697 provides a large number of plans and also gives guidana phosphorus content (SeeAppendù X2).

on the selection ofa plan. When Guide B 697 is specified, the purchaser

and producer need to agree on the plan to be used. 9.3.4 Micrometer Meth0d"Measu-e the part, test

Test Method B 762 can be used only for coating requirements that coupon, or pin in a specific spot before and after plating

have a numerical limit, suchas coating thickness. The last must yield a usinga suitable micrometer. Make sure that the surfaces

numerical value and certain statistical requirements must be met. Test measured are smooth, clean, and dry.

Method B 762 contains several plans and also gives instructions for

calculating plans to meet s p i a l needs The purchaser and producer

9.3.5 Weigh. Plate, Weigh Meth0d"Using a similar sub

may agree on the plan(s)to be used. If they do not, Test Method B 762 strate material of known surface area, weigh to the neafest

idenfifies the plan to be used. milligram before and after plating makingsure that the part

An inspection lotshall be defined as a collection ofcoated parts which or couponis dry and at room temperature for each measure!-

are of the same kind,that have been produced to the same specification, ment. Calculate the thickness Erom the increase in weight,

that have been wated by a single producerat one timeor approximately specific gravity, and area as follows:

thesame timeunderessentiallyidenticalconditions,and that are

submitted for aczeptanœor rejection as a group. coating thickness, Fm = 10 W/(A X D)

8.3 All specimens used in the sampling plan for a m p where:

tance tests shall be made of the same basis material and in W = weight gain in milligrams,

the same metallurgical condition as articles being plated to A = total swface area in square centimetres, and

this specification. D = grams per cubic centimetres(seeAppendix X).

8.4 AU specimens shall be providedby thepurchaser 9.3.6 Coulometric Method-Measure thecoatingthick-

unless otherwiseagreed to by the producer. ness in accordancewith Test Method B 504.The solutionto

NOTEI I-The autocatalytic nickel pnxzss is dynamic and a daily be used shall be in accordanoe with mandachmr's m m -

sampling is recommended. For h q

i

tgrequiring alloy analysis and mendations. The surface of the coating shall be cleaned prior

corrosion testing weekly sampling should be considered as an option. to testing (see Note 14).

9.3.6.1 Calibrate standard thickness specimens with de+

9. Test Methods posits plated in the same solution under the same conditions.

9.1 Deposit Analysis for Phosphorus: 9.3.7 X-Ray Spectrometry-Measure the coating thick-

9.l . 1 Phosphorus Determination-Determine mass ?& ness in accordance withTest Method B 568.The instrument

phosphoruscontentaccording to Practice E 60, Test must be calibrated with standards having the same composi-

Methods E 352, or Test Method E 156 on known weight of tion as the coating.

deposit dissolved in warm concentrated nitric acid. N m I b T h i s method is only realmmended for deposits in the

9.1.2 Composition can be determined by atomic absorp- asplated condition. The phasphorus content of the coating must be

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

~. ~ ~~ ~ ~~

S T D - A S T M B733-ENGL 1777 D 0757530 Ob07737 Sb2

B733

known to calculate the thickness of the deposit. Matrix effect due to the min, nor more than 20 min after the initial application of

distribution of phosphorus in layers of the coating also effect thc heat. Continue to boil the water for 30 min. Then remove

meaJwcmcnt B~CUT&CYand muhthat calibration standards be made the part, air dry, and examine for rust spots, which indicate

under the same conditions as the pmductioo p m

9.4 Adhesion:

Po=.

N m 19-Auated wrta is prepared by bubbling clean cornpnssed

9.4.1 Bend Test (Test M e t M B 571)"A sample spec airthrougbdistilledwrtabymcansofaglaJPdiffusiondiskattoom

imen is bent 180' over a mandrel diameter 4 x the thickness tempaatunfor12h.TbepHoftheaaatedwatasbouhibe6.7+0.5.

(10 mm minimum) of the specimen and examined at 4X 9.6.3 Aerated Water Test for Iron-Base Substrates-Im-

power magnification for Mcing or separation at the inter- mersethepartfor4hinvigorouslyaeratedTypeIVorbettef

&. fine cracks in the mating on the tension side of the water (see Specification D 1193) at 25 f 2% t

emperam

bend are not an indication of poor adhesion. Insertion of a andthenexaminethepartforrustspots.

sharp probe at the intedaœ of the coating and basis metal to 9.6.4 AlizarinTest for AIuminwnAlloys-Wipe the

determine the adhesion is suggested. plated part or specimen with 10 mass 48 d u m hydroxide

NOTE17-Appropriate test specimens are strips approximately25 to solution. After 3 min contact, rinse, and apply a solution of

50mmwide,200to300mmloagand3to6mmthick. alizarin sulfonate prepared by dissolving 1.5 g ofmethyl

9.4.2 Impact Test-A spring-loaded center punch with a œllulosein90mLofboilingwatatowhich,afhcooling,

point having 2 to 3 m m radius is used to test adhesion of the O. 1 g sodium alizarin MOM^, dissolved in 5 mL of ethanol

coating on nonsigni6cant surfaces of the plated part. Make isadded.After4mincontaa,apply~aœticaciduntil

three closely spaced indentations and examine under IOX thevioletcdordisappearsAnyredspots~indicate

magnification forflaking or blistering ofthe coating, which is Po-

cause for rejection. 9.6.5 PorosityTest for Copper Substrutes-Wipe the

9.4.3 ThsnnalShuck-The coated part is beated to 200'C platedpartorspecimenwithglacialaceticacid.After3min,

in an oven and then quencbed in room temperam water. apply a solution ofpotassiumferrocyanide prepared by

The coating is examined for Mistering or other evidence of dissolving I g of potassium fkmcyan3k and 1.5 g methyl

poor adhesion at 4~ magnification. œUulosein9OmLofboilingdistilledwater.Theappearanœ

9.5 híicrokrdness-The microhardness of the coating 0fbrownspotsafter2minindicatepores.

can be measured by Test Metbod B578 using Knmp 9.7 Other Test Method-Test methods which have been

indenter and is reported in Knoop Hardnes Number (HK). developedthatareequaltoorbetterthanthesemaybe

substituted. The w o n and bias requimnents will vary

It will vary depending on loads, type of indenter, and

operator. A L O O g load is recommended. The rhombic foreachtypeoftestIfanalternatetcstisspecifieditshallbe

h o o p indenter gives higher hardness readings than the agreeduponbctwecntheproduœrandthcpwchaser.

squarsbase pyramidal Vickm diamond indenter for 1 0 0 to 10. Re!jdlm d Rehearing

300 g loads, see Ref (6). For maximum accuracy, a min-

imum coating thickness of 75 pm is recommended. Conver- 10.1 Part(s) that thil to conform to the requirements of

sions of Vickm or Knoop hardness number to Rockwell C is thisstandardmayk:rejected.Rejectonshallbereportedto

not recommended. the producer promptly in writing. In the case ofdhatisfb

tionoccurswiththeresultsofatest,theproducermaymake

NOTE1 8 4 thick (75 Fm+) cuatings on steel a surface a claim fora hearing. coatings that show imperfections may

microhardnessdetermination is permissible.

be rejected.

9.6 PorosiwThere is no universally accepted test for

porosity. When required,one of the following tests can be 11. c k r t i f i i

used on the plated part or specimen. 11.1 Whenspecifedinthepurchaseorderorcontmct,the

9.6.1 Ferroxyl Test for Iron Base Substrates-Prepare the purchaser shall be lùmished certitication that the samples

test solution by dissolving25 g of potassium ferricyanide and representing each lot have b n proased, tested and in-

15 g of sodium chloride in 1 L of distilled water. After spected as directed in this specification and the quirements

cleaning, immerse the part for 30 S in the test solution at , h a been met. When specifiedin the purchase oder or

v e

25%. After rinsingand air drying, examine the part for blue contract,areportofthetestresultsshallbefurnished.

spots, which form at pore sites.

9.6.2 Boiling Water Test for Iron-Base Substrates-Com- 12 Keywords

pletely immerse the part to be treated in a vessel filled with 12.1 autmatalytiq chemical nickek coati-, conductive;

aerated water at m m tempemture. Apply heat to the beaker c o d o n resistance; electrolq functional, nickeknickel

atsucharatethatthewa~beginstoboilinnotlessthan15 Phosphorus;"

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall applyonlywhen specified by thepurchaser in the

contract or order.

S1.1 Shot Peening-When specified by the purchaser in S1.7 Conlact Resistance-When specified by thepur-

the ordering information, the part@) shall be shot peened chaser in the ordering information, the coating shall be tested

prior to plating in accordance with Specification B 85 1 or for contactresistance using Test MethodB 667.

MILS13165 S1.8 sOldetabi1ity"when specified by the purchaser in

S1.2 Composition-When specified by thepurchaserin the ordering information, the unaged coating shall pass Test

the ordering information the phosphorus content shall be Method B 678 on solderability.

maintainedinthedeposit to within 1 % . Use the test S1.9 Corrosion Resistance-When specified by the pur-

methods described in9. l. chaser in the ordering information the coating shall pass any

S 1.3 Inert Atmosphere-When specified by the purchaser special corrosion tests agreed to by theproducer. The

corrosion resistance of thecoating to aspecificliquid

in the ordering information, the coating shall be heat treated

medium can be determined by means of immersion tests (see

in avacuum,inert, or reducingatmosphere to prevent practice G 3 I ) or electrochemical test (seePractices G 5 and

surface oxidation of the coating. G 59).

S1.4 HydrogenEmbrittlement-Whenspecifiedby the S1.10 Pitting Corrosion Resiszance-Use Method G 85

purchaser in the ordering information the plating process (aceticacid-saltspraytest),Method B 368 (copper-accel-

shall be evaluated at thetime of processingpartsfor eratedaceticacid-saltspray, C M ) , or Method B380

hydrogen embrittlement using Test Method F 5 19. (Corrodkote) to evaluatethe c~rrosionresistance of the

S1.5 Abrasive Wear-When specified by the purchaser in coating to pitting

theorderinginformation,thecoating shall be testedfor S l. 11 Special Government Requirements:

abrasion wear resistance using the method in Appendix X1 Sl. 1 l . 1 Sampling-Part(s) plated for theUS Government

of thisspecification.Thecoating shall meetamaximum and Military use shall use MILSTD-105 as the sampling

wear rate which is specified by the purchaser and agreed to plan.

by the producer. S1.11.2 Shot P e e n i n g " strength steel part($ p m

S I .6 Adhesive Wear-When specified by the purchaser in cessed for US Government and Military use shall be shot

the orderinginformation,thecoating shall be testedfor peened in acconiance with -13165 orrotary flap

adhesive wear resistance using Test Method D 27 14or Test peened in aa;ordancewith Mil-R-8 184l. (seeNote 6).

Method D 2670. The wear rate shall bespecified by the SI. 1 1.3 Puckugin"parts shall be packaged in accor-

purchaser andagreed to by the producer. danq with Practice D 3951.

APPENDIX

(Nonmandatory Information)

XI. TABER ABRASER WEARTEST"I0D

x1.1 scope X1.2 Apparatus

X l . l. 1 This test methodwlievaluate the resistance of the X 1.2.I TaberAbraser Wear Testing Unit-The unit must

coating to abrasive wear. The test is performed by rotating a be capable ofloading with I O 0 0 g load and operating with a

plated panel under rotating rubber wheels and weighing the vacuum.

panel aller each l o 0 0 cycles for weightloss. Duration of the X1.2.2 Abrasion Wheels-Use Cs10 (resilientrubber)

test is 6000 cycles and itcan be extended to 25 O00 cycles for Taber wheels. To reface the wheels use CS-1 1 discs fkom

more complete results. Taber. The hardness of CS10 wheels can change with time

NOTEX1.I-Variation in results have been attributed to the hu- and can effect thereproducibility of results(seeTest Method

midity in the laboratory and the storage conditions of the CS10 wheels. D 4060).

Care should be.taken to control the humidity between tests. X1.2.3 TestSpecimens-Test specimens shall be made

X l . 1.2 The w d t s are variable between tests and there- fiom 20 gage CR stee.14 by 4 in. (100 by 1 0 0 by 1.3 mm)

fore three plated test specimens should be tested to 6000 with a 0.250 (6.35 mm) hole in the center. Test specimens

cycles each. The results should be averaged withoutthe lïrst are available fiom Taber.

l o 0 0 cycles and the abrasion wear resistance is reported as X1.2.4 Analytical Balance-Scalewhich is capable of

the weight loss in mg/1000cycles (Taber Wear Index). measuring to 150 g k O. 1 mg.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

X13 Procedure X1.3.2.4 Abrasion test the coating with IO00 g load for

X1.3.1 Plate three specimens with 0.001 in. (25 Pm) of ~Ooocycles.

nickel phosphorus mating. X1.3.2.5 Repeat X1.3.2.2, X1.3.2.3and X1.3.2.4 until a

X1.3.2 Wear test the specimens. For each of the three total of 6OOO cycles bave been accomplished for eacb

specimens complete thefollowing steps: specimen.

X1.3.2.1 Run the CS10 wheels on the coating for IO00

cycles to remove any surface rouphness. The wheels shall be

loaddwith IOOOgwithavacuumonhighfortheentiretest. X l A Reparthg

X1.3.2.2 Cool and weigh the specimen to the nearest 0.1 X1.4.1 Determine the average weight loss in m@cams

mg. for each specimen per lo00 cycles Taber Wear Index and the

X1.3.2.3 Dress the CS10 wheels with a C S 1 1 disc for 50 mean weight loss per lo00 cycles for all specimens. Report

cycles. the mean and standard deviation for the coatins

X2. DENSITY OF AUTOCATALYTIC NICKEL DEPOGITS

Density of Electrobs8 Nickel Deposits

Reidel, Wolfgang, Electroless Nickel PLating. ASM International, Metals Park, OH 1991, p92. DIN 50966

IS0 4527. Annex C

Vendor, Elnic, unpublished

Rajarn, K. S. Rajam e t al. Metal Finishing, Vol 88. No 11 119901

NIST, Fielding Ogburn e t al, Plating and Surface Finishing, Vol. 68, No 3 (19811

Kanigen. ASTM STP No. 265, Electroless Nickel Plating 1959

Oak Ridge, D. D. Smith, Thermal Conductivity o f Electroless Nickel-Phosphorus Alloy Plating. National

Science Foundation, 1963

Gorbunova, K. M. Gorbunova and A. A. Nikiforova, Physicochemical

Principles of Nickel Plating, National Science Foundation. 1963

Vendor, Schering, unpublished analytical results. ScheringKG. Berlin 1982

Mallory, Glenn Mallory e t al, Studies and Properties of Very Hard Electroless Nickel Deposits.

EN'95. Gardner Management, Cincinnati. OH, 1995

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

X3. HARDNESS VERSUS HEAT TREATMENT

NICKELvs TEMPERATURE

HARDNESS OF ELECTROLESS vs TYPE

1000

900

I

800

700

600

500

II

, I l I

!I I

I I I I l

t I I

I I I l I

400

O 100 200 300 400 500

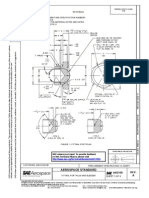

x4. ALLOY TYPES

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

B733

TYPES

HARDNESS MAGNETICS STRENGTH

O

I """"""""

3

4

5

6

P% P%

7

IO

II

12 12

13 I3

.-

IL IL

LOW HIGH LOW

NON HIGH FERRO

MAGNETIC

MAGNETIC

FmX4.1 ~~dA."Nldrd~co11Oho,by"

X5. SUMMARY PROGRAM 14

X5. I Results of 110 Month Exposure of Autocatalytic to evaluatetheformation of diffusion products of iron,

Nickel Depsits at Kure Beach, North Carolina: nickel andphosphorus

X5.1.1 Program 14 is part of an ongoing marine exposure X5.1.3 The following matrix of test panels were prepared

testing process atthe 75 m site at Lame Center for and exposed with subsequent analysis for alloy and thick-

Corrosion Technology, Wrightsville, NC (Kure Beach). The ness. Panels were rated at Kure Beach each year by a team

program c a

U d for the plating of both Type N and Type V from A!RM committee B 8 using Ractice B 537.

deposits on standard smooth and ground steel Q PaneIs. X5.1.4 The interpmtationof the results of these exposure

X5.1.2 There were nineMerent sources of deposits, each test should be made on the basis of general performance of

providing five lots of five panels. The program involved the coating on panels. Base metalcondition, undercoats,

plating 12.5,25, and 75 Fm thicknesses on smooth and surface prcparation,and post processing all have a signiscant

ground surface and one smooth lotheat treated for hardness effect on the performance and should be given mreful

at 550'C for 2 h. The heattreatment temperature was consideraton when designing the part and p&reatment

considerably higher than typical processing and was chosen processing sequenœ.

10

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

S T D - A S T M B733-ENGL L797 W 0 7 5 7 5 3 0 Ob097LI2 72T

1 smooth No 125 3.6 f 3.0

2 smooth No 25 9 2 f 0.3

V G 3 smooth No 75 m5 105 109 10*0

4 smooth YeS 25 92 f O 3

5 Grand No 25 7.0 f 0.4

1 smooth No 12.5 0.0 f 0

2 smooth No 25 0.0 f 0

V E 3 smooth No 75 77 10.0 102 *

9.8 0.4

4 smooth YeS 25 8 2 f 0.8

5 Grand No 25 42 fO A

1 smaoth No 12.5 6.8 f 1.3

2 smooth No 25 6 2 f 0-4

V C 3 smooth No 75 46 9.9 10.4 8.0 f 1.1

4 smooth YeS 25 6.8 f 1.3

5 Grand No 25 0.0 f 0

1 smooth No 12.5 0.0 f o

2 smooth No 25 5.8 f 0.4

IV J 3 smooth No 75 9.0 9.6 f 1.1

4 smooth YeS 25 7.0 f o

5 Grand No 25 1.0f2

1 smooth No 125 0.6 f Ob

2 smooth No 25 7-4 f 0 9

IV 3 smooth No 75 8.9 10.0 f 0

4 smooth YeS 25 4.0 f 1.1

5 Grand No 25 0.0 f 0

1 smooth No 125 0.0 f 0

2 smooth No 25 1.8f 1.6

IV 3 SnKKml No 75 79 8.3 6.0 f 1.0 7.3

4 smooth YeS 25 5.0 f 0

5 (;rand No 25 0.0 f 0

1 smooth No 12.5 0.0 f O

2 smooth No 25 0.0 f 0

IV 3 smooth No 75 77 02 9.5 5.0 f 1A

4 smooth YeS 25 5.4 f 0.5

5 oand No 25 0.0 f 0

1 smooth No 125 0.0 f 0

2 smooth No 25 0.0 f 0

IV K 3 smooth No 75 75 0.6 f 0.8

4 smooth YeS 25 5.6 f 2.8

5 (jmud No 25 0.0 f O

1 smooth No 12.5 0.0 f o

2 srooth No 25 0 2 f 0.4

N I 3 smooth No 75 80 7.1 0.4 f O 5

4 smooth YeS 25 4.6 f 0.0

5 25

REFERENCES

(1) Symposium on ElectrolessNickel Plating, ASTM STP 265, A S M , 12644 Raearch Parkway, Orlando, R.32826, 1986 Chapter 23.

1959. (5) Mallory G., and Hajdu J. " E k ct

ros

l

Phtbg," AESF 12644

(2) Engineering Properties of Electroless Nickel, The International Research Parkway, Orlando, FL 32826,1990.

Nickel Co., Inc., New York, NY. (6) m,K., "Hardmss and Wear Redanœ Tests of F i k c t r o I e s

(3) Gawrilov, C. G.,Chemical (Electroless) Nickel Plating, Portcullis N i Deposi4" W i n g , Vd 61,September 1974.

ReSS, London, 1974. (7) P ar

ke r

, K. of Heat Treatment on thc Ropemes of

(4) Saiìanek, W. H.,The Properties of Electroakposited Metals Md Electrokss Nickel Plating and S@îî Finishing, Vol

Afloys, The American Electroplatersand Sud&ce Finishen Society, 68,December 1981.

11

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

Potrebbero piacerti anche

- Mil C 26074eDocumento11 pagineMil C 26074edharlanuctcomNessuna valutazione finora

- Doall Fu-205 ManualDocumento107 pagineDoall Fu-205 ManualBensend ThompsonNessuna valutazione finora

- As 9100Documento1 paginaAs 9100prash1820Nessuna valutazione finora

- Wiring: Lock, Shear and Seal: Section 2Documento6 pagineWiring: Lock, Shear and Seal: Section 2sancakemreNessuna valutazione finora

- Sae As 81820-4B 2007 (En)Documento4 pagineSae As 81820-4B 2007 (En)Oh No PotatoNessuna valutazione finora

- Nasm 21044Documento4 pagineNasm 21044karthiprojectsNessuna valutazione finora

- Cable TiesDocumento16 pagineCable Tiesrodax4Nessuna valutazione finora

- Astm B 328Documento4 pagineAstm B 328martin andolini100% (1)

- 7178-T6511 Property - ASM Material Data SheetDocumento2 pagine7178-T6511 Property - ASM Material Data SheetptrfmNessuna valutazione finora

- Mil PRF 85285FDocumento26 pagineMil PRF 85285Fchampyjm6532Nessuna valutazione finora

- AN807 Rev7Documento5 pagineAN807 Rev7MAI_QualityNessuna valutazione finora

- 17-7 Material PDFDocumento5 pagine17-7 Material PDFJothi ManiNessuna valutazione finora

- LISI AEROSPACE - New Generation HI-LITE™ PinsDocumento6 pagineLISI AEROSPACE - New Generation HI-LITE™ PinsLeandro González De CeccoNessuna valutazione finora

- Tlulilv: For Polytetrafluoroethylene Molded BasicDocumento6 pagineTlulilv: For Polytetrafluoroethylene Molded BasicjenishjsNessuna valutazione finora

- High Torque Nozzle MK66Documento12 pagineHigh Torque Nozzle MK66Sergio SacristanNessuna valutazione finora

- Standard Specification For Materialsl: This IY L)Documento6 pagineStandard Specification For Materialsl: This IY L)Dŕáğøņ RyzhonNessuna valutazione finora

- Aerospace Material Specification: AMS4154 Rev. RDocumento6 pagineAerospace Material Specification: AMS4154 Rev. Rmarjan banooNessuna valutazione finora

- Bes MSDocumento1 paginaBes MSasdNessuna valutazione finora

- Shroud Segments, Support Segment Rings and Shroud Pads - Inspection/CheckDocumento23 pagineShroud Segments, Support Segment Rings and Shroud Pads - Inspection/CheckdavidNessuna valutazione finora

- AN924Documento8 pagineAN924David WongNessuna valutazione finora

- North Atlantic Treaty Organization: AOP-48 (Edition 2)Documento48 pagineNorth Atlantic Treaty Organization: AOP-48 (Edition 2)deepu1wNessuna valutazione finora

- BAMS 532-018 250 Degree Epoxy Prepreg Fiberglass ClothDocumento22 pagineBAMS 532-018 250 Degree Epoxy Prepreg Fiberglass ClothJohn CollinsNessuna valutazione finora

- Ms 14103Documento3 pagineMs 14103Aleksandr TsymbalNessuna valutazione finora

- An805 8Documento3 pagineAn805 8jcNessuna valutazione finora

- Astm A 336 .03Documento8 pagineAstm A 336 .03FrengkiNessuna valutazione finora

- An3 Thru An20 Rev-12bDocumento2 pagineAn3 Thru An20 Rev-12bffontanaNessuna valutazione finora

- Palmgren Revisited - A Basis For Bearing Life PredictionDocumento12 paginePalmgren Revisited - A Basis For Bearing Life PredictionahemerlyNessuna valutazione finora

- BE-Teklam Product BrochureDocumento21 pagineBE-Teklam Product BrochurecthembreeNessuna valutazione finora

- 516 Vs 515Documento2 pagine516 Vs 515Madan YadavNessuna valutazione finora

- BS 1595 PDFDocumento9 pagineBS 1595 PDFAdesina AlabiNessuna valutazione finora

- SAE - AMS 4050hv004Documento9 pagineSAE - AMS 4050hv004Nilesh PatilNessuna valutazione finora

- A591A591MDocumento4 pagineA591A591MErnesto SanzNessuna valutazione finora

- As 5169Documento5 pagineAs 5169Wuod JipangaNessuna valutazione finora

- Shelf LifeDocumento1 paginaShelf Lifeluis hernandezNessuna valutazione finora

- Shot Peening Coverage Requirements: Academic StudyDocumento6 pagineShot Peening Coverage Requirements: Academic StudyUmit AytarNessuna valutazione finora

- Kaiser Aluminum Soft Alloy Tube PDFDocumento31 pagineKaiser Aluminum Soft Alloy Tube PDFgerrzen64Nessuna valutazione finora

- B467Documento8 pagineB467odqm_25Nessuna valutazione finora

- SAE AMS5699 - RevGDocumento8 pagineSAE AMS5699 - RevGLynn AlgerNessuna valutazione finora

- Tribolube 64Documento2 pagineTribolube 64JasonNessuna valutazione finora

- Fed STD H28aDocumento11 pagineFed STD H28amurphygtNessuna valutazione finora

- FT Grease 22Documento2 pagineFT Grease 22Edgar Leonel CortésNessuna valutazione finora

- Aerospace Standard AS81934/2 Rev. A: Custodian: Sae Airframe Control Bearings GroupDocumento3 pagineAerospace Standard AS81934/2 Rev. A: Custodian: Sae Airframe Control Bearings GroupRanga100% (1)

- Mil PRF 8625 Amend02Documento20 pagineMil PRF 8625 Amend02dan howsNessuna valutazione finora

- Steel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessDocumento7 pagineSteel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessCarolina LeonNessuna valutazione finora

- Material Comparison F316L Vs F321Documento1 paginaMaterial Comparison F316L Vs F321Vivi OktaviantiNessuna valutazione finora

- 03SA0S04Documento5 pagine03SA0S04Jhonny RinconesNessuna valutazione finora

- SB 150Documento4 pagineSB 150AnilNessuna valutazione finora

- SP7012M00D07 000 ADocumento23 pagineSP7012M00D07 000 ABrayhan Alexander PalominoNessuna valutazione finora

- 16899Documento33 pagine16899Edson BastoNessuna valutazione finora

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistanceDocumento4 pagineSteel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistancePham Huu Loc Ho100% (1)

- Nas6703 NationalaerospacestandardDocumento8 pagineNas6703 NationalaerospacestandardSAPTONessuna valutazione finora

- Astm E498-00 PDFDocumento4 pagineAstm E498-00 PDFJORGE ARTURO TORIBIO HUERTA100% (1)

- 1 716554253262394595 PDFDocumento3 pagine1 716554253262394595 PDFAfzaalUmairNessuna valutazione finora

- QPL 46010 - 17 Sep 2019Documento2 pagineQPL 46010 - 17 Sep 2019liuyx8660% (1)

- Bent Tubes: DocumentationDocumento17 pagineBent Tubes: DocumentationAkmal NizametdinovNessuna valutazione finora

- Autocatalytic (Electroless) Nickel-Phosphorus Coatings On MetalDocumento13 pagineAutocatalytic (Electroless) Nickel-Phosphorus Coatings On MetalSathish KumarNessuna valutazione finora

- Astm B733-97 PDFDocumento12 pagineAstm B733-97 PDFAleiser Quevedo AcuñaNessuna valutazione finora

- ASTM B733 - Nickel-Phosphorus CoatingsDocumento14 pagineASTM B733 - Nickel-Phosphorus CoatingsJyothishNessuna valutazione finora

- Composite MaterialsDa EverandComposite MaterialsA.T. Di BenedettoValutazione: 1 su 5 stelle1/5 (1)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumDa EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNessuna valutazione finora

- A1015Documento3 pagineA1015Aleksei AvilaNessuna valutazione finora

- A1001 PDFDocumento5 pagineA1001 PDFJesus VelizNessuna valutazione finora

- BS 5159 (1974)Documento22 pagineBS 5159 (1974)GILBERTO YOSHIDANessuna valutazione finora

- A1025 Standard Specification For Ferroalloys, General Requirements1Documento4 pagineA1025 Standard Specification For Ferroalloys, General Requirements1Jesus VelizNessuna valutazione finora

- Castings, Nickel-Aluminum Ordered Alloy: Standard Specification ForDocumento2 pagineCastings, Nickel-Aluminum Ordered Alloy: Standard Specification ForhamidharvardNessuna valutazione finora

- A 1012 - 02 Qtewmti - PDFDocumento4 pagineA 1012 - 02 Qtewmti - PDFNguyễn Xuân ĐiệpNessuna valutazione finora

- Numbering Metals and Alloys (UNS) : Standard Practice ForDocumento7 pagineNumbering Metals and Alloys (UNS) : Standard Practice ForArmando ArredondoNessuna valutazione finora

- A1001 PDFDocumento5 pagineA1001 PDFJesus VelizNessuna valutazione finora

- A1025 Standard Specification For Ferroalloys, General Requirements1Documento4 pagineA1025 Standard Specification For Ferroalloys, General Requirements1Jesus VelizNessuna valutazione finora

- A1001 PDFDocumento5 pagineA1001 PDFJesus VelizNessuna valutazione finora

- Castings, Nickel-Aluminum Ordered Alloy: Standard Specification ForDocumento2 pagineCastings, Nickel-Aluminum Ordered Alloy: Standard Specification ForhamidharvardNessuna valutazione finora

- Martensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServiceDocumento4 pagineMartensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServicemarceloNessuna valutazione finora

- Carbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsDocumento2 pagineCarbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsJesus VelizNessuna valutazione finora

- A1026Documento2 pagineA1026Jesus VelizNessuna valutazione finora

- Evaluating Machining Performance of Ferrous Metals Using An Automatic Screw/Bar MachineDocumento10 pagineEvaluating Machining Performance of Ferrous Metals Using An Automatic Screw/Bar MachineJesus VelizNessuna valutazione finora

- Astm E588Documento9 pagineAstm E588Jesus VelizNessuna valutazione finora

- Standard Specification For Metal, Expanded, Steel1Documento6 pagineStandard Specification For Metal, Expanded, Steel1Jesus VelizNessuna valutazione finora

- A65Documento3 pagineA65wpwmhatNessuna valutazione finora

- BS 5159 (1974)Documento22 pagineBS 5159 (1974)GILBERTO YOSHIDANessuna valutazione finora

- Astm E618Documento12 pagineAstm E618Jesus VelizNessuna valutazione finora

- Astm e 446 15Documento4 pagineAstm e 446 15Satwant SinghNessuna valutazione finora

- BS 5159 (1974)Documento22 pagineBS 5159 (1974)GILBERTO YOSHIDANessuna valutazione finora

- Evaluating Machining Performance of Ferrous Metals Using An Automatic Screw/Bar MachineDocumento10 pagineEvaluating Machining Performance of Ferrous Metals Using An Automatic Screw/Bar MachineJesus VelizNessuna valutazione finora

- Din 2635Documento2 pagineDin 2635Jesus VelizNessuna valutazione finora

- Titanium and Titanium Alloy Bars and Billets: Standard Specification ForDocumento7 pagineTitanium and Titanium Alloy Bars and Billets: Standard Specification ForJesus VelizNessuna valutazione finora

- Astm A845Documento2 pagineAstm A845Jesus VelizNessuna valutazione finora

- Exam Materials ScienceDocumento10 pagineExam Materials ScienceChimzoe CatalanNessuna valutazione finora

- 704-Article Text-1322-1-10-20190630Documento7 pagine704-Article Text-1322-1-10-20190630Hardi AhmedNessuna valutazione finora

- Insulation Details For Cold Piping PDFDocumento1 paginaInsulation Details For Cold Piping PDFzampacaanasNessuna valutazione finora

- Synthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidDocumento6 pagineSynthesis and Characterization of A Novel Organic Corrosion Inhibitor For Mild Steel in 1â M Hydrochloric AcidRoberta VasquesNessuna valutazione finora

- RODGERS - 553 - Manual de Conservacion para El Arqueologo - 2004Documento122 pagineRODGERS - 553 - Manual de Conservacion para El Arqueologo - 2004d_ugljen4905Nessuna valutazione finora

- Chemistry ReportDocumento109 pagineChemistry ReportMARY JOY PIOSCANessuna valutazione finora

- Materials For Ferrous Powder Metallurgy (P/M) Structural PartsDocumento24 pagineMaterials For Ferrous Powder Metallurgy (P/M) Structural Partshagiang1411Nessuna valutazione finora

- Baia (09092016)Documento555 pagineBaia (09092016)assassaNessuna valutazione finora

- MEM - CH - 3 - MCQsDocumento5 pagineMEM - CH - 3 - MCQsKazuto KirigayaNessuna valutazione finora

- Plasma Arc Machining - Process, Diagram, Advantages and DisadvantagesDocumento15 paginePlasma Arc Machining - Process, Diagram, Advantages and DisadvantagesJarvis EdwinNessuna valutazione finora

- Unit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeDocumento58 pagineUnit VI Corrosion Science: Course Instructor-Dr. Shailesh DhokeLadliNessuna valutazione finora

- DLL 7Documento40 pagineDLL 7Caren Deadio AliligayNessuna valutazione finora

- Review Esas 5 (Engineering Materials)Documento18 pagineReview Esas 5 (Engineering Materials)Araiza FloresNessuna valutazione finora

- Lakhmir Singh Chemistry Class 9 Solutions Chapter 2Documento34 pagineLakhmir Singh Chemistry Class 9 Solutions Chapter 2Devanshi DwivediNessuna valutazione finora

- Alloys: I) IntroductionDocumento12 pagineAlloys: I) IntroductionNikhil ShelarNessuna valutazione finora

- Bahir Dar University Bahir Dar Institute of Technology Faculty of Mechanical and Industrial Engineering Department of Mechanical EngineeringDocumento40 pagineBahir Dar University Bahir Dar Institute of Technology Faculty of Mechanical and Industrial Engineering Department of Mechanical EngineeringEmnet AbNessuna valutazione finora

- Gce o Level Chemistry Syllabus 2013Documento42 pagineGce o Level Chemistry Syllabus 2013Shamala NadarajuNessuna valutazione finora

- Electrode Consumption PDFDocumento1 paginaElectrode Consumption PDFharold_bhieNessuna valutazione finora

- Tds Midnight Black Web 202205Documento1 paginaTds Midnight Black Web 202205LuuThiThuyDuongNessuna valutazione finora

- Chunky GraphiteDocumento16 pagineChunky GraphitesachinguptachdNessuna valutazione finora

- Notes Class 8 Science Chapter 11Documento1 paginaNotes Class 8 Science Chapter 11rekhatyagi55443Nessuna valutazione finora

- EFM - Unit 2 - Engineering Materials (Edited)Documento23 pagineEFM - Unit 2 - Engineering Materials (Edited)truong100% (1)

- MSPL Final ReportDocumento53 pagineMSPL Final ReportKiran RawalNessuna valutazione finora

- Science 7 - Cur - Map.Documento7 pagineScience 7 - Cur - Map.Marl Rina EsperanzaNessuna valutazione finora

- Prodinfo Gardacid-P-4414 Eng FinalDocumento2 pagineProdinfo Gardacid-P-4414 Eng FinalChinawut KhaisilpNessuna valutazione finora

- Flow Meter Brochure-1Documento36 pagineFlow Meter Brochure-1john dimailigNessuna valutazione finora

- Full Download Consumer Behaviour 6th Edition Schiffman Solutions ManualDocumento36 pagineFull Download Consumer Behaviour 6th Edition Schiffman Solutions Manualntunroulia100% (38)

- The Open Civil Engineering JournalDocumento18 pagineThe Open Civil Engineering JournalyouventharanNessuna valutazione finora

- Aluminum Alloys - Mechanical Properties PDFDocumento10 pagineAluminum Alloys - Mechanical Properties PDFMohamed NasrNessuna valutazione finora

- ZINC NIF Revenue Model v2021!06!07Documento14 pagineZINC NIF Revenue Model v2021!06!07JibaNessuna valutazione finora