Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MLX10407 Datasheet Melexis

Caricato da

revisione turbine turbo turbocompressoriTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MLX10407 Datasheet Melexis

Caricato da

revisione turbine turbo turbocompressoriCopyright:

Formati disponibili

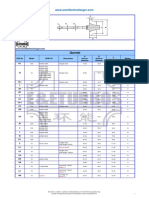

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

FEATURES RST VER VCC VCC GND GND

* Supply voltage up to 12 V.

SIN1P

* Interface directly with 5 V CMOS logic µP. POR SIN1M

* Serial link. BUF 1 COS1P

ROM COS1M

* can drive SCLK SEQ

two actuators 360° CS SERIAL

SIN2P

DIN

three actuators 90° LINK

BUF 2

SIN2M

COS2P

* open circuit or short circuit detection COS2M

of the drivers outputs. OSCI

OSC OUT5

* Small size (SO24 package). OSCO LOGIC SMALL

OUT6

ANGLE

OUT7

ERR TEST

fig 1. Block diagram.

The 10407 is a µP peripheral for logometers control using SIN/COS PWM commands. The circuit

controls two independant sets of CMOS power bridges. A ten bits angle is displayed with a 9 bits per

quadrant resolution PWM whose frequency is set by a crystal oscillator. A power-on self test detects open or

short-circuits outputs for each logometer and a real time angle tracking avoids display errors.

The 10407 can also drive three small angle logometers (90°).

The communication with the µP is done via a three wires serial link.

The 10407 outputs an error status on a special pin.

Ordering Code

Product Code Temperature Code Package Code Option Code Packing Form Code

MLX10407 E DF AAA-000 RE

Legend:

Temperature Code: E for Temperature Range -40°C to 85°C

Package Code: DF for SOIC300Mil

Packing Form: RE for Reel

Ordering example: MLX10407EDF-AAA-000-RE

STANDARD PRODUCT july 9, 1997 PAGE 1, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

PINNING.

Pin 1 : VCC

Pin 2 : SIN1P, Output buffer (coil 1 Logo1 )

Pin 3 : SIN1M, Output buffer (coil 1 Logo1 )

Pin 4 : VSS

Pin 5 : COS1P, Output buffer (coil 2 Logo1 )

VCC 1 24 SIN2P Pin 6 : COS1M, Output buffer (coil 2 Logo1 )

SIN1P 2 23 SIN2M Pin 7 : OUT5, Output buffer ( Logo 3 )

SIN1M 3 22 VSS Pin 8 : OUT6, Output buffer ( Logo 4 )

VSS 4 21 COS2P Pin 9 : OUT7, Output buffer ( Logo 5 )

COS1P 5 20 COS2M

Pin 10 : VCC

COS1M 6 19 OSCI

Pin 11 : CS, Chip select ( Schmitt trigger with 300kΩ pull-down )

OUT5 7 18 OSCO

Pin 12 : SCLK, Serial clock ( Schmitt trigger )

OUT6 8 17 VER

Pin 13 : DIN, Data IN ( Scmitt trigger )

OUT7 9 16 ERR

Pin 14 : TEST input. (1kΩ pull-down)

VCC 10 15 RST

Pin 15 : RSTB, external reset ( Schmitt trigger )

CS 11 14 TEST

Pin 16 : ERRB, Quadrant error output ( Open drain )

12

Pin 17 : VER, Quadrant verification inhibit

SCLK 13 DIN

Pin 18 : OSCO, Crystal oscillator output

10407 Pin 19 : OSCI, Crystal oscillator input

fig.2 Pinning diagram. Pin 20 : COS2M, Output buffer (coil 2 Logo2 )

SO24 PACKAGE

Pin 21 : COS2P, Output buffer (coil 2 Logo2 )

Pin 22 : VSS

Pin 23 : SIN2M, Output buffer (coil 1 Logo2 )

Pin 24 : SIN2P, Output buffer (coil 1 Logo2 )

STANDARD PRODUCT july 9, 1997 PAGE 2, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

OPERATION.

1) Logometers 360°

Immediately after a reset, the I.C. checks if there is any short-circuit or open circuit on each buffer driver

output (This test is not made for outputs 5,6 7). For this test, each buffer is held in a high impedance state

and large internal resistances (100kΩ) are sequentially connected on each pair of buffers (note : the actuator

coil must be connected on each bridge).

VCC

R2 Three tests are done (see fig 3.)

S2

OUT1M

condition test for :

Coil

OUT1P

S1

Test 1 S1 closed, S2 open V1 = VSS

(HI Z) (HI Z)

V1

Test 2 S1 closed, S2 closed V1 = VCC/2

R1 Test 3 S1 open, S2 closed V1 = VCC

VSS

fig 3. Test for short-circuits and open circuits.

During the tests the pin ERRB (16) is at logic level 0. Then after the tests have been done ERRB stays at 0 if

one (or more) test fails or changes to high impedance state if every thing is OK.

These tests last approximately 4 ms with an oscillator clock frequency of 8 Mhz.

After the test all buffers are at VSS. The I.C. waits for the µP to send an angle/quadrant value and then

outputs a PWM signal on every buffer. Every logometer coil is connected in a bridge, so the current Icoil can

be either positive or negative. The total drop-out of a bridge is :

Vd = | VCC - Vcoil |

The four bridges have the same drop-out for the same current Icoil.

Vcoil

OUT1P OUT1M

Coil

Icoil

fig 4. One bridge.

2) Logometers 90°

There are three different PWM outputs for Logo 3, Logo 4, Logo 5.

STANDARD PRODUCT july 9, 1997 PAGE 3, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

SERIAL LINK.

The µP outputs the serial clock SCLK, the chip select CS, the data DIN, and receives from the I.C.

the error status on pin ERRB(16).

The data sent by the µP are latched by the 10407 on the rising edge of SCLK.

The 10407 outputs an error status on pin ERRB (16) on the falling edge of SCLK.

When CS = "0" the serial interface of the 10407 is inactive. When CS goes HIGH the 10407 waits for a

START BIT and then reads the following 15 bits transmitted by the µP (see fig 4.)

The START BIT (D0) must be "1".

The following three bits (D1D2D3) are the operation code for the 10407 :

D1D2D3 = 001 ⇒ Writing request LOGO1

D1D2D3 = 011 ⇒ Writing request LOGO2

D1D2D3 = 100 ⇒ Writing request LOGO3

D1D2D3 = 110 ⇒ Writing request LOGO4

D1D2D3 = 101 ⇒ Writing request LOGO5

Any other codes are reserved for test and will have no effect in normal operation mode.

The following 10 bits (D4D5D6D7D8D9D10D11D12D13) are the value of the angle (D4 = MSB, D13 =

LSB).

The following two bits (D14D15) represent the quadrant (D14=MSB). Note : for Logo1 & 2 only.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

SCLK

CS

1 CODOP 10 BITS ANGLE quad

DIN

z z

ERRB

"0" if error

fig 5. Timing diagram serial link.

The 10407 outputs an error status on pin ERRB (16) on the falling edge of SCLK immediately

following the transmission of the quadrant LSB.

The pin 16 (ERRB) of the 10407 is driven low if there is no continuity between two consecutive

quadrant values sent (for logo1 or logo2). The data is valid till CS is high, then when CS goes low ERRB

returns to high impedance state and the error status is lost.

If the µP has detected an error, it is possible to send data again : the first bit "1" will initiate a new

transmission of 15 data bits.

On the HIGH to LOW transition of CS the values of angle and quadrant are stored into the internal

registers of the 10407 if :

- The µP sent a writing request,

- No quadrant error was detected by the 10407.

Otherwise new values of angle and quadrant are not taken into account by the 10407 and the

previous values are kept. The µP must initialize a new transmission with the 10407.

STANDARD PRODUCT july 9, 1997 PAGE 4, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

It is possible to make the 10407 store all values of angles and quadrant even if there is an error

if the pin 17 (VER) is connected to GND.

STANDARD PRODUCT july 9, 1997 PAGE 5, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

PWM GENERATION.

1) Logometers 360° ( Logo 1 and Logo 2 ) :

From the angle value received from the µP (range [0° - 89.8°]) the 10407 generates two PWM (9 bits

resolution) :

- the first one represents the sinus PWMSIN,

- the second one is the cosinus PWMCOS.

The 10407 uses a ROM 512x9 which contains the sinus of any angle in the range [0° - 89.8°]

(note that the LSB value of the angle is not used).

A value of angle greater than 90° is obtained using different quadrant values :

Q1 (D14D15 = 00) ⇒ 0° ≤ α < 90°

Q2 (D14D15 = 01) ⇒ 90° ≤ α < 180°

Q3 (D14D15 = 10) ⇒ 180° ≤ α < 270°

Q4 (D14D15 = 11) ⇒ 270° ≤ α < 360°

The PWM are switched to the outputs depending on the value of the quadrant :

QUADRANT

90 SIN1M SIN1P COS1M COS1P

Q1 ++ Q2 -+ D14 D15

0 0 0 PWMSIN 0 PWMCOS

0 α α 180 0 1 0 PWMCOS PWMSIN 0

α α 1 0 PWMSIN 0 PWMCOS 0

1 1 PWMCOS 0 0 PWMSIN

Q4 +- Q3 --

270

Logometer 1 is driven by outputs SIN1M/P COS1M/P,

fig 6. Quadrants and PWM sign. Logometer 2 is driven by outputs SIN2M/P COS2M/P.

The PWM frequency is given by :

FPWM = FOSC / 512 (FOSC = Crystal oscillator frequency)

2) Logometers 90° (Logo1, Logo2, Logo3) :

The value transmitted by the µP is directly the PWM value (D4D5D6D7D8D9D10D11D12), D4 is

MSB and D12 LSB. D13 and Quad bits (D14,D15) are not used.

STANDARD PRODUCT july 9, 1997 PAGE 6, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

ABSOLUTE MAXIMUM RATINGS.

parameter symbol min. max. unit

Storage temperature range Tstg -40 +150 °C

Operating temperature range Tamb -40 +85 °C

Supply voltage range (pin 1) VCC -0.3 14.0 V

Input voltage range VI -0.3 VCC + 0.3 V

STANDARD PRODUCT july 9, 1997 PAGE 7, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

ELECTRICAL CHARACTERISTICS.

Tamb = -40 to 85°C, VCC = 5 V to 12 V unless otherwise specified.

parameter conditions symbol min. typ. max. unit

Supply current Inputs at VCC or VSS ICC 5.5 mA

No loads on outputs

VCC=8.5V T=25°C

Maximum power dissipation PDmax 620 mW

Inputs

Input capacitance Cin 10 pF

Pin 11

Pull-down resistance Rpd 125 750 kΩ

input voltage LOW VIL -0.3 1 V

input voltage HIGH VIH 4 VCC+0.3 V

Hysteresis VCC = 8.5 V VHYS 0.5 2.5 V

Leakage current pin at VCC or VSS IL -1 1 µA

Pin 12,13,14,15,17

input voltage LOW VIL -0.3 1 V

input voltage HIGH VIH 4 VCC+0.3 V

Hysteresis VCC = 8.5 V VHYS 0.5 2.5 V

Leakage current (p12,15,17) pin at VCC or VSS IL -1 1 µA

Pull-down resistance (p14) Rpd 0.8 1.5 kΩ

Outputs

Pin 16

Low level output voltage IOUT < 500 µA VOL 0.3 V

High level output leakage VOUT = VCC ILKG 10 µA

current

Pin 2,3,5,6,20,21,23,24

Drop-out voltage for each VCC = 8.5V, Tamb = 25°C Vd 1.6 V

pair of buffers Icoil = 30 mA, see fig. 4

Mismatch of drop-out VCC = 8.5V, Tamb = 25°C ∆Vd ± 50 mV

voltage Icoil = 30 mA, see fig. 4

Pin 7,8,9

Output voltage low VCC = 8.5V, Tamb = 25°C VOL 0.6 1.0 V

Isink = 40mA

Output voltage high VCC = 8.5V, Tamb=25°C VOH 6.8 7.8 V

Isource = 40mA

Oscillator

Pin 18,19

input pin capacitance Cin 10 20 pF

STANDARD PRODUCT july 9, 1997 PAGE 8, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

clock frequency fclk 8 MHz

AC ELECTRICAL CHARACTERISTICS.

Parameter Value unit

Maximum SCLK input frequency 500 kHz

Setup time DIN to SCLK rising 100 ns

Hold time DIN to SCLK rising 100 ns

Setup time CS high to SCLK rising 100 ns

APPLICATION SCHEMATIC.

VCC

LOGO1

VCC SIN2P

1 24 LOGO2

SIN1P SIN2M

2 23

SIN1M VSS

3 22

VSS COS2P

4 21

COS1P COS2M

5 20

COS1M OSCI

6 19

CS OSCO 8MHz *

11 18

µP SCLK

12 17

VER

* Load capacitances are internal

DIN ERR

13 16

VCC RST

10 15

TEST OUT7

14 9

+5V OUT6

OUT5

7 8 LOGO5 LOGO4

Rpup

LOGO3

Fig 7. Typical application

STANDARD PRODUCT july 9, 1997 PAGE 9, REV 4

TYPE 10407

ACTUATOR DRIVER WITH SERIAL LINK

Disclaimer

Devices sold by Melexis are covered by the warranty and patent indemnification provisions appearing in its Term of

Sale. Melexis makes no warranty, express, statutory, implied, or by description regarding the information set forth

herein or regarding the freedom of the described devices from patent infringement. Melexis reserves the right to change

specifications and prices at any time and without notice. Therefore, prior to designing this product into a system, it is

necessary to check with Melexis for current information. This product is intended for use in normal commercial

applications. Applications requiring extended temperature range, unusual environmental requirements, or high

reliability applications, such as military, medical life-support or life-sustaining equipment are specifically not

recommended without additional processing by Melexis for each application.

The information furnished by Melexis is believed to be correct and accurate. However, Melexis shall not be liable to

recipient or any third party for any damages, including but not limited to personal injury, property damage, loss of

profits, loss of use, interrupt of business or indirect, special incidental or consequential damages, of any kind, in

connection with or arising out of the furnishing, performance or use of the technical data herein. No obligation or

liability to recipient or any third party shall arise or flow out of Melexis’ rendering of technical or other services.

© 2012 Melexis NV. All rights reserved.

For the latest version of this document, go to our website at

www.melexis.com

Or for additional information contact Melexis Direct:

Europe, Africa, Asia: America:

Phone: +32 1367 0495 Phone: +1 248 306 5400

E-mail: sales_europe@melexis.com E-mail: sales_usa@melexis.com

ISO/TS 16949 and ISO14001 Certified

STANDARD PRODUCT july 9, 1997 PAGE 10, REV 4

Potrebbero piacerti anche

- ReleaseNotes BODAS-service 3.6.2Documento3 pagineReleaseNotes BODAS-service 3.6.2OHW SERNessuna valutazione finora

- Monitoring Codes of PC300 MachinesDocumento7 pagineMonitoring Codes of PC300 Machinesbjrock123Nessuna valutazione finora

- Phaser 740 Parts ServiceDocumento127 paginePhaser 740 Parts ServicelftrevNessuna valutazione finora

- Operator Training ManualDocumento195 pagineOperator Training ManualIgnacio MuñozNessuna valutazione finora

- Error Codes - DEUTZ EMR3Documento6 pagineError Codes - DEUTZ EMR3Gustavo 008Nessuna valutazione finora

- Bascom Avr TutorialDocumento22 pagineBascom Avr TutorialrezakaihaniNessuna valutazione finora

- Excavator: Inspection Before Engine StartDocumento2 pagineExcavator: Inspection Before Engine StartAkbarNessuna valutazione finora

- SK 200 Lodging ManualDocumento162 pagineSK 200 Lodging ManualEak MachineryNessuna valutazione finora

- Star1 User ManualDocumento83 pagineStar1 User Manualjekicz50% (2)

- 140 1Documento2 pagine140 1Eliel SouzaNessuna valutazione finora

- MX-D2T Schematic DiagramsDocumento14 pagineMX-D2T Schematic Diagramsjota_60254Nessuna valutazione finora

- EN Imapla TroubleshootingDocumento15 pagineEN Imapla TroubleshootingAndrei 26Nessuna valutazione finora

- Cpu, Fuse Box, Monitor Sk200-8Documento11 pagineCpu, Fuse Box, Monitor Sk200-8Agung NugrohoNessuna valutazione finora

- 91 150 PDFDocumento60 pagine91 150 PDFWilson Acosta LiñanNessuna valutazione finora

- Wa0004Documento131 pagineWa0004Serkan GökçeNessuna valutazione finora

- SM Pw170es-6k-962Documento625 pagineSM Pw170es-6k-962Эрнест Бекиров100% (1)

- Engine Control Module (Ecm) : Connector (E100 K)Documento11 pagineEngine Control Module (Ecm) : Connector (E100 K)Ham NgoNessuna valutazione finora

- CS74 PDFDocumento4 pagineCS74 PDFNova KurniawanNessuna valutazione finora

- Liftlux Diesel TrainingDocumento77 pagineLiftlux Diesel TrainingIvaylo Petkov100% (1)

- HYD Rauli C S Y S TE M GE NE RA LDocumento6 pagineHYD Rauli C S Y S TE M GE NE RA LJoniNessuna valutazione finora

- XCMG GR135MAX Maret2021Documento2 pagineXCMG GR135MAX Maret2021RizkiRamadhanNessuna valutazione finora

- Dredging Pumps MaartDocumento20 pagineDredging Pumps MaartHotnCrispy CrispyNessuna valutazione finora

- Instructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Documento838 pagineInstructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Hector Sacaca aliagaNessuna valutazione finora

- Re95201 2012-2Documento16 pagineRe95201 2012-2Vinod HegdeNessuna valutazione finora

- English: Italiano Machine Serial Number Instructions For Use and Maintenance, Comprehensive Catalogue & Spare PartsDocumento68 pagineEnglish: Italiano Machine Serial Number Instructions For Use and Maintenance, Comprehensive Catalogue & Spare PartsVentsislav VenevNessuna valutazione finora

- JCB JS145 Long Reach ExcavatorDocumento6 pagineJCB JS145 Long Reach ExcavatorNitzOONessuna valutazione finora

- DX210WA Hydraulic Schematic: Serial Number 5001 and UpDocumento1 paginaDX210WA Hydraulic Schematic: Serial Number 5001 and UpHaidar SareeniNessuna valutazione finora

- Manual RL200-300-SP BP L200-601 English-050101Documento313 pagineManual RL200-300-SP BP L200-601 English-050101Zdenko TurbaNessuna valutazione finora

- Injection Actuation Pressure Control Valve - Test: TroubleshootingDocumento10 pagineInjection Actuation Pressure Control Valve - Test: TroubleshootingsatyaNessuna valutazione finora

- Status Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Documento9 pagineStatus Report Wickler M315D W5M05442 Low Engine Oil Pressure - PSRPT - 2021-07-19 - 10.08.10Jean DiscretNessuna valutazione finora

- Re NR 72990001Documento2 pagineRe NR 72990001مهدي شقرونNessuna valutazione finora

- c4 2Documento4 paginec4 2Hallex Oliveira100% (1)

- D155ax 8Documento16 pagineD155ax 8eliasNessuna valutazione finora

- Manitou 180 ATJ (EURO 3) Electric CircuitDocumento11 pagineManitou 180 ATJ (EURO 3) Electric CircuitPHÁT NGUYỄN THẾNessuna valutazione finora

- Pc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line L.H.) (Blade)Documento2 paginePc128us-1 S - N 1001-Up - P.P.C. Main Line (P.p.c. Valve Line L.H.) (Blade)februNessuna valutazione finora

- ZF Fiat Installation DataDocumento47 pagineZF Fiat Installation DataBAIJU EVNessuna valutazione finora

- SM - Volvo L110F Wheel LoaderDocumento14 pagineSM - Volvo L110F Wheel LoaderEmanuel VillarruelNessuna valutazione finora

- ESQUEMA ELETRICO 307 E Cat - Dcs.sis - ControllerDocumento13 pagineESQUEMA ELETRICO 307 E Cat - Dcs.sis - Controllerrodinei cesar gomes gomesNessuna valutazione finora

- Mitsubishi PLC FX1S-FX1N-FX2N Series Programming Manual (PDFDrive) PDFDocumento466 pagineMitsubishi PLC FX1S-FX1N-FX2N Series Programming Manual (PDFDrive) PDFHandi KsciNessuna valutazione finora

- Fill d6tDocumento8 pagineFill d6tClaudionorGomesFilhoNessuna valutazione finora

- R210LC-7 ContentsDocumento2 pagineR210LC-7 ContentsKrystian PalaciosNessuna valutazione finora

- S667S52 Int250fr 71000401 1Documento1 paginaS667S52 Int250fr 71000401 1ELECTRO-TECHNICAL OFFICERNessuna valutazione finora

- Final-Hydraulic Schematic Standalone From 9803-4180Documento40 pagineFinal-Hydraulic Schematic Standalone From 9803-4180Marindustrial ServiceNessuna valutazione finora

- Multi Pulse Meter HANYOUNG NUX RP3Documento4 pagineMulti Pulse Meter HANYOUNG NUX RP3RudiNessuna valutazione finora

- Manual de Operación y Mantenimiento D65EX PDFDocumento351 pagineManual de Operación y Mantenimiento D65EX PDFKarlos Ramirez100% (1)

- Re95201 2007-11Documento16 pagineRe95201 2007-11renatNessuna valutazione finora

- RotoTec 1.0 EVDocumento83 pagineRotoTec 1.0 EVروشان فاطمة روشانNessuna valutazione finora

- EC210/EC240 EC290: Volvo ExcavatorsDocumento8 pagineEC210/EC240 EC290: Volvo ExcavatorsEliseeNessuna valutazione finora

- TransmisionDocumento8 pagineTransmisionMarianne Jones100% (1)

- Lsa 37 - 2 Pole - Acc: AlternatorsDocumento16 pagineLsa 37 - 2 Pole - Acc: AlternatorsSubagyo Wahyu RiyadiNessuna valutazione finora

- Bauer GB - 50 - EN - 905 - 748 - 2Documento8 pagineBauer GB - 50 - EN - 905 - 748 - 2zx8Nessuna valutazione finora

- Multiinstrument: With Control and Protection Device For Genset Unit TYPE SPG-120/20Documento2 pagineMultiinstrument: With Control and Protection Device For Genset Unit TYPE SPG-120/20Ya ŞamNessuna valutazione finora

- Cat - Dcs.sis - controller.CSSISImageServlet 2Documento2 pagineCat - Dcs.sis - controller.CSSISImageServlet 2Miguel Jorge Chavez ChavezNessuna valutazione finora

- Operation Manual 1013Documento74 pagineOperation Manual 1013nicoss69Nessuna valutazione finora

- Standard Equipment Optional Equipment: We Build A Better FutureDocumento10 pagineStandard Equipment Optional Equipment: We Build A Better FutureFranco SilvaNessuna valutazione finora

- Triad Diagnostic Solutions Commercial Vehicle Training GuideDocumento138 pagineTriad Diagnostic Solutions Commercial Vehicle Training GuideCarlos AlcantaraNessuna valutazione finora

- Diagrama Electrico D9N-CBJ000481Documento2 pagineDiagrama Electrico D9N-CBJ000481luisitolokitod100% (1)

- Dynapac CA 250 Operations O250enDocumento28 pagineDynapac CA 250 Operations O250enkikoNessuna valutazione finora

- Dimming Ballast Controller IC M8165: Mosdesign Semiconductor CorpDocumento9 pagineDimming Ballast Controller IC M8165: Mosdesign Semiconductor CorpMaria ZageNessuna valutazione finora

- Silan Semiconductors: Remote Fan Control IcDocumento8 pagineSilan Semiconductors: Remote Fan Control IcRudy ArmannNessuna valutazione finora

- Fengcheng Fuda Auto Sensors Co.,Ltd.: No. Descreption PictureDocumento8 pagineFengcheng Fuda Auto Sensors Co.,Ltd.: No. Descreption Picturerevisione turbine turbo turbocompressoriNessuna valutazione finora

- TTT PDFDocumento1 paginaTTT PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Garrett: Compressor WheelDocumento17 pagineGarrett: Compressor Wheelrevisione turbine turbo turbocompressori100% (1)

- Garrett: E&E No. Model Oem P/N Description A C BladesDocumento16 pagineGarrett: E&E No. Model Oem P/N Description A C Bladesrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Fruits 1 SquareDocumento20 pagineFruits 1 Squarerevisione turbine turbo turbocompressoriNessuna valutazione finora

- Garrett: E&E No. Model Oem P/N Description A B C BladesDocumento14 pagineGarrett: E&E No. Model Oem P/N Description A B C Bladesrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Garrett: E&E No. Model Oem P/N Description A Inducer Diameter B Exducer Diameter C Tip Height BladesDocumento20 pagineGarrett: E&E No. Model Oem P/N Description A Inducer Diameter B Exducer Diameter C Tip Height Bladesrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento2 pagineAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento2 pagineAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento1 paginaAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento1 paginaAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento1 paginaAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Attention It PDFDocumento1 paginaAttention It PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Communication Error With Vehicle ECU?Documento2 pagineCommunication Error With Vehicle ECU?revisione turbine turbo turbocompressoriNessuna valutazione finora

- SBT Junction Box Electronics E87 E90 E91 E92 PDFDocumento6 pagineSBT Junction Box Electronics E87 E90 E91 E92 PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Ep2F/Ep1F Series: Automotive RelaysDocumento8 pagineEp2F/Ep1F Series: Automotive Relaysrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Xprog ManualDocumento32 pagineXprog Manualrevisione turbine turbo turbocompressoriNessuna valutazione finora

- A1321 2 3 DatasheetDocumento13 pagineA1321 2 3 DatasheetEwerton BianchiNessuna valutazione finora

- XprogDocumento35 pagineXprogOsval_31Nessuna valutazione finora

- SBT Junction Box Electronics E87 E90 E91 E92 PDFDocumento6 pagineSBT Junction Box Electronics E87 E90 E91 E92 PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Ncsdummy How ToDocumento37 pagineNcsdummy How ToTimSmithNessuna valutazione finora

- Multiecuscan - Diagnostics Software For Italian Cars PDFDocumento51 pagineMultiecuscan - Diagnostics Software For Italian Cars PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Guide To Ista+Documento30 pagineGuide To Ista+Guilherme PfeilstickerNessuna valutazione finora

- Car Key Memory Options0 PDFDocumento12 pagineCar Key Memory Options0 PDFjose alvarezNessuna valutazione finora

- Xprog ManualDocumento32 pagineXprog Manualrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Toolset32 Short Counter ResetDocumento4 pagineToolset32 Short Counter ResetHonk89Nessuna valutazione finora

- SBT Junction Box Electronics E87 E90 E91 E92 PDFDocumento6 pagineSBT Junction Box Electronics E87 E90 E91 E92 PDFrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Ford Injectors Coding With Focom Fip enDocumento5 pagineFord Injectors Coding With Focom Fip endalioroxanaNessuna valutazione finora

- M20 Compatibility ChartDocumento6 pagineM20 Compatibility Chartrevisione turbine turbo turbocompressoriNessuna valutazione finora

- Brochure CAT Advanced series-B-CATADV-112-ENDocumento21 pagineBrochure CAT Advanced series-B-CATADV-112-ENSelk CLNessuna valutazione finora

- Tektronix P6015a 1000x HV TastkopfDocumento74 pagineTektronix P6015a 1000x HV TastkopfMan CangkulNessuna valutazione finora

- SOP For CPU CCP-521Documento5 pagineSOP For CPU CCP-521Mehtab AhmedNessuna valutazione finora

- Sample Swot For An InstitutionDocumento8 pagineSample Swot For An Institutionhashadsh100% (3)

- Managing Successful Projects With PRINCE2 2009Documento134 pagineManaging Successful Projects With PRINCE2 2009mahmud.kabir100% (1)

- Romana T-3805-EDocumento19 pagineRomana T-3805-EjorgeNessuna valutazione finora

- BELLTPO CHARTS WORKSPACE VIDEOLINKS Troubleshooting InstuctionsDocumento3 pagineBELLTPO CHARTS WORKSPACE VIDEOLINKS Troubleshooting InstuctionsRameishYedllaNessuna valutazione finora

- Junos Telemetry InterfaceDocumento150 pagineJunos Telemetry InterfacedeeNessuna valutazione finora

- Data Security in Cloud ComputingDocumento324 pagineData Security in Cloud Computingprince2venkatNessuna valutazione finora

- Puana Cell Phone Search WarrantDocumento24 paginePuana Cell Phone Search WarrantHNN67% (3)

- Decision Support SystemDocumento6 pagineDecision Support SystemNaveenNessuna valutazione finora

- Salterbaxter - Directions Supplement - Online Investor CentresDocumento6 pagineSalterbaxter - Directions Supplement - Online Investor Centressalterbaxter100% (2)

- EWM Transaction CodesDocumento22 pagineEWM Transaction CodesChuks Osagwu100% (1)

- Cs8493 Operating System 3Documento37 pagineCs8493 Operating System 3alexb072002Nessuna valutazione finora

- 19DCS135-Internship ReportDocumento15 pagine19DCS135-Internship ReportDhwani ShethNessuna valutazione finora

- Visual Foxpro Bsamt3aDocumento32 pagineVisual Foxpro Bsamt3aJherald NarcisoNessuna valutazione finora

- Presentations - SPED - Society of Piping Engineers and DesignersDocumento2 paginePresentations - SPED - Society of Piping Engineers and DesignersEsteban CastellanoNessuna valutazione finora

- Asus HS 1000W ManualDocumento13 pagineAsus HS 1000W Manualbmmanuals0% (1)

- Case 06 RPA WALT Robotic Process AutomationDocumento13 pagineCase 06 RPA WALT Robotic Process AutomationPragya JoshiNessuna valutazione finora

- ByD DemoScript Project MGMTDocumento21 pagineByD DemoScript Project MGMTLakhbir SinghNessuna valutazione finora

- Clmd4a Ictg6Documento25 pagineClmd4a Ictg6Rose RamosNessuna valutazione finora

- History of Power IsoDocumento5 pagineHistory of Power IsoFahad Bin ImtiazNessuna valutazione finora

- Primavera P6 Version 20.12 Is Out. Here's What's New 1Documento14 paginePrimavera P6 Version 20.12 Is Out. Here's What's New 1meshmeshNessuna valutazione finora

- Amd Cpu Intel CPU Amd Cpu: Brand New Computer Packages " Super Sale at Very Very Low Prices !!! "Documento2 pagineAmd Cpu Intel CPU Amd Cpu: Brand New Computer Packages " Super Sale at Very Very Low Prices !!! "Bryan BautistaNessuna valutazione finora

- Pipe Culv bbs2Documento2 paginePipe Culv bbs2nuruddin humayunNessuna valutazione finora

- What Is Electronic WritingDocumento2 pagineWhat Is Electronic WritingPriyaNessuna valutazione finora

- Slide Sosialisasi PULDATANDocumento52 pagineSlide Sosialisasi PULDATANKJSB LALU UBAI ABDILLAH - PHLN 2022Nessuna valutazione finora

- Rest Security by Example Frank KimDocumento62 pagineRest Security by Example Frank KimneroliangNessuna valutazione finora

- Chapter 2 - The Origins of SoftwareDocumento26 pagineChapter 2 - The Origins of Softwareلوي وليدNessuna valutazione finora

- Netcat ManualDocumento7 pagineNetcat ManualRitcher HardyNessuna valutazione finora