Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pinnacle Alloys ERNiCrCoMo 1 617

Caricato da

Anonymous PkAjjOZBCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pinnacle Alloys ERNiCrCoMo 1 617

Caricato da

Anonymous PkAjjOZBCopyright:

Formati disponibili

1114REV1

Pinnacle Alloys are products of SOWESCO

ERNiCrCoMo-1 DATA SHEET

Pinnacle Alloys ERNiCrCoMo-1 (617)

AWS CLASS ERNiCrCoMo-1

CODE AND SPECIFICATION DATA:

AWS A5.14 ASME SFA 5.14

DESCRIPTION:

Pinnacle Alloys ERNiCrCoMo-1 is designed to weld nickel-chromium-molybdenum base

material, as well as for joining various dissimilar high temperature alloys. It is designed

for TIG, MIG, and submerged arc welding. The weld metal provides excellent strength

and oxidation resistance above 1500°F. Pinnacle Alloys ERNiCrCoMo-1 can also be

used for overlay welding where a similar chemistry is desired. Pinnacle Alloys

ERNiCrCoMo-1 features a good stability, high creep strength and resistance to oxidation,

pitting, and stress-corrosion cracking. This wire is ideal for high temperature applications,

such as furnace components, heat exchangers, pipelines, and gas turbine parts.

DIAMETERS: .035”, .045”, 1/16”, 3/32”, 1/8”, 5/32”

TYPICAL DEPOSIT COMPOSITION (Wt %):

Aluminum (Al) 1.36

Carbon (C) 0.08

Chromium (Cr) 22.0

Cobalt (Co) 13.0

Copper (Cu) 0.08

Iron (Fe) 0.10

Manganese (Mn) 0.26

Molybdenum (Mo) 8.80

Nickel (Ni) Balance

Phosphorous (P) 0.001

Silicon (Si) 0.28

Sulfur (S) 0.001

TYPICAL MECHANICAL PROPERTIES:

Ultimate Tensile Strength (psi) 100,000 psi

Percent Elongation 45%

1114REV1

Pinnacle Alloys are products of SOWESCO

TYPICAL WELDING PARAMETERS:

Diameter Amperage Volts Shielding Gas

1/16” 80-110

3/32” 90-130

GTAW 100% Ar

1/8” 120-175

5/32” 150-220

.035” 150-190 26-29

GMAW .045” 180-220 28-32 75% Ar/ 25% He

1/16” 200-250 29-33

3/32” 275-350 28-30

SAW Suitable Flux

1/8” 350-450 29-32

NOTICE: The results reported are based upon testing of the product under controlled laboratory conditions

in accordance with American Welding Society Standards. Actual use of the product may produce different

results due to varying conditions. An example of such conditions would be electrode size, plate chemistry,

environment, weldment design, fabrication methods, welding procedure and service requirements. Thus the

results are not guarantees for the use in the field. The manufacturer disclaims any warranty of

merchantability of fitness for any particular purpose with respect to its products.

CAUTION: Consumers should be thoroughly familiar with the safety precautions on the warning label

posted in each shipment and in the American National Standards A49.1, “Safety in Welding and Cutting,”

published by the American Welding Society, 550 NW LeJune Road, Miami, FL 33126: OSHA Safety and

Health Standards 29 CRF 1910 is available from the U.S. Department of Labor, Washington, D.C. 20210.

Pinnacle Alloys MSDS sheet may be obtained at www.pinnaclealloys.com.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Drilling and Workover Aramco Training 2013 - 2 PDFDocumento479 pagineDrilling and Workover Aramco Training 2013 - 2 PDFAnonymous 40IGqsR3jc89% (19)

- Syllabus 2012 Singing 20190122Documento91 pagineSyllabus 2012 Singing 20190122suzypienaarNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Baroque MusicDocumento15 pagineBaroque Musicthot777100% (2)

- Iso 27001 Auditor TrainingDocumento19 pagineIso 27001 Auditor TrainingITOPS TeamNessuna valutazione finora

- Liebherr Brochure Lubricants enDocumento20 pagineLiebherr Brochure Lubricants enAnonymous PkAjjOZB67% (3)

- 4 5994641624901094407Documento20 pagine4 5994641624901094407Success100% (1)

- HazopDocumento4 pagineHazopbaaziz2015Nessuna valutazione finora

- Radiology Final QuestionsDocumento52 pagineRadiology Final QuestionsRashed Shatnawi50% (4)

- Resistoflex Fluoropolymer InnovationDocumento4 pagineResistoflex Fluoropolymer InnovationAnonymous PkAjjOZBNessuna valutazione finora

- 18 WMI-Disciplinary ProgramDocumento4 pagine18 WMI-Disciplinary ProgramAnonymous PkAjjOZBNessuna valutazione finora

- UTP MaintenanceDocumento28 pagineUTP MaintenanceAnonymous PkAjjOZBNessuna valutazione finora

- Pressure Transmitter For General Industrial Applications Model A-10Documento12 paginePressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNessuna valutazione finora

- Fakeeh DBA PDFDocumento236 pagineFakeeh DBA PDFAnonymous PkAjjOZBNessuna valutazione finora

- Daflon 500 MG PDFDocumento9 pagineDaflon 500 MG PDFAnonymous PkAjjOZBNessuna valutazione finora

- Intertek Corporate BrochureDocumento20 pagineIntertek Corporate BrochureShahidNessuna valutazione finora

- Hot Induction BendEnglishDocumento2 pagineHot Induction BendEnglishMohamed DawoudNessuna valutazione finora

- Pressure Transmitter For General Industrial Applications Model A-10Documento12 paginePressure Transmitter For General Industrial Applications Model A-10Anonymous PkAjjOZBNessuna valutazione finora

- Hot Induction BendEnglishDocumento2 pagineHot Induction BendEnglishMohamed DawoudNessuna valutazione finora

- Gulf Talent Employee and Salary PDFDocumento14 pagineGulf Talent Employee and Salary PDFAnonymous PkAjjOZBNessuna valutazione finora

- Hay PulleysDocumento1 paginaHay PulleysAnonymous PkAjjOZBNessuna valutazione finora

- Gulf Talent Employee and Salary PDFDocumento14 pagineGulf Talent Employee and Salary PDFAnonymous PkAjjOZBNessuna valutazione finora

- Wagner-Meinert Disciplinary ProgramDocumento4 pagineWagner-Meinert Disciplinary ProgramAnonymous PkAjjOZBNessuna valutazione finora

- Specialty Maintenance Product Catalog and Price ListDocumento30 pagineSpecialty Maintenance Product Catalog and Price ListAnonymous PkAjjOZBNessuna valutazione finora

- Vent View ProtoectosealDocumento2 pagineVent View ProtoectosealAnonymous PkAjjOZBNessuna valutazione finora

- KippZonen CatalogueDocumento88 pagineKippZonen CatalogueAnonymous PkAjjOZBNessuna valutazione finora

- 1-12 To 4 Guardsman G SeriesDocumento6 pagine1-12 To 4 Guardsman G SeriesAnonymous PkAjjOZBNessuna valutazione finora

- SSWeep MSDSDocumento6 pagineSSWeep MSDSAnonymous PkAjjOZBNessuna valutazione finora

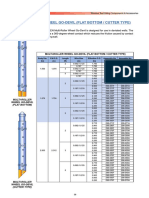

- Multi-Roller Wheel Go-Devil (Flat Bottom Cutter Type)Documento1 paginaMulti-Roller Wheel Go-Devil (Flat Bottom Cutter Type)Anonymous PkAjjOZBNessuna valutazione finora

- HE 850 Horziontal Boring MachineDocumento1 paginaHE 850 Horziontal Boring MachineAnonymous PkAjjOZBNessuna valutazione finora

- Port Pressure Test UnitDocumento1 paginaPort Pressure Test UnitAnonymous PkAjjOZBNessuna valutazione finora

- Micro MV TrainingDocumento6 pagineMicro MV TrainingAnonymous PkAjjOZBNessuna valutazione finora

- FirstDefender RMX SpecSheet ArabicDocumento2 pagineFirstDefender RMX SpecSheet ArabicAnonymous PkAjjOZBNessuna valutazione finora

- Dell Inspiron N5110 Service ManualDocumento45 pagineDell Inspiron N5110 Service ManualMichael Daniel Espinoza BetancoNessuna valutazione finora

- SAEP-127 - Security and Control of Saudi Aramco Engineering DataDocumento9 pagineSAEP-127 - Security and Control of Saudi Aramco Engineering DataAnonymous PkAjjOZBNessuna valutazione finora

- PDFDocumento144 paginePDFAnonymous PkAjjOZBNessuna valutazione finora

- Virtual Art PaperDocumento5 pagineVirtual Art Paperbrandy oldfieldNessuna valutazione finora

- Topic 2Documento6 pagineTopic 2Vince Diza SaguidNessuna valutazione finora

- Sample Management Representation Letter Type II SAS 70 AuditDocumento2 pagineSample Management Representation Letter Type II SAS 70 Auditaaldawi0% (1)

- Academic StyleDocumento4 pagineAcademic StyleHa ToNessuna valutazione finora

- Space Oddity Chords (Ver 2) by David Bowie Tabs at Ultimate Guitar ArchiveDocumento3 pagineSpace Oddity Chords (Ver 2) by David Bowie Tabs at Ultimate Guitar ArchiveEMMANUEL ARNOULDNessuna valutazione finora

- Jurnal Aceh MedikaDocumento10 pagineJurnal Aceh MedikaJessica SiraitNessuna valutazione finora

- Metaswitch Datasheet Network Transformation OverviewDocumento5 pagineMetaswitch Datasheet Network Transformation OverviewblitoNessuna valutazione finora

- Troubleshoot WLAN IssuesDocumento4 pagineTroubleshoot WLAN IssuesIvan Herrera CoronaNessuna valutazione finora

- Calculation of Moments and Shear: Input DataDocumento3 pagineCalculation of Moments and Shear: Input DataARSENessuna valutazione finora

- Chapter 7Documento22 pagineChapter 7one loveNessuna valutazione finora

- Red Lion MP Sensor Product Manual PDFDocumento2 pagineRed Lion MP Sensor Product Manual PDFJigneshNessuna valutazione finora

- Educational PlanningDocumento20 pagineEducational PlanningedelynNessuna valutazione finora

- The Biologic Width: - A Concept in Periodontics and Restorative DentistryDocumento8 pagineThe Biologic Width: - A Concept in Periodontics and Restorative DentistryDrKrishna DasNessuna valutazione finora

- The 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsDocumento17 pagineThe 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsADMINISTRACION LABORATORIO INTERMEDICANessuna valutazione finora

- Blasting 001 Abb WarehouseDocumento2 pagineBlasting 001 Abb WarehouseferielvpkNessuna valutazione finora

- Clare Redman Statement of IntentDocumento4 pagineClare Redman Statement of Intentapi-309923259Nessuna valutazione finora

- (Homebrew) ShamanDocumento15 pagine(Homebrew) ShamanVictor Wanderley CorrêaNessuna valutazione finora

- Right to Personal Liberty and Judicial Process in IndiaDocumento636 pagineRight to Personal Liberty and Judicial Process in IndiaDrDiana PremNessuna valutazione finora

- Datasheet PIC1650Documento7 pagineDatasheet PIC1650Vinicius BaconNessuna valutazione finora

- Service Agreement - Zeroid PDFDocumento2 pagineService Agreement - Zeroid PDFYushau Muhammad LawalNessuna valutazione finora

- Brief History of Gifted and Talented EducationDocumento4 pagineBrief History of Gifted and Talented Educationapi-336040000Nessuna valutazione finora

- Villanueva - Taxation and Regulatory ComplianceDocumento8 pagineVillanueva - Taxation and Regulatory ComplianceEDRICK ESPARRAGUERRANessuna valutazione finora

- Parameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanDocumento2 pagineParameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanKhamdi AfandiNessuna valutazione finora

- Earth's StructureDocumento10 pagineEarth's StructureMaitum Gemark BalazonNessuna valutazione finora