Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

R 312 Rig Specs PDF

Caricato da

MohamedAbdelnasserTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

R 312 Rig Specs PDF

Caricato da

MohamedAbdelnasserCopyright:

Formati disponibili

SOILMEC distributes machinery and structures all over

the world, supported by SOILMEC subsidiary companies

R-312/200

and representative offices as:

SOILMEC LTD - U.K.

SOILMEC MISR S.A.E. Co. - Egypt

SOILMEC (H.K.) Limited - Hong Kong HYDRAULIC ROTARY RIG

SOILMEC JAPAN CO LTD - Japan

SOILMEC MALAYSIA - Malaysia

SOILMEC S.P.A. - Beijing Repr. Office - P.R. China

SOILMEC FAR EAST PTE.LTD - Singapore

SOILMEC EMIRATES - U.A.E.

SOILMEC GULF - U.A.E.

CERTIFIED QUALITY SYSTEM

In 1990 Soilmec was awarded the certification of its own

Quality System to ISO 9001/UNI 29001 series standards.

SOILMEC S.p.A.

Ground Engineering Equipment

5819, via Dismano

47023 Cesena (FC) - Italy

tel. +39-0547-319111

fax +39-0547-318548

http:// www.soilmec.it

e-mail: soilmec@soilmec.it

Ground Engineering Equipment Ground Engineering Equipment

SOILMEC distributes machinery and structures all over

the world, supported by SOILMEC subsidiary companies

R-312/200

and representative offices as:

SOILMEC LTD - U.K.

SOILMEC MISR S.A.E. Co. - Egypt

SOILMEC (H.K.) Limited - Hong Kong HYDRAULIC ROTARY RIG

SOILMEC JAPAN CO LTD - Japan

SOILMEC MALAYSIA - Malaysia

SOILMEC S.P.A. - Beijing Repr. Office - P.R. China

SOILMEC FAR EAST PTE.LTD - Singapore

SOILMEC EMIRATES - U.A.E.

SOILMEC GULF - U.A.E.

CERTIFIED QUALITY SYSTEM

In 1990 Soilmec was awarded the certification of its own

Quality System to ISO 9001/UNI 29001 series standards.

SOILMEC S.p.A.

Ground Engineering Equipment

5819, via Dismano

47023 Cesena (FC) - Italy

tel. +39-0547-319111

fax +39-0547-318548

http:// www.soilmec.it

e-mail: soilmec@soilmec.it

Ground Engineering Equipment Ground Engineering Equipment

R-312/200 6 R-312/200 R-312/200

HYDRAULIC ROTARY RIG LARGE DIAMETER BORED PILE CONTINUOUS FLIGHT AUGER

Working Condition Working Condition

A new model After the success of the R-312 HD Soilmec introduces the new model R-312/200 performing: 1 - Undercarriage with expandable tracks

- bored piles with dry drilling or bentonite mud from 2.5 to 3.7 m by means of hydraulic

830

- continuous flight auger piles (CFA) cylinders

The main features of the R-312/200 are the following: 2 - Turret c/w CUMMINS 6BTA55.9-C200

6000

- new powerful rotary diesel engine and sound proofed canopy,

- high speed drilling mounted on a 360° slew ring

6000

- easy transport: it can be transported with rotary and kelly bar installed 5

3 - Winch assembly

- compliance with the machine laws for safety standards

- total reduction of rig up time, about 20 minutes from arrival to the job site 4 - Parallelogram system allowing

- easy to use and handle working radius adjustment always

- low operating costs maintaining the mast in vertical position.

- wide range of accessories (depthmeter, inclinometer, air conditioning, free fall winch) C/w electronic device for automatic stop ø 750

5 - Self-erecting mast composed by an

21742

intermediate element 11.9 m long and

8646

Large diameter bored pile

a top element 3.5 m long. The max torque 750

10490

can be applied all over the mast length

24900

17784

Max pile diameter mm 1500

1932

Max pile depth m 48 (with 5x11 kelly bar) 6 - Sheave cathead 7

16228

16600

MAX DEPTH: 13000 (19000)

MAX DEPTH: 12500+6000

m 38,5 (with 4x11 kelly bar)

Max nominal torque kNm 7 - Crowd system by means of 3.5 m

13500

130

13000

Max drilling speed rpm 42 hydraulic cylinder

890

Spin off speed rpm 153 8 - Rotary head with 3 drilling speeds and

10500

5250

Main winch nominal line pull kN 133 one high spin off speed. The max torque

3500 PULL DOWN STROKE

Auxiliary winch nominal line pull kN 56

is obtained for each drilling speed

Engine type CUMMINS QSB5.9

3198

Power BHP 200 @ 2200 rpm 9 - Telescopic kelly bar with guide to

Crowd system kN 123.7 / 101.8 mast available with friction or mechanical

4500

2550

Operating weight tons 35 locking type

2553

Transport weight (c/w kelly bar) tons 34

2256

344

The nominal values are referred to 100% total efficiency. 395 750

8

1267

940

885

795

520

Continuous Flight Auger (CFA)

4510 3710

500

450

EXTENDED TRACK WIDTH 3700 mm 3500 3500

3500 3500 (MIN. 3000) 3621 SHOE WIDTH 600 mm

Max pile diameter mm 750 (3000+3500)

(3000÷3500) 3950

MIN. 2750 MAX. 3950

3666

Max pile depth m 13-6

Max nominal extraction force kN 380 9 4 3 2 1 Low overhead version Standard version CFA standard version CFA 360° version

Transport weight tons 31 718

Transport Condition Transport Condition

Friction kelly bar – Ø 355 mm Mechanical locking kelly bar – Ø 355 mm

707 600

1870

1509

12090 12119 WEIGHT: 1000 kg

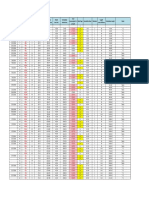

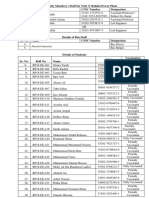

elements length depth weight height elements length depth weight height

no m m tonn m no m m tonn m 1474

4x 6,0 19,0 2,4 5,0 4x 7,5 25,0 2,9 5,0

3277

3426

4x 7,5 25,0 2,9 5,0 4x 9,0 34,0 3,3 5,0

2540

2540

2500

1652

1652

1652

1649

4x 9,0 32,0 3,3 5,0 4x 11,0 38,0 3,9 4,6

1279

952

795

852

885

952

4x 11,0 39,0 3,9 4,6 5x 10,5 46,5 8,5 8,3 1199 1397

WEIGHT: 33000 kg

5x 9,0 40,0 4,3 5,0 5x 11,5 51,5 9,0 8,3 1199

1360 3254

1986

5x 11,0 48,0 5,1 4,6 5x 13,5 62,0 10,3 6,76 3269 4510 4311

3269 4510 4340

5x 15,5 72,0 11,5 4,77

5x 16,5 76,5 12,2 3,86 Inside cabin view

Standard dimension of tool connection is 130x130 mm / H= kelly stub height from ground level

R-312/200 6 R-312/200 R-312/200

HYDRAULIC ROTARY RIG LARGE DIAMETER BORED PILE CONTINUOUS FLIGHT AUGER

Working Condition Working Condition

A new model After the success of the R-312 HD Soilmec introduces the new model R-312/200 performing: 1 - Undercarriage with expandable tracks

- bored piles with dry drilling or bentonite mud from 2.5 to 3.7 m by means of hydraulic

830

- continuous flight auger piles (CFA) cylinders

The main features of the R-312/200 are the following: 2 - Turret c/w CUMMINS 6BTA55.9-C200

6000

- new powerful rotary diesel engine and sound proofed canopy,

- high speed drilling mounted on a 360° slew ring

6000

- easy transport: it can be transported with rotary and kelly bar installed 5

3 - Winch assembly

- compliance with the machine laws for safety standards

- total reduction of rig up time, about 20 minutes from arrival to the job site 4 - Parallelogram system allowing

- easy to use and handle working radius adjustment always

- low operating costs maintaining the mast in vertical position.

- wide range of accessories (depthmeter, inclinometer, air conditioning, free fall winch) C/w electronic device for automatic stop ø 750

5 - Self-erecting mast composed by an

21742

intermediate element 11.9 m long and

8646

Large diameter bored pile

a top element 3.5 m long. The max torque 750

10490

can be applied all over the mast length

24900

17784

Max pile diameter mm 1500

1932

Max pile depth m 48 (with 5x11 kelly bar) 6 - Sheave cathead 7

16228

16600

MAX DEPTH: 13000 (19000)

MAX DEPTH: 12500+6000

m 38,5 (with 4x11 kelly bar)

Max nominal torque kNm 7 - Crowd system by means of 3.5 m

13500

130

13000

Max drilling speed rpm 42 hydraulic cylinder

890

Spin off speed rpm 153 8 - Rotary head with 3 drilling speeds and

10500

5250

Main winch nominal line pull kN 133 one high spin off speed. The max torque

3500 PULL DOWN STROKE

Auxiliary winch nominal line pull kN 56

is obtained for each drilling speed

Engine type CUMMINS QSB5.9

3198

Power BHP 200 @ 2200 rpm 9 - Telescopic kelly bar with guide to

Crowd system kN 123.7 / 101.8 mast available with friction or mechanical

4500

2550

Operating weight tons 35 locking type

2553

Transport weight (c/w kelly bar) tons 34

2256

344

The nominal values are referred to 100% total efficiency. 395 750

8

1267

940

885

795

520

Continuous Flight Auger (CFA)

4510 3710

500

450

EXTENDED TRACK WIDTH 3700 mm 3500 3500

3500 3500 (MIN. 3000) 3621 SHOE WIDTH 600 mm

Max pile diameter mm 750 (3000+3500)

(3000÷3500) 3950

MIN. 2750 MAX. 3950

3666

Max pile depth m 13-6

Max nominal extraction force kN 380 9 4 3 2 1 Low overhead version Standard version CFA standard version CFA 360° version

Transport weight tons 31 718

Transport Condition Transport Condition

Friction kelly bar – Ø 355 mm Mechanical locking kelly bar – Ø 355 mm

707 600

1870

1509

12090 12119 WEIGHT: 1000 kg

elements length depth weight height elements length depth weight height

no m m tonn m no m m tonn m 1474

4x 6,0 19,0 2,4 5,0 4x 7,5 25,0 2,9 5,0

3277

3426

4x 7,5 25,0 2,9 5,0 4x 9,0 34,0 3,3 5,0

2540

2540

2500

1652

1652

1652

1649

4x 9,0 32,0 3,3 5,0 4x 11,0 38,0 3,9 4,6

1279

952

795

852

885

952

4x 11,0 39,0 3,9 4,6 5x 10,5 46,5 8,5 8,3 1199 1397

WEIGHT: 33000 kg

5x 9,0 40,0 4,3 5,0 5x 11,5 51,5 9,0 8,3 1199

1360 3254

1986

5x 11,0 48,0 5,1 4,6 5x 13,5 62,0 10,3 6,76 3269 4510 4311

3269 4510 4340

5x 15,5 72,0 11,5 4,77

5x 16,5 76,5 12,2 3,86 Inside cabin view

Standard dimension of tool connection is 130x130 mm / H= kelly stub height from ground level

R-312/200 6 R-312/200 R-312/200

HYDRAULIC ROTARY RIG LARGE DIAMETER BORED PILE CONTINUOUS FLIGHT AUGER

Working Condition Working Condition

A new model After the success of the R-312 HD Soilmec introduces the new model R-312/200 performing: 1 - Undercarriage with expandable tracks

- bored piles with dry drilling or bentonite mud from 2.5 to 3.7 m by means of hydraulic

830

- continuous flight auger piles (CFA) cylinders

The main features of the R-312/200 are the following: 2 - Turret c/w CUMMINS 6BTA55.9-C200

6000

- new powerful rotary diesel engine and sound proofed canopy,

- high speed drilling mounted on a 360° slew ring

6000

- easy transport: it can be transported with rotary and kelly bar installed 5

3 - Winch assembly

- compliance with the machine laws for safety standards

- total reduction of rig up time, about 20 minutes from arrival to the job site 4 - Parallelogram system allowing

- easy to use and handle working radius adjustment always

- low operating costs maintaining the mast in vertical position.

- wide range of accessories (depthmeter, inclinometer, air conditioning, free fall winch) C/w electronic device for automatic stop ø 750

5 - Self-erecting mast composed by an

21742

intermediate element 11.9 m long and

8646

Large diameter bored pile

a top element 3.5 m long. The max torque 750

10490

can be applied all over the mast length

24900

17784

Max pile diameter mm 1500

1932

Max pile depth m 48 (with 5x11 kelly bar) 6 - Sheave cathead 7

16228

16600

MAX DEPTH: 13000 (19000)

MAX DEPTH: 12500+6000

m 38,5 (with 4x11 kelly bar)

Max nominal torque kNm 7 - Crowd system by means of 3.5 m

13500

130

13000

Max drilling speed rpm 42 hydraulic cylinder

890

Spin off speed rpm 153 8 - Rotary head with 3 drilling speeds and

10500

5250

Main winch nominal line pull kN 133 one high spin off speed. The max torque

3500 PULL DOWN STROKE

Auxiliary winch nominal line pull kN 56

is obtained for each drilling speed

Engine type CUMMINS QSB5.9

3198

Power BHP 200 @ 2200 rpm 9 - Telescopic kelly bar with guide to

Crowd system kN 123.7 / 101.8 mast available with friction or mechanical

4500

2550

Operating weight tons 35 locking type

2553

Transport weight (c/w kelly bar) tons 34

2256

344

The nominal values are referred to 100% total efficiency. 395 750

8

1267

940

885

795

520

Continuous Flight Auger (CFA)

4510 3710

500

450

EXTENDED TRACK WIDTH 3700 mm 3500 3500

3500 3500 (MIN. 3000) 3621 SHOE WIDTH 600 mm

Max pile diameter mm 750 (3000+3500)

(3000÷3500) 3950

MIN. 2750 MAX. 3950

3666

Max pile depth m 13-6

Max nominal extraction force kN 380 9 4 3 2 1 Low overhead version Standard version CFA standard version CFA 360° version

Transport weight tons 31 718

Transport Condition Transport Condition

Friction kelly bar – Ø 355 mm Mechanical locking kelly bar – Ø 355 mm

707 600

1870

1509

12090 12119 WEIGHT: 1000 kg

elements length depth weight height elements length depth weight height

no m m tonn m no m m tonn m 1474

4x 6,0 19,0 2,4 5,0 4x 7,5 25,0 2,9 5,0

3277

3426

4x 7,5 25,0 2,9 5,0 4x 9,0 34,0 3,3 5,0

2540

2540

2500

1652

1652

1652

1649

4x 9,0 32,0 3,3 5,0 4x 11,0 38,0 3,9 4,6

1279

952

795

852

885

952

4x 11,0 39,0 3,9 4,6 5x 10,5 46,5 8,5 8,3 1199 1397

WEIGHT: 33000 kg

5x 9,0 40,0 4,3 5,0 5x 11,5 51,5 9,0 8,3 1199

1360 3254

1986

5x 11,0 48,0 5,1 4,6 5x 13,5 62,0 10,3 6,76 3269 4510 4311

3269 4510 4340

5x 15,5 72,0 11,5 4,77

5x 16,5 76,5 12,2 3,86 Inside cabin view

Standard dimension of tool connection is 130x130 mm / H= kelly stub height from ground level

SOILMEC distributes machinery and structures all over

the world, supported by SOILMEC subsidiary companies

R-312/200

and representative offices as:

SOILMEC LTD - U.K.

SOILMEC MISR S.A.E. Co. - Egypt

SOILMEC (H.K.) Limited - Hong Kong HYDRAULIC ROTARY RIG

SOILMEC JAPAN CO LTD - Japan

SOILMEC MALAYSIA - Malaysia

SOILMEC S.P.A. - Beijing Repr. Office - P.R. China

SOILMEC FAR EAST PTE.LTD - Singapore

SOILMEC EMIRATES - U.A.E.

SOILMEC GULF - U.A.E.

CERTIFIED QUALITY SYSTEM

In 1990 Soilmec was awarded the certification of its own

Quality System to ISO 9001/UNI 29001 series standards.

SOILMEC S.p.A.

Ground Engineering Equipment

5819, via Dismano

47023 Cesena (FC) - Italy

tel. +39-0547-319111

fax +39-0547-318548

http:// www.soilmec.it

e-mail: soilmec@soilmec.it

Ground Engineering Equipment Ground Engineering Equipment

SOILMEC distributes machinery and structures all over

the world, supported by SOILMEC subsidiary companies

R-312/200

and representative offices as:

SOILMEC LTD - U.K.

SOILMEC MISR S.A.E. Co. - Egypt

SOILMEC (H.K.) Limited - Hong Kong HYDRAULIC ROTARY RIG

SOILMEC JAPAN CO LTD - Japan

SOILMEC MALAYSIA - Malaysia

SOILMEC S.P.A. - Beijing Repr. Office - P.R. China

SOILMEC FAR EAST PTE.LTD - Singapore

SOILMEC EMIRATES - U.A.E.

SOILMEC GULF - U.A.E.

CERTIFIED QUALITY SYSTEM

In 1990 Soilmec was awarded the certification of its own

Quality System to ISO 9001/UNI 29001 series standards.

SOILMEC S.p.A.

Ground Engineering Equipment

5819, via Dismano

47023 Cesena (FC) - Italy

tel. +39-0547-319111

fax +39-0547-318548

http:// www.soilmec.it

e-mail: soilmec@soilmec.it

Ground Engineering Equipment Ground Engineering Equipment

Potrebbero piacerti anche

- Gearbox-Mounted Power Take Off: General InstructionsDocumento4 pagineGearbox-Mounted Power Take Off: General InstructionsChimuonechi NyirendaNessuna valutazione finora

- Valve Amplifier For Proportional Directional Valve Type 2WFCDocumento36 pagineValve Amplifier For Proportional Directional Valve Type 2WFCessameldinNessuna valutazione finora

- F-29 Hose Handling CraneDocumento100 pagineF-29 Hose Handling CraneSHANANDNessuna valutazione finora

- Tracked Excavator - Js205 LR: Static Dimensions EngineDocumento4 pagineTracked Excavator - Js205 LR: Static Dimensions EngineMoayed M AhmedNessuna valutazione finora

- VAG HYsec Hydraulic Brake and Lift UnitDocumento3 pagineVAG HYsec Hydraulic Brake and Lift UnitLuka Borna100% (1)

- Technical Proposal ECrane 1000 Series EH7359Documento16 pagineTechnical Proposal ECrane 1000 Series EH7359Satrio Agung WijonarkoNessuna valutazione finora

- ERKE Group, FUWA QUY 500 Crawler Crane CatalogDocumento94 pagineERKE Group, FUWA QUY 500 Crawler Crane CatalogerkegroupNessuna valutazione finora

- Perforatrice Drill Rig MDT230K MDT231KK: Lista Ricambi Consigliati List of Recommended Spare PartsDocumento26 paginePerforatrice Drill Rig MDT230K MDT231KK: Lista Ricambi Consigliati List of Recommended Spare PartsGabriel Amorim100% (1)

- Brochure sr30 PDFDocumento8 pagineBrochure sr30 PDFNishant Sinha100% (1)

- Mine Canadian Royalties: Excavator TrainingDocumento72 pagineMine Canadian Royalties: Excavator Trainingotak04Nessuna valutazione finora

- Electro ValvulasDocumento89 pagineElectro ValvulasJuan Domingo OrlandiniNessuna valutazione finora

- Service Manual E32 Compact Excavator: S/N A94H11001 & Above S/N AC2N11001 & AboveDocumento6 pagineService Manual E32 Compact Excavator: S/N A94H11001 & Above S/N AC2N11001 & AboveMadster Roberts0% (4)

- DFM54 EngDocumento2 pagineDFM54 EngAnonymous KWO434Nessuna valutazione finora

- Operacion y Mantenimiento ManualDocumento42 pagineOperacion y Mantenimiento ManualGARY BAUTISTANessuna valutazione finora

- CraneDocumento3 pagineCraneNgọc Đức ĐoànNessuna valutazione finora

- Hangil Crane Brochure (v1901)Documento8 pagineHangil Crane Brochure (v1901)MadaniNessuna valutazione finora

- UNIC URW-506 DatasheetDocumento1 paginaUNIC URW-506 DatasheetMário BernardoNessuna valutazione finora

- DOWMAXDocumento50 pagineDOWMAXsahil100% (1)

- kh180-3 SPDocumento28 paginekh180-3 SPDouglas LeeNessuna valutazione finora

- Two Way ValveDocumento68 pagineTwo Way ValveSoeAye100% (3)

- AtlasGroup Album enDocumento84 pagineAtlasGroup Album envatasaNessuna valutazione finora

- PK150002Documento8 paginePK150002Mihnea OrzaNessuna valutazione finora

- Sheaves : With Cylindrical Roller BearingsDocumento3 pagineSheaves : With Cylindrical Roller BearingsInhake AutechreNessuna valutazione finora

- Strong and Versatile: PK 8500 PerformanceDocumento8 pagineStrong and Versatile: PK 8500 Performancesmilewithbalajith100% (1)

- Service Manual E45 Compact Excavator: S/N AG3G11001 & Above S/N AHHC11001 & AboveDocumento6 pagineService Manual E45 Compact Excavator: S/N AG3G11001 & Above S/N AHHC11001 & Aboveandy habibiNessuna valutazione finora

- DynasetDocumento64 pagineDynasetAlexis Peña0% (1)

- Unit 4: Hydraulic Fundamentals - Pilot Operated Hydraulic SystemDocumento28 pagineUnit 4: Hydraulic Fundamentals - Pilot Operated Hydraulic Systemoscar el carevergaNessuna valutazione finora

- Wheel LoaderDocumento2 pagineWheel LoaderbonjavaNessuna valutazione finora

- KPM K3VL B Series Marketing KitDocumento167 pagineKPM K3VL B Series Marketing KitClaudiu MorarNessuna valutazione finora

- Aa2fm Model CodeDocumento27 pagineAa2fm Model CodeCristianNessuna valutazione finora

- LSI gs550 PDFDocumento85 pagineLSI gs550 PDFIvan ivan budiNessuna valutazione finora

- SR285R W10 2020 172953Documento2 pagineSR285R W10 2020 172953TigerNessuna valutazione finora

- 345D-Prelim. Excavator Service Tools: Tool Summary New ToolsDocumento6 pagine345D-Prelim. Excavator Service Tools: Tool Summary New ToolsNova kurniawan 34Nessuna valutazione finora

- аксиальник 250Documento70 pagineаксиальник 250anon_757712831Nessuna valutazione finora

- Rotary Drilling Rig: Base Carrier BH 70 BH 70Documento12 pagineRotary Drilling Rig: Base Carrier BH 70 BH 70Vistash Buhary50% (2)

- TadanoDocumento9 pagineTadanoFATCHURNessuna valutazione finora

- PVP41-48 Manual de ServicioDocumento16 paginePVP41-48 Manual de ServicioconimecNessuna valutazione finora

- WAgo PLC ManDocumento506 pagineWAgo PLC ManpaulNessuna valutazione finora

- SPK 32080Documento4 pagineSPK 32080Balaji RathinavelNessuna valutazione finora

- Hitachi Sumitomo SCX2500 - L611-0903 (TW)Documento16 pagineHitachi Sumitomo SCX2500 - L611-0903 (TW)lkc 8Nessuna valutazione finora

- Shotcrete 3 PDFDocumento18 pagineShotcrete 3 PDFCarlos GuerraNessuna valutazione finora

- Valve: Multiple Control Valve: Basic Circuit (Parallel, Tandem, and Series Circuits)Documento18 pagineValve: Multiple Control Valve: Basic Circuit (Parallel, Tandem, and Series Circuits)KadirNessuna valutazione finora

- 32080Documento4 pagine32080Oumarba KamandaNessuna valutazione finora

- Spare Parts Information-HKN 31021701e 01Documento114 pagineSpare Parts Information-HKN 31021701e 01YAKOVNessuna valutazione finora

- SWL 55t Crane CrawlerDocumento32 pagineSWL 55t Crane CrawlerHerberth SilitongaNessuna valutazione finora

- Hydraulic Commissioning ManualDocumento7 pagineHydraulic Commissioning Manualranjit2150Nessuna valutazione finora

- Hydraulic Drill Rig: AF 110 AF 130Documento14 pagineHydraulic Drill Rig: AF 110 AF 130Alton LeeNessuna valutazione finora

- NEW Model: TM-ZT500Documento6 pagineNEW Model: TM-ZT500semindang rinduNessuna valutazione finora

- 8 Series Small Mobile Diesel Air CompressorsDocumento8 pagine8 Series Small Mobile Diesel Air CompressorsGuptaNessuna valutazione finora

- MC 86 Base CarrierDocumento6 pagineMC 86 Base Carriersagar badheNessuna valutazione finora

- Manitou Tyre Handlers enDocumento4 pagineManitou Tyre Handlers enRui FerreiraNessuna valutazione finora

- Brochure bl61b bl71b t3 en 21 20024035 e PDFDocumento24 pagineBrochure bl61b bl71b t3 en 21 20024035 e PDFCristian PatrașNessuna valutazione finora

- Fukurawa Unic UR293a1 Maintenance ManualDocumento77 pagineFukurawa Unic UR293a1 Maintenance ManualRealgazzNessuna valutazione finora

- Cat 950gii HL PDFDocumento96 pagineCat 950gii HL PDFJuniaman SinagaNessuna valutazione finora

- Parts Manual: Hydraulic Power Supply UnitsDocumento41 pagineParts Manual: Hydraulic Power Supply UnitsAnonymous hKGD6RT82Nessuna valutazione finora

- Hydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFDocumento5 pagineHydraulic Control Valve (W-BICS Valve) - (S-N 5122 20298 & Abv, 5124 40721 & Abv, 5126 12258 & Ab - 763 PDFRomusNessuna valutazione finora

- Katalog Powertilt EngDocumento6 pagineKatalog Powertilt Engmatej1992Nessuna valutazione finora

- Soilmec T 108 Drill RigDocumento8 pagineSoilmec T 108 Drill RigEduardo ServínNessuna valutazione finora

- SR100 PDFDocumento6 pagineSR100 PDFSandeep Kumar Dangda100% (1)

- World Health Organization COVID-19 Report - March 28Documento10 pagineWorld Health Organization COVID-19 Report - March 28CityNewsTorontoNessuna valutazione finora

- Env MomentDocumento1 paginaEnv MomentMohamedAbdelnasserNessuna valutazione finora

- Pri.1 October General RevisionDocumento3 paginePri.1 October General RevisionMohamedAbdelnasserNessuna valutazione finora

- Plaxis 3d ModelDocumento1 paginaPlaxis 3d ModelMohamedAbdelnasserNessuna valutazione finora

- Plaxis 1 PenurunanDocumento1 paginaPlaxis 1 PenurunanBagus SetiawanNessuna valutazione finora

- Plaxis 1 PenurunanDocumento1 paginaPlaxis 1 PenurunanBagus SetiawanNessuna valutazione finora

- CH5 Pile Fndns PDFDocumento26 pagineCH5 Pile Fndns PDFDr. MOHAMED ALZAINNessuna valutazione finora

- Env. ShearDocumento1 paginaEnv. ShearMohamedAbdelnasserNessuna valutazione finora

- Q.S SpiralDocumento2 pagineQ.S SpiralMohamedAbdelnasserNessuna valutazione finora

- Plaxis Mum Plaxisbai Course 2012 PDFDocumento638 paginePlaxis Mum Plaxisbai Course 2012 PDFMohamedAbdelnasserNessuna valutazione finora

- Plaxis OutputDocumento1 paginaPlaxis OutputMohamedAbdelnasserNessuna valutazione finora

- Env. HoopDocumento1 paginaEnv. HoopMohamedAbdelnasserNessuna valutazione finora

- Communications Plan Instructions 1.2Documento2 pagineCommunications Plan Instructions 1.2Janaka WempathiNessuna valutazione finora

- Work Breakdown Structure Table: Date / Control NumberDocumento3 pagineWork Breakdown Structure Table: Date / Control Numbernickdash09Nessuna valutazione finora

- What Are Stone ColumnsDocumento2 pagineWhat Are Stone ColumnsgreatwellwisherNessuna valutazione finora

- Piles Shop DrawingDocumento4 paginePiles Shop DrawingMohamedAbdelnasserNessuna valutazione finora

- Annex 1 - Titration Method For Determining Salt Iodate and Iodide ContentDocumento35 pagineAnnex 1 - Titration Method For Determining Salt Iodate and Iodide Contentr0466Nessuna valutazione finora

- Risk ProjectsDocumento5 pagineRisk ProjectsJanaka WempathiNessuna valutazione finora

- SoilmecDocumento12 pagineSoilmecMohamedAbdelnasserNessuna valutazione finora

- Soilmec SR 40Documento8 pagineSoilmec SR 40MohamedAbdelnasserNessuna valutazione finora

- Design Guide For Structural Hollow Section ConnectionsDocumento213 pagineDesign Guide For Structural Hollow Section ConnectionsAnonymous 8f2veZf83% (6)

- QT200 Bored Piles Sls Crack Width - Pile: Section SpecificationDocumento1 paginaQT200 Bored Piles Sls Crack Width - Pile: Section SpecificationMohamedAbdelnasserNessuna valutazione finora

- 905 015 2 BAUER-Bored-Piles en PDFDocumento16 pagine905 015 2 BAUER-Bored-Piles en PDFMohamedAbdelnasser100% (1)

- Execution Piles in WaterDocumento19 pagineExecution Piles in WaterMohamedAbdelnasser100% (1)

- BG 28Documento24 pagineBG 28MohamedAbdelnasser100% (1)

- p.35 Pile Coordinstion-Part 2Documento1 paginap.35 Pile Coordinstion-Part 2MohamedAbdelnasserNessuna valutazione finora

- مستند جديد 2018-09-09 14.39.42 - 2Documento1 paginaمستند جديد 2018-09-09 14.39.42 - 2MohamedAbdelnasserNessuna valutazione finora

- Beshla - ProductionsDocumento8 pagineBeshla - ProductionsMohamedAbdelnasserNessuna valutazione finora

- Abou Quir - ProductionsDocumento3 pagineAbou Quir - ProductionsMohamedAbdelnasserNessuna valutazione finora

- Kuantan PortDocumento11 pagineKuantan PortShashank Shekhar100% (1)

- AIP Singapore GENDocumento28 pagineAIP Singapore GENIvan MilosevicNessuna valutazione finora

- Partnership: Magna International and FordDocumento2 paginePartnership: Magna International and FordFord Motor CompanyNessuna valutazione finora

- Report Tpt250Documento11 pagineReport Tpt250Nur Asyikin binti MahassanNessuna valutazione finora

- Prospectus 17-18 PDFDocumento111 pagineProspectus 17-18 PDFVaibhavNessuna valutazione finora

- Dubaiairports Infographic PDFDocumento1 paginaDubaiairports Infographic PDFJibin J ThomasNessuna valutazione finora

- Quickie Dimension LeafletDocumento36 pagineQuickie Dimension Leafletinfo48260% (1)

- PPP ModelDocumento40 paginePPP ModelMainak BhattacharjeeNessuna valutazione finora

- Wheel Alignment Theory Operation PDFDocumento5 pagineWheel Alignment Theory Operation PDFOskars ŠtālsNessuna valutazione finora

- Roland Berger World Rail Market Presentation FinalDocumento21 pagineRoland Berger World Rail Market Presentation FinalAnand Raj DoraisingamNessuna valutazione finora

- Alfa RomeoDocumento12 pagineAlfa RomeoVidysagar Vvec100% (1)

- Final Design Report: Package-III (Malekhu - Mugling) Ch. 43+542 To Ch. 82+403Documento55 pagineFinal Design Report: Package-III (Malekhu - Mugling) Ch. 43+542 To Ch. 82+403Santosh AryalNessuna valutazione finora

- Ali CVDocumento1 paginaAli CVAli EidNessuna valutazione finora

- A330-A340 Flight Crew Training ManualDocumento307 pagineA330-A340 Flight Crew Training Manualsaudia686100% (1)

- Piping Design Tank FarmDocumento36 paginePiping Design Tank Farmkemo10100% (1)

- Dholera Industrial City Overview PDFDocumento65 pagineDholera Industrial City Overview PDFzaheeruddin_mohdNessuna valutazione finora

- E36 BMW M3: H&R Coilover Installation ForDocumento26 pagineE36 BMW M3: H&R Coilover Installation ForGabriel DKNessuna valutazione finora

- Europe Beverage Dispensers Sales Market Report 2021Documento7 pagineEurope Beverage Dispensers Sales Market Report 2021Hellina MartinsNessuna valutazione finora

- Details of Faculty Member Balloki June 2021Documento34 pagineDetails of Faculty Member Balloki June 2021Muzammil NaeemNessuna valutazione finora

- Magazine EssayDocumento8 pagineMagazine EssayJara PerezNessuna valutazione finora

- SMRT Annual Report 2016Documento141 pagineSMRT Annual Report 2016Sassy TanNessuna valutazione finora

- Pengertian Recount TextDocumento2 paginePengertian Recount Textdede heryadiNessuna valutazione finora

- Oct 18 To Planning CommissionersDocumento12 pagineOct 18 To Planning CommissionerssamtlevinNessuna valutazione finora

- Siglo XVI HolandaDocumento271 pagineSiglo XVI Holandafores2Nessuna valutazione finora

- MBTA Capital Needs Assessment and InventoryDocumento52 pagineMBTA Capital Needs Assessment and InventoryAbby PatkinNessuna valutazione finora

- 747 FB 13-02Documento2 pagine747 FB 13-02JOEL VITOR PEREIRA DOS SANTOSNessuna valutazione finora

- Deck Cadet Monitoring and Onboard Performance ReportDocumento1 paginaDeck Cadet Monitoring and Onboard Performance ReportGrachen Delos SantosNessuna valutazione finora

- AAPA Guide To The Handling Storage Manufacture of PMB's Final Version Jan 2013 PDFDocumento15 pagineAAPA Guide To The Handling Storage Manufacture of PMB's Final Version Jan 2013 PDFhongleukNessuna valutazione finora

- DAILY 4x4: Pt. Chakra Jawara Integrated Transport SolutionsDocumento2 pagineDAILY 4x4: Pt. Chakra Jawara Integrated Transport SolutionsYudhi CiamorienNessuna valutazione finora

- SAP Trg. Log Sheet - All ModulesDocumento51 pagineSAP Trg. Log Sheet - All Modulespawandubey9Nessuna valutazione finora