Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

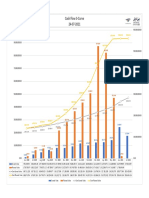

Design of Slabs-On-Ground 360R-35: Fig. 8.4-Calculated Compressive Stresses Induced by Expansion (From ACI 223)

Caricato da

Anonymous a3K3Wg0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni1 paginaThis document discusses the design of slabs-on-ground and concrete expansion. It notes that reinforced and plain concrete slabs display expansion behavior. It also discusses using prism tests to determine expansion potential and estimating compressive stresses in slabs based on reinforcement percentage and expansion. Expansion/isolation joints that can accommodate slab expansion are recommended, and their sizing is discussed. Placement sequence and construction joints are also addressed to allow for concrete expansion.

Descrizione originale:

123

Titolo originale

Construction Joints

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses the design of slabs-on-ground and concrete expansion. It notes that reinforced and plain concrete slabs display expansion behavior. It also discusses using prism tests to determine expansion potential and estimating compressive stresses in slabs based on reinforcement percentage and expansion. Expansion/isolation joints that can accommodate slab expansion are recommended, and their sizing is discussed. Placement sequence and construction joints are also addressed to allow for concrete expansion.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

11 visualizzazioni1 paginaDesign of Slabs-On-Ground 360R-35: Fig. 8.4-Calculated Compressive Stresses Induced by Expansion (From ACI 223)

Caricato da

Anonymous a3K3WgThis document discusses the design of slabs-on-ground and concrete expansion. It notes that reinforced and plain concrete slabs display expansion behavior. It also discusses using prism tests to determine expansion potential and estimating compressive stresses in slabs based on reinforcement percentage and expansion. Expansion/isolation joints that can accommodate slab expansion are recommended, and their sizing is discussed. Placement sequence and construction joints are also addressed to allow for concrete expansion.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

DESIGN OF SLABS-ON-GROUND 360R-35

quarter of the slab. Both reinforced and plain slabs, as well as

fiber-reinforced slabs, displayed this behavior.

8.4.2 Prism and slab expansion strains and stresses—

Because the reinforcement percentage varies, the ASTM C

878 restrained concrete prism test is used to verify the

expansive potential of a given mixture. Figure 8.2 may then

be used to determine the amount of slab expansion (strain)

using the known prism expansion value and the percent of

reinforcement in the slab.

With the use of Fig. 8.2, the amount of internal compressive

force acting on the concrete can be estimated knowing the

maximum member (slab) expansion and the percent of

internal reinforcement in the slab.

8.4.3 Expansion/isolation joints—Because a slab may be

restrained externally on one side by a previously cast slab,

the opposite side should be able to accommodate the expansive

strains. When a slab is also adjacent to a stiff wall, pit wall,

or other slab, external restraint on two opposite sides is

present. Compressive stresses as high as 45 to 172 psi (0.31

to 1.19 MPa) (Russell 1973) have been measured, and if the

external restraints are sufficiently stiff, they may prevent the

concrete from expanding and elongating the steel.

Normal asphaltic premolded fiber isolation joints are far Fig. 8.4—Calculated compressive stresses induced by

too stiff to provide adequate isolation and accommodate expansion (from ACI 223).

expansion as their minimum strength requirements are in the

150 psi (1.0 MPa) range at a compression of 50% of the original

joint thickness. A material with a maximum compressive slab when cast against a rigid element should be free to

strength of 25 psi (0.17 MPa) at 50% deformation according move. A formed edge should have the brace stakes or pins

to ASTM D 1621 or D 3575 should be used. loosened after the final set of the concrete to accommodate

If a slab is allowed to expand only at one end during initial the expansive action.

expansion, the width of the isolation joint (in inches) should The placing sequence should be organized so that the edges

be equal to two times the anticipated slab expansion, as taken of slabs are free to move for the maximum time possible before

from Fig. 8.3, and multiplied by the length of the longest placing adjacent slabs. At least 70% of the maximum measured

dimension of the slab (in inches). For a 100 x 120 ft (30 x 37 m) laboratory expansion per ASTM C 878 should occur before

slab with expansion strain of 0.00035: placing adjacent slabs when a slab is not free to expand on two

opposite ends. Examples of placement patterns are shown in

Joint width = 2 × 120 × 12 × 0.00035 (2 × 36.6 × 1000 × 0.00035) ACI 223. Checkerboarded placements should not be used

unless a compressible joint material is placed between the slab

= 1.008 in. (25.60 mm) before concrete placement as per Section 8.4.3.

Before establishing the placement sequence, results of

Use 1 in. (25 mm) thick joint material if the slab is to expand expansion testing per ASTM C 878 should be considered. A

only at one end; and minimum level of prism expansion of 0.04% is recom-

Use 1/2 in. (13 mm) thick joint material if allowed to expand mended for slabs-on-ground. Higher expansion results

at both ends. would accommodate larger slab placements or slabs that

8.4.4 Construction joints—ACI 223 states that with the use have higher amounts of reinforcements. Trial batches for the

of shrinkage-compensating concrete, slabs may be placed in tested mixture proportion should use materials identical to

areas as large as 16,000 ft2 (1500 m2) without joints. Place- those that will be used during construction and tested at the

ments of this size should only be considered in ideal conditions. proposed slump that will be used in the field.

Placements of 10,000 ft2 (930 m2) or less are more common 8.4.6 Concrete overlays—Overlays are used at times to

with joint spacing of 100 ft (30 m). increase the thickness of a slab during initial construction or

Slab sections should be as square as possible, and provisions as a remedial measure. Improved wear performance or a new

should be made to accommodate differential movement finished floor elevation may be the most frequent reasons for

between adjacent slabs in the direction parallel to the joint using overlays. The two types of overlays—bonded and

between the two slabs. Further explanation and details are nonbonded—are covered in ACI 302.1R as Class 6 and

found in ACI 223. Class 7 floors.

8.4.5 Placing sequence—For slabs-on-ground, the place- Bonded overlays are generally a minimum of 3/4 in. (19 mm)

ment sequence should allow the expansive strains to occur thick, but thicknesses of 3 in. (76 mm) or more are not

against a free and unrestrained edge. The opposite end of a uncommon. Typical bonded overlays are used to improve

Potrebbero piacerti anche

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Concrete Rules of ThumbDocumento8 pagineConcrete Rules of Thumbdeekchik121Nessuna valutazione finora

- Turf Wall Architecture and Turf Furniture Assembly GuideDa EverandTurf Wall Architecture and Turf Furniture Assembly GuideNessuna valutazione finora

- Pile Foundation Design GuideDocumento8 paginePile Foundation Design Guidecabaas hassanNessuna valutazione finora

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDa EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNessuna valutazione finora

- Section 6 - Prestressed Concrete: 6.1 - DESIGNDocumento11 pagineSection 6 - Prestressed Concrete: 6.1 - DESIGNAnonymous mcHqIfbnV1Nessuna valutazione finora

- PCI B - PDPGDocumento13 paginePCI B - PDPGbcbianNessuna valutazione finora

- Astm C 34Documento3 pagineAstm C 34Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- (A) Grading: Lesson 4: Aggregates and Its PropertiesDocumento3 pagine(A) Grading: Lesson 4: Aggregates and Its PropertiesDjonraeNarioGalvezNessuna valutazione finora

- C34 PDFDocumento3 pagineC34 PDFJayakumar AnanthaNessuna valutazione finora

- Joint DetailsDocumento2 pagineJoint Detailsmusibo911Nessuna valutazione finora

- Testing of Concrete BlocksDocumento6 pagineTesting of Concrete BlocksLumine HotaruNessuna valutazione finora

- Control of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part SeriesDocumento4 pagineControl of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part Seriesmyke_0101Nessuna valutazione finora

- Opening in 2 Way SlabDocumento4 pagineOpening in 2 Way SlabGautam PaulNessuna valutazione finora

- Cut Out in RC SlabDocumento4 pagineCut Out in RC SlabAnonymous 1HFV185Sl4Nessuna valutazione finora

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocumento4 pagineNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNessuna valutazione finora

- Advantages of Steel Fibre Reinforced Con PDFDocumento5 pagineAdvantages of Steel Fibre Reinforced Con PDFAce NovoNessuna valutazione finora

- Slabs FinalDocumento30 pagineSlabs FinalMwa100% (1)

- SlabsDocumento29 pagineSlabsPimpa Mwiinga100% (2)

- Allan Block Spec GuidelinesDocumento3 pagineAllan Block Spec GuidelinesEdson Orlando Hoyos CeronNessuna valutazione finora

- Flexural Design Procedure For Singly Reinforced Rectangular BeamsDocumento3 pagineFlexural Design Procedure For Singly Reinforced Rectangular BeamstvelasquezNessuna valutazione finora

- BS 1881-Part 109-83Documento3 pagineBS 1881-Part 109-83AntonNessuna valutazione finora

- Roofing ShinglesDocumento4 pagineRoofing ShinglesFaizal HaziziNessuna valutazione finora

- RCC Is Provision NotesDocumento4 pagineRCC Is Provision NotessameerNessuna valutazione finora

- Reinforced Concrete Slab DesignDocumento30 pagineReinforced Concrete Slab DesignPitolwala ZuzarNessuna valutazione finora

- PCA Concrete Floor Slab OpeningsDocumento4 paginePCA Concrete Floor Slab OpeningsFabrizio BisernaNessuna valutazione finora

- CEB 711 - Structural Design II: Semester 2, 2020 2Documento32 pagineCEB 711 - Structural Design II: Semester 2, 2020 2Asnil PrakashNessuna valutazione finora

- C 36 - C 36M - 99 - Qzm2ltk5rteDocumento3 pagineC 36 - C 36M - 99 - Qzm2ltk5rte2010civ164Nessuna valutazione finora

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocumento4 pagineNcma Tek: Segmental Retaining Wall Units TEK 2-4BjerryNessuna valutazione finora

- Structural Panels in Tension: Standard Test Methods ForDocumento6 pagineStructural Panels in Tension: Standard Test Methods ForeliasNessuna valutazione finora

- Influence of lattice height on shear resistance in RC ribsDocumento10 pagineInfluence of lattice height on shear resistance in RC ribsGuillermo AragonNessuna valutazione finora

- Do's and Dont's in Civil EngineeringDocumento20 pagineDo's and Dont's in Civil EngineeringRam1028100% (1)

- Flooring Design GuideDocumento81 pagineFlooring Design GuideArmin KovacevicNessuna valutazione finora

- Technical Advisory Slab PAVEMENTDocumento6 pagineTechnical Advisory Slab PAVEMENTNoli PaladNessuna valutazione finora

- 8 - Design of Slab Part 1 One Way SlabDocumento27 pagine8 - Design of Slab Part 1 One Way SlabyakaNessuna valutazione finora

- As 1012.5-1999 PDFDocumento9 pagineAs 1012.5-1999 PDFPham Duc QuangNessuna valutazione finora

- Ncma Tek: Empirical Design of Concrete Masonry Walls TEK 14-8ADocumento6 pagineNcma Tek: Empirical Design of Concrete Masonry Walls TEK 14-8Ashamimzubery1969Nessuna valutazione finora

- AWWA Flowtite Buried Pipe Installation GuideDocumento16 pagineAWWA Flowtite Buried Pipe Installation GuideAmrRassemNessuna valutazione finora

- Reinforcing Steel in Slabs On Grade - tcm45-346883Documento3 pagineReinforcing Steel in Slabs On Grade - tcm45-346883Ralf SnellNessuna valutazione finora

- Structural Design - Post Tensioned Slab Design1Documento12 pagineStructural Design - Post Tensioned Slab Design1Chamil MahagamageNessuna valutazione finora

- Chapter 8Documento12 pagineChapter 8gilbert850507Nessuna valutazione finora

- Exp 9Documento10 pagineExp 9sju65Nessuna valutazione finora

- Division 3 Specs WrittingDocumento16 pagineDivision 3 Specs WrittingJaymar Palomares OrilloNessuna valutazione finora

- CH 1Documento49 pagineCH 1Gurinder PalsinghNessuna valutazione finora

- PCA Concrete Floor Slab OpeningsDocumento4 paginePCA Concrete Floor Slab OpeningsRavindra MRNessuna valutazione finora

- Thumb Rules For Steel&Concrete DesignDocumento11 pagineThumb Rules For Steel&Concrete DesigngvgbabuNessuna valutazione finora

- Slab On Grade Reinf DesignDocumento9 pagineSlab On Grade Reinf Designjardean villosoNessuna valutazione finora

- Ribs & Structure DesignDocumento17 pagineRibs & Structure DesignHemanth KathaNessuna valutazione finora

- Base Concrete Placement: 1. SubgradeDocumento1 paginaBase Concrete Placement: 1. Subgradeapuhapuh_153349Nessuna valutazione finora

- ASCC Position Statement 09Documento1 paginaASCC Position Statement 09Hanri PakpahanNessuna valutazione finora

- Wood Structural Panel Shear WallDocumento21 pagineWood Structural Panel Shear WallgullipalliNessuna valutazione finora

- Mini ProjectDocumento14 pagineMini ProjectMr. Himanshu111100% (1)

- Performance of Unreinforced Concrete Bored PilesDocumento19 paginePerformance of Unreinforced Concrete Bored PilesarslanpasaNessuna valutazione finora

- Sand Cement Floor Screeds 18092009Documento12 pagineSand Cement Floor Screeds 18092009David PuenNessuna valutazione finora

- Framing - Gypsum - HandbookDocumento28 pagineFraming - Gypsum - HandbookAsebaho BadrNessuna valutazione finora

- Brick Masonry DesignDocumento34 pagineBrick Masonry DesignWan Rids0% (1)

- LONG-STRIP CONSTRUCTION PREFERRED FOR SLABS ON GROUNDDocumento10 pagineLONG-STRIP CONSTRUCTION PREFERRED FOR SLABS ON GROUNDfNessuna valutazione finora

- Concrete Shear Wall Evolution of Design Codes and Guidelines PDFDocumento4 pagineConcrete Shear Wall Evolution of Design Codes and Guidelines PDFUrsu Claudiu AntonNessuna valutazione finora

- P&C NEW Modified GACA BLD ProjectDocumento9 pagineP&C NEW Modified GACA BLD ProjectAnonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building Project: Procurement Long Lead Items Cut Off Date: 23 10 2021Documento1 paginaGeneral Authority of Civil Aviation Building Project: Procurement Long Lead Items Cut Off Date: 23 10 2021Anonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building Project: Procurement Non Long Lead Items Cut Off Date: 23 10 2021Documento1 paginaGeneral Authority of Civil Aviation Building Project: Procurement Non Long Lead Items Cut Off Date: 23 10 2021Anonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building Project: Construction Activities Cut Off Date: 23 10 2021Documento5 pagineGeneral Authority of Civil Aviation Building Project: Construction Activities Cut Off Date: 23 10 2021Anonymous a3K3WgNessuna valutazione finora

- RDocumento1 paginaRAnonymous a3K3WgNessuna valutazione finora

- GACA Buildings Progress Report 15-05-2021Documento3 pagineGACA Buildings Progress Report 15-05-2021Anonymous a3K3WgNessuna valutazione finora

- GACA weekly progress As per Mashroat Mechanism - 31-8-2021 - خلاصة لمبنى الهيئةDocumento1 paginaGACA weekly progress As per Mashroat Mechanism - 31-8-2021 - خلاصة لمبنى الهيئةAnonymous a3K3WgNessuna valutazione finora

- RBS 30-12-2021.XER-8-ActivitiesDocumento7 pagineRBS 30-12-2021.XER-8-ActivitiesAnonymous a3K3WgNessuna valutazione finora

- Activity and WBS Tracking ReportDocumento388 pagineActivity and WBS Tracking ReportAnonymous a3K3WgNessuna valutazione finora

- Marshall Mix Design ProcedureDocumento31 pagineMarshall Mix Design Procedurebraackw100% (2)

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building Critical Construction ActivitiesDocumento3 pagineGeneral Authority of Civil Aviation Building Critical Construction ActivitiesAnonymous a3K3WgNessuna valutazione finora

- S-Curve 21-08-2021Documento1 paginaS-Curve 21-08-2021Anonymous a3K3WgNessuna valutazione finora

- Progress Report Cut-Off Date: 24-07-2021: Activity Name Performance % Complete Schedule % CompleteDocumento3 pagineProgress Report Cut-Off Date: 24-07-2021: Activity Name Performance % Complete Schedule % CompleteAnonymous a3K3WgNessuna valutazione finora

- MEP Update 10-07-2021Documento90 pagineMEP Update 10-07-2021Anonymous a3K3WgNessuna valutazione finora

- MEP Update 10-07-2021Documento90 pagineMEP Update 10-07-2021Anonymous a3K3WgNessuna valutazione finora

- MEP Update 10-07-2021Documento90 pagineMEP Update 10-07-2021Anonymous a3K3WgNessuna valutazione finora

- S-Curve 13-03-2021Documento1 paginaS-Curve 13-03-2021Anonymous a3K3WgNessuna valutazione finora

- Hot Ashalt Mix Desing System MOTDocumento48 pagineHot Ashalt Mix Desing System MOTAnonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- Table 5.02 - Marshall Mix Design CriteriaDocumento1 paginaTable 5.02 - Marshall Mix Design CriteriaMahesh Kumar sukhadiyaNessuna valutazione finora

- S-Curve 24-07-2021Documento1 paginaS-Curve 24-07-2021Anonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- S-Curve 10-04-2021Documento1 paginaS-Curve 10-04-2021Anonymous a3K3WgNessuna valutazione finora

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsDocumento3 pagineGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgNessuna valutazione finora

- S-Curve 08-05-2021Documento1 paginaS-Curve 08-05-2021Anonymous a3K3WgNessuna valutazione finora

- GACA Buildings Progress Report 15-05-2021Documento3 pagineGACA Buildings Progress Report 15-05-2021Anonymous a3K3WgNessuna valutazione finora

- S-Curve 03-04-2021Documento1 paginaS-Curve 03-04-2021Anonymous a3K3WgNessuna valutazione finora

- Assignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaDocumento4 pagineAssignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaPaulo PimentaNessuna valutazione finora

- GEAS 1 - Chemistry - 2Documento4 pagineGEAS 1 - Chemistry - 2Leoneil Angelo AbreuNessuna valutazione finora

- EE221 Solution Problem Set2Documento10 pagineEE221 Solution Problem Set2srinivasanNessuna valutazione finora

- AP PHYSICS B 1988 MC + AnswersDocumento17 pagineAP PHYSICS B 1988 MC + AnswersbastardNessuna valutazione finora

- Commercial Building Structural Design and AnalysisDocumento19 pagineCommercial Building Structural Design and AnalysisPatrikNessuna valutazione finora

- Appendix JA2 Reference Weather and Climate Zone DataDocumento66 pagineAppendix JA2 Reference Weather and Climate Zone DataJoseph DavidNessuna valutazione finora

- Assignment 2Documento2 pagineAssignment 2ue06037Nessuna valutazione finora

- Carrefour-SA Shopping Center TurkeyDocumento2 pagineCarrefour-SA Shopping Center TurkeyVineet JogalekarNessuna valutazione finora

- McCabe-Thiele Diagrams For Binary DistillationDocumento8 pagineMcCabe-Thiele Diagrams For Binary DistillationwetcoNessuna valutazione finora

- Curriculum-Of Mathematics Government College Women University, SialkotDocumento119 pagineCurriculum-Of Mathematics Government College Women University, SialkotHuzaifa GurmaniNessuna valutazione finora

- Hough Transform in Matlab: - If We Find An Edge Point at (Ix, Iy), We Loop Through All Possible Values of ThetaDocumento11 pagineHough Transform in Matlab: - If We Find An Edge Point at (Ix, Iy), We Loop Through All Possible Values of ThetaLe QuyenNessuna valutazione finora

- A Method of Solving Certain Nonlinear DiophantineDocumento3 pagineA Method of Solving Certain Nonlinear DiophantineArsh TewariNessuna valutazione finora

- EVER11 Final ProgramDocumento20 pagineEVER11 Final ProgramAdrian PopNessuna valutazione finora

- Design of Masonry StructuresDocumento10 pagineDesign of Masonry StructuresmuhammedNessuna valutazione finora

- 6314Documento18 pagine6314Simone RizzoNessuna valutazione finora

- Unit Hydrograph DerivationDocumento7 pagineUnit Hydrograph DerivationSudharsananPRSNessuna valutazione finora

- April 2015-Vacuum Drying Chem Eng PDFDocumento9 pagineApril 2015-Vacuum Drying Chem Eng PDFAlvaro BarbozaNessuna valutazione finora

- Text - Anuario Cader 2018 INGLÉS PDFDocumento57 pagineText - Anuario Cader 2018 INGLÉS PDFmicaelaNessuna valutazione finora

- Chapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NDocumento15 pagineChapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NCedric KouakouNessuna valutazione finora

- General Physics 1 1st Quarter Module 1 ActivitiesDocumento16 pagineGeneral Physics 1 1st Quarter Module 1 ActivitiesMica LopezNessuna valutazione finora

- Sag Slurry PoolingDocumento10 pagineSag Slurry PoolingalgroneNessuna valutazione finora

- Ferroresonance During Single-Phase Switching of Distribution TransformersDocumento6 pagineFerroresonance During Single-Phase Switching of Distribution TransformersDiego Betancourt MejiaNessuna valutazione finora

- LaminateDocumento154 pagineLaminateAbhishek VaggarNessuna valutazione finora

- Piping Support DesignDocumento27 paginePiping Support DesignOmar TocmoNessuna valutazione finora

- Winitzki - Heidelberg Lectures On Advanced General Relativity 2007Documento156 pagineWinitzki - Heidelberg Lectures On Advanced General Relativity 2007winitzkiNessuna valutazione finora

- Midas FEADocumento2 pagineMidas FEACristian Camilo Londoño PiedrahítaNessuna valutazione finora

- DPP-1 QuantizationDocumento1 paginaDPP-1 QuantizationVikasNessuna valutazione finora

- Study Guide For Mid-Term 3 SolutionsDocumento8 pagineStudy Guide For Mid-Term 3 Solutionskuumba0% (3)

- Single Disc Clutch DesignDocumento32 pagineSingle Disc Clutch DesignWeins GemerlapNessuna valutazione finora

- Introduction to Nanorobotics and Their ApplicationsDocumento25 pagineIntroduction to Nanorobotics and Their ApplicationsSharifa RahamadullahNessuna valutazione finora

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (137)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignDa EverandAn Applied Guide to Water and Effluent Treatment Plant DesignValutazione: 5 su 5 stelle5/5 (4)

- Advanced Modelling Techniques in Structural DesignDa EverandAdvanced Modelling Techniques in Structural DesignValutazione: 5 su 5 stelle5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Guidelines for Engineering Design for Process SafetyDa EverandGuidelines for Engineering Design for Process SafetyNessuna valutazione finora

- Guidelines for Siting and Layout of FacilitiesDa EverandGuidelines for Siting and Layout of FacilitiesNessuna valutazione finora

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDa EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Robotics: Designing the Mechanisms for Automated MachineryDa EverandRobotics: Designing the Mechanisms for Automated MachineryValutazione: 4.5 su 5 stelle4.5/5 (8)

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsDa EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNessuna valutazione finora

- Understanding Distillation Using Column Profile MapsDa EverandUnderstanding Distillation Using Column Profile MapsNessuna valutazione finora

- Bow Ties in Risk Management: A Concept Book for Process SafetyDa EverandBow Ties in Risk Management: A Concept Book for Process SafetyNessuna valutazione finora