Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Latapoxy SP 100 TDS 1

Caricato da

Abdul Raheem Syed0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

110 visualizzazioni3 pagineLatapoxy SP 100 TDS 1

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLatapoxy SP 100 TDS 1

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

110 visualizzazioni3 pagineLatapoxy SP 100 TDS 1

Caricato da

Abdul Raheem SyedLatapoxy SP 100 TDS 1

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Limitations

• Light olors a darke slightl fro dire t UV e posure.

LATAPOXY® SP-100 Consult with Technical Services for specific exterior

recommendations.

Stainfree Epoxy Grout • For i dustrial appli atio s e posed to high o e tratio s of

food and mineral acids and to high heat, use LATAPOXY®2000

PRODUCT DESCRIPTION

Industrial Epoxy Grout.

LATAPOXY® SP-100 Stainfree Grout is an epoxy grout • Ma i u stai resista e is a hie ed da s after

specifically designed for use in applications of ceramic tile, installation. Protect from exposure to acids and strong

cleaners during this period.

vitrified tile and stone where staining is expected.

• Not re o e ded for soft, polished ar le or deli ate

Application glazed tiles.

• I stitutio al kitchens • Adhesi es/ asti s, ortars a d grouts for era i tile,

pavers, brick and stone are not replacements for waterproof

• Cafeterias

membranes. When a waterproof membrane is required, use

• I stitutio al fa ilities LATICRETE® Hydroban / 9237 Waterproof Membrane.

•S i i g pools

• Rest roo s Cautions

LATAPOXY® SP-

• S hools

100 EPOXY

Advantages GROUT

Continuo

• Stainfree REAGENT NAME (at

us

Intermittent Splash

70°F/21°C) Exposure exposure

• Colour - fast Exposure

Milk R R R

• Eas to i stall a d lea

**Wine R R R

• Che i al a d te perature resista t Ethanol NR (soft) R R

• No -cracking or powdering *Potassium

NR R R

Permanganate 10%

• Water lea a le he fresh *Potassium

R R R

• A aila le i ra ge of attra ti e olors Permanganate 1%

Tannic Acid to 50% R R R

Tartaric Acid to 50% R R R

Packaging Components: Phosphoric Acid to

R R R

80%

LATAPOXY® SP-100 is a factory proportioned kit with Resin *Sulfuric Acid to 20% R R R

(Part A), Hardener (Part B), and colored filler powder (Part C). Oxalic Acid to 10% R R R

UNIT NET WEIGHT Lactic Acid to 5% R R R

th

1/5 Unit 1.0 kg Acetic Acid to 5% R R R

1 Full unit 5.0 kg Sodium Hydroxide to

R R R

50% Saturated

Benzoic Acid 5% R R R

Coverage: Please refer the coverage chart as it depends

Sea Water R R R

on the tile size, joint width and depth. Fruit Juice R R R

Methanol NR NR R

Shelf Life MEK NR NR R

Factory sealed containers of this product are guaranteed to be Chloroform NR NR NR

of first quality for two (2) years if stored at temperatures Methylene Chloride NR NR NR

>32F (0C) and <110 F (43C). Toluene NR NR R

Xylene NR NR R

MYKL-TDS- SP100 – REV 00; 10/17

•Duri g old eather, prote t fi ished ork fro traffi u til

fully cured.

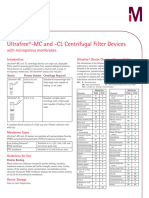

Chemical Resistance Chart (at 70 °F/21 °C)

•U til ured, LATAPOXY® SP-100 Stain free Grout may irritate

*Chemical Resistance depends on exposure levels:

eyes and skin.

•A oid o ta t ith e es or prolo ged o ta t ith ski . I Splash - Minor spill wiped up quickly such as in a laboratory.

case of contact, flush thoroughly with water. Intermittent - exposure to chemicals where clean up takes

•Do ot take i ter all . Sili a sa d a ause a er or place several times a day such as in a commercial kitchen.

serious lung problems. Avoid breathing dust. Wear a

Continuous - heavy exposure to chemicals where clean up is

respirator in dusty areas.

•Keep out of rea h of hildre . less frequent such as in an industrial food plant.

R=Recommended, NR=Not Recommended. Chemical

TECHNICAL DATA

Resistance determined in accordance with ASTM C267-1982.

Applicable Standard

ANSI A118.3 – 1999; EN 13888

NOTES TO SPECIFIER: Use the constant exposure

Physical Properties

recommendations for intermittent exposure to reagents at

TEST Test Method RESULTS

ANSI A 118.3 temperatures above 90F (32C).

Water Cleanability >80 min

1999; E 5.1

ANSI A 118.6

Water Absorption 0.4% INSTALLATION

1999; H 4.4

ANSI A 118.3 Surface Preparation

Initial Setting Time 180 min Before starting to grout, remove debris in grout joints and

1999; E 5.2

ANSI A 118.3 lightly sponge the tile surface to remove dust and dirt. Do not

Service Setting Time <7 days

1999; E 5.2

ANSI A 118.3 clean tiles with acid cleaners. Substrate temperature must

Linear Shrinkage < 0.10%

1999; E 5.3 between 60F (16C) and 90F (32C).

ANSI A 118.3

Sag no change

1999; E 5.4

Bond strength to ANSI A 118.3 > 1200 psi Mixing

quarry tile 1999; E 5.5 (8.2MPa)

Empty entire contents of LATAPOXY® SP-100 Stainfree Grout

Compressive ANSI A 118.3 >7500 psi

Strength 1999; E 5.6 (51.7MPa) Part A and Part B container into a clean mixing pail. Mix

ANSI A 118.3 >1500 psi

Tensile Strength with a margin trowel or a slow speed drill mixer until liquids

1999; E 5.7 (10.3 MPa)

ANSI A 118.3 >1100 psi are completely blended. Add at least ¾ of LATAPOXY ®SP-100

Thermal Shock

1999; E 5.8 (7.5MPa)

Part C Filler Powder and mix to a uniform consistency. Mix

Complies to EN standards: RG

as stiff as possible to work into the joints.

0 0

Working Properties at 70 F ( 21 C )

Pot Life 45 minutes Application

Foot Traffic 24 hours

Immediately pour entire contents of bucket onto working

Heavy Traffic 72 hours

Specifications are subject to change without notification. area. Use a plastic sheet as a drop cloth. Use standard epoxy

Results shown are typical but reflects test procedures used. grouting techniques to work with SP-100 Grout into tile joints.

Actual field performance will depend on installation

methods and site conditions. SP-100 Grout can also be applied with a caulking gun. Be sure

all grout joints are packed full. Remove as much excess

material as possible before initial cleaning with grout float. Do

not leave excess grout on the face of tiles.

MYKL-TDS- SP100 – REV 00; 10/17

NOTE: Keep the working area covered and protected from Sun

light while application of Latapoxy® SP-100, stain free epoxy WARRANTY

grout is applied in open areas like swimming pools etc. Keep MYK LATICRETE India Pvt Ltd warrants that LATICRETE® SP -

the cover for 7 days and till the filling of pools with water 100 Stain free grout is free from manufacturing defects and

after the completion of grouting with Latapoxy ®SP-100, stain will not break down, deteriorate or disintegrate under normal

usage for a period of two (2) years from manufacturing of the

free epoxy grout. product subject to the terms and conditions stated in

LATICRETE® Product Warranty.

Cleaning

TECHNICAL SERVICES

Remove excess grout from the face of the tiles with the edge

0

Technical assistance

of the grout float. Hold the float at a 90 angle and pull it

Information is available by calling the MYK LATICRETE

diagonally across the joints and tile to avoid pulling out the Technical Service at:

Telephone: +91-40-30413100

material.

FAX: +91-40-23378784

Initial Cleaning: After 30-45 min of the application of the E-mail: technicalservices@myklaticrete.com

grout scrub the surface of the tile & joint with clean water

MYK Laticrete India Pvt Ltd.

and scrubber provided to remove any excess grout. Then take

8-2-703/A, Fourth Floor, Leela Gopal Towers

a clean thick towel and drag across the tile to remove any

Road No-12, Banjara Hills, Hyderabad – 500034

residue.

Tel: +91-40—30413100 Fax: +91-40-23378784

Final Cleaning: within 24 hours do a second cleaning with

normal soap detergent to remove any haze from the tile. E-mail: contact@myklaticrete.com

Website: www.myklaticrete.com

AVAILABILITY AND COST

Availability

LATICRETE® and LATAPOXY® materials are available

worldwide.

For distributor information:

Telephone: +91-40-30413100 FAX: +91-40-23378784

E-mail: contact@myklaticrete.com

Cost

Contact a LATICRETE® Distributor in your area.

MAINTENANCE

LATICRETE® and LATAPOXY® grouts require routine cleaning

with neutral pH soap and water or MYK LATICRETE Clenza

series suitable cleaners. All other LATICRETE® and LATAPOXY®

materials require no maintenance but proper installation as

per instruction.

Performance and durability may depend on properly

maintaining of Installed area.

MYKL-TDS- SP100 – REV 00; 10/17

Potrebbero piacerti anche

- Latapoxy SP 100 TDSDocumento3 pagineLatapoxy SP 100 TDSBithika DattaNessuna valutazione finora

- TDS TH 7302Documento3 pagineTDS TH 7302Polem IskandarNessuna valutazione finora

- Chemical Resistant Industrial Grade RTV Silicone Sealants: Typical Properties of AG 300 - RTV 38Documento2 pagineChemical Resistant Industrial Grade RTV Silicone Sealants: Typical Properties of AG 300 - RTV 38Jagdish PatelNessuna valutazione finora

- Red Oxy BrochureDocumento16 pagineRed Oxy BrochureSlick LegionNessuna valutazione finora

- Chemical resistance and superior properties of PVDFDocumento9 pagineChemical resistance and superior properties of PVDFRavi RanjanNessuna valutazione finora

- Acid Proof GroutDocumento3 pagineAcid Proof GroutaasifNessuna valutazione finora

- Rapp-It Catalogue 2018Documento12 pagineRapp-It Catalogue 2018Rafique AjmeriNessuna valutazione finora

- AsphalteneDocumento30 pagineAsphalteneAnand Tanksali100% (1)

- Corrosion & Perfromance Table For Asecor LiningDocumento4 pagineCorrosion & Perfromance Table For Asecor LiningMohammed SafwanNessuna valutazione finora

- Key 467 Esd Urethane Topcoat - 6 26 2020 RevDocumento2 pagineKey 467 Esd Urethane Topcoat - 6 26 2020 Revjfbz1991Nessuna valutazione finora

- Corotech v157 - Tds en OkfDocumento3 pagineCorotech v157 - Tds en OkfNasreldin SamyNessuna valutazione finora

- Corrosion Resistance GuideDocumento26 pagineCorrosion Resistance GuideFrancisco Javier Villegas AndersonNessuna valutazione finora

- Chemical Resistance Chart PDFDocumento3 pagineChemical Resistance Chart PDFJaya LakshmiNessuna valutazione finora

- Millipore Ultrafree-MC Centrifugal Filter Units 0,22 M Pr04184-Rev0618Documento2 pagineMillipore Ultrafree-MC Centrifugal Filter Units 0,22 M Pr04184-Rev0618Ana SmolkoNessuna valutazione finora

- A Rough Guide To Chemical ResistanceDocumento8 pagineA Rough Guide To Chemical ResistancewantamanualNessuna valutazione finora

- CHEMICAL RESISTANCEDocumento1 paginaCHEMICAL RESISTANCEAllahbaksh ShaikhNessuna valutazione finora

- VpCI-416_PDS_ELDocumento2 pagineVpCI-416_PDS_ELcongnghiephoachat01Nessuna valutazione finora

- Chemical Resistance Guide Feb 2019Documento28 pagineChemical Resistance Guide Feb 2019Henry AguileraNessuna valutazione finora

- Syringe Filters Solvent Compatibility Chart: Pure ChromatographyDocumento2 pagineSyringe Filters Solvent Compatibility Chart: Pure ChromatographyParijat DasNessuna valutazione finora

- Technical Guide - 56 - Series - BrochureDocumento12 pagineTechnical Guide - 56 - Series - BrochureTom CullNessuna valutazione finora

- Linceed Oil - VpCI - 422 Method ApplicationDocumento2 pagineLinceed Oil - VpCI - 422 Method ApplicationRajendraNessuna valutazione finora

- DescalingChemicals PDFDocumento2 pagineDescalingChemicals PDFsanjay ukalkarNessuna valutazione finora

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Documento3 pagineDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Amr RagabNessuna valutazione finora

- Binders TableDocumento1 paginaBinders TableBrad SmolekNessuna valutazione finora

- Fibreglass Facts Aug 06Documento6 pagineFibreglass Facts Aug 06phatmatNessuna valutazione finora

- X-RAY FILM PROCESSING STEPSDocumento67 pagineX-RAY FILM PROCESSING STEPSAjay KhadkaNessuna valutazione finora

- Abecote 400 HBDocumento3 pagineAbecote 400 HBengramir07Nessuna valutazione finora

- TDS Fosroc Nitocote EP405 SEADocumento4 pagineTDS Fosroc Nitocote EP405 SEAPT PP BIH SanurNessuna valutazione finora

- Resinex KW 8 LDocumento2 pagineResinex KW 8 LplennyNessuna valutazione finora

- Kraton Adhesive BrochureDocumento14 pagineKraton Adhesive BrochureTélémaqueNessuna valutazione finora

- 4.3 Lodos Base AceiteDocumento52 pagine4.3 Lodos Base AceiteJonathan DarioNessuna valutazione finora

- Laropal A81: Industrial CoatingsDocumento3 pagineLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNessuna valutazione finora

- Laropal A 81 June 2014 R2 ICDocumento3 pagineLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Acid Additives and Their UsesDocumento25 pagineAcid Additives and Their UsesPablo SotoNessuna valutazione finora

- Everlube 620 TDSDocumento2 pagineEverlube 620 TDSValentinNessuna valutazione finora

- Chemical Resistance Chart: What We Need To KnowDocumento7 pagineChemical Resistance Chart: What We Need To Knowcipta karyaNessuna valutazione finora

- Product Brochure With Industrial ApplicationDocumento9 pagineProduct Brochure With Industrial Applicationanon_159986285Nessuna valutazione finora

- Brass PlatingDocumento2 pagineBrass PlatingHomayoon GeramifarNessuna valutazione finora

- Lieferprogramm Phosphate EstersDocumento12 pagineLieferprogramm Phosphate Estersjangri1098100% (1)

- Technical Datasheet: Acrylate Gel For Structure Leak SealDocumento7 pagineTechnical Datasheet: Acrylate Gel For Structure Leak SealAyman ElMawardyNessuna valutazione finora

- Foam ConcentratesDocumento2 pagineFoam ConcentratesSupakanit LimsowanNessuna valutazione finora

- MET-KLEEN 140 Multi-Purpose Alkaline Metal CleanerDocumento1 paginaMET-KLEEN 140 Multi-Purpose Alkaline Metal CleanertribolasNessuna valutazione finora

- Ketonic ResinDocumento2 pagineKetonic ResinFadi MagdyNessuna valutazione finora

- Chemical resistance of Polyester to common products like acids and oilsDocumento5 pagineChemical resistance of Polyester to common products like acids and oilsGuz UchihaNessuna valutazione finora

- Datasheet Z-PrimercoatDocumento1 paginaDatasheet Z-PrimercoatСтанислав ПодольскийNessuna valutazione finora

- DEGALAN® For Metal Coatings (English)Documento2 pagineDEGALAN® For Metal Coatings (English)Manoj Lalita GoswamiNessuna valutazione finora

- Avitera Rose SeDocumento2 pagineAvitera Rose SeruestchivaNessuna valutazione finora

- Lwtech LW-1 T LW4CR TDocumento4 pagineLwtech LW-1 T LW4CR TSony CNessuna valutazione finora

- Carbothane 134 HS PDSDocumento4 pagineCarbothane 134 HS PDSDuongthithuydungNessuna valutazione finora

- Catalogue Lubrification-GBc WebDocumento2 pagineCatalogue Lubrification-GBc WebEfimNessuna valutazione finora

- Solvoya CP5607-WR TDSDocumento1 paginaSolvoya CP5607-WR TDSI Love MusicNessuna valutazione finora

- Datasheet - BN Lubricoat WH BL PDFDocumento1 paginaDatasheet - BN Lubricoat WH BL PDFJC MonseesNessuna valutazione finora

- Carbothane 134 HS PDSDocumento4 pagineCarbothane 134 HS PDSQuy RomNessuna valutazione finora

- 06-Additives - ProppantsDocumento30 pagine06-Additives - ProppantsОлеся КокоринецьNessuna valutazione finora

- Chemical Compatibility Guide For Multiscreen Filter Plates: ReferenceDocumento5 pagineChemical Compatibility Guide For Multiscreen Filter Plates: ReferenceMưa Tháng TưNessuna valutazione finora

- Price List January 2019Documento3 paginePrice List January 2019Alan Winston SedzeNessuna valutazione finora

- New - Colacarb TDCDocumento3 pagineNew - Colacarb TDCmndmattNessuna valutazione finora

- Raybo 75 Tri FoldDocumento2 pagineRaybo 75 Tri FoldLong An DoNessuna valutazione finora

- 05 - Max GuardDocumento6 pagine05 - Max GuardMari WellNessuna valutazione finora

- Yassarnal Quran EN PDFDocumento70 pagineYassarnal Quran EN PDFzahiid munir100% (3)

- Yassarnalquranpdfeasydownload 150708175054 Lva1 App6892Documento49 pagineYassarnalquranpdfeasydownload 150708175054 Lva1 App6892Abdul Raheem SyedNessuna valutazione finora

- Fateha EnglishDocumento3 pagineFateha EnglishAbdul Raheem Syed70% (10)

- L 9237 WaterproofDocumento4 pagineL 9237 WaterproofAbdul Raheem SyedNessuna valutazione finora

- MYK Grout Card 2Documento2 pagineMYK Grout Card 2Abdul Raheem SyedNessuna valutazione finora

- CSWIP 3.1 - Welding Inspector WIS5 (2017)Documento699 pagineCSWIP 3.1 - Welding Inspector WIS5 (2017)reezman96% (69)

- Yassarnal Quran EN PDFDocumento70 pagineYassarnal Quran EN PDFzahiid munir100% (3)

- Laticrete Hydroban Tds NFDocumento6 pagineLaticrete Hydroban Tds NFAbdul Raheem SyedNessuna valutazione finora

- Reliability Presentation FormatDocumento12 pagineReliability Presentation FormatAbdul Raheem SyedNessuna valutazione finora

- Product Recommendation ChartDocumento2 pagineProduct Recommendation ChartAbdul Raheem SyedNessuna valutazione finora

- All India Dealer Price List III Wef 01.12.18Documento4 pagineAll India Dealer Price List III Wef 01.12.18Abdul Raheem SyedNessuna valutazione finora

- FF 4620 Anchor BoltsDocumento1 paginaFF 4620 Anchor BoltsAbdul Raheem SyedNessuna valutazione finora

- Gas Turbine Theory and Construction ExplainedDocumento29 pagineGas Turbine Theory and Construction ExplainedDee ⎝⏠⏝⏠ DeeNessuna valutazione finora

- FAQs - LATAPOXY® SP 100Documento2 pagineFAQs - LATAPOXY® SP 100Abdul Raheem SyedNessuna valutazione finora

- Spectra Lock Pro Premium Grout Technical Data Sheet 1Documento4 pagineSpectra Lock Pro Premium Grout Technical Data Sheet 1Abdul Raheem SyedNessuna valutazione finora

- GE Centrifugal and Axial CompressorsDocumento28 pagineGE Centrifugal and Axial Compressorsewok2030Nessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 113Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 113Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 37Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 37Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 27Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 27Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 112Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 112Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 102Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 102Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 42Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 42Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 36Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 36Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 39Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 39Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 104Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 104Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 35Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 35Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 32Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 32Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 110Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 110Abdul Raheem SyedNessuna valutazione finora

- Installation, Operation, Maintenance & Lub. Manual 38Documento1 paginaInstallation, Operation, Maintenance & Lub. Manual 38Abdul Raheem SyedNessuna valutazione finora

- FPR 10 1.lectDocumento638 pagineFPR 10 1.lectshishuNessuna valutazione finora

- Surah 25. Al-Furqan, Ayat 63-69 PDFDocumento1 paginaSurah 25. Al-Furqan, Ayat 63-69 PDFMusaab MustaphaNessuna valutazione finora

- Organisation Study of KAMCODocumento62 pagineOrganisation Study of KAMCORobin Thomas100% (11)

- 05 Gregor and The Code of ClawDocumento621 pagine05 Gregor and The Code of ClawFaye Alonzo100% (7)

- Should Animals Be Banned From Circuses.Documento2 pagineShould Animals Be Banned From Circuses.Minh Nguyệt TrịnhNessuna valutazione finora

- Activity 1 DIASSDocumento3 pagineActivity 1 DIASSLJ FamatiganNessuna valutazione finora

- AVX EnglishDocumento70 pagineAVX EnglishLeo TalisayNessuna valutazione finora

- BI - Cover Letter Template For EC Submission - Sent 09 Sept 2014Documento1 paginaBI - Cover Letter Template For EC Submission - Sent 09 Sept 2014scribdNessuna valutazione finora

- McLeod Architecture or RevolutionDocumento17 pagineMcLeod Architecture or RevolutionBen Tucker100% (1)

- Tutorial 3 Ans Tutorial 3 AnsDocumento3 pagineTutorial 3 Ans Tutorial 3 AnsShoppers CartNessuna valutazione finora

- Digi-Notes-Maths - Number-System-14-04-2017 PDFDocumento9 pagineDigi-Notes-Maths - Number-System-14-04-2017 PDFMayank kumarNessuna valutazione finora

- Barra de Pinos 90G 2x5 P. 2,54mm - WE 612 010 217 21Documento2 pagineBarra de Pinos 90G 2x5 P. 2,54mm - WE 612 010 217 21Conrado Almeida De OliveiraNessuna valutazione finora

- Leku Pilli V Anyama (Election Petition No 4 of 2021) 2021 UGHCEP 24 (8 October 2021)Documento52 pagineLeku Pilli V Anyama (Election Petition No 4 of 2021) 2021 UGHCEP 24 (8 October 2021)Yokana MugabiNessuna valutazione finora

- Detailed Lesson Plan in Bread and Pastry Production NC IiDocumento3 pagineDetailed Lesson Plan in Bread and Pastry Production NC IiMark John Bechayda CasilagNessuna valutazione finora

- FSW School of Education Lesson Plan Template: E1aa06cb3dd19a3efbc0/x73134?path JavascriptDocumento7 pagineFSW School of Education Lesson Plan Template: E1aa06cb3dd19a3efbc0/x73134?path Javascriptapi-594410643Nessuna valutazione finora

- ms3 Seq 01 Expressing Interests With Adverbs of FrequencyDocumento3 paginems3 Seq 01 Expressing Interests With Adverbs of Frequencyg27rimaNessuna valutazione finora

- 2 - How To Create Business ValueDocumento16 pagine2 - How To Create Business ValueSorin GabrielNessuna valutazione finora

- Compro Russindo Group Tahun 2018 UpdateDocumento44 pagineCompro Russindo Group Tahun 2018 UpdateElyza Farah FadhillahNessuna valutazione finora

- Earth Drill FlightsDocumento2 pagineEarth Drill FlightsMMM-MMMNessuna valutazione finora

- Autos MalaysiaDocumento45 pagineAutos MalaysiaNicholas AngNessuna valutazione finora

- Bandwidth and File Size - Year 8Documento2 pagineBandwidth and File Size - Year 8Orlan LumanogNessuna valutazione finora

- Database Interview QuestionsDocumento2 pagineDatabase Interview QuestionsshivaNessuna valutazione finora

- HERMAgreenGuide EN 01Documento4 pagineHERMAgreenGuide EN 01PaulNessuna valutazione finora

- Abbreviations (Kısaltmalar)Documento4 pagineAbbreviations (Kısaltmalar)ozguncrl1Nessuna valutazione finora

- DLL - Science 6 - Q3 - W3Documento6 pagineDLL - Science 6 - Q3 - W3AnatasukiNessuna valutazione finora

- The Steriotypes: Cultural StereotypeDocumento8 pagineThe Steriotypes: Cultural StereotypeRosbeyli Mazara ReyesNessuna valutazione finora

- Toxicology: General Aspects, Types, Routes of Exposure & AnalysisDocumento76 pagineToxicology: General Aspects, Types, Routes of Exposure & AnalysisAsma SikanderNessuna valutazione finora

- Consumer Behavior Paper PLDTDocumento6 pagineConsumer Behavior Paper PLDTAngeline Santiago100% (2)

- GDJMDocumento1 paginaGDJMRenato Alexander GarciaNessuna valutazione finora

- Nazi UFOs - Another View On The MatterDocumento4 pagineNazi UFOs - Another View On The Mattermoderatemammal100% (3)