Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6284 4 05 PDF

Caricato da

Dibyendu ChakrabortyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6284 4 05 PDF

Caricato da

Dibyendu ChakrabortyCopyright:

Formati disponibili

SECTION 4.

05

FUEL SYSTEM MAINTENANCE

F18/H24 AND L36/P48 ENGINES NOTE: The information below is provided as a quick

reference guide. Go to the page listed to see the fuel

PHYSICAL REQUIREMENTS adjustment procedure for specific engine setups.

Gas supply, pressure, and regulator type will vary with F18G and H24G with Impco 200 D, 400 VF3

each application. Refer to S6656-23 for applicable or 600 VFI Carburetors...................................... 4.05-2

regulator information.

F18GL/H24GL and L36GL/P48GL with

1. Regulators and fuel shutoff valves are to be Impco 200 D or 600 VFI Carburetors

mounted as close to the carburetor as possible (see — Natural Gas (Blow-Thru Carburetion) ........... 4.05-3

S-07763-16 for fuel system information). F18GL/H24GL with Impco 400 VF3 Carburetors

2. Check/adjust the linkage from the governor to the —Natural Gas or Low Compression Ratio

throttle (butterfly) valve to assure that the butterfly is (Natural Gas or Propane)

(Blow-Thru Carburetion) .................................... 4.05-4

closed when the governor is in the minimum stroke

position. When the governor goes to full stroke, the F18GLD/H24GLD and L36GLD/P48GLD

butterfly must not over travel the wide open, straight with Impco 600 VFI Carburetors

up and down position. An angle of 5° toward closing (Draw-Thru Carburetion) ................................... 4.05-5

from wide open is acceptable. F18GLD/H24GLD and L36GLD/P48GLD

3. Ensure that the fuel supply pressure to the regula- with Deltec Carburetors

(Draw-Thru Carburetion) ................................... 4.05-7

tor inlet is within the acceptable range for the regulator

being used. See Tech Data S6656-23. L36GSID/P48GSID with Deltec Carburetors

—Natural Gas or Propane

Engines equipped with

CAUTION ejector breather sys-

(Draw-Thru Carburetion) ................................... 4.05-9

F18/H24GSID with Impco 600 VFI Carburetor

tem –O2 must be sampled pre-turbine.

—Natural Gas

(Draw-Thru Carburetion) ................................... 4.05-9

4. Remove the pipe plug from the exhaust elbow and

install the exhaust emission probe and sample line F18/H24G Dual Fuel—Natural Gas

with an on/off valve. Connect this sample line to an or Propane....................................................... 4.05-10

exhaust emission analyzer capable of measuring oxy- F18G/H24G Dual Fuel—Natural Gas

gen (O2) and carbon monoxide (CO) concentrations. or Digester Gas ............................................... 4.05-11

NOTE: L36 and P48 engines with IMPCO carburetors F18G/H24GLD and L36/P48GLD/GSID

should have pre-turbine sample lines for each bank to with Deltec Carburetors—Dual Fuel ................ 4.05-12

assure that the exhaust oxygen of each bank is

176/200 BMEP (12.1/13.7 Bar) High Rating (HR)

adjusted properly. For Deltec carburetor systems, use

with Deltec Carburetors ................................... 4.05-13

a slant tube or digital manometer to measure the

gas/air pressure differential accurately.

5. Install a water manometer and shutoff valves to

measure the gas over air (gas/air) pressure differential

between the carburetor fuel inlet pipe and the carbure-

tor air horn.

FORM 6284 Third Edition 4.05-1

FUEL SYSTEM MAINTENANCE

F18G AND H24G WITH IMPCO 200 D, NOTE: If the correct O2 level cannot be obtained at

400 VF3 OR 600 VFI CARBURETORS rated speed and load, readjust the gas/air pressure as

necessary.

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE

STARTUP • On 200 D carburetors rotate the mixture valve

toward “L” (Lean) to increase the exhaust O2 level

and toward “R” (Rich) to decrease the O2 level.

WARNING • On 400 VF3 and 600 VFI carburetors, turn the mix-

Do not inhale gaseous fuels. Some components of ture screw in CW to increase O2 and out CCW to

fuel gas are odorless, tasteless, and highly toxic. decrease exhaust O2.

Inhalation of gaseous fuels can cause severe per-

sonal injury or death. Impco 200 D carburetors only: If the fuel mixture

adjustment is very coarse or if the correct O2 level

1. Adjust the gas regulator to obtain the proper gas cannot be obtained at rated speed and load, check to

over air (gas/air) pressure (see Table 4.05-1). see that the proper fuel orifice has been installed in the

carburetor fuel inlet (see Table 4.05-2). If the proper

Table 4.05-1 Gas Over Air Settings orifice is present, readjust gas/air pressure as neces-

sary to obtain the desired O2 level.

FUEL LOW

HEAT VALUE GAS/AIR

Table 4.05-2 Impco 200 D Fuel Orifice Requirements

FUEL TYPE MJ/M3 PRESSURE

[25, V(0;101.325)] CM H2O (IN. H2O)

FUEL ORIFICE ID F18GL H24GL

(BTU/FT3)

(in.) 0.591 0.650

Natural Gas 33.40– 35.38 12.7 ± 1.3 (5 ± 0.5)

(850 – 900) (mm) 15 16.5

Digester Gas 19.65 – 25.55 15.2 ± 1.3 (6 ± 0.5) 1. At rated load and speed, adjust the carburetor mix-

(500 – 650)

ture as follows:

15.73 – 19.65

Landfill Gas (400 – 500) 25.4 ± 1.3 (10 ± 0.5)

A. For Best Power:

2. F18G/H24G Engines (IMPCO 200 D)

1) Adjust the carburetor mixture to obtain

A. Adjust the carburetor idle air bleed screw full in approximately 0.18% exhaust O2 and 0.3 to

(rich). This bleed screw will remain in this posi- 1.0% carbon monoxide (CO).

tion and not be used again.

or

B. Adjust the fuel mixture valve at the fuel inlet to

2) Adjust the carburetor mixture to obtain the

the mid-position between L and R.

maximum intake manifold vacuum setting or

3. F18G/H24G Engines (400 VF3 and IMPCO 600 VFI) to obtain the highest exhaust temperature.

A. Adjust the mixture screw approximately 4 to 5 B. For Best Economy:

turns out counterclockwise (CCW) from the full-

1) Adjust the carburetor mixture to obtain 2.4%

in clockwise (CW) position.

exhaust O2 and 0.02% CO.

PRELIMINARY SETTINGS AFTER ENGINE

or

STARTUP

2) Adjust the carburetor mixture to obtain the

1. At idle speed (700 + 50 rpm) and no load, adjust

maximum intake manifold vacuum setting (i.e.

the gas regulator to obtain the gas/air pressure listed

highest exhaust temperature) and then lean

in Table 4.05-1.

out mixture to decrease vacuum by 1.5 in. of

2. Follow break-in procedure if not previously broken- mercury (Hg).

in.

FINAL FUEL SYSTEM ADJUSTMENTS

Always verify that all

CAUTION cylinders are firing

before adjusting the carburetor. Exhaust manifold

thermocouples (optional equipment) will assist in

diagnosing misfiring cylinders. Unstable or high

exhaust O2 levels may also indicate misfires. Fail-

ure to do so may cause serious engine damage.

4.05-2 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

EXHAUST

INTAKE INTERCOOLER

MANIFOLD FUEL PRESSURE

TAP LOCATION

PIPE PLUG

FUEL

INLET

AIR PRESSURE

TAP LOCATION

FUEL MIXTURE

SCREW

FUEL BALANCE LINE

REGULATOR CARBURETOR

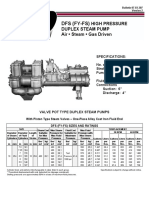

Figure 4.05-1 Typical High Pressure Fuel System (In-line Engine Shown)

F18GL/H24GL AND L36GL/P48GL WITH 3. L36GL/P48GL Engines (IMPCO 600 VFI)

IMPCO 200 D OR 600 VFI CARBURETORS A. Adjust the mixture screw to approximately 4 to 5

NATURAL GAS (BLOW-THRU turns out counterclockwise (CCW) from the full-

CARBURETION) in clockwise (CW) position.

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE PRELIMINARY SETTINGS AFTER ENGINE STARTUP

STARTUP

1. Adjust the gas regulator to obtain the proper gas WARNING

over air (gas/air) pressure (see Table 4.05-3). For typi- Do not inhale gaseous fuels. Some components of

cal pressure tap locations see Figure 4.05-1. fuel gas are odorless, tasteless, and highly toxic.

Inhalation of gaseous fuels can cause severe per-

Table 4.05-3 Gas/Air And Exhaust Oxygen Settings

sonal injury or death.

EXHAUST

IMPCO GAS/AIR PRESSURE 1. At idle speed (700 ± 50 rpm) and no load, adjust

MODEL OXYGEN

CARB. CM H2O (IN. H2O) the gas regulator to obtain the proper gas/air pressure

(% O2)

F18GL/H24GL 200 D 7.6 ± 2.54 (3 ± 1.0) 7.8 ± 0.1 (see Table 4.05-3).

L36GL/P48GL 600 VFI 15.2 ± 1.27 (6 ± 0.5) 7.8 ± 0.1 2. Follow break-in procedure (if not previously bro-

2. F18GL/H24GL Engines (IMPCO 200 D) ken-in) up to rated speed and 2/3 of rated load

(approximately 23.7 – 30.5 kPa (7 – 9 in.) of mercury

A. Adjust the carburetor idle air bleed full in (rich). (Hg) gauge positive intake manifold pressure). Adjust

This bleed screw will remain in this position and the fuel mixture valve to obtain 7.8 ± 0.5% exhaust

not be used again. oxygen (O2).

B. Adjust the fuel mixture valve at the fuel inlet to

the mid-position between L and R.

C. Turn the butterfly valve adjusting screw 1-1/2

turns open.

FORM 6284 Third Edition 4.05-3

FUEL SYSTEM MAINTENANCE

FINAL FUEL SYSTEM ADJUSTMENTS F18GL/H24GL WITH IMPCO 400 VF3

Always verify that all CARBURETORS — NATURAL GAS OR

CAUTION cylinders are firing LOW COMPRESSION RATIO

before adjusting the carburetor. Exhaust manifold (NATURAL GAS OR PROPANE)

thermocouples (optional equipment) will assist in (BLOW-THRU CARBURETION)

diagnosing misfiring cylinders. Unstable or high

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE

exhaust O2 levels may also indicate misfires. Fail- STARTUP

ure to do so may cause serious engine damage.

1. Adjust the gas regulator to obtain the proper gas

1. At rated speed and load, check the gas/air pres- over air (gas/air) pressure (see Table 4.05-5).

sure and readjust to specified value (see

2. Adjust the fuel mixture screw to approximately two

Table 4.05-3), if necessary.

to three turns out counterclockwise (CCW) from the

Table 4.05-4 Impco 200 D Fuel Orifice Requirements full-in clockwise (CW) position.

FUEL ORIFICE ID F18GL H24GL Table 4.05-5 F18GL/H24GL Gas/Air Settings

(in.) 0.591 0.650

GAS/AIR EXHAUST

(mm) 15 16.5 IMPCO

COMPRESSION CM H2O OXYGEN

CARB.

(IN. H2O) (%O2)

2. F18GL/H24GL Engines

Low 400 VF3 7.6 ± 2.54 7.8 ± 0.1

A. On 200 D carburetors rotate the mixture valve (8.7:1) Pistons (3 ± 1.0)

toward “L” (Lean) to increase the exhaust O2 Standard 400 VF3 12.7 ± 2.54 7.8 ± 0.1

(11:1) Pistons (5 ± 1.0)

level, toward “R” (Rich) to decrease the O2

level. PRELIMINARY SETTINGS AFTER ENGINE

STARTUP

B. If the fuel mixture adjustment is very coarse or if

the correct O2 level cannot be obtained at rated 1. At idle speed (700 ± 50 rpm) and no load, adjust

the gas regulator to obtain the proper gas/air pressure

speed and load, check to see that the proper

(see Table 4.05-5).

fuel orifice has been installed in the carburetor

fuel inlet (see Table 4.05-4). If the proper orifice 2. Follow the break-in procedure if not previously bro-

is present, readjust gas/air pressure as neces- ken-in up to rated speed and 2/3 load (approximately

sary to obtain the desired O2 level. 23.7 – 30.5 kPa (7 - 9 in.) of mercury (Hg) gauge posi-

tive intake manifold pressure). Adjust the fuel mixture

3. L36GL/P48GL Engines screw to obtain 7.8 ± 0.5 % exhaust oxygen (O2).

NOTE: On L36/P48 GLD and GSID engines the left FINAL FUEL SYSTEM ADJUSTMENTS

bank carburetor will affect the right bank O2 level, and

Always verify that all

CAUTION

the right bank carburetor will affect the left bank O2

level. cylinders are firing

before adjusting the carburetor. Exhaust manifold

NOTE: After testing at standard exhaust oxygen,

reset the exhaust O2 to the setting indicated on the thermocouples (optional equipment) will assist in

engine nameplate. diagnosing misfiring cylinders. Unstable or high

exhaust O2 levels may also indicate misfires. Fail-

A. On 600 VFI carburetors, rotate the fuel mixture ure to do so may cause serious engine damage.

valves CW (lean) to increase exhaust %O2 level

and CCW (rich) to decrease exhaust %O2 level. 1. At rated speed and load, check the gas/air pres-

sure and, if necessary, readjust to obtain the proper

pressure (see Table 4.05-5).

A. Rotate the fuel mixture screw CW (lean) to

increase exhaust %O2 level and CCW (rich) to

decrease exhaust %O2 level.

NOTE: After testing at standard exhaust O2, reset the

exhaust O2 to the setting indicated on the engine

nameplate.

4.05-4 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

TO INTERCOOLER EXHAUST

PIPE PLUG

AIR PRESSURE

CARBURETOR TAP LOCATION

BALANCE LINE

FUEL MIXTURE SCREW

FUEL INLET

AIR CLEANER FUEL PRESSURE FUEL

COARSE UPSTREAM REGULATOR

MIXTURE VALVE TAP LOCATION

Figure 4.05-2 Typical Low Pressure Fuel System (Inline Engine Shown)

F18GLD/H24GLD AND L36GLD/P48GLD

WITH IMPCO 600 VFI CARBURETORS

(DRAW-THRU CARBURETION)

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE

STARTUP

1. Adjust the gas regulator(s) to obtain a gas over air

(gas/air) pressure listed in Table 4.05-6.

Table 4.05-6 Gas/Air Settings

FUEL LOW GAS/AIR

EXHAUST

FUEL HEAT PRESSURE

OXYGEN

TYPE VALUE CM H2O

(% 02)

(BTU/FT3) (IN. H2O)

Natural Gas 850 – 900 7.6 ± 1.27 7.8 ± 0.1

(3 ± 0.5)

See

See

Digester Gas 500 – 650 Figure 4.05-3 Figure 4.05-4

on next page

Figure 4.05-3 Gas/Air Pressure vs. Fuel LHV

See See

Landfill Gas 400 – 500 Figure 4.05-4

Figure 4.05-3 on next page PRELIMINARY SETTINGS AFTER ENGINE

STARTUP

2. F18GLD/H24GLD Engines

A. Adjust the fuel mixture screw to approximately 4

to 5 turns out counterclockwise (CCW) from the

WARNING

full-in clockwise (CW) position (see Do not inhale gaseous fuels. Some components of

Figure 4.05-2). The coarse upstream mixture fuel gas are odorless, tasteless, and highly toxic.

valve, if equipped, can be left in the full open Inhalation of gaseous fuels can cause severe per-

position at this time. sonal injury or death.

3. L36GLD/P48GLD Engines 1. At idle speed (700 ± 50 rpm) and no load, adjust

A. Adjust the fuel mixture screw to approximately the gas regulator(s) to obtain a gas/air pressure listed

4 turns out CCW from the full-in CW position. in Table 4.05-6.

Set both upstream mixture valves, if equipped,

to approximately 30° from full closed.

FORM 6284 Third Edition 4.05-5

FUEL SYSTEM MAINTENANCE

2. Follow break-in procedure if not previously broken-

Table 4.05-7 Gas/Air Settings

in up to rated speed and 2/3 load (approximately

23.7 – 30.5 kPa (7 –9 in.) of mercury (Hg) gauge FUEL LOW GAS/AIR

intake manifold pressure). EXHAUST

FUEL HEAT PRESSURE

OXYGEN

TYPE VALUE CM H2O

A. Adjust the coarse upstream mixture valve, if (% 02)

(BTU/FT3) (IN. H2O)

equipped, to obtain the required exhaust O2 level 7.6 ± 1.27

Natural Gas 850 – 900 7.8 ± 0.1

listed in Table 4.05-6 to within ± 0.5% O2. If not (3 ± 0.5)

equipped with a coarse mixture valve, use the Digester Gas 500 – 650 See See

Figure 4.05-3 Figure 4.05-4

carburetor mixture screw to adjust the exhaust

See See

O 2. Landfill Gas 400 – 500 Figure 4.05-3 Figure 4.05-4

3. L36GLD/P48GLD Engines

A. Adjust both upstream mixture valves, if equipped,

to obtain the required exhaust O2 level listed in

Table 4.05-6 to within ± 0.5% O2.

NOTE: To change the exhaust O2 of the left bank,

adjust the mixture valve on the right side of the engine.

To change the exhaust O2 of the right bank, adjust the

mixture valve on the left side of the engine.

FINAL FUEL SYSTEM ADJUSTMENTS

Always verify that all

CAUTION cylinders are firing

before adjusting the carburetor. Exhaust manifold

thermocouples (optional equipment) will assist in

diagnosing misfiring cylinders. Unstable or high

exhaust O2 levels may also indicate misfires. Fail-

ure to do so may cause serious engine damage.

1. F18GLD/H24GLD Engines

Figure 4.05-4 Exhaust Oxygen vs. Fuel LHV

A. At rated speed and load, check the gas/air pres-

sure and readjust, if necessary, to the appropriate NOTE: To change the exhaust O2 of the left bank,

setting listed in Table 4.05-7. Adjust the carburetor adjust the mixture valve on the right side of the engine.

mixture screw to obtain an appropriate exhaust, O2 To change the exhaust O2 of the right bank, adjust the

level as listed in Table 4.05-7 to within ± 0.1% O2. mixture valve on the left side of the engine.

NOTE: After testing at standard exhaust O2, reset the

2. L36GLD/P48GLD Engines

exhaust O2 to the setting indicated on the engine

A. At rated speed and load, check the gas/air pres- nameplate.

sure and readjust, if necessary, to the appropri-

ate setting listed in Table 4.05-7. Adjust the

carburetor mixture screw to obtain an appropri-

ate exhaust O2 level as listed in Table 4.05-7 to

within ± 0.1% O2.

4.05-6 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

AIR

AIR CARBURETOR TURBOCHARGER

CLEANER

MAIN ADJUSTING

SCREW (MAS)

BALANCE

LINE SECOND CARBURETOR

APPLIES ONLY TO L36 AND

P48 ENGINES

GAS

PRESSURE CUSTOMER SUPPLIED

BALANCE LINE

AIR

AIR

CLEANER CARBURETOR TURBOCHARGER

CUSTOMER

SUPPLIED

FLEXIBLE

CONNECTION

FUEL

REGULATOR

CUSTOMER SUPPLIED AIR

EXTERNAL CONTROL LINE PRESSURE

FOR 3 INCH REGULATOR

(GLD/GSID ONLY)

SOLENOID

SHUTOFF VALVE

GAS

Figure 4.05-5 Deltec Fuel Schematic

F18GLD/H24GLD AND L36GLD/P48GLD

WITH DELTEC CARBURETORS WARNING

(DRAW-THRU CARBURETION) The Deltec carburetion system must have a posi-

PHYSICAL REQUIREMENTS tive gas shutoff valve that opens upon cranking

and closes whenever engine rotation stops. Fail-

• See "Physical Requirements" on page 4.05-1 for all ure to provide the valve will cause an explosive

VGF F18/H24 and L36/P48 Models. environment resulting in severe personal injury or

• Regulators are to be mounted less than 0.91 m death.

(3 ft) before the Main Adjustment Screw (MAS) with

• A quick acting, manual shutoff valve, placed up

no elbows or other plumbing restrictions.

stream of the engine regulator (high pressure gas

• Fuel shutoff valves must be mounted prior to the line), is recommended. This valve will assist initial

engine gas regulator. engine startup and will act as a visual gas shutoff

when the engine is not in operation.

FORM 6284 Third Edition 4.05-7

FUEL SYSTEM MAINTENANCE

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE 4. Close manual gas shutoff valve.

STARTUP

5. Crank engine with ignition off for ten seconds to

purge the engine of gas fumes.

WARNING PRELIMINARY SETTINGS AFTER ENGINE

Do not inhale gaseous fuels. Some components of STARTUP

fuel gas are odorless, tasteless, and highly toxic.

1. Open manual gas shutoff valve and start the

Inhalation of gaseous fuels can cause severe per-

engine.

sonal injury or death.

2. Follow break-in procedure up to rated speed and

2/3 load (approximately 23.7 – 30.5 kPa (7 – 9 in.) of

WARNING mercury (Hg) gauge positive intake manifold pres-

sure), if not previously broken in. Adjust the exhaust

When the manual gas shutoff valve is open, gas

oxygen (O2) to 7.0 ± 0.5% using only the MAS.

flows both into the exhaust and back through the

intake and air cleaners. Adjustments should be 3. Once engine coolant and oil temperatures have

made quickly to avoid severe personal injury or sufficiently warmed up 60 – 71° C (140 – 160° F),

death. increase engine to rated speed.

1. Open manual gas shutoff valve.

2. Adjust the gas regulator to obtain a gas over air

(gas/air) pressure listed in Table 4.05-8.

Table 4.05-8 Gas/Air And Exhaust Oxygen Settings

IDLE GAS

FUEL LOW

AIR EXHAUST

FUEL HEAT

PRESSURE OXYGEN

TYPE VALUE

CM H2O (%O2)

(BTU/FT3)

(IN. H2O)

0.5 ± 0.25

Natural Gas 850 – 900 (0.2 ± 0.1) 7.8 ± 0.1

Digester Gas 500 – 650 See See

Figure 4.05-6 Figure 4.05-7

19.5 ± 6.4

Landfill Gas 400 – 500 (7.62 ± 2.54) 7.5 ± 0.1

Propane Gas 2200 – 2500 9.6 ± 6.4 8.2 ± 0.1 Figure 4.05-7 Exhaust Oxygen vs. Fuel LHV Deltec

(3.81 ± 2.54)

Carburetion

FINAL FUEL SYSTEM ADJUSTMENTS

Always verify that all

CAUTION cylinders are firing

before adjusting the carburetor or mixture valves.

Exhaust manifold thermocouples (optional equip-

ment) will assist in diagnosing misfiring cylinders.

Unstable or high exhaust O2 levels may also indi-

cate misfires. Failure to do so may cause serious

engine damage.

1. At rated speed and no load, adjust the gas/air to

the pressure listed in Table 4.05-8, using only the

MAS.

NOTE: Adjust gas/air pressure within the tolerance

Figure 4.05-6 Gas/Air vs. Fuel LHV Deltec Carburetion

band to optimize starting for all fuels.

2. Reduce speed and load to idle, and check gas/air

3. Adjust the MAS approximately eight turns out from pressure. If gas/air is out of specification (see

full closed. Table 4.05-8), readjust the gas regulator as necessary.

4.05-8 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

3. Increase the load to 100% and check exhaust O2 3. Adjust the MAS approximately eight turns out from

(see Table 4.05-8). If exhaust O2 is out of specifica- full closed.

tion, readjust MAS as necessary.

4. Close manual gas shutoff valve.

4. Stop engine and check starting performance.

5. Crank engine with ignition off for ten seconds to

L36GSID/P48GSID WITH DELTEC purge engine of gas fumes.

CARBURETORS – NATURAL GAS OR FINAL FUEL SYSTEM ADJUSTMENTS

PROPANE (DRAW-THRU CARBURETION) Always verify that all

PHYSICAL REQUIREMENTS CAUTION cylinders are firing

before adjusting the carburetor or mixture valves.

• See page 4.05-1 for "Physical Requirements" on all

Exhaust manifold thermocouples (optional equip-

VGF F18/H24 and L36/P48 Models.

ment) will assist in diagnosing misfiring cylinders.

• Regulators are to be mounted less than 0.91 m Unstable or high exhaust O2 levels may also indi-

(3 ft.) before the Main Adjustment Screw (MAS) with cate misfires. Failure to do so may cause serious

no elbows or other plumbing restrictions.

engine damage.

• Fuel shutoff valves must be mounted prior to the

engine gas regulator. 1. At rated speed and load, adjust the MAS valve to

obtain an exhaust stack carbon monoxide (CO) level

of 0.3 – 0.4%. Turn the MAS clockwise (CW) to reduce

WARNING CO, or counterclockwise (CCW) to increase CO.

The Deltec carburetion system must have a posi- NOTE: Exhaust tap location should be such that is

tive gas shutoff valve that opens upon cranking simultaneously sampling exhaust from both the left

and closes whenever engine rotation stops. Fail- and right banks.

ure to provide the valve will cause an explosive

environment resulting in severe personal injury or 2. Reduce the engine speed and load to idle. Verify that

death. the gas/air pressure is still within 0 – 2.54 mm (0 – 0.1 in.)

of H2O. Readjust the gas regulator if necessary.

• A quick acting, manual shutoff valve, placed up

3. Increase the speed and load to 100%. Verify that

stream of the engine regulator (high pressure gas

the exhaust stack CO level is still within 0.3 – 0.4%.

line), is recommended. This valve will assist initial

Readjust the MAS if necessary.

engine startup and will act as a visual gas shutoff

when engine is not in operation. 4. Stop the engine and recheck starting performance.

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE NOTE: Adjust the gas/air pressure within the

STARTUP tolerance band to optimize starting for all fuels.

F18/H24GSID WITH IMPCO 600 VFI

WARNING CARBURETOR – NATURAL GAS

Do not inhale gaseous fuels. Some components of (DRAW-THRU CARBURETION)

fuel gas are odorless, tasteless, and highly toxic.

Inhalation of gaseous fuels can cause severe per- FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE

sonal injury or death. STARTUP

1. Adjust the gas regulator to obtain a gas/air pressure

of 6.35 ± 1.27 cm (2.5 ± 0.5 in.) of water column (H2O).

WARNING 2. Adjust the fuel mixture screw six turns out counter-

When the manual gas shutoff valve is open, gas clockwise (CCW) from the full-in clockwise (CW) posi-

flows both into the exhaust and back through the tion.

intake and air cleaners. Adjustments should be

made quickly to avoid severe personal injury or

death.

1. Open manual gas shutoff valve.

2. Adjust the gas regulator to obtain a gas over air

(gas/air) pressure of 0 – 2.54 mm (0 – 0.1 in.) of water

column (H2O).

FORM 6284 Third Edition 4.05-9

FUEL SYSTEM MAINTENANCE

PRELIMINARY SETTINGS AFTER ENGINE PRELIMINARY SETTINGS AFTER ENGINE

STARTUP STARTUP

WARNING WARNING

Do not inhale gaseous fuels. Some components of Do not inhale gaseous fuels. Some components of

fuel gas are odorless, tasteless, and highly toxic. fuel gas are odorless, tasteless, and highly toxic.

Inhalation of gaseous fuels can cause severe per- Inhalation of gaseous fuels can cause severe per-

sonal injury or death. sonal injury or death.

At idle speed (700 ± 50 rpm) and no load, adjust the

1. Idle the engine at 700 ± 50 rpm and adjust the nat-

gas regulator to obtain a gas/air pressure of

ural gas regulator for an outlet pressure of

6.35 ± 1.27 cm (2.5 ± 0.5 in.) of H2O.

12.7 ± 1.27 cm (5 ± 0.5 in.) of water column (H2O) gas

FINAL FUEL SYSTEM ADJUSTMENTS over air (gas/air).

At rated load and speed, adjust the carburetor mixture NOTE: The intake manifold vacuum reading can be

screw to obtain 0.18% exhaust oxygen (O2) and 0.3 to taken at the instrument panel gauge, if equipped. If not

0.4% carbon monoxide (CO). equipped, remove the plug at the top rear of the intake

manifold and install a gauge.

F18G/H24G DUAL FUEL – NATURAL GAS

2. At governed speed and rated load, adjust the car-

OR PROPANE

buretor mixture valve as follows:

NOTE: Refer to Figure 4.05-8 for the VGF Dual Fuel

A. For Best Power do one of the following:

System Diagram.

1) Adjust the carburetor mixture valve to approx-

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE

imately 0.18% oxygen (O2) and 0.3 – 1.0%

STARTUP

carbon monoxide (CO) in the exhaust.

1. Set the line regulator to provide the proper fuel gas

or

inlet pressures to the engine mounted regulators in

accordance with the settings below (see Table 4.05-9). 2) Adjust the carburetor mixture valve to obtain

the maximum intake manifold vacuum setting.

Table 4.05-9 Fuel Regulator Pressure Settings

B. For Best Economy do one of the following:

REGULATOR FUEL INLET OUTLET

TYPE TYPE PRESSURE PRESSURE 1) Adjust the carburetor mixture valve to approx-

imately 2.4% O2 and 0.02% CO.

Fisher S201 Natural 34.5 – 69.0 kPa 12.7 ± 1.27 cm

Gas (5 – 10 psi) (5 ± 0.5 in.) H2O

or

Natural 2.0 – 5.0 kPa 7.6 ± 1.27 cm

Maxitrol RV91 (3 ± 0.5 in.) H2O

Gas (8 – 20 in. H2O) 2) Adjust the carburetor mixture valve to the

Fisher Y610-A Propane 34.5 – 69.0 kPa -2.54 – -5.1 cm maximum intake manifold vacuum setting and

w/ Fisher S201 Gas (5 – 10 psi) (-1 – -2 in.) H2O

then lean out by 3.8 cm (1.5 in.) of mercury

Fisher Y610-A Propane 34.5 – 69.0 kPa 10.2 ± 1.27 cm (Hg).

w/Maxitrol RV91 Gas (5 – 10 psi) (-4 ± 0.5 in.) H2O

2. If equipped with an IMPCO 200D carburetor: 3. Return to idle.

A. Adjust the carburetor idle bleed valve full in 4. Close the natural gas solenoid valve and open the

(rich). propane solenoid valve.

B. Adjust the carburetor mixture valve to mid posi- 5. Adjust the propane regulator outlet pressure to

tion. 3.8 ± 1.2 cm (1.5 ± 0.5 in.) of H2O gas/air.

3. If equipped with an IMPCO 600 VFI carburetor: 6. At governed speed and rated load, adjust the mix-

ture adjusting valve for Best Economy or Best Power

A. Adjust the carburetor mixture screw 4 to 5 turns in accordance with Step 2.

out counterclockwise (CCW) from the full-in

clockwise (CW) position.

4. Close the propane solenoid valve and open the

natural gas solenoid valve.

4.05-10 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

MIXTURE VALVE

P AIR

AIR

CARBURETOR INTAKE

MANIFOLD

MIXTURE

ADJUSTING VALVE

PGAS PGAS

NATURAL

GAS

REGULATOR

DIGESTER

GAS

REGULATOR BALANCE

LINE FLEXIBLE

CONNECTION

BALANCE

LINE

FLEXIBLE

CONNECTION

SOLENOID

SHUTOFF VALVE

SOLENOID

SHUTOFF VALVE

NATURAL

GAS SUPPLY

DIGESTER GAS

Figure 4.05-8 Typical VGF Dual Fuel System

F18G/H24G DUAL FUEL – NATURAL GAS 2. Adjust carburetor mixture valve to mid-position (4 or

OR DIGESTER GAS 5 turns out).

NOTE: Refer to Figure 4.05-8 for the VGF Dual Fuel 3. Shut the natural gas solenoid valve and open the

System Diagram. digester gas solenoid valve.

FUEL SYSTEM ADJUSTMENT PRIOR TO ENGINE PRELIMINARY SETTINGS AFTER ENGINE

STARTUP STARTUP

1. Set the line regulator to provide the proper fuel gas

inlet pressures to the engine mounted regulators in WARNING

accordance with the settings below (see Do not inhale gaseous fuels. Some components of

Table 4.05-10). fuel gas are odorless, tasteless, and highly toxic.

Table 4.05-10 Fuel Regulator Pressure Settings Inhalation of gaseous fuels can cause severe per-

sonal injury or death.

REGULATOR FUEL INLET OUTLET

TYPE TYPE PRESSURE PRESSURE 1. Idle the engine at 700 ± 50 rpm and adjust the

Fisher Y610-A Natural 34.5 – 69.0 kPa -12.7 ± -15.3 cm digester gas regulator to the outlet pressure shown in

P/N 209678-S Gas (5 – 10 psi) (-5 – -6 in.) H2O Table 4.05-10.

Digester 20 – 50.8 cm 15.3 ± 1.27 cm

Maxitrol RV91 Gas (8 – 20 in.) H2O (6 ± 0.5 in.) H2O

Fisher Y610-A Natural 34.5 – 69.0 kPa -5.1 ± 1.27 cm

P/N 209678-C Gas (0.75 – 10 psi) (-2 ± 0.5 in.) H2O

Digester 2.0 – 5.0 kPa 12.7 ± 1.27 cm

Maxitrol RV91 Gas (8 – 20 in. H2O) (5 ± 0.5 in.) H2O

FORM 6284 Third Edition 4.05-11

FUEL SYSTEM MAINTENANCE

2. At governed speed and rated load, adjust the car-

buretor mixture valve as follows: WARNING

NOTE: The intake manifold vacuum reading can be The Deltec carburetion system must have a posi-

taken at the instrument panel gauge, if equipped. If not tive gas shutoff valve that opens upon cranking

equipped, remove the plug at the top rear of the intake and closes whenever engine rotation stops. Fail-

manifold and install a gauge. ure to provide the valve will cause an explosive

A. For Best Power do one of the following: environment resulting in severe personal injury or

death.

1) Adjust the carburetor mixture valve to approx-

imately 0.18% oxygen (O2) and 0.3 – 1.0% • A quick acting, manual shutoff valve, placed up

carbon monoxide (CO). stream of the engine regulator (high pressure gas

line), is recommended. This valve will assist initial

or

engine startup and will act as a visual gas shutoff

2) Adjust the carburetor mixture valve to the when engine is not in operation.

maximum intake manifold vacuum setting.

FUEL SYSTEM ADJUSTMENT PROCEDURE

B. For Best Economy do one of the following:

1) Adjust the carburetor mixture valve to approx- WARNING

imately 2.4% O2 and 0.02% CO.

Do not inhale gaseous fuels. Some components of

or fuel gas are odorless, tasteless, and highly toxic.

Inhalation of gaseous fuels can cause severe per-

2) Adjust the carburetor mixture valve to the

sonal injury or death.

maximum intake manifold vacuum setting and

then lean out by 3.8 cm (1.5 in.) of mercury

(Hg).

WARNING

3. Return to idle.

When the manual gas shutoff valve is open, gas

4. Close the digester gas solenoid valve and open flows both into the exhaust and back through the

the natural gas solenoid valve. intake and air cleaners. Adjustments should be

made quickly to avoid severe personal injury or

5. Adjust the natural gas regulator as indicated in

death.

Table 4.05-10.

6. Return to idle. 1. Shut off the downstream fuel valve, and open the

upstream fuel valve.

7. Close the digester gas solenoid valve and open

the natural gas solenoid valve. NOTE: The higher Btu fuel is always downstream of

the lower Btu fuel (see Figure 4.05-9).

8. Adjust natural gas regulator according to

Table 4.05-10. 2. Adjust the gas regulator to obtain a gas over air

(gas/air) pressure of 0 – 2.54 mm (0 – 0.1 in.) of water

9. At the governed speed and rated load, adjust the column (H2O).

mixture adjusting valve for best economy or best

power in accordance with Step 2. 3. Adjust the MAS approximately eight turns out from

full closed.

F18/H24GLD AND L36/P48GLD/GSID

4. Close the manual gas shutoff valve.

WITH DELTEC CARBURETORS – DUAL

FUEL 5. Crank engine with ignition off for ten seconds to

purge engine of gas fumes.

PHYSICAL REQUIREMENTS

Always verify that all

• See "Physical Requirements" on page 4.05-1 for all CAUTION cylinders are firing

VGF F18/H24 and L36/P48 Models. before adjusting the carburetor or mixture valves.

• Regulators are to be mounted less than 0.91 m Exhaust manifold thermocouples (optional equip-

(3 ft.) before the Main Adjustment Screw (MAS) with ment) will assist in diagnosing misfiring cylinders.

no elbows or other plumbing restrictions. Unstable or high exhaust O2 levels may also indi-

• Fuel shutoff valves must be mounted prior to the cate misfires. Failure to do so may cause serious

engine gas regulator. engine damage.

4.05-12 FORM 6284 Third Edition

FUEL SYSTEM MAINTENANCE

6. At rated speed and load, adjust the MAS valve to 8. Increase the speed and load to 100%. Verify that

obtain an exhaust stack carbon monoxide (CO) level the exhaust stack CO level is still within 0.3 – 0.4%.

of 0.3 – 0.4%. Turn the MAS clockwise (CW) to reduce Readjust the MAS if necessary.

CO, or counterclockwise (CCW) to increase CO.

9. Stop the engine.

NOTE: The exhaust tap location should be such that it

10. Shut off the upstream fuel valve, and open the

is simultaneously sampling exhaust from both the left

downstream fuel valve.

and right banks.

11. Repeat Steps 2 – 9 and adjust the downstream

NOTE: Adjust the gas/air pressure within the

fuel settings.

tolerance band to optimize starting for all fuels.

12. Recheck starting performance.

7. Reduce the engine speed and load to idle. Verify that

the gas/air pressure is still within 0 – 2.54 mm (0 – 0.1 in.)

of H2O. Readjust the gas regulator if necessary.

REGULATOR LOW BTU

HIGH BTU REGULATOR

FUEL INLET FUEL INLET

SOLENOID

VALVE MAS VALVE SOLENOID

MAS VALVE

VALVE

BALANCE BALANCE

LINE LINE

MIXTURE MIXTURE

ADJUSTING AIR/FUEL ADJUSTING

VALVE AIR INLET

OUTLET VALVE

DELTEC CARBURETOR

TURBOCHARGER

AIR CLEANER

Figure 4.05-9 L36/P48 VGF Dual Fuel System With Deltec Carburetor

HIGH RATING (HR) 12.1/13.7 BAR

(176/200 BMEP) GLD/2 WITH DELTEC WARNING

CARBURETORS AND DUNGSâ The Deltec carburetion system must have a posi-

REGULATOR tive gas shutoff valve that opens upon cranking

and closes whenever engine rotation stops. Fail-

PHYSICAL REQUIREMENTS ure to provide the valve will cause an explosive

• See "Physical Requirements" on page 4.05-1 for all environment resulting in severe personal injury or

VGF F18/H24 and L36/P48 Models. death.

• Regulators are to be mounted less than 0.91 m • A quick acting, manual shutoff valve, placed up

(3 ft.) before the Main Adjustment Screw (MAS) with stream of the engine regulator (high pressure gas

no elbows or other plumbing restrictions. line), is recommended. This valve will assist initial

engine startup and will act as a visual gas shutoff

• Fuel shutoff valves must be mounted prior to the

when engine is not in operation.

engine gas regulator.

FORM 6284 Third Edition 4.05-13

FUEL SYSTEM MAINTENANCE

FUEL SYSTEM ADJUSTMENT PROCEDURE 3. Remove four hex head screws that secure cover to

Dungs regulator (see Figure 4.05-10). Remove cover

WARNING to expose valve.

Do not inhale gaseous fuels. Some components of

COVER

fuel gas are odorless, tasteless, and highly toxic.

Inhalation of gaseous fuels can cause severe per-

sonal injury or death.

Always verify that all

CAUTION cylinders are firing

before adjusting the carburetor or mixture valves.

Exhaust manifold thermocouples (optional equip-

ment) will assist in diagnosing misfiring cylinders.

Unstable or high exhaust O2 levels may also indi-

cate misfires. Failure to do so may cause serious

engine damage.

The “start circuit” consists of fuel at supply pressure ADJUSTMENT

provided to a fuel solenoid. This solenoid is acti- SCREW

vated/opened when the starter is engaged. The fuel at

that time flows from the solenoid to a needle valve Figure 4.05-10 Dungs Regulator

which is set to deliver 7 mm (0.276 in.) H2O pressure.

This pressure is applied on top of the diaphragm which 4. Turn adjustment screw so valve travels down and

lowers/closes the valve and leans out the mixture to “just touches” seat. Verify valve position through top

about 0 mm (0 in.) H2O G/A. When the starter disen- cover opening (see Figure 4.05-10). When valve is

gages the fuel flow stops and the regulator goes back closed, gas over air (G/A) pressure is 0 mm (0 in.) of

to delivering about 7 mm (0.276 in.) H2O G/A for throt- water column (H2O).

tle advancement. 5. Install regulator cover and secure with four hex

The “cold run circuit” was developed because the head screws.

standard G/A proved to be too lean when the intake

manifold temperature is less than 60° C (140° F). This

is a normal condition when the engine is first started. It

WARNING

takes a little time for the intake manifold to come up to When the manual gas shutoff valve is open, gas

normal temperatures. To increase the G/A mixture an flows both into the exhaust and back through the

additional circuit has been added. Fuel at supply pres- intake and air cleaners. Adjustments should be

sure is provided to a fuel solenoid. This solenoid is made quickly to avoid severe personal injury or

activated/opened when the thermistor/sending unit in death.

the intake manifold detects mixture that is less than

NOTE: A “hot wire” that can provide momentary

60° C (140° F). The fuel at that time flows from the

power to the fuel solenoid must be installed. The

solenoid to a needle valve which is set to deliver about

power lead from the starter must be disconnected at

8 mm (0.32 in.) H2O G/A to the Deltec carburetor.

the fuel solenoid after the engine is started. This will

When the thermistor/sending unit detects mixture at

prevent the voltage from back feeding to the starter.

60° C (140° F) or more the solenoid is closed and the

G/A defaults back to the main regulator setting. 6. Start engine and adjust G/A to 7 mm (0.276 in.)

H2O and advance throttle to 1500 rpm.

NOTE: A gas over air (G/A) pressure of 0 mm (0 in.)

of water column (H2O) is correct for initial start (crank 7. Disconnect power lead from fuel solenoid to starter

mode), but proves to be too lean when advancing the (this prevents the starter from running when power is

throttle. A gas/air pressure of 7 mm (0.276 in.) H2O is applied to the fuel solenoid).

required for throttle advancement, however this is too

8. Apply power (bypass starter) to the fuel solenoid

rich for initial start. To solve this problem the following

valve (this will allow fuel to flow through to the needle

procedure has been developed.

valve). Adjust the needle valve until a G/A pressure of

1. Close manual gas shutoff valve. 0 mm (0 in.) H2O is reached.

2. Crank engine with ignition off for ten seconds to

purge engine of gas fumes.

4.05-14 FORM 6284 Third Edition

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Er-63 1Documento3 pagineEr-63 1Dibyendu ChakrabortyNessuna valutazione finora

- Er 82Documento2 pagineEr 82Dibyendu ChakrabortyNessuna valutazione finora

- Er-10 4 0Documento6 pagineEr-10 4 0Dibyendu ChakrabortyNessuna valutazione finora

- Er 63Documento7 pagineEr 63Dibyendu ChakrabortyNessuna valutazione finora

- Ashok Leyland ALGO0DTGE-125kva Parts CatalogDocumento71 pagineAshok Leyland ALGO0DTGE-125kva Parts CatalogDibyendu ChakrabortyNessuna valutazione finora

- Waukesha Upgradation Kit G-962-540 - BOMDocumento2 pagineWaukesha Upgradation Kit G-962-540 - BOMDibyendu ChakrabortyNessuna valutazione finora

- G 962 1188 - BomDocumento8 pagineG 962 1188 - BomDibyendu ChakrabortyNessuna valutazione finora

- Principle of Operation: Waukesha Stepper Motor Fisher Regulator Afr Working PrincipleDocumento4 paginePrinciple of Operation: Waukesha Stepper Motor Fisher Regulator Afr Working PrincipleDibyendu ChakrabortyNessuna valutazione finora

- Ashok Leyland CNG Powerpacks v2-4D&6E-Part CatalogeDocumento18 pagineAshok Leyland CNG Powerpacks v2-4D&6E-Part CatalogeDibyendu Chakraborty100% (1)

- 2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDocumento6 pagine2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDibyendu Chakraborty100% (1)

- Compressor Divider Block InstructionDocumento19 pagineCompressor Divider Block InstructionDibyendu ChakrabortyNessuna valutazione finora

- 6284 2 00 PDFDocumento5 pagine6284 2 00 PDFDibyendu ChakrabortyNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Catalogo Mcbee Caterpillar C12, C13, C15,3406E 2019 PDFDocumento36 pagineCatalogo Mcbee Caterpillar C12, C13, C15,3406E 2019 PDFAlexis SanchezNessuna valutazione finora

- Preparation 2zr-Fbe Engine Mechanical SST PDFDocumento3 paginePreparation 2zr-Fbe Engine Mechanical SST PDFAlbert BriceñoNessuna valutazione finora

- Suzuki GS850 Service ManualDocumento454 pagineSuzuki GS850 Service ManualAndre Serjey Paseschnikoff67% (3)

- QSK23-G6: Emissions Compliance: EPA NSPS Stationary Emergency Tier 2Documento2 pagineQSK23-G6: Emissions Compliance: EPA NSPS Stationary Emergency Tier 2Jeferson RibeiroNessuna valutazione finora

- Passat No. 102 / 1: 2.3 l/125 KW - Motronic, Engine Code AZXDocumento17 paginePassat No. 102 / 1: 2.3 l/125 KW - Motronic, Engine Code AZXriho09Nessuna valutazione finora

- Catalog - JU4H-UF 12 & 20Documento2 pagineCatalog - JU4H-UF 12 & 20Teguh Setiono0% (1)

- Small Biogas Engine Conversion Kit Rural ApplicationDocumento43 pagineSmall Biogas Engine Conversion Kit Rural Applicationgkarthikeyan100% (1)

- Opposed Piston Engine - 1 - Mechanical Seminar TopicsDocumento4 pagineOpposed Piston Engine - 1 - Mechanical Seminar Topicssumitsinha89Nessuna valutazione finora

- Dfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenDocumento2 pagineDfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenMaria Julieta Calderon OrtizNessuna valutazione finora

- VSE2020.V2: Cylinder Leakage TesterDocumento2 pagineVSE2020.V2: Cylinder Leakage Testerwalson glen CrastaNessuna valutazione finora

- 3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsDocumento1.200 pagine3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsMartin ZaehNessuna valutazione finora

- Code No. Diagnosis Item Engine Warning LampDocumento3 pagineCode No. Diagnosis Item Engine Warning LampIsack Soto MedinaNessuna valutazione finora

- Catalogo de Partes Matrix Racing Sport 150 2007Documento46 pagineCatalogo de Partes Matrix Racing Sport 150 2007Alirio Medina CondeNessuna valutazione finora

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocumento23 pagineSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- Eco 100 +Documento66 pagineEco 100 +Leidy Viviana Ramírez SánchezNessuna valutazione finora

- Chery Tiggo Esquema PDFDocumento1 paginaChery Tiggo Esquema PDFtadeu70% (10)

- 2 Pulsar 135 LS SPC 15 02 2013 PDFDocumento78 pagine2 Pulsar 135 LS SPC 15 02 2013 PDFOpik Biasa100% (1)

- Topic: Design and Analysis of Inlet Valves and Its Optimisation in IC Engine Using FEADocumento13 pagineTopic: Design and Analysis of Inlet Valves and Its Optimisation in IC Engine Using FEAnaveen guptaNessuna valutazione finora

- Operation and Maintenance Manual: 800 Industrial EngineDocumento76 pagineOperation and Maintenance Manual: 800 Industrial EngineMohammed ElbadriNessuna valutazione finora

- CG - MaxxForce DT Troubleshooting For MisfireDocumento12 pagineCG - MaxxForce DT Troubleshooting For Misfireford62b0% (1)

- CZ Sincro DG83Documento14 pagineCZ Sincro DG83JoNessuna valutazione finora

- Linde Forklift Series 352 Service TrainingDocumento20 pagineLinde Forklift Series 352 Service Trainingmarie100% (47)

- 403A-11G1 ElectropaK PN2004Documento2 pagine403A-11G1 ElectropaK PN2004Md ShNessuna valutazione finora

- Chevrolet Spark 2014Documento496 pagineChevrolet Spark 2014osvaldo valladares100% (1)

- Electromagnetic EngineDocumento2 pagineElectromagnetic EngineGiri Wip NxNessuna valutazione finora

- Nissan - H20 II Operation - ManualDocumento48 pagineNissan - H20 II Operation - ManualStephen Rivett86% (7)

- OBD-II Codes HondaDocumento4 pagineOBD-II Codes HondaFarrukh Javed BegNessuna valutazione finora

- Motorcycling's Sacred Cows: #6, Cast vs. Forged Pistons: Piston BasicsDocumento4 pagineMotorcycling's Sacred Cows: #6, Cast vs. Forged Pistons: Piston BasicsDebasis SoorNessuna valutazione finora

- Hyundai-B&w 1Documento201 pagineHyundai-B&w 1shujauddin84100% (1)

- Sebu6100-02 MDocumento74 pagineSebu6100-02 MSa CruCerNessuna valutazione finora