Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ijciet 08 04 143

Caricato da

Filmon SolomonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ijciet 08 04 143

Caricato da

Filmon SolomonCopyright:

Formati disponibili

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 4, April 2017, pp. 1268–1278 Article ID: IJCIET_08_04_143

Available online at http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=4

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

COMPARATIVE BEHAVIOURAL STUDY OF

CURVED COMPOSITE STEEL BOX AND I

GIRDER USING MIDAS

Vinitha. P

M. Tech Structural Engineering, School of Mechanical and Building Science,

VIT University, Chennai

Ajay VJ

M. Tech Structural Engineering, School of Mechanical and Building Science,

VIT University, Chennai

Prof. M Senthil Pandian

School of Mechanical and Building Science, VIT University, Chennai

ABSTRACT

As the development today includes the consideration of having fewer disturbances

and more economic, curves in flyovers or bridges are an obvious attempt to maintain

it. Curved girders are mostly provided in steel in India as it is more economical as

compared to steel. The curvature of the bridge can be varied as required but in some

cases there are no options due to the surrounding restrictions. There are various types

of steel girders that can be provided at curves, I girders and Box girders are the most

common among them. In this paper the detail analytical study of both the types will be

carried with an objective to find which type of cross section is suitable in which case to

be more economical. The design of bridges depends mainly on the radius of curvature

and the diaphragm spacing in case of curved girder especially. In this paper, models of

box girder and I girder bridges are created in MIDAS Civil software which is found to

give very accurate results. The models are made with varying radius of curvature and

bracing spacing to study their influence in the analysis results. Torsion study will be

the main area of research in this paper. The results will be studied and the conclusion

will be drawn and also the most economical design and the type of bridge for curves.

Key words: Curved Steel Girder; Composite Bridges; I Girder; Box Girder; Torsion;

Construction Stages; Metro Loading.

Cite this Article: Vinitha .P, Ajay VJ and Prof. M Senthil Pandian, Comparative

Behavioural Study of Curved Composite Steel Box and I Girder Using Midas,

International Journal of Civil Engineering and Technology, 8(4), 2017, pp.1268-1278

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=4

http://www.iaeme.com/IJCIET/index.asp 1268 editor@iaeme.com

Comparative Behavioural Study of Curved Composite Steel Box and I Girder Using Midas

1. INTRODUCTION

Steel has been well recognized as the economic option around the world for the infrastructure

from very large to very small. It is a versatile and effective material that provides efficient and

sustainable solutions. It dominates the markets for long span bridges, railway

bridges, footbridges, and medium span highway bridges. It is now also the choice for shorter

span highway structures due to its light weight property and quick erection. When steel girders

are curved in plan, torsional effects are introduced and these effects must be considered when

designing the beams. Society gains in many ways from the benefits delivered by the

infrastructure development. Landmark steel bridges involve good design, they are fast to build

and have stimulated the regeneration of many former industrial, dock and canal side regions.

Steel bridges are an essential feature of a nation’s infrastructure and landscape. There have

been numerous manmade structures until now that have been constructed and have marked

themselves as the landmark in different localities.

Steel bridges when compared with concrete girders, have an advantage of offsite

prefabrication of steel components that causes construction time on site, often in hostile

environments, is minimised. The speed of bridge construction made possible by steel allows

the disruption to road and rail users to be kept to a minimum. The low self weight allows of

steel permits the option of longer spans and faster erection by different ways. Sometimes the

whole span is erected at a go if the equipment has enough capacity and if the spans are too long

there is segmental construction with splicing at weaker junctions. After the girder is erected the

slab has to be casted over it using the formwork and hence until the wet concrete dries the

girder has to take the concrete weight. But, once the concrete hardens there is composite action

taking place due to the interference of two different materials with the help of shear connectors

that are provided in the form of steel studs or channels at required spacing and are welded to

the flange of the girder section. Steel also has greater efficiency than concrete structures in

resisting seismic forces and blast loading and also has greater life.

Plate girders have a very low torsional stiffness and a very high ratio of major axis to minor

axis moment of inertia. Therefore when they bend about the major axis, high lateral torsional

stability occurs. To avoid this instability, has to be provided with lateral bracings for the

bending of the girders and the flanges of the girders is taken care by the deck slab. Loads acting

on the girders also cause lateral bending like wind load forces and hence the lateral bracing

must be designed for the same.

This paper includes the comparison of box and I girder types in curves. As discussed earlier

the I girder has more instability in lateral bending due to its section properties where as in case

of box girders, since the moments of inertia in the major and minor axis does not differ much

there is more stability and is therefore expected to be more suitable in case of curved girder. If

the choice of curve layout is available the type of girder and the radius could be fixed in such

a way that the design is economical.

Since the box girder is more stable in torsion than that of I girder section and hence the

spacing of lateral bracings become more important in that case. The behaviour of the I girder

would vary with different bracing spacing and this will be studied in this paper. The radius of

the curve is fixed by the horizontal profile of the highway or the railway line. in case of the

trains the radius is generally limited to 90m because of the bogie length. In this paper three

different radii of each type of bridge will be studied to understand the change in the behaviour

and analysis of the curved girder with respect to the radius. In case of the I girder, different

analysis is done for both the varying radii as well as varying lateral bracings to study their effect

as well.

The Midas civil software uses the grillage model analysis for all the loads and the required

conditions including the moving load cases and the construction stages. To check the accuracy

http://www.iaeme.com/IJCIET/index.asp 1269 editor@iaeme.com

Vinitha .P, Ajay VJ and Prof. M Senthil Pandian

of the analysis results of the grillage analysis one model is done using finite element analysis

using Midas Fea. It has to be checked if the practical conditions at site are met within the

modelling using software.

The vehicle taken in this paper for the moving load case is a metro rolling stock on the two

lanes. The construction stages are also defined as they are critical in case of curved bridges.

When the slab is hardened the deck slab helps in restraining the top flanges of the I girders but,

before the concrete hardens the girder has high instability which has to be deeply studied in the

construction stages. In the final stage, when the bridge is composite, the torsion effects result

in a different distribution of vertical bending between the girders and in bending of the bottom

flange between bracing positions.

2. METHODOLOGY

2.1. General section

A general steel section of curved I girder and tub girder is considered for the modelling as

shown in the figures. The single span of 66m bridge is taken from the reference papers and

existing bridges with different radii of 90m, 155m and 250m in each model. The spacing of the

bracing are also varied in case of I girder bridge which is provided in the form of X bracings

using double angle sections at 6m and 3m in different models. It is a general composite section

as the concrete deck slab is casted over the steel girder. The thickness of the slab is taken as

250mm and wearing course as 80mm.

Figure 1 General section for I Girder Curved Bridge

Figure 2 General section for Tub Girder Curved Bridge

http://www.iaeme.com/IJCIET/index.asp 1270 editor@iaeme.com

Comparative Behavioural Study of Curved Composite Steel Box and I Girder Using Midas

2.2. Modelling

The composite girder bridge is modelled in Midas Civil using the Steel composite bridge

wizard, which is used to create a three dimensional grillage model of the I girder. The tub girder

is modelled as line element to obtain the three dimensional model.

Figure 3 3D Model of Curved Tub Girder

Figure 4 3D Model of Curved I Girder

2.3. Material Properties

The material properties are assigned to concrete and steel as follows:-

• Concrete:-

M40

• Steel:-

Fe 490

2.4. Live Load

The curved bridges are assumed to be functioned as metro bridges and therefore the loading

of the modern rolling stock is applied on the bridge. The two lanes are defined as per the

standard track width of a metro train both moving in the opposite direction. The live load case

is defined as moving load case in which the software will place the loads at various points

within the defined lane width and the maximum effect is taken as critical.

http://www.iaeme.com/IJCIET/index.asp 1271 editor@iaeme.com

Vinitha .P, Ajay VJ and Prof. M Senthil Pandian

Configuration:

a = 2.5 m, b = 2.30 m , c = 12.4 m

Figure 5 Metro Rolling Stock and lane configuration

2.5. Boundary conditions

The curved bridges are provided with fixed – fixed supports as single span models are created.

These are the permanent supports. As the span of 66m is too long to be erected with the end

supports alone and therefore temporary supports are provided at the required distances below

the steel girders. Since the bridge is composite it requires construction stages and these

temporary supports are removed once the wet concrete hardens and the composite action takes

place.

Figure 6 Position of temporary supports during construction

2.6. Construction Stage Load

As discussed in the introduction, the composite action becomes active when the wet concrete

deck slab hardens. There are four different stages of construction that are defined to activate

and deactivate different structure group and load cases. Temporary supports are activated in

the first stage where the wet concrete load is carried by the steel girders and when it hardens

the temporary supports are deactivated and also the wet concrete load.

http://www.iaeme.com/IJCIET/index.asp 1272 editor@iaeme.com

Comparative Behavioural Study of Curved Composite Steel Box and I Girder Using Midas

Figure 7 Summary of Construction stages

2.7. Composite Section for Construction stage

Since the steel girder and the concrete deck act as separate elements before the composite

action, the composite section is to be defined mentioning the stages at which each element

would be activated.

Figure 8 Activation of Composite section during Construction stage

2.8. Other Loads

The other loads that are applied on the models include the wearing surface, additional load of

dead manufacture and utilities. The wet concrete loads are applied at the required construction

stages before composite action takes place. The formwork loads are not considered for the

analysis. All these loads are applied are uniform area loads throughout the carriage width. Since

the bridge is considered as a metro bridge no footpath or crash barrier loads are applied on the

models for the analysis.

2.9. Analysis

The model is analysed with moving load analysis and construction stage analysis along with

other dead loads and additional components. The stresses, torsional moments and deformations

are obtained at critical points and interpreted for different load cases and construction stages.

Comparison between both the type of bridges as well as variation with radii and bracing spacing

is done which is discussed under the results. Six models of I girder bridges and three models of

tub girder bridges are analysed and the results are obtained as follows.

http://www.iaeme.com/IJCIET/index.asp 1273 editor@iaeme.com

Vinitha .P, Ajay VJ and Prof. M Senthil Pandian

3. RESULTS

The grillage analysis for moving load and construction stage analysis of both the type of

models were carried out and the results are discussed as follows. Output figures of one model

of each I girder and box girder have been shown for visual understanding. However,

comparison details and graphs will be later plotted for all the models during interpretation and

conclusion section of the paper.

3.1. Total deformation

The deformation was studied in both the type of bridge models and a typical displacement

contour was obtained as shown below.

Figure 9 Displacement contour of box type curved girder

Figure 10 Displacement contour of box type curved girder during Construction stage 1

Figure 11 Displacement contour of I type curved girder

http://www.iaeme.com/IJCIET/index.asp 1274 editor@iaeme.com

Comparative Behavioural Study of Curved Composite Steel Box and I Girder Using Midas

Figure 12 Displacement contour of I type curved girder during Construction stage 1

3.2. Torsional Moment

Due to the presence of the curvature of the girders and their section properties, these steel

sections tend to bend out of their plane and this force is called as torsion. As described in the

introduction the box girders are found to have less torsion and the variation with other

parameters is plotted in the conclusions. This property is the most governing in the curved

girder steel bridges. The bridges are designed for the obtained torsion. The most economical

type of girder can be concluded from this factor.

Figure 13 Torsional moment diagrams in Box girder bridge model

Figure 14 Torsional moment diagrams in I girder bridge model

3.3. Beam stresses

Due to the presence of torsion in the curved girders the cross section tends to twist and therefore

causes axial stresses which are shown below as contour diagram. The bending stresses in major

http://www.iaeme.com/IJCIET/index.asp 1275 editor@iaeme.com

Vinitha .P, Ajay VJ and Prof. M Senthil Pandian

axis are also shown. The torsion causes additional forces to occur in the girder which will act

in opposite directions on either side of the centre of gravity. Therefore the stresses add up on

one side and get deducted on the other side effectively.

Figure 15 Axial Beam stress contour in I girder model

Figure 16 Bending stress contour in Box girder model

3.4. Influence Line Diagram

The moving load tracer can be used to find the placing of the vehicle load for the most critical

output of an element.

Figure 11 Position of Live load for Moving load analysis.

http://www.iaeme.com/IJCIET/index.asp 1276 editor@iaeme.com

Comparative Behavioural Study of Curved Composite Steel Box and I Girder Using Midas

4. CONCLUSIONS

Graph 1 Comparative results for the Dead load

Graph 2 Comparative results for the Live load

Following conclusions can be inferred from the above graphs for Dead load and Live load

values:-

• It can be observed from the comparison of values with the varying radii that the torsional

moments and stresses increase with decrease in the radii and therefore minimum radius of

curvature must be provided as possible.

• It can be observed from the comparison of values with different bracing spacing that the

torsional moments and stresses are more in case of less centre to centre spacing of bracing hence

must be provided as such.

• It can be observed from the torsional moment values that its value is almost negligible in case

of I girder bridge compared to that of Box girder bridge due to shear flow through the cross

section of the box.

The main objective of this paper was to find the effect of torsion on different type of steel

girders and radius of curvature and from the above conclusions it can be found that the I girder

curved bridges are more economical as compared to box girder curved bridges. Also, less radius

of curvature and bracing spacing would be more economical.

http://www.iaeme.com/IJCIET/index.asp 1277 editor@iaeme.com

Vinitha .P, Ajay VJ and Prof. M Senthil Pandian

REFERENCES

[1] BMRCL Design Basis Report for Viaduct.

[2] MIDAS Civil 2017 Documentation and Tutorials.

[3] A study of Effect of shear connector in Composite beam in combined bending and shear by

Ansys, P.S.Patil, International journal of innovative and exploring engineering , Aug 2013.

[4] A study of shear connector in Composite beam in under combined bending and shear,

Manoj Bhutada, ISSN, May 2015.

[5] Indian Roads Congress 6 – 2000.

[6] Daniel G Linzell, Curved Steel Bridges – Experimental and Analytical Studies in the United

States.

[7] Yanling Zhang, Zhongming, Yunsheng, Yuanqing, Torsional behaviour of curved

Composite beams in Construction stage and Diaphragm effects, Journal of Constructional

Research 108 (2015) 1-10.

[8] Mozhdeh Amani, M.M.Alinia, The flexural behaviour of horizontally curved steel I-girder

bridge systems and single girders, Journal of Constructional Research 118 (2016) 145- 155.

[9] Vasanth K., Performance of the Curved steel Composite and PSC Box girder bridges.

[10] A. Zureick, D.Linzell, R.T.leon, Burrell, Curved steel I-Girder bridges: experimental and

Analytical studies, Engineering Structures 22 (2000) 180-190.

[11] IRC 24 Steel Bridges.

[12] Jerome. F. Hajjar, Dan Krzmarzick, Luis Pallares, Measured behaviour of a curved

composite I-girder bridge, Journal of Constructional Steel Research 66 (2010) 351-368.

[13] S.J. Fatemi, M.S. Mohamed Ali, A.H.Sheikh, Load Distribution for composite steel

concrete horizontally curved box girder bridge, Journal of Constructional Steel Research

116 (2016) 19-28.

[14] Theodoros Adamakos, IoannisVayas, Stelios Petridis, Aristidis Illiopoulos, Modelling of

curved composite I-girder bridges using spatial systems of beam elements, Journal of

Constructional Steel Research 67 (2011) 462-470.

[15] N.E.Shanmugam, M.Mahendrakumar, V.Thevendran, Ultimate load behaviour of

horizontally curved plate girders, Journal of Constructional Steel Research 59 (2003) 509-

529.

[16] Patil M.B, Y.P.Pawar, S.S.Kadam, D.D.Mohite, S.V. Lale, C.M. Deshmukh and C.P. Pise,

Analysis and Comparative Study of Composite Bridge Girders. International Journal of

Civil Engineering and Technology, 7(3), 2016, pp.354–364.

[17] Sallal R. Abid, Salih Alrebeh, Nildem Tayşi and Mustafa Özakça. Finite Element Thermal

Analysis of Deep Box-Girders. International Journal of Civil Engineering and Technology,

7(1), 2016, pp. 128-139.

[18] K.Baskar, N.E.Shanmugam, Steel-concrete composite plate girders subject to combined

shear and bending, Journal of Constructional Steel Research 59 (2003) 531-557.

[19] Gaby Issa El Khoury, Daniel G.Linzell, Louis F.Geschwindner, Computational studies of

horizontally curved, longitudinally stiffened, plate Girder webs in flexure, Journal of

Constructional Steel Research 93 (2014) 97-106.

http://www.iaeme.com/IJCIET/index.asp 1278 editor@iaeme.com

Potrebbero piacerti anche

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNessuna valutazione finora

- Review On Analysis of Structure and Design of Steel Bridge Using Staad Pro SoftwareDocumento8 pagineReview On Analysis of Structure and Design of Steel Bridge Using Staad Pro SoftwareIJRASETPublicationsNessuna valutazione finora

- A Review On Comparative Study Between Girder Bridge and Extradosed Bridge by Using Staad - Pro SoftwareDocumento3 pagineA Review On Comparative Study Between Girder Bridge and Extradosed Bridge by Using Staad - Pro SoftwarePrabhnoorNessuna valutazione finora

- Analysis of Plate Girder Bridge For Class-AA Loadings (Tracked Vehicles)Documento11 pagineAnalysis of Plate Girder Bridge For Class-AA Loadings (Tracked Vehicles)amitNessuna valutazione finora

- BEI 2023 Paper On Steel Ortho BoxDocumento5 pagineBEI 2023 Paper On Steel Ortho BoxDhrubojyoti SenguptaNessuna valutazione finora

- Steel Bridges SeminarDocumento21 pagineSteel Bridges SeminarAamodh Kuthethur100% (2)

- Structural Performance Evaluation of A Precast PSC Curved Girder Bridge Constructed Using Multi-Tasking FormworkDocumento18 pagineStructural Performance Evaluation of A Precast PSC Curved Girder Bridge Constructed Using Multi-Tasking FormworkAvinash ManglamNessuna valutazione finora

- 2 CompositeDocumento9 pagine2 CompositeSurumi Rasia SalimNessuna valutazione finora

- Review On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureDocumento11 pagineReview On Comparative Analysis of PSC Box Girder Bridge and PSC Precast I Girder Bridge StructureIJRASETPublicationsNessuna valutazione finora

- Rahul VyasDocumento48 pagineRahul VyasRahul VyasNessuna valutazione finora

- Research Paper On Analysis and Design ofDocumento16 pagineResearch Paper On Analysis and Design ofPalesaNessuna valutazione finora

- Srividya College of Engineering and Technology Question BankDocumento8 pagineSrividya College of Engineering and Technology Question BankAravindNessuna valutazione finora

- Jembt Trisula BlitarDocumento11 pagineJembt Trisula Blitargian felix sihombingNessuna valutazione finora

- Design and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Documento8 pagineDesign and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Pritesh RAINessuna valutazione finora

- Analysis of Prestressed Solid and Voided Slab Type Bridge Superstructure On Curved AlignmentDocumento7 pagineAnalysis of Prestressed Solid and Voided Slab Type Bridge Superstructure On Curved AlignmentankitNessuna valutazione finora

- COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646Documento11 pagineCOMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646NikhilARNessuna valutazione finora

- Parametric Evaluation On Reinforced Concrete Solid Slab Bridges by Staad-Pro SoftwareDocumento6 pagineParametric Evaluation On Reinforced Concrete Solid Slab Bridges by Staad-Pro SoftwareIJRASETPublicationsNessuna valutazione finora

- Consideration of Seismic Design of Multistoried Steel StructureDocumento6 pagineConsideration of Seismic Design of Multistoried Steel StructureAnonymous KyLhn6Nessuna valutazione finora

- Earthquake ReportDocumento9 pagineEarthquake Reportgokul vvNessuna valutazione finora

- M Tech DP 1 ...... 21.2.20Documento44 pagineM Tech DP 1 ...... 21.2.20Himani PatelNessuna valutazione finora

- Review On Behavior of Foot Over BridgeDocumento4 pagineReview On Behavior of Foot Over BridgeMD. ASIKUR RAHMANNessuna valutazione finora

- A Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC AbutmentsDocumento3 pagineA Comparative Design of RCC and Prestressed Concrete Flyover Along With RCC AbutmentsPriyanka BasuNessuna valutazione finora

- Stochastic Shear Strength of Plate Girder in Highway BridgeDocumento40 pagineStochastic Shear Strength of Plate Girder in Highway BridgeAbdulrasheed Muhammad KardiNessuna valutazione finora

- Design of Castellated Column in Finite Element AnalysisDocumento10 pagineDesign of Castellated Column in Finite Element AnalysisIJRASETPublicationsNessuna valutazione finora

- Effect of Skew Angles On Longitudinal Girder and Deck Slab of Prestressed Concrete T Beam Girder BridgesDocumento9 pagineEffect of Skew Angles On Longitudinal Girder and Deck Slab of Prestressed Concrete T Beam Girder BridgesIJRASETPublicationsNessuna valutazione finora

- Optimum Design of Vertical Steel Tendons Profile Layout of Post-Tensioning Concrete Bridges: Fem Static AnalysisDocumento14 pagineOptimum Design of Vertical Steel Tendons Profile Layout of Post-Tensioning Concrete Bridges: Fem Static AnalysisNader OkashaNessuna valutazione finora

- Analysis of Cable Stayed Bridge and Girder Bridge Considering Seismic Forces and I.R.C. LoadingDocumento11 pagineAnalysis of Cable Stayed Bridge and Girder Bridge Considering Seismic Forces and I.R.C. LoadingIJRASETPublicationsNessuna valutazione finora

- Manual Analysis and Design of Post Tensioned Pre-Stressed Concrete T-Beam Segment Bridge Using Proto-Type ModelDocumento16 pagineManual Analysis and Design of Post Tensioned Pre-Stressed Concrete T-Beam Segment Bridge Using Proto-Type ModelemirterNessuna valutazione finora

- 1532 4516 1 PB PDFDocumento11 pagine1532 4516 1 PB PDFDanu AdiNessuna valutazione finora

- Engineering Journal - First Quarter 2017Documento69 pagineEngineering Journal - First Quarter 2017gilmarNessuna valutazione finora

- Kamal - 2015 - Encased Beam With Variable Upper SteelDocumento8 pagineKamal - 2015 - Encased Beam With Variable Upper SteelRene Rodrigues O. SilvaNessuna valutazione finora

- IJCRT2303651Documento4 pagineIJCRT2303651pankaj645924Nessuna valutazione finora

- Study and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadDocumento5 pagineStudy and Analysis of Cable Stayed Bridges Using STAAD Pro: Nayan K. Janbandhu, Sandeep GaikwadMananNessuna valutazione finora

- Construction Stage Analysis of Three-Dimensional Cable-Stayed BridgesDocumento15 pagineConstruction Stage Analysis of Three-Dimensional Cable-Stayed BridgesOlivia OeyNessuna valutazione finora

- tmpC1DB TMPDocumento12 paginetmpC1DB TMPFrontiersNessuna valutazione finora

- Base-Plate Calculation Under Tension.: ArticleDocumento24 pagineBase-Plate Calculation Under Tension.: ArticlePanos SpNessuna valutazione finora

- Comparative Analysis and Design of Solid Deck Slab of Minor Bridge by Effective Width Method and Finite Element Method IJERTCONV4IS30021Documento3 pagineComparative Analysis and Design of Solid Deck Slab of Minor Bridge by Effective Width Method and Finite Element Method IJERTCONV4IS30021piyush tiwariNessuna valutazione finora

- Study On Steel Railings Installed On Concave - and Convex-Curved BridgeDocumento14 pagineStudy On Steel Railings Installed On Concave - and Convex-Curved BridgeRyan ColaoNessuna valutazione finora

- Iare DSSD Lecture Notes-ModifiedDocumento124 pagineIare DSSD Lecture Notes-ModifiedDPJAIN INFRASTRUCTURENessuna valutazione finora

- Ijciet 08 01 018 PDFDocumento19 pagineIjciet 08 01 018 PDFIAEME PublicationNessuna valutazione finora

- Effect of Skew For Various Irc Loadings On A T-Beam Bridge SectionDocumento8 pagineEffect of Skew For Various Irc Loadings On A T-Beam Bridge SectionIAEME PublicationNessuna valutazione finora

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocumento13 pagineAnalysis and Design of Prestressed Concrete Box Girder BridgehimabindugvsdNessuna valutazione finora

- Experimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewDocumento4 pagineExperimental Stress Analysis of Trapezoidal Corrugated Steel Web Beam - A ReviewAsr FlowerNessuna valutazione finora

- Aerodynamic Stability of Cable-Stayed-Suspension Hybrid Bridges - Zhang2005Documento6 pagineAerodynamic Stability of Cable-Stayed-Suspension Hybrid Bridges - Zhang2005jaswantNessuna valutazione finora

- Qassim 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012101Documento9 pagineQassim 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012101Huda AlrikabiNessuna valutazione finora

- Analysis and Design of Box Culvert For 70R LoadingDocumento22 pagineAnalysis and Design of Box Culvert For 70R LoadingPratyasha PadalNessuna valutazione finora

- Design of Reinforced Concrete Circular Slabs by Two-Way Isotropic Straight JoistsDocumento11 pagineDesign of Reinforced Concrete Circular Slabs by Two-Way Isotropic Straight Joistswhite peacockNessuna valutazione finora

- Maheri-Sahebi (ES-1997)Documento8 pagineMaheri-Sahebi (ES-1997)abdullahNessuna valutazione finora

- Design of Long Span Exhibition Hall of Steel StructureDocumento5 pagineDesign of Long Span Exhibition Hall of Steel StructureInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Self-Anchored Suspension Bridge With Ultra-Wide Box GirderDocumento15 pagineSelf-Anchored Suspension Bridge With Ultra-Wide Box GirderCristian Camilo Londoño PiedrahítaNessuna valutazione finora

- Comparative Study On I Girder and Box Girder For Design of PSC BridgeDocumento10 pagineComparative Study On I Girder and Box Girder For Design of PSC BridgePrabhnoorNessuna valutazione finora

- Analysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureDocumento9 pagineAnalysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureUsha EngineeringNessuna valutazione finora

- Finite Element Analysis and OptimizationDocumento11 pagineFinite Element Analysis and OptimizationS.m. MoniruzzamanNessuna valutazione finora

- 23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareDocumento9 pagine23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareSandy KavitakeNessuna valutazione finora

- Artikel-Struktural Behavior ExtradosedDocumento6 pagineArtikel-Struktural Behavior ExtradosedReza HidayatNessuna valutazione finora

- Government Technical Institute (MAGWAY) : Department of Civil EngineeringDocumento12 pagineGovernment Technical Institute (MAGWAY) : Department of Civil EngineeringBanyar Thiha ZawNessuna valutazione finora

- Design and Analysis of Beam Supported BridgeDocumento8 pagineDesign and Analysis of Beam Supported BridgeBhanu Prakash BNessuna valutazione finora

- Analysis and Comparative Study of Composite Bridge GirdersDocumento11 pagineAnalysis and Comparative Study of Composite Bridge GirdersIAEME PublicationNessuna valutazione finora

- Comparative Study of RCC T-Beam Bridge byDocumento32 pagineComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- London Guidebook en ES ITDocumento96 pagineLondon Guidebook en ES ITnoe_llo2367Nessuna valutazione finora

- The Opportunities of Flexible HousingDocumento18 pagineThe Opportunities of Flexible HousingdrikitahNessuna valutazione finora

- Power Plant OperationDocumento148 paginePower Plant Operationkeerthi dayarathna100% (1)

- KVM RextronDocumento1 paginaKVM RextronStephen BNessuna valutazione finora

- Architecture at The End of The EarthDocumento29 pagineArchitecture at The End of The EarthDuke University Press100% (1)

- Property Printable Listing-20171110Documento18 pagineProperty Printable Listing-20171110chek86351Nessuna valutazione finora

- AC O& M City Mall Version 1.0Documento12 pagineAC O& M City Mall Version 1.0yewminyun6098Nessuna valutazione finora

- Software Certification PathDocumento12 pagineSoftware Certification PathtinaldinoNessuna valutazione finora

- KasthamandapDocumento2 pagineKasthamandapHarshita SinghNessuna valutazione finora

- Design of FootingsDocumento42 pagineDesign of Footingsxaekne91% (11)

- 7279 Creo Afx DsDocumento3 pagine7279 Creo Afx DsNatalie Wyatt0% (1)

- BCA - Builder's Guide On Measuring Productivity 2012Documento86 pagineBCA - Builder's Guide On Measuring Productivity 2012lwin_oo243567% (3)

- Approach To Actionable Business ArchitectureDocumento24 pagineApproach To Actionable Business ArchitectureDave Sen100% (3)

- 1.1 Pertapakan Shti Di Pulau PinangDocumento20 pagine1.1 Pertapakan Shti Di Pulau PinangMohd Shahrul IbrahimNessuna valutazione finora

- Plumbing Isometric DiagramDocumento1 paginaPlumbing Isometric Diagramdan PioquintoNessuna valutazione finora

- Dell Latitude E5400 E5500 Specsheet Au PDFDocumento2 pagineDell Latitude E5400 E5500 Specsheet Au PDFAbdul RehmanNessuna valutazione finora

- Kerbstones Installation GuidelinesDocumento4 pagineKerbstones Installation Guidelinespartha_svnitNessuna valutazione finora

- Basilica of TrajanDocumento9 pagineBasilica of TrajanKavya Eranagoudar MallanagoudarNessuna valutazione finora

- Watts Radiant Full Line Catalog En-20100519Documento112 pagineWatts Radiant Full Line Catalog En-20100519Pexheat.comNessuna valutazione finora

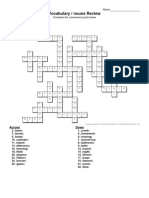

- Vocabulary / Nouns Review: Across DownDocumento1 paginaVocabulary / Nouns Review: Across DownNeyde BalsaNessuna valutazione finora

- Art Appreciation Module #7Documento1 paginaArt Appreciation Module #7Angela ReyesNessuna valutazione finora

- XOS 9.0.3 Release NotesDocumento14 pagineXOS 9.0.3 Release Notesmike15rorkNessuna valutazione finora

- Consideration of Iacs Unified Interpretations Pdf275Documento9 pagineConsideration of Iacs Unified Interpretations Pdf275Jym GensonNessuna valutazione finora

- Selenium OverviewDocumento26 pagineSelenium OverviewAacharya Rakesh TiwariNessuna valutazione finora

- Naveed Ur Rahman: Curriculum VitaeDocumento2 pagineNaveed Ur Rahman: Curriculum VitaeNaveed ur RahmanNessuna valutazione finora

- OPNET Model LibraryDocumento4 pagineOPNET Model LibraryRodrigo Zapata100% (1)

- Designing Combined Standpipe and Sprinkler SystemDocumento3 pagineDesigning Combined Standpipe and Sprinkler SystemMohammed Abdul MoiedNessuna valutazione finora

- An Essay On The Architectural Sojourn in ManilaDocumento4 pagineAn Essay On The Architectural Sojourn in ManilaMae Francis V. MiguelNessuna valutazione finora

- Barcos de Concreto (Inf)Documento257 pagineBarcos de Concreto (Inf)hectorSTNessuna valutazione finora

- Pre-Chamber RegulatorDocumento3 paginePre-Chamber RegulatorfahadullahNessuna valutazione finora