Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asn 690

Caricato da

fikriimam1Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asn 690

Caricato da

fikriimam1Copyright:

Formati disponibili

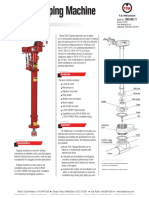

■SPECIFICATIONS

Model name ASN-690

ASN-690 Series Machine head

Application

MO-6904S (Super-high-speed, 1-needle overlock machine)

Serging of skirts, pants, jeans, etc.

Automatic Serging Machine Max. sewing speed 8,000sti/min*

Stitch length 0.8∼4mm

Overedging width (mm) 4.0, 4.8, 5.6

Differential feed ratio For gathering 1:2 (max. 1:4), For stretching 1:0.7 (max. 1:0.6)

Needle DC ×27 (#11) #9∼#14

Thread trimming device Exclusive pneumatic side cutter

Lubrication Automatic

Lubricating oil JUKI MACHINE OIL 18 (equivalent to ISO VG18)

Compressed air 0.5MPa

Power consumption 590VA

〔Long-table type〕 〔Short-table type〕

Power requirement Single-phase 200∼240V, 3-phase 200∼380V

Long-table type (L): 160kg (with stacker)

Machine weight

Short-table type (S): 110kg (with stacker)

Long-table type (L) with stacker: 1,800mm (W) × 790mm (D) × 880mm (H)

Long-table type (L) without stacker: 1,500mm (W) × 790mm (D) × 880mm (H)

Dimensions ( When the Cloth table (KM-5) is used, the width is 2,100mm for the machine with a stacker, or

1,800mm for the one without a stacker. )

Short-table type (S) with stacker: 790mm (W) × 875mm (D) × 880mm (H)

Short-table type (S) without stacker: 790mm (W) × 575mm (D) × 880mm (H)

*"sti/min" stands for "Stitches per Minute."

■WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

Sewing table Code Power supply Code

Long-table without sub-table Z Stacker Code 200∼240V K

Single-phase

Long-table type L Not provided Z CE 200∼240V N

Short-table type S Pneumatic stacker A 3-phase 200∼240V D

ASN690□□□□□□

Overedging width Code Option

AK-139 CL-5 PF-10 PK-79 KM-5*

4.0mm E

Differential

Presser Silencer Curve 3-pedal Code

4.8mm F feed amount Cloth table

foot lifter sensor switch unit

changing device

5.6mm G

− ○ − − − − A1

− ○ − − − ○ A2

− ○ ○ ○ ○ ○ A3

Long-table type ○ ○ − − − − A5

○ ○ − − − ○ A6

○ ○ ○ ○ ○ − A7

○ ○ ○ ○ ○ ○ A8

*The short-table type machine cannot be combined with the KM-5.

●To order, please contact your nearest JUKI distributor.

Short-table type

Registered Organization : Head Office

The Scope of the Registration : The activities of research,

development, design, sales, distribution, and maintenance

ASN-690 Series

services of industrial sewing machines, household sewing

machines and industrial robots, etc., including sales and

maintenance services of data entry systems.

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO 206-8551, JAPAN

PHONE : (81) 42-357-2370

FAX : (81) 42-357-2274

Super-high-speed serging machine developed to SEWING MACHINERY BUSINESS UNIT http://www.juki.com

✽ Specifications and appearance are subject to change without prior notice for improvement.

achieve a simple structure and ease of use ✽ Read the instruction manual before putting the machine into service to ensure safety.

✽ This catalogue prints with environment-friendly soyink on recycle paper.

JUNE, 2016 Printed in Japan(C)

Super-high-speed serging machine developed to achieve a simple structure and ease of use Increased productivity is required in the serging process. JUKI has launched

ASN-690 Series

its super-high-speed machine developed in pursuit of simple-in-operation and

ease-of-use. To fully support the operator so that he/she can carry out

serging speedily, the machine comes in two different types; the long-table

type and the short-table type which permits easy handling of the material.

Many different technologies which have gone into the simple operation.

■The machine is equipped with the super-high-

speed overlock machine head MO-6904S.

The machine achieves the high-speed performance of up to 8,000

sti/min to promise increased productivity. The machine performs

serging according to the material used, is capable of sewing with

reduced thread tension and promises consistent seam quality free from

slip-off seams at curved parts of the material.

■Flexible cloth guide

The cloth guide can easily be adjusted in height according to the

material to be used without using a tool. It eliminates the troublesome

changing of spacers.

ASN-690L-AF-A8D ■Looper cleaner

A dust extractor is equipped as standard in the upper looper arm section

where dust is likely to gather. It helps prevent dust from accumulating inside

the cloth chip cover.

■Micro-lifter device

〔Long-table type〕 The machine is provided as standard with a micro-lifter device which

adjusts the lifting amount of the presser foot to the material thickness to

achieve improved seam quality, while preventing puckering and material

Looper cleaner Micro-lifter device

damage.

■Air-blow table

The machine comes with an air-blow table, which issues a jet of air from

its air nozzles at three locations to contribute to smoother handling of

the material.

〔Short-table type〕 Air blowing direction Material feeding direction

The table shape of the short-table type machine permits Material

easy handling of the material to perform serging of a long Table

Layer of air

ASN-690S-AF-A7D material even when the work space is small.

Manual stacker switch

■Easy-to-use stacker switch

The machine is applicable to the over casting of material The stacker automatically actuates according to the preset number of

fabrics cut into various jeans, pants and skirt shapes. seams. In addition, the stacker can also be actuated by operating the

large easy-to-press manual stacker switch.

Example of a serging process

Back-body serging Front-body serging Ladies' skirts

(without knee lining/right and left) Front- and back-body

serging

Lots of optional device have been prepared to help the operator.

Silencer GMC080530A0 It is a device for reducing the noise generated by the dust extractor during sewing.

dB

Cloth table The table is used for placing sewing materials near the sewing table.

40082456

KM-5 (Only for the long-table type)

Presser foot lifter

The ASN-690 Series are eco-friendly products which complies with 40082451 This is a device for lifting the presser foot automatically.

JUKI ECO PRODUCTS JUKI ECO PRODUCTS standards for protecting the environment. AK-139

This model has cleared "JUKI Group's Green Procurement Guideline*", a set of standards stricter than the relevant The 3-pedal switch unit works as the pause switch, high-/low-speed changeover switch and

3-pedal switch unit

international restrictions on the use of hazardous chemical substances (e.g., the RoHS Directive*). 40082455 differential feed switch. The differential feed switch has to be used in combination with the

The introduction of a servomotor has reduced electrical power consumption by half, for improved energy-saving performance.

PK-79 differential feed amount changing device (PF-10).

Through design adjustments in the mechanical balance, the vibration of the new model is reduced by 2 dB, Differential feed amount This is a device for changing the differential feed amount. It can widely support the

as compared with the conventional model. 40082454

changing device serging of various items.

The number of man-hours required to manufacture the sewing machine has been reduced by 44%, PF-10

contributing to reduced energy consumption during the production process.

For details of JUKI ECO PRODUCTS, refer to : http://www.juki.co.jp/eco_e/index.html Curve sensor This is a sensor for detecting the in-curve shape and changing the speed of the stitch

40082453

* The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE) in electrical and electronic equipment. The CL-5 and differential feed amount accordingly.

Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only the aforementioned six substances, but also other ones which also adversely affect the environment.

Potrebbero piacerti anche

- dln6390 PDFDocumento4 paginedln6390 PDFKalim KamNessuna valutazione finora

- DDL 8000 ADocumento2 pagineDDL 8000 AYM Tsai100% (1)

- 760C Tapping MachineDocumento6 pagine760C Tapping MachineTunjung Wicaksana RanukusumaNessuna valutazione finora

- Height Depth: The World's Is Determined by Our DrillingDocumento2 pagineHeight Depth: The World's Is Determined by Our Drillingrandy yupanquiNessuna valutazione finora

- Grooming MowerDocumento1 paginaGrooming MowerRaheem m.aNessuna valutazione finora

- Height Depth: The World's Is Determined by Our DrillingDocumento2 pagineHeight Depth: The World's Is Determined by Our DrillingrU sNessuna valutazione finora

- Apw 895 NeDocumento2 pagineApw 895 NeCarlos Paul TorresNessuna valutazione finora

- SP125 Sports Brochure Latest FileDocumento8 pagineSP125 Sports Brochure Latest FileSibi SundarNessuna valutazione finora

- Excavator - Komatsu PC-200Documento2 pagineExcavator - Komatsu PC-200AshokNessuna valutazione finora

- Hot TappingMachine 760Documento6 pagineHot TappingMachine 760Anonymous 7xbdR5Nessuna valutazione finora

- XC74 75 76 - MinicargadorDocumento6 pagineXC74 75 76 - Minicargadorfernando ivan castillo rojasNessuna valutazione finora

- DDL 8000 ADocumento2 pagineDDL 8000 AfatagiuNessuna valutazione finora

- 660C Tapping MachineDocumento6 pagine660C Tapping MachineOliver KrausNessuna valutazione finora

- FLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Documento4 pagineFLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Sayantan RahaNessuna valutazione finora

- Sunstar KM-2300Documento2 pagineSunstar KM-2300jairo rodriguez100% (1)

- Document 3a118812Documento2 pagineDocument 3a118812ratul.iba.ruNessuna valutazione finora

- Height Depth: The World's Is Determined by Our DrillingDocumento2 pagineHeight Depth: The World's Is Determined by Our Drillingyo2k_123Nessuna valutazione finora

- KM-T20 CatalogDocumento1 paginaKM-T20 CatalogJackson SilvaNessuna valutazione finora

- Supreme SP-3020ASDocumento2 pagineSupreme SP-3020ASAlexandruNessuna valutazione finora

- Powered by ExperienceDocumento8 paginePowered by ExperienceFigo ChengNessuna valutazione finora

- Juki Series C Mo6900cDocumento2 pagineJuki Series C Mo6900cKabir MahlotraNessuna valutazione finora

- Self Propelled High Clearance Boom Sprayer: Protektor 600Documento2 pagineSelf Propelled High Clearance Boom Sprayer: Protektor 600Ketul ShahNessuna valutazione finora

- R 2000ic 100P Flyer ENDocumento2 pagineR 2000ic 100P Flyer ENperop123Nessuna valutazione finora

- Dr3ib 8l Flyer enDocumento2 pagineDr3ib 8l Flyer enEdwin ReinosoNessuna valutazione finora

- Height Depth: The World's Is Determined by Our DrillingDocumento2 pagineHeight Depth: The World's Is Determined by Our DrillingSiva ChellamNessuna valutazione finora

- Sany Crane-Brochure SAC1600S7Documento16 pagineSany Crane-Brochure SAC1600S7Martin ElmenzoNessuna valutazione finora

- Sigma II Servo System Product Catalog Supplement 2009Documento202 pagineSigma II Servo System Product Catalog Supplement 2009Trí ChốtNessuna valutazione finora

- Unicorn 150Documento2 pagineUnicorn 150Nirmal GoreNessuna valutazione finora

- Brother Bas-311h Leaflet PDFDocumento2 pagineBrother Bas-311h Leaflet PDFAshraaf aushiNessuna valutazione finora

- Long Arm Excavator SeriesDocumento4 pagineLong Arm Excavator SeriesBryson PlazosNessuna valutazione finora

- Hand Stacker, Semi-Electric StackerDocumento1 paginaHand Stacker, Semi-Electric StackerYong Khar HohNessuna valutazione finora

- Meb 3200 PDFDocumento6 pagineMeb 3200 PDFWajid WajidNessuna valutazione finora

- Cronerlke 210 H 26 Specksheet 2075760570Documento2 pagineCronerlke 210 H 26 Specksheet 2075760570Phước NguyễnNessuna valutazione finora

- SR155C10 4P enDocumento2 pagineSR155C10 4P enrian1099Nessuna valutazione finora

- High and Long Arm Sewing Machine With Automatic Thread TrimmerDocumento2 pagineHigh and Long Arm Sewing Machine With Automatic Thread TrimmerSheikh RizwanNessuna valutazione finora

- M-900 Robot Working Range: 330 KG 3203 MMDocumento1 paginaM-900 Robot Working Range: 330 KG 3203 MMjosjcrsNessuna valutazione finora

- H08B Brochure - PortuguesDocumento2 pagineH08B Brochure - PortuguesJoãoMassudaJuniorNessuna valutazione finora

- Tapping Machine Mar 2021Documento6 pagineTapping Machine Mar 2021Remmy Torres VegaNessuna valutazione finora

- EH SeriesDocumento8 pagineEH Seriessobirin100% (1)

- Power ManDocumento3 paginePower ManManuel Armando Salazar BravoNessuna valutazione finora

- Sany SR235 TerbaruDocumento2 pagineSany SR235 TerbaruMenara Hijau MandiriNessuna valutazione finora

- Kubota - Excavator KX033 4Documento6 pagineKubota - Excavator KX033 4Juan GranaraNessuna valutazione finora

- BroucherDocumento2 pagineBroucherVishal PoulNessuna valutazione finora

- Sany Crane-Brochure SAC600EDocumento9 pagineSany Crane-Brochure SAC600ERexNessuna valutazione finora

- Catalogue HACINT MEGAINDUS 2023 Fully Automatic MachineDocumento31 pagineCatalogue HACINT MEGAINDUS 2023 Fully Automatic MachineNabil daiouneNessuna valutazione finora

- 4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeDocumento2 pagine4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeOnagro XNessuna valutazione finora

- Insstruction Manual Zoje Zj-5780Documento30 pagineInsstruction Manual Zoje Zj-5780MaskusyaniNessuna valutazione finora

- En Henkelman AtmozDocumento3 pagineEn Henkelman AtmozKrisTina MKmNessuna valutazione finora

- L K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To OperatorsDocumento4 pagineL K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To Operatorsdharmik borisagarNessuna valutazione finora

- 7 Ton Forklift CPCD70Documento1 pagina7 Ton Forklift CPCD70Mehadi HasanNessuna valutazione finora

- Yanmar4JH3 TETechnical DataDocumento2 pagineYanmar4JH3 TETechnical DatababunyarokNessuna valutazione finora

- S6 Ecoline - DC - enDocumento2 pagineS6 Ecoline - DC - enRobert Utrecht HutapeaNessuna valutazione finora

- OHC Singgle Girder SWL 2x3,2 T MDO - R00BDocumento1 paginaOHC Singgle Girder SWL 2x3,2 T MDO - R00BFebri Heru PurnomoNessuna valutazione finora

- General View: Option Ring Bit 94×73.1Documento2 pagineGeneral View: Option Ring Bit 94×73.1Jayantha parakrama ThennakoonNessuna valutazione finora

- 650tlx Stage3b PRDocumento6 pagine650tlx Stage3b PRДмитрий БакайNessuna valutazione finora

- Hino-5 Ton LorryDocumento2 pagineHino-5 Ton LorrythowchinNessuna valutazione finora

- Brochure of Stackers Standing TypeDocumento2 pagineBrochure of Stackers Standing TypeSamuel Villa FloresNessuna valutazione finora

- My Mother at 66Documento6 pagineMy Mother at 66AnjanaNessuna valutazione finora

- Test 51Documento7 pagineTest 51Nguyễn Hiền Giang AnhNessuna valutazione finora

- Astm B19Documento6 pagineAstm B19Davor IbarraNessuna valutazione finora

- JIS G 3141: Cold-Reduced Carbon Steel Sheet and StripDocumento6 pagineJIS G 3141: Cold-Reduced Carbon Steel Sheet and StripHari0% (2)

- DLP - Light Science 7Documento6 pagineDLP - Light Science 7Samara M. SalacayanNessuna valutazione finora

- UltimateBeginnerHandbookPigeonRacing PDFDocumento21 pagineUltimateBeginnerHandbookPigeonRacing PDFMartinPalmNessuna valutazione finora

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Documento22 pagineMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCNessuna valutazione finora

- Peer PressureDocumento13 paginePeer PressuremightymarcNessuna valutazione finora

- Umwd 06516 XD PDFDocumento3 pagineUmwd 06516 XD PDFceca89Nessuna valutazione finora

- Fire Protection in BuildingsDocumento2 pagineFire Protection in BuildingsJames Carl AriesNessuna valutazione finora

- Phytotherapy On CancerDocumento21 paginePhytotherapy On CancerSiddhendu Bhattacharjee100% (1)

- Pg2022 ResultDocumento86 paginePg2022 ResultkapilNessuna valutazione finora

- PFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023Documento1 paginaPFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023adyhugoNessuna valutazione finora

- SachinDocumento3 pagineSachinMahendraNessuna valutazione finora

- Modlist - Modlist 1.4Documento145 pagineModlist - Modlist 1.4Tattorin vemariaNessuna valutazione finora

- LP For EarthquakeDocumento6 pagineLP For Earthquakejelena jorgeoNessuna valutazione finora

- Illustrating An Experiment, Outcome, Sample Space and EventDocumento9 pagineIllustrating An Experiment, Outcome, Sample Space and EventMarielle MunarNessuna valutazione finora

- Iguana Joe's Lawsuit - September 11, 2014Documento14 pagineIguana Joe's Lawsuit - September 11, 2014cindy_georgeNessuna valutazione finora

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorDocumento21 pagineLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimNessuna valutazione finora

- Lamentation of The Old Pensioner FinalDocumento17 pagineLamentation of The Old Pensioner FinalRahulNessuna valutazione finora

- Business Plan in BDDocumento48 pagineBusiness Plan in BDNasir Hossen100% (1)

- Health Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyDocumento3 pagineHealth Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyihealthmailboxNessuna valutazione finora

- Resume: Mr. Shubham Mohan Deokar E-MailDocumento2 pagineResume: Mr. Shubham Mohan Deokar E-MailAdv Ranjit Shedge PatilNessuna valutazione finora

- Core ValuesDocumento1 paginaCore ValuesIan Abel AntiverosNessuna valutazione finora

- PSA Poster Project WorkbookDocumento38 paginePSA Poster Project WorkbookwalliamaNessuna valutazione finora

- Final Project Strategic ManagementDocumento2 pagineFinal Project Strategic ManagementMahrukh RasheedNessuna valutazione finora

- Drive LinesDocumento30 pagineDrive LinesRITESH ROHILLANessuna valutazione finora

- Nanolithography - Processing Methods PDFDocumento10 pagineNanolithography - Processing Methods PDFNilesh BhardwajNessuna valutazione finora

- Apple Change ManagementDocumento31 pagineApple Change ManagementimuffysNessuna valutazione finora

- Neonatal Mortality - A Community ApproachDocumento13 pagineNeonatal Mortality - A Community ApproachJalam Singh RathoreNessuna valutazione finora