Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

14WN Test 2

Caricato da

Ahsan AvioniqueCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

14WN Test 2

Caricato da

Ahsan AvioniqueCopyright:

Formati disponibili

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

** ON A/C ALL

TASK 34-22-25-790-001-A

Low range Leak Test of the Standby Pneumatic circuits

WARNING: MAKE SURE THAT ALL THE CIRCUITS IN MAINTENANCE ARE ISOLATED BEFORE YOU

SUPPLY ELECTRICAL POWER TO THE AIRCRAFT. UNWANTED ELECTRICAL POWER CAN

BE DANGEROUS.

WARNING: MAKE SURE THAT THE SAFETY DEVICES AND THE WARNING NOTICES ARE IN POSITION

BEFORE YOU START A TASK ON OR NEAR:

- THE FLIGHT CONTROLS

- THE FLIGHT CONTROL SURFACES

- THE LANDING GEAR AND RELATED DOORS

- COMPONENTS THAT MOVE.

MOVEMENT OF COMPONENTS CAN KILL OR CAUSE INJURY TO PERSONS AND/OR DAM-

AGE TO EQUIPMENT.

WARNING: MAKE SURE THAT THE TRAVEL RANGES OF THE FLIGHT CONTROL SURFACES ARE

CLEAR BEFORE YOU PRESSURIZE/DEPRESSURIZE A HYDRAULIC SYSTEM.

AUTOMATIC MOVEMENT OF THE FLIGHT CONTROL SURFACES CAN BE DANGEROUS

AND/OR CAUSE DAMAGE.

CAUTION: TO PREVENT DAMAGE TO INSTRUMENTS, OBEY THESE PRECAUTIONS WHEN YOU DO

THE TEST:

- THE PRESSURES SET MUST NOT BE MORE THAN 1050 HPA (31 IN HG) OR LESS THAN

115 HPA (3.39 IN HG)

- CHANGES IN STATIC AND TOTAL PRESSURES MUST NOT BE MORE THAN 6000 FEET/

MINUTE

- DO NOT SUDDENLY OPEN LINES TO AMBIENT AIR WHILE THE PRESSURE GENERATOR

IS CONNECTED.

CAUTION: THE TOTAL PRESSURE IN THE PITOT SYSTEM MUST NEVER BE LESS THAN THE STAT-

IC PRESSURE. THE DIFFERENCE BETWEEN THE PITOT AND THE STATIC PRESSURE CIR-

CUITS MUST NEVER BE MORE THAN 368 HPA (10.86 IN HG).

1. Reason for the Job

Refer to the MPD TASK: 342200-05

LOW RANGE LEAK TEST OF STANDBY PNEUMATIC CIRCUITS

To make sure that there are no leaks in the standby static and standby pitot circuits.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR SAFETY CLIP - CIRCUIT BREAKER

No specific AR TAPE - ADHESIVE

(36122) 1 ADAPTOR-CHARGING,PITOT PROBE

OR OR

(98F34103001000) 1 ADAPTER-PITOT PROBE

(98D10103500001) 1 COVER-STATIC PROBE

(98D34003500000) 1 ADAPTER COVER-STATIC PORT

Print Date: March 04, 2019 Page 1 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

REFERENCE QTY DESIGNATION

(ALT34100001) 1 PITOT AND STATIC TEST SET

(P75701-4C) 1 ADAPTER-PITOT PROBE

B. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

120 AVIONICS COMPARTMENT

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

C. Referenced Information

REFERENCE DESIGNATION

(Ref. 24-41-00-861-002-A). Energize the Aircraft Electrical Circuits from the External Power

(Ref. 24-41-00-861-002-A-01). Energize the Aircraft Electrical Circuits from the APU

(Ref. 24-41-00-861-002-A-02). Energize the Aircraft Electrical Circuits from Engine 1(2)

(Ref. 24-41-00-862-002-A). De-energize the Aircraft Electrical Circuits Supplied from the External

Power

(Ref. 24-41-00-862-002-A-01). De-energize the Aircraft Electrical Circuits Supplied from the APU

(Ref. 24-41-00-862-002-A-02). De-energize the Aircraft Electrical Circuits Supplied from the Engine

1(2)

(Ref. 27-50-00-866-009-A). Retraction of the Flaps on the Ground

(Ref. 27-50-00-866-009-A-01). Retraction of the Flaps/Slats on the Ground

(Ref. 31-60-00-860-001-A). EIS Start Procedure

(Ref. 31-60-00-860-002-A). EIS Stop Procedure

(Ref. 34-11-15-200-001-A). Inspection/Check of the Pitot Probe

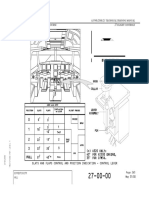

Setting of the AOA Sensor Vane to the High Stop Position SHEET 1

Print Date: March 04, 2019 Page 2 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

A

FR26

FR25

3FP2

Z230 C

A 3FP1

Z120 E B

B

3FP3

HIGH STOP 85 DEG

POSITION

FR24

FR23

UP

E

D

HIGH STOP 85 DEG

C

POSITION

UP

N_MM_342225_5_AAM0_01_01

Figure 34-22-25-991-00800-00-A / SHEET 1/1 - Setting of the AOA Sensor Vane to the High Stop Position

** ON A/C ALL

Print Date: March 04, 2019 Page 3 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

3. Job Set-up

Subtask 34-22-25-860-053-A

A. Energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-861-002) .

Subtask 34-22-25-875-050-A

WARNING: OPEN CIRCUIT BREAKER 7XE. THIS WILL PREVENT A POSSIBLE DEPLOYMENT OF THE

RAT IF THE MAIN AC BUSBARS 1XP AND 2XP BECOME ISOLATED.

B. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

105VU ELEC/CSM/G /EV AUTO/SPLY 7XE C01

122VU ANTI ICE/PROBES/3/PITOT 3DA3 Z16

122VU ANTI ICE/PROBES/3/STATIC 5DA3 Z14

Subtask 34-22-25-865-053-A

C. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

49VU NAV/STBY/INST 5FN F12

** ON A/C ALL

EMB SB 34-1335 for A/C 001-003

105VU NAV/STBY/INST/BAT 23FN J01

** ON A/C ALL

Subtask 34-22-25-420-050-A

D. Connection of the Ground Pressure Generator

(1) Remove the slip on covers from the static probes 7DA3, 8DA3 and the pitot probe 9DA3 of the

standby system.

(2) Connect the PITOT AND STATIC TEST SET (ALT34100001) to one standby static probe with the

ADAPTER COVER-STATIC PORT (98D34003500000) (98D34003500100).

(3) Connect the ground pressure generator to the standby pitot probe with the ADAPTOR-

CHARGING,PITOT PROBE (36122) or ADAPTER-PITOT PROBE (98F34103001000) for Thales

probe, or the ADAPTER-PITOT PROBE (P75701-4C) for Rosemount (Aerospace)/Goodrich probe.

(4) Seal the opposite standby static probe with a piece of plastic (see CAUTION para.(5) below) and with

the COVER-STATIC PROBE (98D10103500001) (98D34003500103).

CAUTION: WHEN YOU SEAL THE DRAIN HOLE IN THE PITOT PROBE, DO NOT SEAL THE

HOLE DIRECTLY WITH THE COLORED ADHESIVE TAPE. ALWAYS PUT A PIECE OF

PLASTIC ON THE HOLE FIRST AND USE THE COLORED ADHESIVE TAPE TO AT-

TACH THE PLASTIC.

IF YOU SEAL THE DRAIN HOLE DIRECTLY WITH THE ADHESIVE TAPE, THERE IS

A RISK THAT SOME OF THE ADHESIVE WILL STAY ON THE HOLE AND COLLECT

PARTICLES. THIS CAN SUBSEQUENTLY CAUSE BLOCKAGE OF THE HOLE AND

THUS INCORRECT OPERATION OF THE PROBE.

Print Date: March 04, 2019 Page 4 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

(5) Seal the drain holes:

Seal the drain holes of the pitot probe with a piece of plastic and/or TAPE - ADHESIVE of very bright

color.

(6) Turn the vane of the AOA sensor 3 to the high stop position.

(Ref. Fig. Setting of the AOA Sensor Vane to the High Stop Position SHEET 1)

Maintain the vane in position with colored adhesive tape.

Subtask 34-22-25-860-067-A

E. Aircraft Maintenance Configuration

(1) Do the EIS start procedure (PFD only) (Ref. AMM TASK 31-60-00-860-001) .

(2) Make sure that the flaps are in the fully retracted position (Ref. AMM TASK 27-50-00-866-009) .

(3) On the ADIRS CDU, set the OFF/NAV/ATT selector switches to NAV.

(4) Start the ground pressure generator.

4. Procedure

Subtask 34-22-25-790-050-A

A. Leak Test

NOTE: You can do the test that follows for a static pressure of 691.4 hPa and an impact pressure of 59

hPa (or a total pressure of 750.4 hPa) but it is not as accurate. On the SWITCHING panel 8VU set

the AIR DATA selector switch to CAPT ON 3 (or F/O ON 3) position. Make sure that:

- The CAPT (or F/O) PFD shows 10 237 ft +/- 30 ft and 190 kts +/- 3 kts

- The ISIS indicator show 10 201 ft +/- 50 ft and airspeed 189 kts +/- 5 kts.

After 5 minutes:

- The change of altitude must not be more than 370 ft

- The change of speed must not be more than 10 Kts.

NOTE: The input parameters for the ground test (speed and altitude) and the values shown on the cockpit

displays are different because of the sum of the tolerances of the air data circuit (ground test unit,

ADMs, ADIRUs).

ACTION RESULT

1.On the center instrument panel 401VU, on the IS- On the bottom of the ISIS indicator screen, the STD

IS indicator: setting comes into view.

· Put the barometric (BARO) selector knob to set

the altitude reference to STD.

2.On the FCU, pull the CAPT (F/O) PULL STD ba- On the PFD, the STD setting comes into view below

rometric setting knob. the altitude scale.

3.On the ground pressure generator:

· Set a static pressure of 455.4 hPa.

· Set an impact pressure of 186.4 hPa (or a total

pressure of 641.8 hPa) (or 320 kts).

· Close the electrovalves to isolate the static and · Make sure that:

pitot circuits of the aircraft from the ground pres- The CAPT (or F/O) PFD shows 21 369 ft +/- 40 ft

sure generator. and 341 kts +/- 3 kts,

The ISIS indicator shows 20 529 ft +/- 85 ft and

329 kts +/- 8 kts.

After 5 minutes, on the ISIS display and on the

CAPT (or F/O) PFD:

Print Date: March 04, 2019 Page 5 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

ACTION RESULT

· Make sure that the change of altitude is not more

than 500 ft.

After 10 minutes:

· Make sure that the change of speed is not more

than 20 Kts.

· Open the electrovalves and slowly balance the The rate of descent must not be more than 6000 ft/

pressure in the standby static and pitot circuits. mn.

5. Close-up

Subtask 34-22-25-020-050-A

A. Removal of the Ground Pressure Generator

(1) Stop the ground pressure generator.

(2) Disconnect the ground pressure generator.

(3) Remove the adaptors from the standby static probe and the standby pitot probe.

(4) Remove the cover from the opposite standby static probe.

(5) Remove the piece of plastic and the colored adhesive tape from the drain holes of the standby pitot

probe.

(6) Remove the colored adhesive tape from the vane of the AOA.

(7) Install the slip on covers on the standby static probes and the standby pitot probe.

Subtask 34-22-25-875-051-A

B. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

105VU ELEC/CSM/G /EV AUTO/SPLY 7XE C01

122VU ANTI ICE/PROBES/3/PITOT 3DA3 Z16

122VU ANTI ICE/PROBES/3/STATIC 5DA3 Z14

Subtask 34-22-25-860-054-A

C. Put the aircraft back to its initial configuration.

(1) On the SWITCHING panel 8VU set the AIR DATA selector switch to NORMAL position.

(2) Do the EIS stop procedure (PFD only) (Ref. AMM TASK 31-60-00-860-002) .

(3) On the ADIRS CDU, set the OFF/NAV/ATT selector switches to OFF.

(4) Do a reset of each ELAC:

· on the panel 49VU, open then close the ELAC1 C/B,

· on the panel 121VU, open then close the ELAC2 C/B.

(5) De-energize the aircraft electrical circuits

(Ref. AMM TASK 24-41-00-862-002) .

(6) Make sure that the work area is clean and clear of tools and other items.

(7) Make sure that the drain holes on the pitot probes are not blocked by unwanted materials

(Ref. AMM TASK 34-11-15-200-001)

Print Date: March 04, 2019 Page 6 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : PIA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : Feb 01, 2019

34-22-25-790-001-A - Low range Leak Test of the Standby Pneumatic circuits

End of document

Print Date: March 04, 2019 Page 7 of 7

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Potrebbero piacerti anche

- Job Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..Documento10 pagineJob Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..billyNessuna valutazione finora

- GVI Brake Units - 32-40-00-210-801-A PDFDocumento4 pagineGVI Brake Units - 32-40-00-210-801-A PDFpannNessuna valutazione finora

- On A/C All: Reference Qty DesignationDocumento7 pagineOn A/C All: Reference Qty DesignationRicardoBillEdwinNessuna valutazione finora

- EfcsDocumento4 pagineEfcsJai DeepNessuna valutazione finora

- ON A/C 051-100: Zone/Access Zone DescriptionDocumento7 pagineON A/C 051-100: Zone/Access Zone DescriptionEder LucianoNessuna valutazione finora

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDa EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireNessuna valutazione finora

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Documento16 pagineService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNessuna valutazione finora

- Offwing Alide InstallDocumento16 pagineOffwing Alide InstallAndreea MăgureanuNessuna valutazione finora

- A330 Easa Tcds A.004 - Issue 50Documento64 pagineA330 Easa Tcds A.004 - Issue 50Pablo CarmonaNessuna valutazione finora

- Brake InspectionDocumento5 pagineBrake InspectionbillyNessuna valutazione finora

- Hydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidDocumento12 pagineHydraulic Systems No. 1 or No. 2 - Fill With Hydraulic FluidaliNessuna valutazione finora

- A320 Fam Air Wing Leaks Spurious WRNDocumento8 pagineA320 Fam Air Wing Leaks Spurious WRNMCC GoairNessuna valutazione finora

- Isi-45.00.00039 01dec2017.p6Documento40 pagineIsi-45.00.00039 01dec2017.p6sithuNessuna valutazione finora

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocumento11 pagineService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNessuna valutazione finora

- Bite Test PDFDocumento3 pagineBite Test PDFbillyNessuna valutazione finora

- Cao 20.7.1BDocumento16 pagineCao 20.7.1BChris BarryNessuna valutazione finora

- LIM LimitationsDocumento152 pagineLIM LimitationsQuynh NguyenNessuna valutazione finora

- 71-00-00-710-004-B - Engine Manual StartDocumento9 pagine71-00-00-710-004-B - Engine Manual StartEder LucianoNessuna valutazione finora

- Airbus Commercial Aircraft AC A320 PDFDocumento399 pagineAirbus Commercial Aircraft AC A320 PDFTania AriasNessuna valutazione finora

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Documento6 pagineAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNessuna valutazione finora

- Alert Service BulletinDocumento94 pagineAlert Service BulletinFrank MasonNessuna valutazione finora

- Master Minimum Equipment List for Bombardier CS100 and CS300 AircraftDocumento364 pagineMaster Minimum Equipment List for Bombardier CS100 and CS300 Aircraftbasem_androidNessuna valutazione finora

- A319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDocumento3 pagineA319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDavid OwenNessuna valutazione finora

- MEL ATR Rev.07 PDFDocumento398 pagineMEL ATR Rev.07 PDFyooghi yahuiNessuna valutazione finora

- JCP TitleDocumento14 pagineJCP Titlebilly100% (1)

- Fin EntryDocumento60 pagineFin EntryPanagiotis DiakidisNessuna valutazione finora

- Exterior Inspection B737-800Documento14 pagineExterior Inspection B737-800Me KeenNessuna valutazione finora

- Airnavx Standalone User GuideDocumento34 pagineAirnavx Standalone User GuideUtku OzdoganNessuna valutazione finora

- 787故障快速处理参考手册R2Documento211 pagine787故障快速处理参考手册R2Chen AndyNessuna valutazione finora

- 32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelDocumento40 pagine32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelalfonsofelipesaraviaNessuna valutazione finora

- Control Pitch, Roll and Yaw Axis of AircraftDocumento49 pagineControl Pitch, Roll and Yaw Axis of AircraftRavi PansheriyaNessuna valutazione finora

- Lopa A330-202 Version 269pax (7T-VJV-JZ) Rev 03Documento1 paginaLopa A330-202 Version 269pax (7T-VJV-JZ) Rev 03Hache HBNessuna valutazione finora

- Advance Trim Balance LEAP 1ADocumento7 pagineAdvance Trim Balance LEAP 1AAbhishekprasad royNessuna valutazione finora

- Air Conditionning System: CB - List - 330 200.xls Sheet1Documento29 pagineAir Conditionning System: CB - List - 330 200.xls Sheet1Sergio SouzaNessuna valutazione finora

- Computer Reset AirbusDocumento10 pagineComputer Reset AirbusAlexander Aguirre Calderón100% (1)

- ATA 05 Limits Maintenance ChecksDocumento51 pagineATA 05 Limits Maintenance ChecksRafael Nuñez100% (1)

- 71-00-00-710-006-B - Minimum Idle CheckDocumento6 pagine71-00-00-710-006-B - Minimum Idle CheckEder LucianoNessuna valutazione finora

- A320-Mel-Cdl-Cdd StatusDocumento18 pagineA320-Mel-Cdl-Cdd StatusvproNessuna valutazione finora

- 343 Rack 800vuDocumento1 pagina343 Rack 800vuMohammad NorouzzadehNessuna valutazione finora

- BTK - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - J. AIDS MCDU FunctionsDocumento44 pagineBTK - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - J. AIDS MCDU FunctionsIrfan05Nessuna valutazione finora

- HP Bleed Valve FaultDocumento9 pagineHP Bleed Valve FaultSuman BajracharyaNessuna valutazione finora

- Airbus A318/A319/A320/A321 General Familiarization Training: (CFM56 & IAE V2500 & PW1100G & CFM LEAP-1A)Documento2 pagineAirbus A318/A319/A320/A321 General Familiarization Training: (CFM56 & IAE V2500 & PW1100G & CFM LEAP-1A)John Emeil Llemit0% (1)

- Fault IsolationDocumento226 pagineFault Isolationfarazh.oneNessuna valutazione finora

- Ignition Starting and Continuous Relight ProceduresDocumento4 pagineIgnition Starting and Continuous Relight ProceduresAndrea StoneNessuna valutazione finora

- A320neo PDFDocumento72 pagineA320neo PDFDinuNessuna valutazione finora

- Emergency Generator TestDocumento4 pagineEmergency Generator TestSarbari SenguptaNessuna valutazione finora

- 737C1 FMC DatasheetDocumento2 pagine737C1 FMC DatasheetLebediyosAsnakeNessuna valutazione finora

- A318/A319/A320/A321: Service BulletinDocumento58 pagineA318/A319/A320/A321: Service BulletinPradeep K sNessuna valutazione finora

- Printed Shannon Chart Valid Until 02 Sep 2021Documento19 paginePrinted Shannon Chart Valid Until 02 Sep 2021Tweed3A100% (1)

- EMBRAER - Proper Use of Deceleration Devices RE Prev PDFDocumento62 pagineEMBRAER - Proper Use of Deceleration Devices RE Prev PDFMambox21Nessuna valutazione finora

- Engine Variant: V2527-A5Documento12 pagineEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Easa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012Documento35 pagineEasa TCDS A.084 - Atr - 42 - Atr - 72 03 17102012mpusNessuna valutazione finora

- Aircraft Tow Bar X PD FDocumento12 pagineAircraft Tow Bar X PD FMohammad Azam100% (1)

- Combined Reset Tables Mod6Documento275 pagineCombined Reset Tables Mod6Sallak IdrisNessuna valutazione finora

- ATR 72-500 Systems Overview SyllabusDocumento2 pagineATR 72-500 Systems Overview SyllabusBENoNessuna valutazione finora

- 24 Electrical PowerDocumento164 pagine24 Electrical PowermarkNessuna valutazione finora

- A320 30 L1 TMDocumento48 pagineA320 30 L1 TMSaman Mahdi Abadi100% (2)

- Memo Items Cards-ATR72-200 Series-Issue1Documento18 pagineMemo Items Cards-ATR72-200 Series-Issue1Abu Zafar Md Shiblee SultanNessuna valutazione finora

- Winsheld PDFDocumento34 pagineWinsheld PDFAnonymous FAa4A3akdNessuna valutazione finora

- Avionics A320 Master Questions: Ata 25 - Equipment/FurnishingsDocumento2 pagineAvionics A320 Master Questions: Ata 25 - Equipment/FurnishingsAhsan AvioniqueNessuna valutazione finora

- A320 Flight Deck and Systems BriefingDocumento223 pagineA320 Flight Deck and Systems Briefingpontoo100% (6)

- Parking and storage FAQs for aircraft maintenanceDocumento19 pagineParking and storage FAQs for aircraft maintenanceAhsan AvioniqueNessuna valutazione finora

- Repeated Defects and Weak AreasDocumento15 pagineRepeated Defects and Weak AreasAhsan AvioniqueNessuna valutazione finora

- 14WN Switch PDFDocumento3 pagine14WN Switch PDFAhsan AvioniqueNessuna valutazione finora

- Airbus FAST55Documento40 pagineAirbus FAST55Suraj SinghNessuna valutazione finora

- Aircraft Electrical Failure Investigation ReportDocumento68 pagineAircraft Electrical Failure Investigation ReportwilliamjotaNessuna valutazione finora

- 11b Critical Task FPLDocumento34 pagine11b Critical Task FPLVerickNessuna valutazione finora

- 14WN Pressure SwitchDocumento5 pagine14WN Pressure SwitchAhsan AvioniqueNessuna valutazione finora

- 14WN Pressure SwitchDocumento5 pagine14WN Pressure SwitchAhsan AvioniqueNessuna valutazione finora

- 14WN Pressure SwitchDocumento5 pagine14WN Pressure SwitchAhsan AvioniqueNessuna valutazione finora

- MOE Issue 02 Rev 00 Feb 2016Documento246 pagineMOE Issue 02 Rev 00 Feb 2016alirezaghasemibarzegar1376100% (1)

- Chapter 62 - Main Rotor: BHT-412-CR&O-3Documento194 pagineChapter 62 - Main Rotor: BHT-412-CR&O-3252nd PAS100% (1)

- Poh Cherokee 28 140 PDFDocumento144 paginePoh Cherokee 28 140 PDFYeison ChavezNessuna valutazione finora

- Data Consistency Check - PDMS Macro PDFDocumento8 pagineData Consistency Check - PDMS Macro PDFLOKESHNessuna valutazione finora

- Type-Certificate Data Sheet: No. EASA - IM.A.526Documento21 pagineType-Certificate Data Sheet: No. EASA - IM.A.526Jonnathan LudeñaNessuna valutazione finora

- PC 753-816Documento431 paginePC 753-816adi100% (1)

- Module 11 CompleteDocumento1.227 pagineModule 11 CompleteHADNASIRI91% (44)

- ENR 2.1-31 AIP South AfricaDocumento2 pagineENR 2.1-31 AIP South AfricaKHUSHAL BANSALNessuna valutazione finora

- Status Report Cessna 180Documento7 pagineStatus Report Cessna 180cristian ledesmaNessuna valutazione finora

- Ata 21Documento32 pagineAta 21Nikolay RomadanovNessuna valutazione finora

- Aircraft Information: Pipistrel Alpha ElectroDocumento23 pagineAircraft Information: Pipistrel Alpha Electrocarlos castroNessuna valutazione finora

- Service Kit: Single EngineDocumento11 pagineService Kit: Single EngineKamal Jit DhimanNessuna valutazione finora

- Maintenance Manual PDFDocumento624 pagineMaintenance Manual PDFSantiago AlthabeNessuna valutazione finora

- Ad 80-19-01Documento3 pagineAd 80-19-01Yarisa VangeNessuna valutazione finora

- Chapter - 01 AIRCRAFT GENERALDocumento544 pagineChapter - 01 AIRCRAFT GENERALdavid ramirezNessuna valutazione finora

- Best Maintenance Practices For Redundant SystemsDocumento7 pagineBest Maintenance Practices For Redundant Systemstrankhanhstock2019Nessuna valutazione finora

- EASA-OEB-Jetprop LLC Piper (PA - 46 Jetprop DLX) - 28062012Documento10 pagineEASA-OEB-Jetprop LLC Piper (PA - 46 Jetprop DLX) - 28062012M052221Nessuna valutazione finora

- Annex I to ED Decision 2016/011/R Acceptable Means of Compliance (AMC) and Guidance Material (GM) to Annex I (PART-M) to Commission Regulation (EU) No 1321/2014Documento117 pagineAnnex I to ED Decision 2016/011/R Acceptable Means of Compliance (AMC) and Guidance Material (GM) to Annex I (PART-M) to Commission Regulation (EU) No 1321/2014Karol PolaczekNessuna valutazione finora

- ATR Systems Supp - Auto FlightDocumento20 pagineATR Systems Supp - Auto FlightslsalescoNessuna valutazione finora

- Merchant Ship Construction - D. A. TaylorDocumento125 pagineMerchant Ship Construction - D. A. TaylorAmar Shyam Ahuja100% (9)

- Sea Horizon - Vessel Specifications - Rv3-18-Aug-21Documento3 pagineSea Horizon - Vessel Specifications - Rv3-18-Aug-21Ibinabo ImabiboNessuna valutazione finora

- © 2009 Cessna Aircraft CompanyDocumento15 pagine© 2009 Cessna Aircraft CompanyAntonio CorteNessuna valutazione finora

- Doc. No. 4 - AMDocumento17 pagineDoc. No. 4 - AMDanutirta ChrisraftianoNalaraka'19Nessuna valutazione finora

- INTRODUCTION TO SHIPHANDLINGDocumento60 pagineINTRODUCTION TO SHIPHANDLINGsnhz555100% (1)

- Articles Powxags2 Manuals 03-Powx0614-EnDocumento10 pagineArticles Powxags2 Manuals 03-Powx0614-EnHewa PCNessuna valutazione finora

- ATR72-AIRCRAFT MAINTENANCE MANUAL - Description/Operation: Printed in FranceDocumento4 pagineATR72-AIRCRAFT MAINTENANCE MANUAL - Description/Operation: Printed in FranceJuan TorresNessuna valutazione finora

- Instruccion Conversion EFI T53-160 Review DraftDocumento24 pagineInstruccion Conversion EFI T53-160 Review DraftLucas EloyNessuna valutazione finora

- Removal v2500Documento32 pagineRemoval v2500Magureanu ValeriuNessuna valutazione finora

- D1 P3 Go Around Performance Certification Vs Operations Paya ArnaudDocumento54 pagineD1 P3 Go Around Performance Certification Vs Operations Paya ArnaudTsambikos VarelisNessuna valutazione finora

- Honda HA420 HondaJet Pilot Operating ManualDocumento408 pagineHonda HA420 HondaJet Pilot Operating ManualVincent Lefeuvre100% (2)