Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Zeze 7&aal. 37e/arz.: No. 405,068, Patented June 11, 1889

Caricato da

Daniel Goff0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni3 pagineJ Arkel Patent

Titolo originale

Us 405068

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoJ Arkel Patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni3 pagineZeze 7&aal. 37e/arz.: No. 405,068, Patented June 11, 1889

Caricato da

Daniel GoffJ Arkel Patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

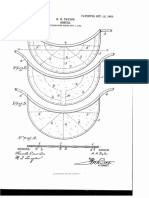

(No Model.

)

J. ARKELL.

... SOFT TIE PAPER BAG.

No. 405,068, Patented June 11, 1889

FIG.3

rt

AT TEST w

Zeze 7&aal. 37e/arz.

photo-Lithographer, Washington, D.C.

UNITED STATES PATENT OFFICE.

JAMES ARKELL, OF CANAJOHARIE, NEW YORK, ASSIGNOR TO SARAH HALL

ARKELL OF SAME PLACE.

SOFT-TIE PAPER BAG.

SPECIFICATION forming part of Letters Patent No. 405,068, dated June 11, 1889.

Application filed February 27, 1889, Serial No. 301,370, (No model.)

To all willion it may concern: making a soft-tie paper bag with the crimped

Beit known that I, JAMES ARKELL, of Cana portion of the stock provided with a series of

joharie, in the county of Montgomery and much finer corrugations than heretofore used,

State of New York, have invented a new and indentations about equal in depth to the

useful Improved Bag or Sack; and I do here thickness of the paper of which the bag may 55

by declare that the following is a full, clear, be made, and that by subjecting the paper to

and exact description thereof, reference be a greater degree of pressure while being thus

ing had to the accompanying drawings, mak crimped than it is possible to subject the

ing part of this application. fabric to, without tearing it, while produc

O My present invention relates to the type of ing deeper flutes, a soft-tie device is produced 6o

manufacture known in the art as the “soft far superior to any heretofore made, and to

tie ' paper bag or sack patented on the 6th provide for general use such better article is

day of June, 1865, No. 48,036, to Arkell and the main object of my invention, which to

Smith, and has for its main object to improve this end may be said to consist, essentially,

this kind of paper bag. in a soft-tie paper bag or sack having the 65

In what is known as the “soft-tie' paper crimped portion of the article made With cor

bag the paper in the vicinity of the mouth or rugations or indentations of a depth. Sub

Open end of the sack is deprived of its natu stantially equal to the thickness of the paper

ral Stiffness, and thus rendered eapable of be of which the bag may be made, all as will be

ing more readily compacted or gathered to hereinafter more fully explained, and as Will 7 O

gether within the binding cord or string by be more distinctly pointed out in the claim of

which the mouth end or portion of the filled this specification.

sack is tied up, after the same fashion in which To enable those skilled in the art to which

Cotton or other textile fabric sacks altese my improvement pertains to make and use

Cllred against escape of the contents; but in soft-tie paper bags according to my invention, 75

this kind of bag as heretofore made that por I will now proceed to more fully explain the

tion of the paper thus rendered more pliable latter, referring by letters to the accompany

for the purpose mentioned has been softened ing drawings, which form part of this specifi

by Subjecting it to a crimping or fluting op cation, and in which I have shown my inven

3O eration between rolls which operated to pro tion carried into effect in the precise manner 8o

duce comparatively deep flutes or corruga in which I have so far practiced it.

tions at the vicinity at which the paper has In the drawings, Figure 1 is a face view or

to be gathered together and bound around or elevation of a soft-tie bag in a flattened con

tied up with the securing-string. It has been dition and made substantially as such bags

35 customary, it is true, for many years in the have been made for years and are now sold in 85

manufacture of the soft-tie paper bag to have the market. Fig. 2 is a detail section at a ac,

the crimping-rolls so made and the treatment Fig. 1, but showing only one ply. Fig. 3 is a

of the paper by them such that the crimps or similar view of a flattened paper bag of the

corrugations in the bag were of less depth at the same size and made of the same paper, but

vicinity of the ends nearer the body portion of having my improved soft-tie device. Fig. 4. 9o

the bag, or, in other words, were tapered off to is a detail section at y i?, Fig. 3, showing only

nothing in depth at these ends; but the only one ply. Fig. 5 is a perspective view of the

object and effect of this peculiarity were to bag seen at Fig. 3, but filled and tied up se

avoid any abrupt and injurious terminations curely.

45 on the body portion of the bag of these crimps As will be seen by reference to Fig. 1, (and 95

and to effect the gradual tapering off of the as well understood by those skilled in the art,.)

softened or readily collapsible portion of the the corrugations or crimps of the old-fashioned

bag into the stiff body portion of the latter. soft tie are of a depth equal to ten or more

I have discovered and have verified through times the thickness of the paper, while those

a course of tests and experiments that by of my improved soft tie are made of a depth IOO

2. 405,068

preferably not greater than the thickness of ing the paper. Therefore in a practical point 35

the fabric. of view the Soft tie shown at Figs. 3, 4, and 5,

In Figs, 3, 4, and 5 the crimps fare made as produced (as all such mechanical softening of

narrow as it may be practicable to form the cor the paper must be produced) by the passage

5 rugations by the action of rolls having their of the fabric of the bag between fluted roll

peripheries fluted lengthwise, and the corru ers under pressure, differs not merely in de

gating action to which the paper is subjected gree (or merely as to the size of its crimps)

is such as to exert much more pressure on the from the old-fashioned soft tie, but is differ

stock of the fabric than is possible in the case ent in kind, since by the severe pressure

Io of making the old-fashioned kind of crimps, treatment (impossible in the case of deep cor

(seen at Fig. 1) and hence instead of obtain rugations) a different effect in the paper is

ing only the softening or crimping effects produced and an improvement in the char

acter or qualities of the manufactured article

gained in the old-fashioned form of soft tie I attained.

gain the further advantage due to the break Having now so fully explained the charac

I5 ing up of the combined pulp fiber and size of ter and advantages of my improvement that

the fabric that results from this excessive

creasing pressure on the paper, and this fur those skilled in the art can understand and

ther advantage I gain without diminishing practice my invention, what I claim as new,

either the tensile strength or the toughness and desire to secure by Letters Patent, is

2O of the paper. The improved soft-tie paper bag hereinbe

In making the old-fashioned soft tie the size fore described, the mouth end or portion of

or depth of the corrugations was such that it which has compressed corrugations or crimps

was practically impossible to run the stock of a depth about equal to the thickness of

through the fluting-rolls under very much the paper, whereby said mouth end or portion

compression of the fabric, since under much is softened without detriment to the strength

pressure (as will be easily understood) the of the fabric, all substantially as hereinbefore

paper, being gathered into so great an extent set forth.

and being non-stretchable, would inevitably In witness whereof I have hereunto set my

tear during its passage between the rolls; but hand this 28th day of January, 1889.

3o in the making of the crimps of the character JAMES ARKEII.

seen at Figs. 3, 4, and 5 the stock may be sub

jected to severe pressure, and thus the fiber In presence of

and stiffening of the fabric may be more com E. B. BURNAP,

pletely softened without any danger of tear JAS. D. MICDIARMID.

--ali

Potrebbero piacerti anche

- 1955 - Patente - Velvet Type Fabric and Method of Producing SameDocumento3 pagine1955 - Patente - Velvet Type Fabric and Method of Producing SamePaulo De Melo MacedoNessuna valutazione finora

- Ambalaje 3Documento5 pagineAmbalaje 3Cristina AlexandraNessuna valutazione finora

- Scott & Williams, Inc. v. Lasticnit Co., Inc, 186 F.2d 416, 1st Cir. (1951)Documento5 pagineScott & Williams, Inc. v. Lasticnit Co., Inc, 186 F.2d 416, 1st Cir. (1951)Scribd Government DocsNessuna valutazione finora

- NEWBOOKBINDER Alternative BookstructureDocumento4 pagineNEWBOOKBINDER Alternative BookstructurePatricia WayarNessuna valutazione finora

- A Bookbinder's Guide to Sewing - A Selection of Classic Articles on the Methods and Equipment of BookbindingDa EverandA Bookbinder's Guide to Sewing - A Selection of Classic Articles on the Methods and Equipment of BookbindingNessuna valutazione finora

- Mechanics 4 Young America 1910Documento129 pagineMechanics 4 Young America 1910filipe01976100% (1)

- 3.4 E6.4-Tavre 22 Foz: W. Z. W. ChapmanDocumento2 pagine3.4 E6.4-Tavre 22 Foz: W. Z. W. ChapmanJagannathan ArumugamNessuna valutazione finora

- Folding MachineDocumento5 pagineFolding MachineShubhamNessuna valutazione finora

- Filed March 3, 1941: Apparatus For Making Hollow Rubber ArticlesDocumento3 pagineFiled March 3, 1941: Apparatus For Making Hollow Rubber ArticlesAnonymous A4K7XMfNessuna valutazione finora

- 42ace (Us: 1,110,487. E-Patented Sept, 15, 1914Documento3 pagine42ace (Us: 1,110,487. E-Patented Sept, 15, 1914MURALIPRAKASH.S 18BIT131Nessuna valutazione finora

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Documento3 pagineQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNessuna valutazione finora

- US741184Documento3 pagineUS741184Katrin MoragNessuna valutazione finora

- July 9, 1929. O, Becker 1,719,961: Filed June'5. 1926 ' - Beets-Sheet 1Documento11 pagineJuly 9, 1929. O, Becker 1,719,961: Filed June'5. 1926 ' - Beets-Sheet 1Andrei PoseaNessuna valutazione finora

- Us465588 PDFDocumento2 pagineUs465588 PDFEmmanuel Avalos HuarteNessuna valutazione finora

- Facts for Everybody: An Encyclopædia of Useful KnowledgeDa EverandFacts for Everybody: An Encyclopædia of Useful KnowledgeNessuna valutazione finora

- Merit Mfg. Co. v. Hero Mfg. Co., Inc. Merit Mfg. Co. v. Schreiner, 185 F.2d 350, 2d Cir. (1950)Documento4 pagineMerit Mfg. Co. v. Hero Mfg. Co., Inc. Merit Mfg. Co. v. Schreiner, 185 F.2d 350, 2d Cir. (1950)Scribd Government DocsNessuna valutazione finora

- Detective CameraDocumento3 pagineDetective CameraAndrei PoseaNessuna valutazione finora

- Basketmaking 00 MorsDocumento44 pagineBasketmaking 00 MorsAmandeep SinghNessuna valutazione finora

- Bookbinding, and the Care of Books: A Handbook for Amateurs, Bookbinders & LibrariansDa EverandBookbinding, and the Care of Books: A Handbook for Amateurs, Bookbinders & LibrariansNessuna valutazione finora

- 1706 09883 PDFDocumento14 pagine1706 09883 PDFterawNessuna valutazione finora

- Camera ProjectDocumento3 pagineCamera ProjectAndrei PoseaNessuna valutazione finora

- The Quarter-Joint Case and Its Potential As A Conservation Binding PDFDocumento3 pagineThe Quarter-Joint Case and Its Potential As A Conservation Binding PDFCibele AndradeNessuna valutazione finora

- Movement of The Book Spine, Tom ConroyDocumento79 pagineMovement of The Book Spine, Tom ConroyKevin ShebyNessuna valutazione finora

- US3253969Documento4 pagineUS3253969Sebastian GonzalezNessuna valutazione finora

- Diamond International Corporation, A Corporation of Delaware v. Maryland Fresh Eggs, Inc., A Corporation of Maryland, 523 F.2d 113, 4th Cir. (1975)Documento8 pagineDiamond International Corporation, A Corporation of Delaware v. Maryland Fresh Eggs, Inc., A Corporation of Maryland, 523 F.2d 113, 4th Cir. (1975)Scribd Government DocsNessuna valutazione finora

- Us4171605 PDFDocumento13 pagineUs4171605 PDFkartikkeyyanNessuna valutazione finora

- United States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605Documento13 pagineUnited States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605kartikkeyyanNessuna valutazione finora

- Us3320883 PDFDocumento3 pagineUs3320883 PDFchecolonoskiNessuna valutazione finora

- Bergeron On Flute-MakingDocumento11 pagineBergeron On Flute-MakingAnton StylesNessuna valutazione finora

- US2126921Documento5 pagineUS2126921Jhonnatan E Avendaño Florez100% (1)

- Re. 25,363 April 2, 1963: Original Filled Oct. 27, 1961Documento4 pagineRe. 25,363 April 2, 1963: Original Filled Oct. 27, 1961francisco perezNessuna valutazione finora

- Knots, Splices and Rope-Work: An Illustrated HandbookDa EverandKnots, Splices and Rope-Work: An Illustrated HandbookValutazione: 3.5 su 5 stelle3.5/5 (6)

- مهمDocumento7 pagineمهمAmany ElsaeedNessuna valutazione finora

- United States Patent (19) : Jul. 5, 1977 (JP Japan .................................. 52-79532Documento8 pagineUnited States Patent (19) : Jul. 5, 1977 (JP Japan .................................. 52-79532Andrew StarkNessuna valutazione finora

- Nov. 27, 1934. - H. E. Peterson 1,982,142: ' ?Enrgepel'Ens'OhDocumento4 pagineNov. 27, 1934. - H. E. Peterson 1,982,142: ' ?Enrgepel'Ens'OhJorge MartinezNessuna valutazione finora

- US4483464Documento6 pagineUS4483464Joao LemesNessuna valutazione finora

- BY Javé C L They: Aug. 10, 1965 S.B. Maerov Etal 3,199,281Documento13 pagineBY Javé C L They: Aug. 10, 1965 S.B. Maerov Etal 3,199,281Thuận LêNessuna valutazione finora

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Documento3 pagineDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891Nessuna valutazione finora

- June 17, 1952 P. A. Derham 2,601,101: y Philip A. DerhanDocumento7 pagineJune 17, 1952 P. A. Derham 2,601,101: y Philip A. DerhanJagannathan ArumugamNessuna valutazione finora

- Practical Taxidermy A manual of instruction to the amateur in collecting, preserving, and setting up natural history specimens of all kinds. To which is added a chapter upon the pictorial arrangement of museums. With additional instructions in modelling and artistic taxidermy.Da EverandPractical Taxidermy A manual of instruction to the amateur in collecting, preserving, and setting up natural history specimens of all kinds. To which is added a chapter upon the pictorial arrangement of museums. With additional instructions in modelling and artistic taxidermy.Nessuna valutazione finora

- 史东门箱包制作Ⅰ手工皮革艺术leather+caseDocumento118 pagine史东门箱包制作Ⅰ手工皮革艺术leather+caseBonanza Chan100% (18)

- Us 60951Documento2 pagineUs 60951asdfasfNessuna valutazione finora

- Us2511005 PDFDocumento2 pagineUs2511005 PDFchecolonoskiNessuna valutazione finora

- Research Report - RBD PDFDocumento3 pagineResearch Report - RBD PDFJaime WhiteNessuna valutazione finora

- Sept. 20, 1971 H. J. Girard 3,605,159: Pipe Line Pig or SwipeDocumento5 pagineSept. 20, 1971 H. J. Girard 3,605,159: Pipe Line Pig or SwipeOngollo RegisNessuna valutazione finora

- History and Practice of Photogenic Drawing on the True Principles of the Daguerreotype, with the New Method of Dioramic Painting: Secrets Purchased By The French Government, And By Their Command Published For The Benefit Of The Arts And ManufacturesDa EverandHistory and Practice of Photogenic Drawing on the True Principles of the Daguerreotype, with the New Method of Dioramic Painting: Secrets Purchased By The French Government, And By Their Command Published For The Benefit Of The Arts And ManufacturesNessuna valutazione finora

- Nov. 4, 1969 R. Norton: Original Filed May 19, 1965Documento8 pagineNov. 4, 1969 R. Norton: Original Filed May 19, 1965Malik AtikNessuna valutazione finora

- 4in Color Wstrobe ReportsDocumento3 pagine4in Color Wstrobe Reportskrstas774Nessuna valutazione finora

- Luva de CouroDocumento6 pagineLuva de CouroGabriel AlvesNessuna valutazione finora

- Handling Recommendations For Paper SacksDocumento6 pagineHandling Recommendations For Paper SacksDaniel GoffNessuna valutazione finora

- Advantage Semi ExtensibleDocumento2 pagineAdvantage Semi ExtensibleDaniel GoffNessuna valutazione finora

- Quickfill White Se: White Sack Kraft PaperDocumento1 paginaQuickfill White Se: White Sack Kraft PaperDaniel GoffNessuna valutazione finora

- T494Documento28 pagineT494FERNANDO VALERA RUIZNessuna valutazione finora

- Digital Pasting and Conventional PastingDocumento5 pagineDigital Pasting and Conventional PastingDaniel GoffNessuna valutazione finora

- T494Documento28 pagineT494FERNANDO VALERA RUIZNessuna valutazione finora

- Mondi Advantage Kraft PaperDocumento2 pagineMondi Advantage Kraft PaperDaniel GoffNessuna valutazione finora

- Paper and Board Manufacture and Properties WorkshopDocumento99 paginePaper and Board Manufacture and Properties WorkshopDaniel GoffNessuna valutazione finora

- A Method For Preparing Extensible Paper On The Laboratory ScaleDocumento6 pagineA Method For Preparing Extensible Paper On The Laboratory ScaleDaniel GoffNessuna valutazione finora

- Sack Kraft PaperDocumento8 pagineSack Kraft PaperDaniel GoffNessuna valutazione finora

- Essence: V I I I: RhythmDocumento4 pagineEssence: V I I I: RhythmDaniel GoffNessuna valutazione finora

- Horvath Gaal 15Documento9 pagineHorvath Gaal 15Daniel GoffNessuna valutazione finora

- T494Documento28 pagineT494FERNANDO VALERA RUIZNessuna valutazione finora

- The Role of Product Design in Product Related Consumer JudgementsDocumento222 pagineThe Role of Product Design in Product Related Consumer JudgementsDaniel GoffNessuna valutazione finora

- The Role of Product Design in Product Related Consumer JudgementsDocumento222 pagineThe Role of Product Design in Product Related Consumer JudgementsDaniel GoffNessuna valutazione finora

- T494Documento28 pagineT494FERNANDO VALERA RUIZNessuna valutazione finora

- Work Rhythm, Flow and Success in A ProjectDocumento91 pagineWork Rhythm, Flow and Success in A ProjectDaniel GoffNessuna valutazione finora

- Designing For Product Success PDFDocumento17 pagineDesigning For Product Success PDFDaniel GoffNessuna valutazione finora

- Synch With Me SpillersDocumento17 pagineSynch With Me SpillersDaniel GoffNessuna valutazione finora

- 22 Rhythm JFoARDocumento6 pagine22 Rhythm JFoARDaniel GoffNessuna valutazione finora

- Volvo V50 Owners Manual 2006Documento234 pagineVolvo V50 Owners Manual 2006Daniel GoffNessuna valutazione finora

- Art - StudioArts - Elements - Principles - ResourceDocumento3 pagineArt - StudioArts - Elements - Principles - ResourceDaniel GoffNessuna valutazione finora

- Visual RhythmDocumento29 pagineVisual RhythmDaniel Goff100% (1)

- Package Design: Colour Harmony and Consumer ExpectationsDocumento18 paginePackage Design: Colour Harmony and Consumer ExpectationsDaniel GoffNessuna valutazione finora

- Visual Tension in Graphic DesignDocumento43 pagineVisual Tension in Graphic DesignDaniel GoffNessuna valutazione finora

- 2012 Parry and Skala - David Best On Rhy PDFDocumento9 pagine2012 Parry and Skala - David Best On Rhy PDFDaniel GoffNessuna valutazione finora

- Published-Pdf-0140-6-Reviewing Visual Elements of Rhythm, Balance and Movement of Forms and Motifs in Filigree Work of Zanjan PDFDocumento9 paginePublished-Pdf-0140-6-Reviewing Visual Elements of Rhythm, Balance and Movement of Forms and Motifs in Filigree Work of Zanjan PDFDaniel GoffNessuna valutazione finora

- Visual MerchandisingDocumento68 pagineVisual Merchandisingjavier731480% (5)

- Designing For Product SuccessDocumento17 pagineDesigning For Product SuccessDaniel GoffNessuna valutazione finora

- Medical Malpractice Claim FormDocumento2 pagineMedical Malpractice Claim Formq747cxmgc8Nessuna valutazione finora

- 031 Barrameda Vs MoirDocumento2 pagine031 Barrameda Vs MoirTaz Tanggol Tabao-Sumpingan100% (2)

- Sinif Matemati̇k Eşli̇k Ve Benzerli̇k Test PDF 2Documento1 paginaSinif Matemati̇k Eşli̇k Ve Benzerli̇k Test PDF 2zboroglu07Nessuna valutazione finora

- Water Quality Categorization Using WQI in Rural Areas of Haridwar, IndiaDocumento16 pagineWater Quality Categorization Using WQI in Rural Areas of Haridwar, IndiaESSENCE - International Journal for Environmental Rehabilitation and ConservaionNessuna valutazione finora

- RIBA WorkstagesDocumento1 paginaRIBA WorkstagesCong TranNessuna valutazione finora

- Ratio AnalysisDocumento36 pagineRatio AnalysisHARVENDRA9022 SINGHNessuna valutazione finora

- Icici Marketing Strategy of Icici BankDocumento68 pagineIcici Marketing Strategy of Icici BankShilpi KumariNessuna valutazione finora

- Romans 12 (1 2) What Is True WorshipDocumento4 pagineRomans 12 (1 2) What Is True Worshipapi-249086759100% (1)

- Mathematical Solutions - Part ADocumento363 pagineMathematical Solutions - Part ABikash ThapaNessuna valutazione finora

- In The Supreme Court of India Criminal Appellate JurisdictionDocumento8 pagineIn The Supreme Court of India Criminal Appellate JurisdictionSheetalNessuna valutazione finora

- Housing LawsDocumento114 pagineHousing LawsAlvin Clari100% (2)

- Sample of Notarial WillDocumento3 pagineSample of Notarial WillJF Dan100% (1)

- April, 2020 DOM: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 712282339453Documento1 paginaApril, 2020 DOM: Customer Number: Billing Month: Tariff/Customer Class: Bill ID: 712282339453maazraza123Nessuna valutazione finora

- Conflict Management HandbookDocumento193 pagineConflict Management HandbookGuillermo FigueroaNessuna valutazione finora

- Petitioner FinalDocumento20 paginePetitioner FinalAdv AAkanksha ChopraNessuna valutazione finora

- George F. Nafziger, Mark W. Walton-Islam at War - A History - Praeger (2008)Documento288 pagineGeorge F. Nafziger, Mark W. Walton-Islam at War - A History - Praeger (2008)موسى رجب100% (2)

- Deed of Real Estate MortgageDocumento6 pagineDeed of Real Estate MortgageCristopher ReyesNessuna valutazione finora

- United States Court of Appeals, Third CircuitDocumento25 pagineUnited States Court of Appeals, Third CircuitScribd Government DocsNessuna valutazione finora

- 02 Ching Kian Chuan v. CADocumento2 pagine02 Ching Kian Chuan v. CACarissa Bonifacio100% (2)

- CloverfieldDocumento1 paginaCloverfieldKaran HanamanNessuna valutazione finora

- Solved Problems in Compound InterestDocumento3 pagineSolved Problems in Compound Interestjaine ylevreb100% (1)

- Trellick Tower PresentationDocumento2 pagineTrellick Tower PresentationCheryl Ng100% (1)

- 5000 English Frequency WordsDocumento234 pagine5000 English Frequency WordsAlice Turnbull100% (1)

- Hacienda Luisita Inc. (HLI) v. Presidential Agrarian Reform CDocumento5 pagineHacienda Luisita Inc. (HLI) v. Presidential Agrarian Reform CJetJuárezNessuna valutazione finora

- Compiled Case Digest For Criminal LawDocumento54 pagineCompiled Case Digest For Criminal LawMicah Clark-Malinao100% (7)

- Strategic Litigation Impacts, Insight From Global ExperienceDocumento144 pagineStrategic Litigation Impacts, Insight From Global ExperienceDhanil Al-GhifaryNessuna valutazione finora

- DL Services GhashyamDocumento2 pagineDL Services GhashyamGhanshyam ChaudharyNessuna valutazione finora

- Answerkey PDFDocumento9 pagineAnswerkey PDFParas MalhotraNessuna valutazione finora

- Fireworks 1 PDFDocumento6 pagineFireworks 1 PDFDali MondalNessuna valutazione finora

- Indian Exhibition Industry Association (IEIA)Documento6 pagineIndian Exhibition Industry Association (IEIA)Anurag KanaujiaNessuna valutazione finora