Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NZS 3101-06 RC-SL-001

Caricato da

renzo1221Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NZS 3101-06 RC-SL-001

Caricato da

renzo1221Copyright:

Formati disponibili

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE NZS 3101-06 RC-SL-001

Slab Flexural Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab flexural design in SAFE.

A one-way, simple-span slab supported by walls on two opposite edges is

modeled using SAFE. The slab is 150 mm thick and spans 4 meters between

walls. To ensure one-way action, Poisson’s ratio is taken to be zero. The slab is

modeled using thin plate elements. The walls are modeled as line supports

without rotational stiffnesses and with very large vertical stiffness (11015

kN/m). The computational model uses a finite element mesh, automatically

generated by SAFE. The maximum element size is specified as 1.0 meter. To

obtain factored moments and flexural reinforcement in a design strip, one 1-

meter-wide strip is defined in the X-direction on the slab, as shown in Figure 1.

Simply

Simply

4 m span supported

supported

edge at wall

edge at wall

Free edge

Y 1 m design strip

X Free edge

Figure 1 Plan View of One-Way Slab

One dead load case (DL4KPa) and one live load case (LL5KPa) with uniformly

distributed surface loads of magnitudes 4 and 5 kN/m2, respectively, are defined

in the model. A load combination (COMB5kPa) is defined using the NZS 3101-

06 load combination factors, 1.2 for dead loads and 1.5 for live loads. The model

is analyzed for both load cases and the load combination.

The slab moment on a strip of unit width is computed analytically. The total

factored strip moments are compared with the SAFE results. After completing

analysis, design is performed using the NZS 3101-06 code by SAFE and also by

hand computation. Table 1 shows the comparison of the design reinforcements

computed using the two methods.

EXAMPLE NZS 3101-06 RC-SL-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

GEOMETRY, PROPERTIES AND LOADING

Thickness T, h = 150 mm

Depth of tensile reinf. dc = 25 mm

Effective depth d = 125 mm

Clear span ln, l1 = 4000 mm

Concrete strength fc = 30 MPa

Yield strength of steel fsy = 460 MPa

Concrete unit weight wc = 0 N/m3

Modulus of elasticity Ec = 25000 MPa

Modulus of elasticity Es = 2106 MPa

Poisson’s ratio = 0

Dead load wd = 4.0 kPa

Live load wl = 5.0 kPa

TECHNICAL FEATURES OF SAFE TESTED

Calculation of flexural reinforcement

Application of minimum flexural reinforcement

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments in the design

strip with the moments obtained by the hand computation method. Table 1 also

shows the comparison of design reinforcements.

Table 1 Comparison of Design Moments and Reinforcements

Reinforcement Area

Strip (sq-cm)

Load Moment

Level Method (kN-m) As+

SAFE 24.597 5.238

Medium

Calculated 24.6 5.238

A s ,min = 380.43 sq-mm

EXAMPLE NZS 3101-06 RC-SL-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

COMPUTER FILE: NZS 3101-06 RC-SL-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE NZS 3101-06 RC-SL-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

HAND CALCULATION

The following quantities are computed for the load combination:

b = 0.85

b = 1000 mm

1 0.85 for f c 55MPa

1 0.85 for f c 30,

c

cb d = 70.7547

c f y Es

amax = 0.751cb= 45.106 mm

For the load combination, w and M* are calculated as follows:

w = (1.2wd + 1.5wt) b

wl12

Mu

8

f c

bw d 372.09 sq-mm

4 fy

As ,min max

1.4 bw d 380.43 sq-mm

fy

= 380.43 sq-mm

COMB100

wd = 4.0 kPa

wt = 5.0 kPa

w = 12.3 kN/m

M*-strip = 24.6 kN-m

M*-design = 24.6331 kN-m

The depth of the compression block is given by:

2 M*

ad d 2

= 9.449 mm < amax

1 f c bb

EXAMPLE NZS 3101-06 RC-SL-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

The area of tensile steel reinforcement is then given by:

M*

As = 523.799 sq-mm > As,min

a

b f y d

2

As = 5.238 sq-cm

EXAMPLE NZS 3101-06 RC-SL-001 - 5

Potrebbero piacerti anche

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- NZS 3101-06 RC-BM-001Documento7 pagineNZS 3101-06 RC-BM-001renzo1221Nessuna valutazione finora

- NZS 3101-06 RC-PN-001 PDFDocumento6 pagineNZS 3101-06 RC-PN-001 PDFHaytham ZaghloulNessuna valutazione finora

- NZS 3101-2006 Example 001Documento8 pagineNZS 3101-2006 Example 001RMM100% (1)

- Inverted-T Bent Cap Calculations V1Documento20 pagineInverted-T Bent Cap Calculations V1satyaNessuna valutazione finora

- Methodolgy A Nonlinear Analysis Method For Performance Based Seismic Design (1) - NewDocumento8 pagineMethodolgy A Nonlinear Analysis Method For Performance Based Seismic Design (1) - Newsalmantop1Nessuna valutazione finora

- Analysis and Design of Hollow Reinforced Concrete ColumnsDocumento5 pagineAnalysis and Design of Hollow Reinforced Concrete ColumnsEditor IJRITCC100% (1)

- Seismic Performance PresentationDocumento993 pagineSeismic Performance PresentationJuan Carlos Donayre Salas100% (2)

- Steel Ch4 - Beams MoviesDocumento80 pagineSteel Ch4 - Beams Moviesomar45Nessuna valutazione finora

- CE 581 Reinforced Concrete StructuresDocumento82 pagineCE 581 Reinforced Concrete StructuresCelil OrakNessuna valutazione finora

- Floor Vibrations: Steel Industry Guidance NotesDocumento2 pagineFloor Vibrations: Steel Industry Guidance NotesTitas JegorovasNessuna valutazione finora

- ADAPT TN290 Vibration AnalysisDocumento20 pagineADAPT TN290 Vibration AnalysisMai KawayapanikNessuna valutazione finora

- ADAPT TN290 Vibration AnalysisDocumento20 pagineADAPT TN290 Vibration AnalysisNanthakumarNessuna valutazione finora

- Assignment #4Documento2 pagineAssignment #4Aly Arquillano JrNessuna valutazione finora

- Effects of Column Creep and Shrinkage in Tall StructuresDocumento3 pagineEffects of Column Creep and Shrinkage in Tall StructuresMagellan ChiritescuNessuna valutazione finora

- Capacity Spectrum MethodDocumento8 pagineCapacity Spectrum MethodJashwin UllalNessuna valutazione finora

- Precast Frame - 5 Floor DiaphragmsDocumento15 paginePrecast Frame - 5 Floor DiaphragmsWahid OmarNessuna valutazione finora

- Steel Ch3 - Columns MovieDocumento60 pagineSteel Ch3 - Columns Movieomar45Nessuna valutazione finora

- 9.7 Vibration in Concrete Structures: PCI Design Handbook/Sixth Edition First Printing/CD-ROM EditionDocumento9 pagine9.7 Vibration in Concrete Structures: PCI Design Handbook/Sixth Edition First Printing/CD-ROM Editionomar42170Nessuna valutazione finora

- Comparative Study On Dynamic Analysis of Irregular Building With Shear WallsDocumento9 pagineComparative Study On Dynamic Analysis of Irregular Building With Shear WallsKyle NewmanNessuna valutazione finora

- Reinforcement For Slabs On GroundDocumento7 pagineReinforcement For Slabs On GroundfordesignNessuna valutazione finora

- Treatment of Shear WallsDocumento8 pagineTreatment of Shear Wallsakash kumarNessuna valutazione finora

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDocumento13 pagineRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubeNessuna valutazione finora

- Connections Between Failure Modes Observed in Shake Table Testing of Models in Building Contest and Earthquake Damage To Actual BuildingsDocumento19 pagineConnections Between Failure Modes Observed in Shake Table Testing of Models in Building Contest and Earthquake Damage To Actual BuildingsSuresh BabuNessuna valutazione finora

- Bond, Anchor and ShearDocumento15 pagineBond, Anchor and ShearBatepola BacNessuna valutazione finora

- 8 Storey Project Report - FINAL PDFDocumento110 pagine8 Storey Project Report - FINAL PDFNeil Norman Simon MAnansalaNessuna valutazione finora

- Axial Shortening MendisDocumento6 pagineAxial Shortening Mendisjoaobarbosa22Nessuna valutazione finora

- Reiher Meister ScaleDocumento91 pagineReiher Meister ScaleBijoy KorothNessuna valutazione finora

- Ns 18 Steel DesignDocumento50 pagineNs 18 Steel DesignproahyNessuna valutazione finora

- C 5 - Shear in BeamsDocumento32 pagineC 5 - Shear in BeamsRekanNessuna valutazione finora

- Structural Dynamics - SDOF - PpsDocumento13 pagineStructural Dynamics - SDOF - PpsSai KumarNessuna valutazione finora

- Beam Column Joint IIT RoorkeeDocumento109 pagineBeam Column Joint IIT RoorkeeMayank RajputNessuna valutazione finora

- Design - Calcs - Coupling Beams 4-7Documento4 pagineDesign - Calcs - Coupling Beams 4-7Krishna AnishNessuna valutazione finora

- Lecture 4B.5: Calculation Examples: Example 1: Critical Temperature of Tension MemberDocumento6 pagineLecture 4B.5: Calculation Examples: Example 1: Critical Temperature of Tension MemberMihajloDjurdjevicNessuna valutazione finora

- Advanced Etabs DocumentDocumento6 pagineAdvanced Etabs DocumentAlen ShresthaNessuna valutazione finora

- Why Slabs Curl - Part2Documento6 pagineWhy Slabs Curl - Part2Tim LinNessuna valutazione finora

- Vibration Performance of Composite Floors Using Slim Floor BeamsDocumento14 pagineVibration Performance of Composite Floors Using Slim Floor BeamsBala SubramanianNessuna valutazione finora

- Earthquake Resistant Design of Foundations: Lecture 1: IntroductionDocumento31 pagineEarthquake Resistant Design of Foundations: Lecture 1: IntroductionRITES LTD. SITE OFFICE ,ROURKELANessuna valutazione finora

- Civl101 - Introduction To Tall Building StructuresDocumento13 pagineCivl101 - Introduction To Tall Building StructuresAravind BhashyamNessuna valutazione finora

- Hinge PropertiesDocumento2 pagineHinge PropertiesSantiago Felix Mota Paez100% (1)

- ADAPT TN388 Vibration Footfall ExampleDocumento11 pagineADAPT TN388 Vibration Footfall ExampleMohammadreza MollaeiNessuna valutazione finora

- Seismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingDocumento8 pagineSeismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingSherif FodaNessuna valutazione finora

- CVL-243 Reinforced Concrete Design Semester 1, 2020-21: Sahil Bansal, IIT Delhi 1Documento23 pagineCVL-243 Reinforced Concrete Design Semester 1, 2020-21: Sahil Bansal, IIT Delhi 1Ekant YadavNessuna valutazione finora

- Dynamic Analysis of Steel Structure With Bracings and Dampers Under Wind and Earthquake LoadsDocumento5 pagineDynamic Analysis of Steel Structure With Bracings and Dampers Under Wind and Earthquake LoadsEditor IJTSRDNessuna valutazione finora

- URM Infill Wall Modelling PEER8102 Kadysiewski Mosalam RDocumento144 pagineURM Infill Wall Modelling PEER8102 Kadysiewski Mosalam RcegincNessuna valutazione finora

- Basement Wall Design NotesDocumento5 pagineBasement Wall Design NotesGermar PorquerinoNessuna valutazione finora

- What Is Meant by Solidity Ratio in Structural Engineering - QuoraDocumento3 pagineWhat Is Meant by Solidity Ratio in Structural Engineering - Quoramn_sundaraamNessuna valutazione finora

- Laos EarthquakeDocumento2 pagineLaos EarthquakeShreyansh Manojkumar AjmeraNessuna valutazione finora

- Material Time-Dependent Properties at Sap 2000Documento43 pagineMaterial Time-Dependent Properties at Sap 2000Nyein ZawNessuna valutazione finora

- CE 809 - Lecture 4 - Response of SDF Systems To Periodic LoadingDocumento32 pagineCE 809 - Lecture 4 - Response of SDF Systems To Periodic LoadingArslan UmarNessuna valutazione finora

- Design of Steel Structures-DeepaDocumento13 pagineDesign of Steel Structures-DeepaSai Albet BillaNessuna valutazione finora

- 025-Su, Wong - Seismic Behavior of Slender Reinforced Concrete Shear Walls Under High Axial Load Ratio PDFDocumento9 pagine025-Su, Wong - Seismic Behavior of Slender Reinforced Concrete Shear Walls Under High Axial Load Ratio PDFLuis Eduardo GonzalezNessuna valutazione finora

- Asian Journal of Civil Engineering-Pushover Analysis of Reinforced Concrete FrameDocumento9 pagineAsian Journal of Civil Engineering-Pushover Analysis of Reinforced Concrete FrameFady W. IskanderNessuna valutazione finora

- Chapter 2 Reinforced Concrete Beams and SlabsDocumento56 pagineChapter 2 Reinforced Concrete Beams and SlabsHasnain BukhariNessuna valutazione finora

- As 3600-09 RC-SL-001Documento4 pagineAs 3600-09 RC-SL-001Bunkun15Nessuna valutazione finora

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Documento7 pagineSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221Nessuna valutazione finora

- KBC 2009 Example 001Documento6 pagineKBC 2009 Example 001RMMNessuna valutazione finora

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Documento7 pagineSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- Hong Kong CoP-04 RC-PN-001 PDFDocumento5 pagineHong Kong CoP-04 RC-PN-001 PDFrenzo1221Nessuna valutazione finora

- En 2-2004 RC-SL Example 001Documento10 pagineEn 2-2004 RC-SL Example 001Aashu chaudharyNessuna valutazione finora

- VB4-24 - Footing DesignDocumento16 pagineVB4-24 - Footing Designrenzo1221Nessuna valutazione finora

- Analytical ThinkingDocumento1 paginaAnalytical Thinkingrenzo1221Nessuna valutazione finora

- Rectangular Beam Design - 2010 NSCPDocumento2 pagineRectangular Beam Design - 2010 NSCPrenzo1221Nessuna valutazione finora

- Checklist For Concrete Shear Wall (ACI 318-14)Documento5 pagineChecklist For Concrete Shear Wall (ACI 318-14)renzo1221Nessuna valutazione finora

- Software Verification: Example Hong Kong Cp-04 Rc-Bm-001Documento7 pagineSoftware Verification: Example Hong Kong Cp-04 Rc-Bm-001renzo1221Nessuna valutazione finora

- Contracts 2019Documento37 pagineContracts 2019renzo1221Nessuna valutazione finora

- WT 4x A0 X 1Z, I X 1e.g W T 4 X 1 4 X 1 2 WT 4 X 10, I XG Tfiff 4 X Z.G X - B - G x5 WT 3 X 14,5 X 1 0Documento3 pagineWT 4x A0 X 1Z, I X 1e.g W T 4 X 1 4 X 1 2 WT 4 X 10, I XG Tfiff 4 X Z.G X - B - G x5 WT 3 X 14,5 X 1 0renzo1221Nessuna valutazione finora

- Hong Kong CoP-04 RC-PN-001 PDFDocumento5 pagineHong Kong CoP-04 RC-PN-001 PDFrenzo1221Nessuna valutazione finora

- App5 - EC2 Design PDFDocumento70 pagineApp5 - EC2 Design PDFrenzo1221Nessuna valutazione finora

- Handout (Final) 071517 - Carlos M. Villaraza PDFDocumento3 pagineHandout (Final) 071517 - Carlos M. Villaraza PDFrenzo1221Nessuna valutazione finora

- Software Verification: Example 12Documento6 pagineSoftware Verification: Example 12renzo1221Nessuna valutazione finora

- 2-Way Yield Line TheoryDocumento1 pagina2-Way Yield Line Theoryrenzo1221Nessuna valutazione finora

- Railway Development in Metro Manila: Engr. Deo Leo N. Manalo, PHDDocumento29 pagineRailway Development in Metro Manila: Engr. Deo Leo N. Manalo, PHDrenzo1221Nessuna valutazione finora

- Road Tunnel Projects in ASEAN RegionDocumento52 pagineRoad Tunnel Projects in ASEAN Regionrenzo1221Nessuna valutazione finora

- Piled Raft Foundations For Tall BuildingsDocumento8 paginePiled Raft Foundations For Tall Buildingsrenzo1221Nessuna valutazione finora

- Ysly-Jz CablesDocumento2 pagineYsly-Jz CablesCarlos AlbertoNessuna valutazione finora

- Astm 495Documento5 pagineAstm 495Eligio A CerdaNessuna valutazione finora

- 10 1 1 475 5570Documento7 pagine10 1 1 475 5570joni indoNessuna valutazione finora

- Extreme Weather Concrete (CTE)Documento16 pagineExtreme Weather Concrete (CTE)Sidharth KambleNessuna valutazione finora

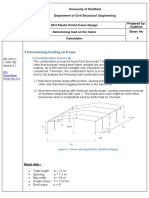

- 2) Determing The LoadingDocumento5 pagine2) Determing The LoadingLuísNessuna valutazione finora

- E211P ELECTRICAL FIRST FLOOR PLAN - POWER - AREA 1 - PHASE 1 Rev.6Documento1 paginaE211P ELECTRICAL FIRST FLOOR PLAN - POWER - AREA 1 - PHASE 1 Rev.6Suren VelletheryNessuna valutazione finora

- The Practice of Warping Double TeesDocumento17 pagineThe Practice of Warping Double Teesunix0123Nessuna valutazione finora

- Draught: (Chimney Design)Documento5 pagineDraught: (Chimney Design)just randomNessuna valutazione finora

- Dando Terrier PercussionDocumento2 pagineDando Terrier Percussionapi-105789617Nessuna valutazione finora

- Pages From B1-20-1 - 2013 PDFDocumento3 paginePages From B1-20-1 - 2013 PDFAhmad Jukliv Pandu YoedhawanNessuna valutazione finora

- Development Length Shear and Torsion PDFDocumento11 pagineDevelopment Length Shear and Torsion PDFAmrit RegmiNessuna valutazione finora

- Lecture 1 FinalDocumento35 pagineLecture 1 FinalJayHatNessuna valutazione finora

- Mirillas Rectangulares LumiglasDocumento2 pagineMirillas Rectangulares Lumiglasluis fernando veraNessuna valutazione finora

- Failure in Castings and Application To Chassis Parts - Paul Du BoisDocumento41 pagineFailure in Castings and Application To Chassis Parts - Paul Du BoisN.g. NagarajNessuna valutazione finora

- CG - Eng .223 Drill Pipe Care and HandlingDocumento12 pagineCG - Eng .223 Drill Pipe Care and Handlingjinyuan74Nessuna valutazione finora

- Space Efficiency in High-Rise Office BuildingsDocumento21 pagineSpace Efficiency in High-Rise Office BuildingsSrvt Snr100% (1)

- 1202 516353J00145 Env2Documento676 pagine1202 516353J00145 Env2Yavuz ErcanliNessuna valutazione finora

- PH1950 - Associates Guidance-Workshops CHS-Pr-Reg Presentation 2015-02-18Documento58 paginePH1950 - Associates Guidance-Workshops CHS-Pr-Reg Presentation 2015-02-18Pieter HerbstNessuna valutazione finora

- Vendor Civil All 4 PDFDocumento320 pagineVendor Civil All 4 PDFShashishekhar ChaturvediNessuna valutazione finora

- Mim0701 Unit 10 ModernismDocumento11 pagineMim0701 Unit 10 ModernismMukhammadjonNessuna valutazione finora

- Tenarishydril Wedge 513: Pipe Body DataDocumento1 paginaTenarishydril Wedge 513: Pipe Body DataCARLOS SANCHEZNessuna valutazione finora

- Aci 207.3R-94Documento16 pagineAci 207.3R-94farhadam100% (1)

- AP-R531-16 Specification of Geopolymer Concrete General GuideDocumento22 pagineAP-R531-16 Specification of Geopolymer Concrete General GuidePanayioti ZoupantisNessuna valutazione finora

- Engineering Exam Sample QuestionsDocumento4 pagineEngineering Exam Sample QuestionsCampus ReformNessuna valutazione finora

- Texto Guia de Ingenieria AntisismicaDocumento825 pagineTexto Guia de Ingenieria AntisismicaFrancisco Calderon100% (1)

- Design PhilosophyDocumento49 pagineDesign PhilosophyAnuj ChandiwalaNessuna valutazione finora

- Roofing and Waterproofing: Standard Terminology Relating ToDocumento9 pagineRoofing and Waterproofing: Standard Terminology Relating ToRONALD MUELLERNessuna valutazione finora

- Pits Gullies Method Statement-DRAFTDocumento26 paginePits Gullies Method Statement-DRAFTMahmoud FakhereddinNessuna valutazione finora

- Development of Block 45 ApcDocumento272 pagineDevelopment of Block 45 ApcNone None None100% (1)

- Firmlok SelectionGuideDocumento48 pagineFirmlok SelectionGuideDanusha EgodawatteNessuna valutazione finora