Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample Project 03

Caricato da

Robert Blake DesignsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample Project 03

Caricato da

Robert Blake DesignsCopyright:

Formati disponibili

NOTES

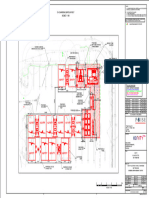

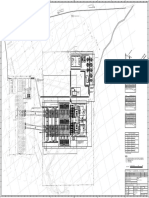

B C LEGEND: STRUCTURAL MEMBERS SCHEDULE LOADS (uls)

MVR

A B C A B C Existing wall

STEEL BEAMS kNm kN kN

1. THIS DRAWING IS TO BE READ IN CONJUNCTION

01 01 01

Existing loadbearing stud wall

Provide 9mm OSB/3 sheathing

B1 EXISTING MEMBER TO REMAIN 15 15 20 WITH THE ARCHITECTS DRAWINGS AND THE

both sides B2 EXISTING MEMBER TO REMAIN 30 55 55 PROJECT SPECIFICATION. DO NOT SCALE OFF THE

B2a 152x89x16 UB 10 10 10

New wall

B3 EXISTING MEMBER TO REMAIN 95 60 65

DRAWING.

New loadbearing stud wall B4 2No. 75x275dp C24 timber joists 5 10 10 2. ALL DIMENSIONS AND LEVELS TO BE CHECKED BY

A

New 20N/mm² masonry brick wall

B5 2No. 75x275dp C24 timber joists 15 15 15 THE BUILDER BEFORE ORDERING ANY STEELWORK.

B6 150x90x24 PFC (shape to suit) 15 20 20

02 02 02 Demolition B7 150x90x24 PFC 10 20 20

3. ALL STEELWORK IS TO BE GRADE S275, SHOT

B8 152x152x30 UC 40 45 45 BLASTED AND PAINTED WITH 2 COATS OF ZINC

Walls under

B9 152x152x30 UC 35 30 35 PHOSPHATE PRIMER OR RED OXIDE PRIMER

B10 200x100x8 RHS laid flat + bottom plate 20 25 25

New ceiling joists CJ1 above

All Ceiling joists CJ1 TBC on site B11 300x100x10 RHS laid flat + bottom plate 25 30 30 UNLESS NOTED ON DRAWING AS GALVANISED, OR

B12 FLITCH BEAM- 2No. 60x225dp C24 timber joists 20 20 40 CONCRETE CASED. ALL BOLTS ARE TO BE GRADE

Existing structure to remain + 1No. 10thk M.S plate bolted together using M12

bolts @400c/c

8.8. ALL FABRICATION IS TO BE DONE IN

Reinforced Existing structure

03 03 03 B13 203 x 203 x 86 UC + end plate 160 200 200 ACCORDANCE WITH BS5950.

New structural member B13a 203x133x30UB + end plate 55 100 100

B14 254x254x73 UC - splice connection 150 65 65

4. ALL NEW TIMBER IS TO BE C24 GRADE (UNLESS

ExJ

04 04 04

Existing Floor / Roof Joists

B15 EXISTING MEMBER TO REMAIN 35 30 30 NOTED AS C16 ON THE DRAWING) AND TANALISED.

New Floor / Ceiling / Roof Joists B16 EXISTING MEMBER TO REMAIN 10 25 25 PAINT ALL CUT ENDS WITH TIMBER PRESERVATIVE,

Blocking up existing B17 203x102x23 UB 20 30 30

window opening using

All joist sizes noted on the drawings are to B18 203x203x86UC 195 165 165

ON SITE. PLYWOOD MUST COMPLY WITH EN636,

B

B

matching bricks

be a minimum as specified on the B19 254x254x73 UC 180 100 140 CLASS 3.

L2 drawings, if the existing is less than shown

on the drawings they must be replaced to

B20 203x203x60 UC + 15thk bottom plate 35 40 40 5. ALL BRICKWORK TO BE 20.5 N/mm² IN 1:1:6 MORTAR.

05 05 suit the specified size B21 FLITCH BEAM- 2No. 70x200dp C24 timber joists 6. ALL CONCRETE (EXCEPT BLINDING CONCRETE) IS

+ 1No. 12thk M.S plate bolted together using M12 20 25 25

All studwalls parallel to the floor joists to TO BE MINIMUM 30 N/mm2 WITH 20 DIAMETER

50x200dp @350c/c

For joists support refer B21 bolts @400c/c

Joists arrangement to to drawing 2081-07 be supported using double up joists

u/s of Mezzanine Unit FR1 150x175 C24 Timber Posts + 150x225dp C24 AGGREGATE AND IS TO BE MECHANICALLY

34 tbc on site. Timber Beam as Timber Frame

PROVIDE FULL LENGTH BEARING ON

ALL PADSTONES FR2 2No.50x100 C16 + Ex. 80x100+Ex 80x100

VIBRATED, WHEN PLACED. ALL CONCRETE WORK

EXJ / 60x275dp

@350c/c

Timber Post + 2No. 80x100dp C16 Timber Header MUST COMPLY WITH BS 8110.

06 06 Contractor to check the existing timber COLUMNS

floor masonry supports 7. BEAMS SUPPORTING CAVITY WALLS TO HAVE 15THK

Provide min 100mm UNIT 34 C1 80x80x5 SHS + top and bottom plates

UNIT 34 bearing each end of C2 203x102x23 UB + top and bottom plate MM PLATE WELDED TO TOP, TO WIDTH OF WALL

B8 P1 B5 Contractor to provide lateral stability in

P1

Beam B2A Accordance with Approved Document A of C3 200x120x10 RHS + top and bottom plates 8. ALL EXTERNAL WALLS TO HAVE WALL STRAPS AT

Building Regulations. C4 80x80x5 SHS + top and bottom plates

New stairs

CJ1

Lateral restraint straps required to walls

2.0m c/c's HORIZONTALLY AND VERTICALY FOR THE

above C5 3No.72 x100 C24 studs

B4

up

by others FJ2 parallel to joists and timber roof spans. ROOF.

B6

EXJ / 60x275dp C6 4No.72 x100 C24 studs or 300x100x10 RHS

FJ4

Straps to be at maximum 1.2m c/c apart

@350c/c 9. TIMBER JOISTS WITH A SPAN OVER 2.5m TO HAVE

B7

and fixed to minimum of 3 No. joists. All C7 100 x100 C24 timber stud

07 07 07

FJ2

straps installed to BS5268 & BS8103. LINTELS ONE ROW OF NOGGINS AT THIRD SPAN. TIMBER

L1 2No. 50x200dp C24 timber joists, bolted

C1 Where Architects indicated storage area together using M12 bolts @400c/c NOGGINS CAN BE REPLACED WITH HERRINGBONE

below above, use CJ1 for 1.8m max span

P1 B9 C1 P1

New ceiling up P1

L2 CX 90/100 Catnic Lintel STRUTTING

joists CJ1 B2A L3 3No. 50x200dp C24 timber joists, bolted

above

**ALL EXISTING STRUCTURAL

MEMBERS TO REMAIN IF MEET THE together using M12 bolts @400c/c 10.ALL JOISTS ON WALLS TO BE CROSS NAILED

08 08 08 **B2

CRITERIA OF MINIMUM STRUCTURAL L4 100w x 140dp Precast Concrete Lintel 11.ALL STUDWALLS PARALLEL TO THE FLOOR JOISTS

C7 L1 (over) MEMBER SIZE REQUIRED SHOWN ON

(under)

C7 2No. 50x200dp C24 timber joists, bolted

L5 TO BE SUPPORTED USING DOUBLE JOISTS BOLTED

B

B

L1

under STRUCTURAL MEMBERS SCHEDULE. together using M12 bolts @400c/c

ALL EXISTING STRUCTURAL MEMBERS

TO BE REINFORCED OR REPLACED TO L6 2No. 100w x 140dp Prestressed Concrete Lintels TOGETHER USING M12 BOLTS WITH 50x50mm

C7

MEET THE REQUIRED STRUCTURAL L7 2No. 100w x 290dp Prestressed Concrete Lintels WASHERS @500mm c/c

UNIT 23 CJ1 MEMBER SIZE. L8 2No. 100w x 290dp Prestressed Concrete Lintels

12.ALL BEAMS TO BE LOADED CENTRALLY ON

Second Floor

Existing stud wall to remain

Existing stud wall and flitch

above L9 2No.50x100dp C24 timber joists

Mezzanine Plan Lintel L1

LINTELS

PADSTONES PADSTONES. BEAMS TO EXTEND TO END OF

beam under to remain

· For spans greater than 1200mm,

Scale 1:50 2No.50x200dp on UNIT 33 lintels should be adequately propped P1 440 x100wd x150dp Concrete Padstone PADSTONE.

100x100 C24 Timber

during construction at a maximum of P2 215 x215wd x150dp Concrete Padstone

CJ1 Post (C7 below) 1200mm centres. Props should not be

13.THE CONTRACTOR MUST PROVIDE FULL DETAILS OF

B1

above P3 750 x100wd x 215dp Concrete Padstone

CJ1 removed until the mortar has matured.

P4 440x 215wd x 150dp Concrete Padstone THEIR PROPOSED TEMPORARY WORKS, BEFORE

above · Lintel should be bedded on a level full

mortar bed each end. Min end bearing P5 660 x100wd x 150dp Concrete Padstone COMMENCING THE STRUCTURAL WORKS.

150mm P6 440 x215wd x 215dp Concrete Padstone

LBW1 LBW1 · No rebate must be formed/cut into A P7 450 x100wd x 150dp Concrete Padstone

09 09 PRESTRESSED lintels, or holes drilled

P8 960 x100wd x 215dp Concrete Padstone

for chemical anchors. Plugging and

CJ1 drilling is acceptable providing that the P9 880 x100wd x 215dp Concrete Padstone

above location of prestressing tendons is not P10 660x 215wd x 215dp Concrete Padstone

compromised. P11 330 x100wd x 150dp Concrete Padstone

CJ1 B3

10 above 10 FLOOR JOISTS

CJ1 ALL STEEL CONNECTIONS ARE TO BE

above FJ1 2No. 50x100dp C24 timber joists @250c/c 555

CJ1 DESIGNED BY SPECIALIST

above MANUFACTURER USING SPECIFIED FJ2 50x150dp C24 timber joists @400c/c 555

FACTORED LOADS (ULS) SHOWN ON FJ3 50x175dp C24 timber joists @400c/c 5 10 10

STRUCTURAL MEMBERS SCHEDULE CJ1/FJ4 50x100dp C24 timber joists @400c/c 111

Existing stud

LOADBEARING WALLS

wall to remain All Timber to timber connection are to

IMPERIUM ENGINEERING LIMITED

CJ1 LBW1 72x100 C24 timber studs @400c/c +OSB / 3

be on joist hangers. 20-22 Wenlock Road

above sheathing both sides

UNIT 22 UNIT 21 N1 7GU, London info@imperiumengineering.co.uk

EXJ / 60x275dp

Contractor to provide adequate joist

11 11 hangers using specified loads

LBW2 72x100 C24 timber studs @400c/c +OSB / 3 Tel. 020 3441 7606 www.imperiumengineering.co.uk

(factored) shown on Structural Members sheathing both sides

@350c/c

Schedule. If unsure, contact Structural ROOF BEAMS DRAWING TITLE:

EXJ / 75x280dp Engineer RB1 203x203x46 UC - splice connection 70 65 65

@350c/c *Contractor to use slope adjustable joist 25 30 30

hangers where required (Roof level)

RB2 203x102x23 UB PROPOSED STRUCTURAL

RB3 203x102x23 UB 20 25 25

RB4 254x254x73 UC - splice connection 160 65 105

SECOND FLOOR, SECOND FLOOR

When demolition, all walls to be made

good using matching bricks fully toothed RB5 254x254x73 UC - splice connection 160 65 105 MEZZANINE AND THIRD FLOOR PLAN

UNIT 32 UNIT 31 and bonded into existing RB6 203x203x46 UC - splice connection 60 35 35

RB7 203x203x46 UB under balustrade-spliced 40 30 30

· All Structural Elements to be measured

connection PROJECT:

on site prior to ordering. Imperium

Engineering is NOT responsible for beam FLAT ROOF JOISTS

12 12 length measurements RJ1 44x240dp C24 timber joists @400c/c 555

· Any alterations or amendments to be

ROOF TRIMMERS

approved in writing by Structural

Engineer prior to carrying out on site. TR1 2No. 44x240dp C24 timber joists bolted 555

· Imperium Engineering to be notified if together using M12 bolts @400c/c

joist spans and sizes noted on the GA TR2 3No. 44x240dp C24 timber joists bolted 10 10 10

drawing are any different prior to ordering together using M12 bolts @400c/c

of Steel Beams.

· All padstones on party walls are 100mm TR3 2No. 44x240dp C24 timber joists bolted 555 CLIENT:

wide. Contractor to inform Imperium together using M12 bolts @400c/c

Engineering if different. TR4 FLITCH BEAM- 2No. 75x280dp C24 timber joists 5 10 10

13 13 · All workmanship and materials to be in

+ 15thk M.S plate bolted together using M12

accordance with all current relevant

bolts @400c/c

Codes of Practice, British Standards and

Current CDM Regulations TR5 FLITCH BEAM- 2No. 75x280dp C24 timber joists 40 30 35

· Structural Elements to be installed in + 15thk M.S plate bolted together using M12 bolts

accordance with current CDM @400c/c

Regulations

TR6 3No. 44x240dp C24 timber joists bolted 10 15 15

together using M12 bolts @400c/c

All existing foundations are to be agreed

with Building Control. Contractor / TR7 3No. 44x240dp C24 timber joists bolted 5 15 15

Building Control to confirm capacity of together using M12 bolts @400c/c

existing foundation. If found inadequate

or unsure, contact Structural Engineer Loads (shown on Structural Member Schedule):

M - indicate max Moment (kNm)

V- indicate max Shear (kN)

14 14 R- indicate max Reaction (kN)

NOTE: Loads given in the Structural Members Schedule are to the

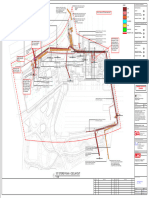

SITE BOUNDARY

SITE BOUNDARY

SITE BOUNDARY

SITE BOUNDARY

A

nearest value of 5. Please refer to Structural Calculation Pack if unsure.

Temporary Works Notes:

N° 73

N° 73

N° 69

N° 69

It is the responsibility of the main contractor to consider the need for temporary works - props, shores, bracing, needles

A B C A B C etc - to provide suitable temporary works where required;

Second Floor Plan Third Floor Plan Maintain the integrity of the existing structure and temporary support throughout the duration of the project and appoint

Scale 1:50 Scale 1:50 a temporary works Engineer if deemed necessary.

Potrebbero piacerti anche

- DIN StandardsDocumento284 pagineDIN Standardsz80% (15)

- Astm D4445 10Documento5 pagineAstm D4445 10Cristian Castillo0% (1)

- Container and Vertical GardeningDocumento14 pagineContainer and Vertical GardeningSanjeev Kumar100% (1)

- Astm D3200Documento2 pagineAstm D3200btwilliNessuna valutazione finora

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocumento1 paginaBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNessuna valutazione finora

- Vectorworks Educational Version: Sense and SensibilityDocumento1 paginaVectorworks Educational Version: Sense and Sensibilityapi-510574946Nessuna valutazione finora

- Notes - 2Documento1 paginaNotes - 2Suhas VNessuna valutazione finora

- Sense and Sensibility: Lighting Ground PlanDocumento1 paginaSense and Sensibility: Lighting Ground Planapi-509024597Nessuna valutazione finora

- Pm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...Documento1 paginaPm210011-Nui900-Rd2-00026 - 01 - Slab On Grade - Grade Beam SCH, Sec & Details...MOHAMMAD JAKARIA HASANNessuna valutazione finora

- 9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)Documento1 pagina9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)jmdavies.isNessuna valutazione finora

- HV Compression Connectors: SYS SYT YcakaDocumento1 paginaHV Compression Connectors: SYS SYT YcakaGERARDONessuna valutazione finora

- 33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)Documento1 pagina33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)SUSOVAN BISWASNessuna valutazione finora

- Bruce StructuralsDocumento4 pagineBruce StructuralsAllan MwesigwaNessuna valutazione finora

- Buseko WarehouseDocumento1 paginaBuseko Warehouselenganji simwandaNessuna valutazione finora

- Alta Prima Conv S-2Documento1 paginaAlta Prima Conv S-2Ronnel John CruzNessuna valutazione finora

- Current 1 FDTNDocumento1 paginaCurrent 1 FDTNAugustine yigaNessuna valutazione finora

- Revision Table: It Room Panels RoomDocumento1 paginaRevision Table: It Room Panels RoomevillamayorNessuna valutazione finora

- 2022 11 18 - Lc95 - Lhs Gad - r3 - Rev As Per Site CommenyDocumento1 pagina2022 11 18 - Lc95 - Lhs Gad - r3 - Rev As Per Site CommenyDGM DrawingNessuna valutazione finora

- Sac NH 365BG PKG Iv Sic STR BC 112+017 - R0Documento3 pagineSac NH 365BG PKG Iv Sic STR BC 112+017 - R0kotarajeshreddyNessuna valutazione finora

- Level 3 General Arrangement Plan: A B C D E F G Suspended Slab NotesDocumento1 paginaLevel 3 General Arrangement Plan: A B C D E F G Suspended Slab NotesSubhekshya ShresthaNessuna valutazione finora

- Smwsasbt CPG STM SN100 TW PKG 032901Documento4 pagineSmwsasbt CPG STM SN100 TW PKG 032901MassimilianoTerenziNessuna valutazione finora

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Documento1 paginaSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNessuna valutazione finora

- Kurukshetra DDP 2031Documento1 paginaKurukshetra DDP 2031Mayank PalNessuna valutazione finora

- PLANDocumento1 paginaPLANF1030 Iman FaizNessuna valutazione finora

- General Arrangement Plan - Podium Level 00: NotesDocumento1 paginaGeneral Arrangement Plan - Podium Level 00: Notesprasahnthrk07Nessuna valutazione finora

- 522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Documento1 pagina522445-AUR901-DRG-BC-5600-CIVIL TYPICAL UNDERGROUND SERVICES DETAILS SHEET 1 OF 4油罐间Gibson SitumorangNessuna valutazione finora

- A102 - Proposed Setting Out PlanDocumento1 paginaA102 - Proposed Setting Out PlanØwięs MØhãmmedNessuna valutazione finora

- Level 3 MEP ServicesDocumento2 pagineLevel 3 MEP ServicesLeyla MoranNessuna valutazione finora

- Notes:: 0 04.06.17 WA Issued For Client's ApprovalDocumento1 paginaNotes:: 0 04.06.17 WA Issued For Client's ApprovaltogireeshNessuna valutazione finora

- Lbd-Bmc57-Deck-1a & 1b-Mep - Ug-Csd-011Documento1 paginaLbd-Bmc57-Deck-1a & 1b-Mep - Ug-Csd-011Benigno SudarioNessuna valutazione finora

- Notes:: 0 04.06.17 WA Issued For Client's ApprovalDocumento1 paginaNotes:: 0 04.06.17 WA Issued For Client's ApprovaltogireeshNessuna valutazione finora

- 3.1 Plant LayoutDocumento1 pagina3.1 Plant LayoutSatyaprakash SharadNessuna valutazione finora

- 2047 1803 Est Dla 7011 - A PDFDocumento1 pagina2047 1803 Est Dla 7011 - A PDFrameshbathalaNessuna valutazione finora

- Ekpsip E1 C1 9802 W 02Documento1 paginaEkpsip E1 C1 9802 W 02S Rao CheepuriNessuna valutazione finora

- MC Nichols Grip Strut DrawingsDocumento4 pagineMC Nichols Grip Strut Drawingsananda ganeshNessuna valutazione finora

- GMR10-07203 Current Frame T10 Rev02Documento7 pagineGMR10-07203 Current Frame T10 Rev02Mladen NinkovicNessuna valutazione finora

- SAN BARTOLO FINAL-ModelDocumento1 paginaSAN BARTOLO FINAL-ModelCarlos BazalarNessuna valutazione finora

- Floor PlanDocumento1 paginaFloor PlanShweta SainiNessuna valutazione finora

- Structural Engineering DrawingsDocumento7 pagineStructural Engineering DrawingsObaidullah ObaidNessuna valutazione finora

- Notes:: 0 04.06.17 WA Issued For Client's ApprovalDocumento1 paginaNotes:: 0 04.06.17 WA Issued For Client's ApprovaltogireeshNessuna valutazione finora

- Notes:: 0 04.06.17 WA Issued For Client's ApprovalDocumento1 paginaNotes:: 0 04.06.17 WA Issued For Client's ApprovaltogireeshNessuna valutazione finora

- GEM Ranger 2.3 LDocumento1 paginaGEM Ranger 2.3 LgabrielNessuna valutazione finora

- AANK-012 Chaboba rev.1-CM-20x30-P1Documento1 paginaAANK-012 Chaboba rev.1-CM-20x30-P1anarzo.chccNessuna valutazione finora

- Fully Book of Drawing May 16-2020 With Catch Water Drain PDFDocumento17 pagineFully Book of Drawing May 16-2020 With Catch Water Drain PDFDaniel Pasy SelekaNessuna valutazione finora

- Nolimit Wahda Floor LayoutDocumento1 paginaNolimit Wahda Floor Layoutvasanth kumarNessuna valutazione finora

- MASTER SLD - NEW UPDATE-ModelDocumento1 paginaMASTER SLD - NEW UPDATE-Modeldhiansyah 92lifeNessuna valutazione finora

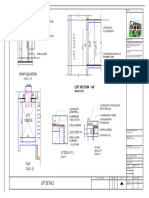

- Lift DetailsDocumento1 paginaLift DetailsSOUNDARYA CHOTHENessuna valutazione finora

- Lotizacion Primera Etapa CapoteDocumento1 paginaLotizacion Primera Etapa CapoteGiancarlo Andre Pacheco BravoNessuna valutazione finora

- General Construction Notes: Typical Column Elev. Showing Dowels and Ties SpacingDocumento1 paginaGeneral Construction Notes: Typical Column Elev. Showing Dowels and Ties SpacingChristian Kyle BeltranNessuna valutazione finora

- (Steps Going To Deck Roof) : LegendDocumento1 pagina(Steps Going To Deck Roof) : LegendLowie Torres TonioNessuna valutazione finora

- Sheet Notes: A.5 A.08 C D A.9 B.1N B.9 A.2 B.14 A.1 B.0.5 B.1.9 A.09Documento1 paginaSheet Notes: A.5 A.08 C D A.9 B.1N B.9 A.2 B.14 A.1 B.0.5 B.1.9 A.09Cristina Mauren P. PajesNessuna valutazione finora

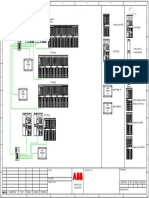

- C-Hmi Server Client: ABB ABBDocumento1 paginaC-Hmi Server Client: ABB ABBmahmoud sheblNessuna valutazione finora

- Ee PlanDocumento1 paginaEe PlanPaul MendozaNessuna valutazione finora

- A1.24a Reflected Ceiling Plan West Level 4 Rev.4Documento1 paginaA1.24a Reflected Ceiling Plan West Level 4 Rev.4Miguel CasianoNessuna valutazione finora

- 19BL VSH LFT SCT G1G2 0016 1Documento1 pagina19BL VSH LFT SCT G1G2 0016 1Rajiv NagarathinamNessuna valutazione finora

- Detalle Placa Fácil: ApliqueDocumento1 paginaDetalle Placa Fácil: ApliqueEdwardRomeroNessuna valutazione finora

- 18 Ocs General Assemblies OverlapDocumento36 pagine18 Ocs General Assemblies OverlapMounikaNessuna valutazione finora

- Ib Mon CD Master Plan Layout Ground FloorDocumento1 paginaIb Mon CD Master Plan Layout Ground FloorsedanaNessuna valutazione finora

- PL-EST - 003: Escala 1:50 3 / 4Documento1 paginaPL-EST - 003: Escala 1:50 3 / 4Difracol EmpresaNessuna valutazione finora

- A TA 075 49 009B Layout1Documento1 paginaA TA 075 49 009B Layout1prasahnthrk07Nessuna valutazione finora

- Composite Wall Type Schedule BDocumento1 paginaComposite Wall Type Schedule BfereetNessuna valutazione finora

- Grand l02 Scut Gah 20200721Documento1 paginaGrand l02 Scut Gah 20200721Ricardo Alejandro Oyarce ArmijoNessuna valutazione finora

- Steel Bollard Details: Buro HappoldDocumento1 paginaSteel Bollard Details: Buro Happoldrichrd villanuevaNessuna valutazione finora

- Instant Assessments for Data Tracking, Grade 1: Language ArtsDa EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNessuna valutazione finora

- Scanner 20190118 151051Documento1 paginaScanner 20190118 151051Robert Blake DesignsNessuna valutazione finora

- Fgfsghns - Design TDocumento1 paginaFgfsghns - Design TRobert Blake DesignsNessuna valutazione finora

- 15 Year Warranty: Q-Deck /Q-Grip Timber Decking ComponentsDocumento1 pagina15 Year Warranty: Q-Deck /Q-Grip Timber Decking ComponentsRobert Blake DesignsNessuna valutazione finora

- Draft: First Floor Showing Roof Structure OverDocumento1 paginaDraft: First Floor Showing Roof Structure OverRobert Blake DesignsNessuna valutazione finora

- John Endicott PDFDocumento46 pagineJohn Endicott PDFRobert Blake Designs100% (1)

- 2216 pdf7 PDFDocumento6 pagine2216 pdf7 PDFRobert Blake DesignsNessuna valutazione finora

- A1 - 05 PDFDocumento1 paginaA1 - 05 PDFRobert Blake DesignsNessuna valutazione finora

- Eb 8Documento7 pagineEb 8SyedjamelNessuna valutazione finora

- Static-Manual Connectors 2020-2Documento72 pagineStatic-Manual Connectors 2020-2Keyvan GhasemiNessuna valutazione finora

- Introduction To The Use of Wood As A Building MaterialDocumento84 pagineIntroduction To The Use of Wood As A Building Materialaulas0% (1)

- Mustang Lumber Inc. vs. Court of AppealsDocumento2 pagineMustang Lumber Inc. vs. Court of AppealsMrln VloriaNessuna valutazione finora

- Roofing TechniqueDocumento30 pagineRoofing TechniqueLuke Obusan100% (1)

- Historia de KalmarDocumento49 pagineHistoria de KalmarJuanMiguel Carranza Cruzado100% (1)

- Log Home Living - May 2019 PDFDocumento92 pagineLog Home Living - May 2019 PDFSilviuOlariuNessuna valutazione finora

- Ancon Wall Ties & Restraint FixingsDocumento32 pagineAncon Wall Ties & Restraint FixingsAngela KeithNessuna valutazione finora

- Fire and Materials - 2004 - K Nig - Structural Fire Design According To Eurocode 5 Design Rules and Their BackgroundDocumento17 pagineFire and Materials - 2004 - K Nig - Structural Fire Design According To Eurocode 5 Design Rules and Their BackgroundMiguel ÂngeloNessuna valutazione finora

- Doka Formwork SheetsDocumento48 pagineDoka Formwork SheetsJasmine Tso100% (1)

- Woodworking Guide A Step by Step Approach To WoodworkingDocumento38 pagineWoodworking Guide A Step by Step Approach To WoodworkingDarko Vazanski0% (1)

- Tyndall Furniture Company (B) EnglishDocumento2 pagineTyndall Furniture Company (B) EnglishProcusto LNessuna valutazione finora

- Mos ScaffolidingDocumento32 pagineMos ScaffolidingIMTIYAZ ALINessuna valutazione finora

- Specification For Building-Works-New Build West Green RoadDocumento99 pagineSpecification For Building-Works-New Build West Green RoadMaria100% (1)

- Tender Document Deas Sea Panoramic ComplexDocumento151 pagineTender Document Deas Sea Panoramic ComplexLe Thi Anh TuyetNessuna valutazione finora

- Factory Price Laminate Bamboo Lumber 100% Solid Bamboo Beams - Buy Laminated Bamboo Lumber, Laminated Bamboo, Bamboo Beams Product OnDocumento12 pagineFactory Price Laminate Bamboo Lumber 100% Solid Bamboo Beams - Buy Laminated Bamboo Lumber, Laminated Bamboo, Bamboo Beams Product OnJhake Bayuga PascuaNessuna valutazione finora

- 2019 Pardee Annual Report - Low ResolutionDocumento36 pagine2019 Pardee Annual Report - Low ResolutionNate Tobik100% (2)

- BOWMAC Structrual Brackets 08 - 2011Documento6 pagineBOWMAC Structrual Brackets 08 - 2011bobcalleydaya0% (1)

- BOLESA Residence - Architectural SpecificationDocumento18 pagineBOLESA Residence - Architectural SpecificationMarilou Basallo100% (1)

- Chapter 07Documento76 pagineChapter 07raiNessuna valutazione finora

- Building and Environment: Freya Morris, Stephen Allen, Will HawkinsDocumento10 pagineBuilding and Environment: Freya Morris, Stephen Allen, Will HawkinsKareem AbushamaNessuna valutazione finora

- SLM 2 Carpentry 9 4th QuarterDocumento13 pagineSLM 2 Carpentry 9 4th QuarterDaniel100% (1)

- 10 InstallguideDocumento36 pagine10 InstallguidechrisallNessuna valutazione finora

- Kermode Bungalow 1945Documento2 pagineKermode Bungalow 1945droshkyNessuna valutazione finora

- Company Profile 2021Documento36 pagineCompany Profile 2021Anonymous H9Qg1iNessuna valutazione finora

- CE102Documento2 pagineCE102Jian BonaguaNessuna valutazione finora