Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Y Strainer-100mm PDF

Caricato da

Kailas NimbalkarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Y Strainer-100mm PDF

Caricato da

Kailas NimbalkarCopyright:

Formati disponibili

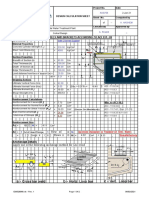

Pressure Drop Calculations for Item No:.

2412A/B

Density :.992.85 Kg/m3

Viscocity:. 1 Cp

Process At 100% Clean At 50% Clogged

Strainer Pipe Screen Condition Condition

Parameters

Outside

Size(mm) 100 (4") 11.43 Diameter of Screen(cm) 12.00 p - Density of Liquid in gm/cm3 0.993 0.993

Diameter(cm)

Type Y STRAINER Pipe Schedule(Sch) STD Length of Screen(cm) 27.50 μ - viscosity of Liquid in gm/cm-s 0.010 0.010

Surface Area

Class Rating 150 Thickness (cm) 0.478 1036.86 Flow in Cm3/sec 8888.640 8888.640

of Screen(SAS) (cm2) at Clean Condition

V - Superficial Velocity of fluid

Surface Area of Screen 1t 50%

Inside Diameter 10.5 518.43 based upon the gross area of the 33.869 67.739

Clogged

screen cm/sec

Net Area of Screen used for filtering (cm2)

Area of Pipe 86.2 262.44 V/α = 133.814 267.627

at Clean Condition

Net Area of Screen used for filtering @ 50%

131.22 (p/μ) = 99.285 99.285

Clogged (cm2)

Ratio at Clean Condition 3.05 Re - Reynolds No=D*(V/α)*(p/μ) 499.409 998.819

C - Coefficient of discharge

Ratio at 50% Clogged 1.52 1.000 1.200

(From Perry page no. 5-40)

Q - % opening in 20 Wire Mesh for 28 SWG 49.60 g - Gravitational force cm/sec2 981.000 981.000

K - Velocity Head Loss =

P- Perforation (6mm Hole,8mm pitch) 51.03 14.609 10.145

(1/(C*C) * (1-(α*α)/(α*α)))

Pressure Drop (ΔP) =

D - Opening Width (cm) 0.04 8.481 23.558

(K*p*V*V)/2*g

Pressure Drop (ΔP) Inches of

α - Effective opening area mmSq 0.25 3.339 9.275

Water

Pressure Drop (ΔP) Kg/cm2(g) 0.008 0.023

Pressure Drop (ΔP) mBar 8.153 22.647

Potrebbero piacerti anche

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportDa EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNessuna valutazione finora

- Materials Science and Technology of Optical FabricationDa EverandMaterials Science and Technology of Optical FabricationNessuna valutazione finora

- Pressure Drop Calculation for Item No. 2432 at Varying Clog ConditionsDocumento1 paginaPressure Drop Calculation for Item No. 2432 at Varying Clog ConditionsKailas NimbalkarNessuna valutazione finora

- Pressure drop calculations for item no. 8402 A/BDocumento1 paginaPressure drop calculations for item no. 8402 A/BKailas Nimbalkar0% (1)

- Pressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPDocumento1 paginaPressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPAssure TurbinesNessuna valutazione finora

- Pressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CPDocumento1 paginaPressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CPAssure TurbinesNessuna valutazione finora

- Conical Strainer PDC 40NBDocumento1 paginaConical Strainer PDC 40NBKailas Nimbalkar0% (1)

- FRNT ColDocumento96 pagineFRNT ColARUN RAWATNessuna valutazione finora

- DESIGN OF RC RETAINING WALLDocumento1 paginaDESIGN OF RC RETAINING WALLAHSANNessuna valutazione finora

- Purlin - Check - Hat SectionDocumento2 paginePurlin - Check - Hat SectionPrince MittalNessuna valutazione finora

- Retaining Wall ExcelDocumento82 pagineRetaining Wall ExcelOuseppachan AmbookenNessuna valutazione finora

- ALDECK3Documento5 pagineALDECK3Mustafa ÇakırNessuna valutazione finora

- ACI CorbelDocumento2 pagineACI CorbelmohamedNessuna valutazione finora

- Grade Slab ACI 150thkDocumento7 pagineGrade Slab ACI 150thkraahul_nNessuna valutazione finora

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocumento28 pagineCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNessuna valutazione finora

- Crack Width CheckDocumento2 pagineCrack Width CheckJitendra SinghNessuna valutazione finora

- Strainer Pre. Drop and Sizing CalcDocumento6 pagineStrainer Pre. Drop and Sizing CalcChandrakant SalunkheNessuna valutazione finora

- Reliance: Mangalore ST 12-May-2020 1 - 4068Documento4 pagineReliance: Mangalore ST 12-May-2020 1 - 4068Anilkumar VidelaNessuna valutazione finora

- Design of SlabsDocumento42 pagineDesign of SlabsMuralidargouda BhagavantagoudarNessuna valutazione finora

- Design of Isolated Footing (ECP-202)Documento18 pagineDesign of Isolated Footing (ECP-202)mahmoud mohamedNessuna valutazione finora

- Butterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Documento6 pagineButterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Ly Thanh HaNessuna valutazione finora

- Design of two-way reinforced concrete slabDocumento15 pagineDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNessuna valutazione finora

- 25nb y StrainerDocumento1 pagina25nb y StrainerKailas NimbalkarNessuna valutazione finora

- Slab design with discontinuous edgesDocumento11 pagineSlab design with discontinuous edgesRajesh Mangavu MaranNessuna valutazione finora

- Laboratory Test ResultDocumento1 paginaLaboratory Test ResultAwan KintonNessuna valutazione finora

- Annexure - Ix: Design Basis For Storm Water Drainage SystemDocumento3 pagineAnnexure - Ix: Design Basis For Storm Water Drainage SystemVaibhav SharmaNessuna valutazione finora

- DESIGN OF FLOOR SLAB (0.15m Thick)Documento9 pagineDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Crack Width Check BS5400 4Documento4 pagineCrack Width Check BS5400 4fontec.info2023Nessuna valutazione finora

- Lowering in Calculation: Calculation of Deflection CheckDocumento5 pagineLowering in Calculation: Calculation of Deflection CheckVinodParameswaran NairNessuna valutazione finora

- 30m monopole foundation design calculationsDocumento11 pagine30m monopole foundation design calculationsEhtesham AliNessuna valutazione finora

- WEB - Welding DesignDocumento2 pagineWEB - Welding DesignAdam MillerNessuna valutazione finora

- Slope Towards Heel: (Note:-Submerged 2/3rd Dry)Documento2 pagineSlope Towards Heel: (Note:-Submerged 2/3rd Dry)AHSANNessuna valutazione finora

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Documento4 pagineProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNessuna valutazione finora

- STUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and ThrustDocumento9 pagineSTUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and Thrustraja mistryNessuna valutazione finora

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Documento2 pagineAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Isolated Footing DesignDocumento24 pagineIsolated Footing DesignSANJEEV GANDOTRANessuna valutazione finora

- HTRI Heat Exchanger Rating SummaryDocumento6 pagineHTRI Heat Exchanger Rating SummaryCami Vander MeyNessuna valutazione finora

- Jpf5-E-0022 - 17 08 22Documento10 pagineJpf5-E-0022 - 17 08 22pradeep yadavNessuna valutazione finora

- RC RetainDocumento2 pagineRC RetainnikiiteaNessuna valutazione finora

- B41OA Data Sheet 2015-2016Documento10 pagineB41OA Data Sheet 2015-2016Leanne ChewNessuna valutazione finora

- Wind Girder Calculations: Appendix 'M' Is Applicable?Documento8 pagineWind Girder Calculations: Appendix 'M' Is Applicable?Anonymous LKi1w1uNessuna valutazione finora

- Weight CalculationDocumento13 pagineWeight CalculationPankaj BijweNessuna valutazione finora

- Item Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemiDocumento8 pagineItem Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemipradeeshNessuna valutazione finora

- Annexure-2 (Section Design Calcs)Documento107 pagineAnnexure-2 (Section Design Calcs)blisscutest beagleNessuna valutazione finora

- Name of Project-Development of Sewerage System Involving STP, Trunk Sewer Allied Works Including 5 Year Operation Maintenance at NainitalDocumento1 paginaName of Project-Development of Sewerage System Involving STP, Trunk Sewer Allied Works Including 5 Year Operation Maintenance at NainitalProject ManagerStructuresNessuna valutazione finora

- Engineering and Development Corporation of The PhilippinesDocumento4 pagineEngineering and Development Corporation of The Philippinesmark ignacioNessuna valutazione finora

- Slab Thickness Calculation With AGPADocumento2 pagineSlab Thickness Calculation With AGPAMohammad IqbalNessuna valutazione finora

- Load2: Analysis of Deck SlabDocumento12 pagineLoad2: Analysis of Deck SlabJunaid100% (1)

- Calcs for Concrete Industrial Ground Floor DesignDocumento3 pagineCalcs for Concrete Industrial Ground Floor DesignRuemu Godwin InikoriNessuna valutazione finora

- Stair Case Design: Schematic PlanDocumento6 pagineStair Case Design: Schematic Planthanigai veluNessuna valutazione finora

- ACI CorbelDocumento2 pagineACI CorbelFranklyn GenoveNessuna valutazione finora

- One Way SlabDocumento23 pagineOne Way SlabmeerahNessuna valutazione finora

- Hasen Design Summary 20 MetreDocumento2 pagineHasen Design Summary 20 MetreAgshin PirimovNessuna valutazione finora

- Hence The Spcacing Between Rod Is (MM) 105 O.KDocumento1 paginaHence The Spcacing Between Rod Is (MM) 105 O.KVijay KumarNessuna valutazione finora

- Two Way Slab - IS Code - LSMDocumento12 pagineTwo Way Slab - IS Code - LSMNitesh SinghNessuna valutazione finora

- Design of base plate for columnDocumento6 pagineDesign of base plate for columnsoumyaNessuna valutazione finora

- ACI-Beam LedgeDocumento7 pagineACI-Beam Ledgeja'far baderNessuna valutazione finora

- Pressuremeter Testing: Methods and InterpretationDa EverandPressuremeter Testing: Methods and InterpretationValutazione: 5 su 5 stelle5/5 (2)

- MOS Integrated Circuit DesignDa EverandMOS Integrated Circuit DesignE. WolfendaleNessuna valutazione finora

- Laser Technology: Applications in Adhesion and Related AreasDa EverandLaser Technology: Applications in Adhesion and Related AreasNessuna valutazione finora

- Radhika Waste ManagementDocumento28 pagineRadhika Waste ManagementKailas NimbalkarNessuna valutazione finora

- Authorization LetterDocumento1 paginaAuthorization LetterKailas NimbalkarNessuna valutazione finora

- Problem Solving in Solid Waste Engineering: January 2012Documento66 pagineProblem Solving in Solid Waste Engineering: January 2012Kailas Nimbalkar100% (1)

- PROPOSAL OF GREEN HC - MSW - Eng - Ver.1Documento77 paginePROPOSAL OF GREEN HC - MSW - Eng - Ver.1Kailas NimbalkarNessuna valutazione finora

- Specification SheetDocumento1 paginaSpecification SheetKailas NimbalkarNessuna valutazione finora

- Kailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Documento6 pagineKailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Kailas NimbalkarNessuna valutazione finora

- Performance LogDocumento1 paginaPerformance LogKailas NimbalkarNessuna valutazione finora

- THERMODYNAMIC PROPERTIESDocumento15 pagineTHERMODYNAMIC PROPERTIESKailas NimbalkarNessuna valutazione finora

- Abhijit Lagare 2018 - 3Documento3 pagineAbhijit Lagare 2018 - 3Kailas NimbalkarNessuna valutazione finora

- 2 Mass Production ProductsDocumento12 pagine2 Mass Production ProductsKailas NimbalkarNessuna valutazione finora

- MKT 078 04 AG ST Bioactive Surface TreatmentDocumento2 pagineMKT 078 04 AG ST Bioactive Surface TreatmentKailas NimbalkarNessuna valutazione finora

- Nabl 400Documento481 pagineNabl 400parveshnain19Nessuna valutazione finora

- MouDocumento4 pagineMouadishNessuna valutazione finora

- Contact Details of RTAsDocumento487 pagineContact Details of RTAsnir0% (1)

- OPERATIONS-Hyderabad CompressedDocumento16 pagineOPERATIONS-Hyderabad CompressedKailas NimbalkarNessuna valutazione finora

- Fungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalDocumento7 pagineFungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalKailas NimbalkarNessuna valutazione finora

- ACAC Council-Certified Indoor Environmental ConsultantDocumento1 paginaACAC Council-Certified Indoor Environmental ConsultantKailas NimbalkarNessuna valutazione finora

- Service Customer DetailsDocumento12 pagineService Customer DetailsKailas NimbalkarNessuna valutazione finora

- Pune Cs CX Mar12Documento42 paginePune Cs CX Mar12Kailas NimbalkarNessuna valutazione finora

- Method Statement Titania VS 1 2 and Titania FAir (INDIA)Documento12 pagineMethod Statement Titania VS 1 2 and Titania FAir (INDIA)Kailas NimbalkarNessuna valutazione finora

- GOALSDocumento4 pagineGOALSKailas NimbalkarNessuna valutazione finora

- Bharti Tools Payment 12980Documento1 paginaBharti Tools Payment 12980Kailas NimbalkarNessuna valutazione finora

- Pressure Vessel & Air Receiver CatalogDocumento16 paginePressure Vessel & Air Receiver CatalogrenebbNessuna valutazione finora

- GoalsDocumento8 pagineGoalsKailas NimbalkarNessuna valutazione finora

- E-Way Bill System-DELIVERY CHALLAN-1Documento1 paginaE-Way Bill System-DELIVERY CHALLAN-1Kailas NimbalkarNessuna valutazione finora

- Smart OrbitersDocumento2 pagineSmart OrbitersKailas NimbalkarNessuna valutazione finora

- StepsDocumento1 paginaStepsKailas NimbalkarNessuna valutazione finora

- Eaton Self Cleaning StrainerDocumento40 pagineEaton Self Cleaning StrainerKailas NimbalkarNessuna valutazione finora

- BSF CatalogDocumento2 pagineBSF CatalogKailas NimbalkarNessuna valutazione finora

- Air Receivers: Technology You Can TrustDocumento6 pagineAir Receivers: Technology You Can TrustNorman FerdianNessuna valutazione finora

- The Second Term Exam of EnglishDocumento2 pagineThe Second Term Exam of Englishsof chimiste100% (1)

- Lift EstimationDocumento5 pagineLift EstimationAvinash SinghNessuna valutazione finora

- cO2CH4 Permselective GassensorDocumento5 paginecO2CH4 Permselective GassensorKartik RamasubramanianNessuna valutazione finora

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkDocumento287 pagineStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkluis morales100% (2)

- F1223 1479757-1Documento9 pagineF1223 1479757-1Thaweekarn ChangthongNessuna valutazione finora

- A Brief Overview of The Holographic TechnologyDocumento5 pagineA Brief Overview of The Holographic TechnologyAltiel Ltd.Nessuna valutazione finora

- The D and F Block Elements PDFDocumento8 pagineThe D and F Block Elements PDFTr Mazhar PunjabiNessuna valutazione finora

- Signature RedactedDocumento49 pagineSignature RedactedG Pavan KumarNessuna valutazione finora

- Review: Modeling Damping in Mechanical Engineering StructuresDocumento10 pagineReview: Modeling Damping in Mechanical Engineering Structuresuamiranda3518Nessuna valutazione finora

- 1 Design Basis 1.1 Material and Properties 1.1 Material and PropertiesDocumento13 pagine1 Design Basis 1.1 Material and Properties 1.1 Material and PropertiesDarshan PanchalNessuna valutazione finora

- Chapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NDocumento15 pagineChapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NCedric KouakouNessuna valutazione finora

- HW1Documento8 pagineHW1Anonymous fXSlye100% (1)

- Formulae and Design Rules To Ec2Documento45 pagineFormulae and Design Rules To Ec2moodoo100% (4)

- P 211enDocumento26 pagineP 211enRadhakrishnan BalasubramanianNessuna valutazione finora

- Vector CalculusDocumento62 pagineVector CalculuswaleedNessuna valutazione finora

- D V V U: T A.II.i.4. M P BS 1178Documento4 pagineD V V U: T A.II.i.4. M P BS 1178ShubhamRanjanNessuna valutazione finora

- ELIMINATION REACTIONS: AN OVERVIEWDocumento19 pagineELIMINATION REACTIONS: AN OVERVIEWSyuhadah NoordinNessuna valutazione finora

- Led t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaDocumento3 pagineLed t5 Eco Batten - 93044476 - Lbte 4 5 WW 1ft Eco - 221864 - EmeaNailza BizerraNessuna valutazione finora

- Fourier Transform and Its Medical ApplicationDocumento55 pagineFourier Transform and Its Medical Applicationadriveros100% (1)

- ME 555 Stress Analysis Unit 4Documento57 pagineME 555 Stress Analysis Unit 4TheoNessuna valutazione finora

- Reability PDFDocumento396 pagineReability PDFMarcelo Ziulkoski100% (1)

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Documento9 pagineCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jesús Luis Arce GuillermoNessuna valutazione finora

- Rectilinear Motion and Rotating VesselDocumento4 pagineRectilinear Motion and Rotating VesselJack PresadoNessuna valutazione finora

- Ferroresonance During Single-Phase Switching of Distribution TransformersDocumento6 pagineFerroresonance During Single-Phase Switching of Distribution TransformersDiego Betancourt MejiaNessuna valutazione finora

- Gujarat Technological University: Page 1 of 3Documento3 pagineGujarat Technological University: Page 1 of 3DaxNessuna valutazione finora

- Atlas Copco: Parts ListDocumento152 pagineAtlas Copco: Parts ListChathura SenanayakeNessuna valutazione finora

- Bradford AssayDocumento2 pagineBradford AssayCNessuna valutazione finora

- DWC ElecConduit Is 16205 P24 2018Documento11 pagineDWC ElecConduit Is 16205 P24 2018Vamsi Manoj60% (5)

- Introducing JiFi ST Petersburg 2014Documento4 pagineIntroducing JiFi ST Petersburg 2014danjohhnNessuna valutazione finora