Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PDF Vacuumpump Maintanance

Caricato da

Carla Samantha MontiverdeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PDF Vacuumpump Maintanance

Caricato da

Carla Samantha MontiverdeCopyright:

Formati disponibili

InCarrier L/UL Service and Maintenance

Preventive Maintenance Yearly

3.2.4.4 Vacuum Pump - Replacement of Teflon Membrane

No. of the spare parts:

Teflon membrane MPG.490 (4x)

Valve MPV.442 (8x)

Position of the vacuum pump (1).

Position of vacuum pump

1. Remove cover to get access to the vacuum

pump (1).

Remove cover

2. Disconnect the rear hose (1).

Rear hose

Version 3.14 3-219

15.01.20.00.00 05.06.2015

Service and Maintenance InCarrier L/UL

Yearly Preventive Maintenance

3. Disconnect power plug (1).

Position of power plug inside the right frame strut

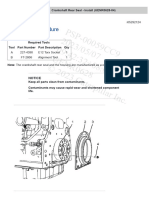

4. Remove fastening screws (1).

Fastening screws

5. Take vacuum pump out.

6. Disconnect lower hose (1).

Lower hose

3-220 Version 3.14

05.06.2015 15.01.20.00.00

InCarrier L/UL Service and Maintenance

Preventive Maintenance Yearly

7. Remove the two fastening screws (1) from the

ground plate.

Ground plate

8. Loosen the four hose connectors (1) at the top.

Hose connectors top side

9. Loosen the four hose connectors (1) at the bot-

tom.

Hose connectors lower side

Version 3.14 3-221

15.01.20.00.00 05.06.2015

Service and Maintenance InCarrier L/UL

Yearly Preventive Maintenance

10. Remove the four connector heads (1), (only two

shown).

Remove connector heads

11. Remove the O-rings (2) and the valves (3) from

the connector head (1).

12. Clean connector head with Isopropyl alcohol.

Connector head removed

13. Remove the four pump heads (1) (only two

shown) and clean them with Isopropyl alcohol.

Pump heads

3-222 Version 3.14

05.06.2015 15.01.20.00.00

InCarrier L/UL Service and Maintenance

Preventive Maintenance Yearly

Note

Procedure is the same for all four

positions.

14. Use a pin type face wrench (1) to remove the

strain washer (2).

Loosen strain washer

Strain washer (1), pressure disc (2) and old

Teflon membrane (3) removed.

Old Teflon membrane removed

15. Assemble new Teflon membrane (1) and

strain washer (2).

Teflon membrane and strain washer

Version 3.14 3-223

15.01.20.00.00 05.06.2015

Service and Maintenance InCarrier L/UL

Yearly Preventive Maintenance

Note

Pay attention, that the round

edge (1) faces to the membrane.

16. Place the pressure disc on the threaded pin (2).

Pressure disc

17. Attach complete assembly (1) to the plunger (2).

Membrane assembly complete

18. Use the pin type face wrench (1) to fasten the

strain washer (2).

Fasten membrane assembly

3-224 Version 3.14

05.06.2015 15.01.20.00.00

InCarrier L/UL Service and Maintenance

Preventive Maintenance Yearly

19. Replace O-rings (1) by new ones.

20. Replace valves (2) by new ones.

21. Attach pump head (3) again. Pay attention to the

coded hole and pin (4).

Attaching parts

22. The pin (2) must fit into the deep hole (1)

Coded by pin and hole

Note

Arrows of flow direction must point

down.

23. Attach the four connector heads (1) again with a

torque force of 3 - 4 Nm.

Flow direction

Version 3.14 3-225

15.01.20.00.00 05.06.2015

Service and Maintenance InCarrier L/UL

Yearly Preventive Maintenance

24. Connect hoses (1) again at the upper and lower

side.

Hose connectors top side

25. Attach the ground plate and fasten the two

screws (1) at the ground plate.

Ground plate

26. Place vacuum pump near the machine and con-

nect the lower hose (1) again.

Lower hose

3-226 Version 3.14

05.06.2015 15.01.20.00.00

InCarrier L/UL Service and Maintenance

Preventive Maintenance Yearly

Note

Pay attention to correct fit of the

springs.

27. Place vacuum pump in the machine and fasten

the two screws (1).

Fastening screws

28. Connect power plug (1).

Position of power plug inside the right frame strut

29. Connect the pressure measuring device (1) to

the upper connector (2).

Connect pressure measuring device

Version 3.14 3-227

15.01.20.00.00 05.06.2015

Service and Maintenance InCarrier L/UL

Yearly Preventive Maintenance

DANGER

Machine powered on, while cover is removed!

Electrical shock or squeezing by moving parts.

) Take care, that nobody reaches into the opened

area.

) Make sure nobody starts the machine.

30. Power on the machine.

31. Wait at least 5 minutes, until the vacuum pump reaches its operation temperature.

32. Check the pressure.

Value must be between -0.86 bar and -0.99 bar.

33. Power off machine and disconnect pressure measuring device.

34. If value is not ok, check complete vacuum pump assembly again.

35. If value is ok, connect the vacuum hose of the machine to the vacuum pump and attach

cover again.

3-228 Version 3.14

05.06.2015 15.01.20.00.00

Potrebbero piacerti anche

- Failure Analysis in Engineering ApplicationsDa EverandFailure Analysis in Engineering ApplicationsValutazione: 1 su 5 stelle1/5 (1)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999Da EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999Nessuna valutazione finora

- Caterpillar C7 - C9 - Sample EngDocumento11 pagineCaterpillar C7 - C9 - Sample Engpp100% (4)

- 2 5-In. MPV Pressure-Test Bypass Valve: SectionDocumento26 pagine2 5-In. MPV Pressure-Test Bypass Valve: Sectionsong LiNessuna valutazione finora

- Engine 12V140E-3 Series: 50 Disassembly and AssemblyDocumento19 pagineEngine 12V140E-3 Series: 50 Disassembly and AssemblyЕгорNessuna valutazione finora

- Contents:: Choke Valve Installation & Maintenance ManualDocumento10 pagineContents:: Choke Valve Installation & Maintenance Manualimam susantoNessuna valutazione finora

- Min Jcwupgrade Gen1Documento12 pagineMin Jcwupgrade Gen1Simon CooperNessuna valutazione finora

- E70 Running Board InstallDocumento7 pagineE70 Running Board InstallLuis PérezNessuna valutazione finora

- Boletín de Servicio NissanDocumento14 pagineBoletín de Servicio NissanJuan Fernando Ortiz MedelNessuna valutazione finora

- Compressor ClutchDocumento6 pagineCompressor Clutchbobbynicky007100% (1)

- 01 29 0 432 167 Aluminium Running Boards Retrofit KitDocumento5 pagine01 29 0 432 167 Aluminium Running Boards Retrofit Kitmagakavkaz1991Nessuna valutazione finora

- MM32-30-31-02.full - Selector Valve - PracticesDocumento4 pagineMM32-30-31-02.full - Selector Valve - PracticesIng NavaNessuna valutazione finora

- 2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Documento9 pagine2946 1186 00 Maintenance Procedure GA 11-30 (VSD)Rui FortunaNessuna valutazione finora

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Documento26 pagineCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNessuna valutazione finora

- Wiper and Washer SystemsDocumento12 pagineWiper and Washer SystemsRuben MoncalunaNessuna valutazione finora

- Main Valve Block, Removal: Información de ServicioDocumento8 pagineMain Valve Block, Removal: Información de ServicioWesley MonsaNessuna valutazione finora

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3Documento65 pagineTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 3AdvocateNessuna valutazione finora

- 3523en PDFDocumento13 pagine3523en PDFSlawomir PajakNessuna valutazione finora

- Cambio Di Velocita' DifferenzialeDocumento7 pagineCambio Di Velocita' DifferenzialewezawezaNessuna valutazione finora

- N52 StarterreplacementDocumento18 pagineN52 StarterreplacementsamadNessuna valutazione finora

- 12-2218-r01 (59552105) SP5Documento11 pagine12-2218-r01 (59552105) SP5Brad KerrNessuna valutazione finora

- Rep Rep Raf1051 5142000 - Vin7 D490248Documento4 pagineRep Rep Raf1051 5142000 - Vin7 D490248jamesNessuna valutazione finora

- Vsa Maintenance 1000-1200 - enDocumento14 pagineVsa Maintenance 1000-1200 - enMabel LimNessuna valutazione finora

- Caterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)Documento27 pagineCaterpillar Cat 330B L Excavator (Prefix 5LR) Service Repair Manual (5LR00001 and Up)kfm8seuudu100% (1)

- Communication System ComDocumento10 pagineCommunication System ComThomas ZoumbouliasNessuna valutazione finora

- Fendt HidraulicDocumento5 pagineFendt HidraulicDainius SimonaitisNessuna valutazione finora

- Turbocharger - Remove - First Stage Turbocharger: Shutdown SISDocumento5 pagineTurbocharger - Remove - First Stage Turbocharger: Shutdown SISMbahdiro KolenxNessuna valutazione finora

- EECD0001Documento36 pagineEECD0001Sergey Gusev100% (3)

- Truck Adjuster DisDocumento2 pagineTruck Adjuster DisaungaungoomanualNessuna valutazione finora

- Sfi System: PrecautionDocumento141 pagineSfi System: PrecautionHtet Arkar KyawNessuna valutazione finora

- Canon New F-1: Service Manual Exploded Views AND Parts ListDocumento125 pagineCanon New F-1: Service Manual Exploded Views AND Parts ListTLONessuna valutazione finora

- DE TS Diesel Engine: Disassembly & AssemblyDocumento78 pagineDE TS Diesel Engine: Disassembly & AssemblyBulgantamir DorjsurenNessuna valutazione finora

- SECTION 9001 Cab RemovalDocumento12 pagineSECTION 9001 Cab Removallungu mihaiNessuna valutazione finora

- Apollo Rack & Pinion Pneumatic ActuatorDocumento10 pagineApollo Rack & Pinion Pneumatic ActuatorDelta ProductionNessuna valutazione finora

- 32 Crankshaft Rear Seal - InstallDocumento4 pagine32 Crankshaft Rear Seal - InstallgwahyudinnNessuna valutazione finora

- SEN00321-01 50 Disassembly and AssemblyDocumento6 pagineSEN00321-01 50 Disassembly and AssemblyЕгорNessuna valutazione finora

- Voice Coil CleaningDocumento24 pagineVoice Coil CleaningCarla Samantha MontiverdeNessuna valutazione finora

- TM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3Documento130 pagineTM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3AdvocateNessuna valutazione finora

- Wi - Chemical Unloading Pump Disassembly & InspectionDocumento10 pagineWi - Chemical Unloading Pump Disassembly & InspectionMuhammad Hasbi AsidiqiNessuna valutazione finora

- Instruction Guide Combiflex Crimping ToolDocumento2 pagineInstruction Guide Combiflex Crimping ToolAE,110 KV KanjikodeNessuna valutazione finora

- Lý thuyết màng thẩm thấu ngược (tiếng Anh)Documento111 pagineLý thuyết màng thẩm thấu ngược (tiếng Anh)BajaminhNessuna valutazione finora

- Use and Maintenance Manual: Pneumatic L SealerDocumento20 pagineUse and Maintenance Manual: Pneumatic L SealerYoslen NuñezNessuna valutazione finora

- MC 10174415 0001 PDFDocumento22 pagineMC 10174415 0001 PDFgerbin gaytan riveraNessuna valutazione finora

- MN 03007Documento16 pagineMN 03007hyarub9Nessuna valutazione finora

- P QUIP Swab and Pony RodDocumento5 pagineP QUIP Swab and Pony Rodkrishnsgk0% (1)

- 19 - Replacement of Horizontal Gear BoxDocumento7 pagine19 - Replacement of Horizontal Gear BoxTanweer KhanNessuna valutazione finora

- SERVICE ALERT #387 Automatic Drain Wear KitDocumento5 pagineSERVICE ALERT #387 Automatic Drain Wear KitvaleryNessuna valutazione finora

- 2020-06-14 K-4101 BCL Overhaul Job ReportDocumento33 pagine2020-06-14 K-4101 BCL Overhaul Job ReportShahid RazzaqNessuna valutazione finora

- 2o66 Luh 11Documento25 pagine2o66 Luh 11György SzenciNessuna valutazione finora

- Caterpillar Cat 336F LN Excavator (Prefix WTZ) Service Repair Manual (WTZ00001 and Up)Documento30 pagineCaterpillar Cat 336F LN Excavator (Prefix WTZ) Service Repair Manual (WTZ00001 and Up)kfsmmeNessuna valutazione finora

- 8 7 PDFDocumento54 pagine8 7 PDFHector Renzo Zarate RodriguezNessuna valutazione finora

- Load Control Valve (Boom Cylinder) - AssembleDocumento6 pagineLoad Control Valve (Boom Cylinder) - AssemblechanlinNessuna valutazione finora

- Power Train: Procedures and Suggestions For Removal and InstallationDocumento11 paginePower Train: Procedures and Suggestions For Removal and InstallationPepe AlNessuna valutazione finora

- Perkins 1103 Valve InstallDocumento10 paginePerkins 1103 Valve InstallInkanata SacNessuna valutazione finora

- Mtu 4000 Water Pump DismantleDocumento93 pagineMtu 4000 Water Pump DismantlesxturboNessuna valutazione finora

- PERKINS 800D SERVICE MANUAL Pages Copy 804D-33 804D-33 UK UL Courtesy of Worldwide Parts Source LLC Phone 269 673 2313 Engine PartsDocumento97 paginePERKINS 800D SERVICE MANUAL Pages Copy 804D-33 804D-33 UK UL Courtesy of Worldwide Parts Source LLC Phone 269 673 2313 Engine PartsPedro Lorenço Jorge100% (1)

- Install Piston and ConrodDocumento8 pagineInstall Piston and ConrodLUIZ GUSTAVONessuna valutazione finora

- Remove Fresh Air Grill in Footwell.: Release Center Console at RearDocumento3 pagineRemove Fresh Air Grill in Footwell.: Release Center Console at Rearapi-3744308Nessuna valutazione finora

- ML B 200 b200fmm1035Documento11 pagineML B 200 b200fmm1035Marco Antonio PrietoNessuna valutazione finora

- EIV DISASSEMBLY&REPLACEMENT ReussDocumento117 pagineEIV DISASSEMBLY&REPLACEMENT ReussNguyễn ThànhNessuna valutazione finora

- The Economic Feasibility of Solar Panels For The University of Nebraska-LincolnDocumento22 pagineThe Economic Feasibility of Solar Panels For The University of Nebraska-LincolnCarla Samantha MontiverdeNessuna valutazione finora

- Wind Power StudiesDocumento13 pagineWind Power StudiesCarla Samantha MontiverdeNessuna valutazione finora

- Feasibility Study of Economics and Performance of Solar Photovoltaics in Nitro, West VirginiaDocumento54 pagineFeasibility Study of Economics and Performance of Solar Photovoltaics in Nitro, West VirginiaCarla Samantha MontiverdeNessuna valutazione finora

- An Empirical Perspective On The Energy Payback Time For Photovoltaic ModulesDocumento12 pagineAn Empirical Perspective On The Energy Payback Time For Photovoltaic ModulesCarla Samantha MontiverdeNessuna valutazione finora

- Iram236 1067aDocumento17 pagineIram236 1067aCarla Samantha Montiverde100% (1)

- Voice Coil CleaningDocumento24 pagineVoice Coil CleaningCarla Samantha MontiverdeNessuna valutazione finora

- Sample References 1Documento6 pagineSample References 1Carla Samantha MontiverdeNessuna valutazione finora

- How To Write A Research Paper: I. Topic SelectionDocumento7 pagineHow To Write A Research Paper: I. Topic SelectionCarla Samantha MontiverdeNessuna valutazione finora

- ATV21 Programlama Kılavuzu enDocumento145 pagineATV21 Programlama Kılavuzu enUsman KhanNessuna valutazione finora

- Seminar On: Vlan TechnologyDocumento17 pagineSeminar On: Vlan Technologyfinnyfound100% (1)

- Thinclient 19Documento9 pagineThinclient 19api-3833258100% (2)

- F 90Documento35 pagineF 90ulises100% (1)

- Eng TELE-satellite 1205Documento276 pagineEng TELE-satellite 1205Alexander WieseNessuna valutazione finora

- Ansys All You Need To Know About Hardware For SimulationDocumento36 pagineAnsys All You Need To Know About Hardware For Simulationnovkovic1984Nessuna valutazione finora

- Introduction To DBMSDocumento28 pagineIntroduction To DBMSapi-19922433Nessuna valutazione finora

- RN4870 71 Bluetooth Low Energy Module User Guide DS50002466CDocumento75 pagineRN4870 71 Bluetooth Low Energy Module User Guide DS50002466CDev SaneNessuna valutazione finora

- HP Probook 4520s QUANTA GC9A Rev 1A SchematicsDocumento57 pagineHP Probook 4520s QUANTA GC9A Rev 1A SchematicssanathNessuna valutazione finora

- RTLFC 16609e 1108Documento38 pagineRTLFC 16609e 1108jharold22Nessuna valutazione finora

- Windows7 SuperguideDocumento60 pagineWindows7 SuperguideRichard Canar PerezNessuna valutazione finora

- S7 Distributed Safety Configuring and Programming en US en-USDocumento356 pagineS7 Distributed Safety Configuring and Programming en US en-USFrancescoNessuna valutazione finora

- Q250 SM Pneumatic Spinning WrenchDocumento11 pagineQ250 SM Pneumatic Spinning WrenchGianna FrolaNessuna valutazione finora

- Apxvbll15xt CDocumento2 pagineApxvbll15xt CSvetovidPerunsinNessuna valutazione finora

- 2012 - Q2 All 100Documento84 pagine2012 - Q2 All 100zaskribdoNessuna valutazione finora

- MS309 Manual - V1.01 PDFDocumento32 pagineMS309 Manual - V1.01 PDFtidchong prakoonmongkoneNessuna valutazione finora

- ASUS M50S X55S Rev2.0Documento96 pagineASUS M50S X55S Rev2.0Martin CervasioNessuna valutazione finora

- Debug Howto - Android-X86 - Porting Android To x86Documento2 pagineDebug Howto - Android-X86 - Porting Android To x86nurbogNessuna valutazione finora

- 62786Documento13 pagine62786abbassNessuna valutazione finora

- Behaviour of OFDM System Using MATLAB SimulationDocumento5 pagineBehaviour of OFDM System Using MATLAB Simulationsreekanthreddy peramNessuna valutazione finora

- Data Sheet ZNX:EIP-200S: General InformationDocumento2 pagineData Sheet ZNX:EIP-200S: General InformationVasile TothNessuna valutazione finora

- 2012 06 Openwells Mobile For Workovers Data Sheet PDFDocumento2 pagine2012 06 Openwells Mobile For Workovers Data Sheet PDFWilman Ardila BarbosaNessuna valutazione finora

- Ee 465 Lab 5Documento8 pagineEe 465 Lab 5api-302211966Nessuna valutazione finora

- Service Manual Viasonix PletismógrafoDocumento33 pagineService Manual Viasonix PletismógrafodhcastanoNessuna valutazione finora

- Ashok Leyland ReportDocumento7 pagineAshok Leyland ReportJay Surya100% (1)

- Antenna Alignment SPAA05 NEX Brochure 2Documento4 pagineAntenna Alignment SPAA05 NEX Brochure 2furqansNessuna valutazione finora

- Arduino S3v3 ManualDocumento7 pagineArduino S3v3 ManualJiradech SaiNessuna valutazione finora

- GSK 928 TeiiDocumento3 pagineGSK 928 TeiiAndersonNessuna valutazione finora

- Fa5590n Fa5591nDocumento21 pagineFa5590n Fa5591nАлександр АндриановNessuna valutazione finora

- Spice Model of DiodeDocumento20 pagineSpice Model of DiodeharizNessuna valutazione finora