Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WPAR

Caricato da

Sc TanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WPAR

Caricato da

Sc TanCopyright:

Formati disponibili

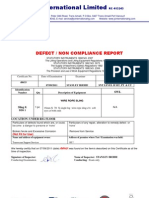

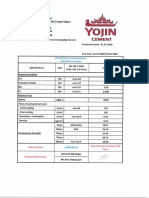

Welding Procedure Approval Record Form (WPAR) (PROPOSED)

Welding Procedure Approval-Test Certificate

Manufacturer’s Welding Procedure Examiner or test body :

Reference No.: PQR-EN-03-TSH-04 Reference No.:

Page no.: 1 of 2

Manufacturer Name and Address : Gulf Marine Maintanence and Offshore Service Co.

: P.O.Box 4613, DUBAI – U.A.E

Code/Testing Standard : EN 288 PART – 3 Date of Welding: 14th July 2004

Extent of Approval : Thickness 3mm Upto 22.2mm, Diameter 2”NPS to 8”NPS

Welding Process : 141 + 111. Joint Type: BUTT

Parent metal, Conditions of tempered: A333 Gr.6 ( Group2), Tempered at 675 + 80 C for 72 Minutes

Metal Thickness (mm) : 11.1mm Outside Diameter (mm): 4 .5”

Filler Metal Type : SG1 for 141 and E46 5B 32 H5 for 111.

Shielding Gas/Flux : 99.9% Argon for 141, N.A. for 111.

Type of Welding Current : DC EN for 141, DC EP for 111.

Welding Positions : HL045

Preheat : 400 C.

Post Weld Heat Treatment and/or

Ageing : NA Other information : AS IN NEXT PAGE.

Certified that test welds prepared, welded and tested satisfactorily in accordance

With the requirements of the code testing standard indicated above.

Location Date of issue Examiner or test body

GMMOS WORKSHOP 26.01.2005

Name,date & Signature

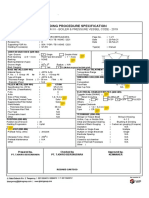

WPS NO: EN – 03 – TS - 04 WPAR NO.: PQR-EN-03-TS-04 (PROPOSED)

PAGE NO.: 2 Of 2

Joints Design Welding Sequences

a a - 60 0 1.Root and hotpass by

g – 2+1 mm. 141.

f – 2 mm 2. Fill and cap by 111.

t - 11.1 mm

t

Backing : NIL

f

g

WELDING PROCESS

Run Welding

Size Current Type Voltage Type Wire feed Travel Speed Heat

process

of “ Ampere” “Volts” Of Speed (inch/minute) input*

Filler current/

Metal Polarity

REFER RECORD OF ACTUAL VARIABLES SHEET FOR VALUES.

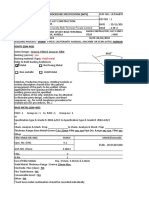

TEST RESULTS

VISUAL EXAMINATION : RADIOGRAPHY :

PENETRANT / M.P. EXAMINATION : ULTRASONIC EXAMINATION:

TENSILE TEST

TYPE/ SIZE AREA YIELD ULTIMATE ULTIMATE %ELONGATIO FRACTURE REMARKS

NO mm mm2 STRESS LOAD TENSILE N LOCATION

(KN) STRESS

TT 1

TT 2

ALL WELD TENSILE TEST :N.A.

BEND TEST

TYPE /NO MANDREL DIA/ ANGLE RESULT

FACE BEND – 1, 2 4T /120

ROOT BEND – 1, 2 4T /120

WELD MACRO EXAMINATION : MACRO –1,

IMPACT TESTING. TYPE : CHARPY V NOTCH SIZE:10 X 10 X 55 TEST TEMPARATURE : (MINUS )

LOCATION VALUES( JOULES) MEAN(JOULES) REMARKS

WCL

HAZ

HARDNESS HV10 PIPE1, PIPE2

PM WM (141) WM (111) HAZ

MINIMUM

MAXIMUM

WELDED BY:, W#

TESTING CARRIED OUT BY :

WELDING AND TESTING WITNESSSED BY :

RECORD OF ACTUAL VARIABLES

PREPARED BY: APPROVED BY: WITNESSED AND CERTIFIED BY:

GMMOS QA/QC ENGINEER GMMOS QA/QC MANAGER

K.RAJAGOPAL P.NATARAJAN

DATE: 26.01.2005 DATE: 26.01.2005

Potrebbero piacerti anche

- Euroclad Guide To Design and Installation of Trapezoidal SystemsDocumento0 pagineEuroclad Guide To Design and Installation of Trapezoidal Systemsssss2345Nessuna valutazione finora

- HeaDocumento1 paginaHeaRianto HalimNessuna valutazione finora

- Welding Instruction Manual PDFDocumento96 pagineWelding Instruction Manual PDFyud100% (1)

- Tekla Structures: Modeling ManualDocumento173 pagineTekla Structures: Modeling ManualKa KaNessuna valutazione finora

- Galv Eye&EyeDocumento1 paginaGalv Eye&EyeTulang RorobotNessuna valutazione finora

- Din 1732-3-2007Documento5 pagineDin 1732-3-2007Luis PaletoNessuna valutazione finora

- Chanels Tapered Flange Metric and Universal Beams and Columns Imperial Units and UPNDocumento3 pagineChanels Tapered Flange Metric and Universal Beams and Columns Imperial Units and UPNPratama YogaNessuna valutazione finora

- Universal BeamDocumento17 pagineUniversal BeamHazwan AzamanNessuna valutazione finora

- BS en 15614 Welder Tests Template1Documento14 pagineBS en 15614 Welder Tests Template1delta lab sangliNessuna valutazione finora

- EN - 583-2 - (2001) - Non-Destructive Testing. Ultrasonic Examination. Sensitivity and Range SettingDocumento47 pagineEN - 583-2 - (2001) - Non-Destructive Testing. Ultrasonic Examination. Sensitivity and Range SettingMarcelo RodriNessuna valutazione finora

- Corporate Presentation 3/26/2013 - 1Documento18 pagineCorporate Presentation 3/26/2013 - 1Jose ManuelNessuna valutazione finora

- Doors & WindowsDocumento21 pagineDoors & Windows200211555Nessuna valutazione finora

- Aluzinc Corrosion Resistance en 2012Documento17 pagineAluzinc Corrosion Resistance en 2012electronicmail2ughf6525Nessuna valutazione finora

- Cai Mep International Container Terminal: Method Statement of Piling Works For BuildingsDocumento21 pagineCai Mep International Container Terminal: Method Statement of Piling Works For BuildingskarfungNessuna valutazione finora

- Ecotek DesignManual v2015 02Documento44 pagineEcotek DesignManual v2015 02benNessuna valutazione finora

- Din 1480 2005Documento6 pagineDin 1480 2005PacoNessuna valutazione finora

- CS Colours2011-1 PDFDocumento3 pagineCS Colours2011-1 PDFmanbkk100% (1)

- Welding ElotrodeDocumento3 pagineWelding ElotrodeNiranjan khatuaNessuna valutazione finora

- Australian/New Zealand Standard: Tolerances For Flat-Rolled Steel ProductsDocumento7 pagineAustralian/New Zealand Standard: Tolerances For Flat-Rolled Steel ProductsZohaib Rafiq0% (1)

- En 1090Documento1 paginaEn 1090Anonymous pgQIReuNessuna valutazione finora

- Ok Tigrod 12.64 Gtaw enDocumento2 pagineOk Tigrod 12.64 Gtaw ensoft4gsmNessuna valutazione finora

- Carbon Arc Cutting PDFDocumento44 pagineCarbon Arc Cutting PDFMark InnesNessuna valutazione finora

- Texmaco Limited: Welding Process InstructionDocumento15 pagineTexmaco Limited: Welding Process InstructionArvindshuklamechNessuna valutazione finora

- 242 MIG Settings ChartDocumento1 pagina242 MIG Settings ChartKarthik Dasari100% (1)

- Bohler CatalogDocumento308 pagineBohler CatalogPerumal GovindanNessuna valutazione finora

- Welding PlanDocumento1 paginaWelding Planapi-298346841Nessuna valutazione finora

- DINEN29692 (Weld Joint Preparation)Documento17 pagineDINEN29692 (Weld Joint Preparation)thanghanvicoNessuna valutazione finora

- CHG 55B2Documento1 paginaCHG 55B2Nhien ManNessuna valutazione finora

- EN 1993-1-12-2007 Eurocode 3  " Design of Steel Structures  " Part 1-12 Additional Rules For The Extension of EN 1993 Up To Steel Grades S 700Documento12 pagineEN 1993-1-12-2007 Eurocode 3  " Design of Steel Structures  " Part 1-12 Additional Rules For The Extension of EN 1993 Up To Steel Grades S 700Gökhan Çiçek100% (1)

- BP3 Trowel Finished ConcreteDocumento1 paginaBP3 Trowel Finished ConcretepipiNessuna valutazione finora

- WPS PQR-07Documento8 pagineWPS PQR-07Ranjan KumarNessuna valutazione finora

- BS en 13141-7 2004 Ventilation For Buildings PDFDocumento24 pagineBS en 13141-7 2004 Ventilation For Buildings PDFRamiAl-fuqahaNessuna valutazione finora

- Manufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoDocumento2 pagineManufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoAMIT SHAHNessuna valutazione finora

- JIS G3452 PipeDocumento0 pagineJIS G3452 PipefaridyeniNessuna valutazione finora

- H Section JIS G 3192Documento9 pagineH Section JIS G 3192Sudath KularathnaNessuna valutazione finora

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocumento33 pagine(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- MSFC Spec 3679 PDFDocumento102 pagineMSFC Spec 3679 PDFDragan Sorin100% (1)

- Aquasafe Septic SystemDocumento22 pagineAquasafe Septic Systemsygmadude100% (1)

- Vicwest Hi-Bond Composite Deck Design ManualDocumento42 pagineVicwest Hi-Bond Composite Deck Design ManualMike Smith100% (1)

- ArcelorMittal DOMSpecsDocumento12 pagineArcelorMittal DOMSpecsAnurag DixitNessuna valutazione finora

- Steel-Product Catalog enDocumento75 pagineSteel-Product Catalog enmohammad_reza_49Nessuna valutazione finora

- Visual Inspection - AWS & BS PDFDocumento22 pagineVisual Inspection - AWS & BS PDFSelvakpm06Nessuna valutazione finora

- As 4458 - Amd1Documento9 pagineAs 4458 - Amd1Nang TruongNessuna valutazione finora

- Defect / Non Compliance ReportDocumento12 pagineDefect / Non Compliance ReportMichael OkwuwaNessuna valutazione finora

- Thermal ConductivityDocumento9 pagineThermal ConductivityKilaru HareeshNessuna valutazione finora

- E 310 - 99 - Rtmxma - PDFDocumento4 pagineE 310 - 99 - Rtmxma - PDFUpul Eranda AbeyrathnaNessuna valutazione finora

- NDT RT PDFDocumento13 pagineNDT RT PDFck19654840Nessuna valutazione finora

- AWS D1.1-D1.1M-2015 - Pagina-110Documento1 paginaAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezNessuna valutazione finora

- Strength of SteelsDocumento12 pagineStrength of Steelssureshs83Nessuna valutazione finora

- KTC Catalog1Documento318 pagineKTC Catalog1Langgeng PrasetyoNessuna valutazione finora

- Beam - Design ProcessDocumento2 pagineBeam - Design ProcessKory EstesNessuna valutazione finora

- Welding Studs Drawn Arc PDFDocumento52 pagineWelding Studs Drawn Arc PDFCesarNessuna valutazione finora

- Method Statement - Erection of Main TrussDocumento2 pagineMethod Statement - Erection of Main TrussAli WaqasNessuna valutazione finora

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Documento3 pagineWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNessuna valutazione finora

- Final WPS - ItdcDocumento2 pagineFinal WPS - ItdcsarancivilrajNessuna valutazione finora

- Wps For Akbtpl E-6013 - ModifiedDocumento13 pagineWps For Akbtpl E-6013 - ModifiedvinayNessuna valutazione finora

- WC9Documento5 pagineWC9Suresh KrishnanNessuna valutazione finora

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- WCBDocumento5 pagineWCBSuresh KrishnanNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- 0 10a Cylinder Head Cover ADocumento5 pagine0 10a Cylinder Head Cover ARusmansyahNessuna valutazione finora

- Riveting and Welding: Ship ConstructionDocumento77 pagineRiveting and Welding: Ship ConstructionChristopher Hawley100% (1)

- Fastener Type Chart - ReconDocumento5 pagineFastener Type Chart - ReconRam TejaNessuna valutazione finora

- XLR XX SeriesDocumento1 paginaXLR XX SeriesJuan FerchoNessuna valutazione finora

- Iso 15618-2-2001Documento30 pagineIso 15618-2-2001abdulkadir aliNessuna valutazione finora

- Unified Screw Threads Threads Per InchDocumento15 pagineUnified Screw Threads Threads Per Inchcqh53xn100% (1)

- Cawangan Pakar Dan Kejuruteraan Awam Jabatan Kerja Raya Malaysia, Kuala LumpurDocumento2 pagineCawangan Pakar Dan Kejuruteraan Awam Jabatan Kerja Raya Malaysia, Kuala LumpurHidayah A.RahmanNessuna valutazione finora

- Daily Progress Report 30 - 10 - 2020Documento2 pagineDaily Progress Report 30 - 10 - 2020Jagadeesan S MNessuna valutazione finora

- Din 914Documento6 pagineDin 914Mark802Nessuna valutazione finora

- ERNiCrCoMo 1Documento1 paginaERNiCrCoMo 1Vajid MadathilNessuna valutazione finora

- Ktu Manufacturing Technology PDFDocumento5 pagineKtu Manufacturing Technology PDFseminarprojectNessuna valutazione finora

- ASME Section VIII Division 1 Surface Finish of Welds: UW-35 Finished Longitudinal and Circumferntial JointsDocumento1 paginaASME Section VIII Division 1 Surface Finish of Welds: UW-35 Finished Longitudinal and Circumferntial JointsAkhtarcmti1342Nessuna valutazione finora

- Welding Procedure SpecificationDocumento21 pagineWelding Procedure Specificationboypardede100% (7)

- Types of WeldingDocumento10 pagineTypes of WeldingMuhammad Tauseef ZafarNessuna valutazione finora

- BS EN 1011 - 8 - 2003 - DraftDocumento22 pagineBS EN 1011 - 8 - 2003 - DraftMichael Andrews100% (2)

- 06 Fire Water Piping Welding ProcedureDocumento10 pagine06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)

- Wis5 Cswip2 2013Documento304 pagineWis5 Cswip2 2013sindalisindiNessuna valutazione finora

- Size - Bolt Depot - US Recommended Bolt Torque TableDocumento2 pagineSize - Bolt Depot - US Recommended Bolt Torque Tableirfan KahramanNessuna valutazione finora

- WPQT List Pt. AbgDocumento5 pagineWPQT List Pt. AbgabdiNessuna valutazione finora

- R3540-3009-B Hub AssemblyDocumento1 paginaR3540-3009-B Hub AssemblyKarikalan JayNessuna valutazione finora

- RF ToolsDocumento17 pagineRF Toolsketab_doostNessuna valutazione finora

- 167 Gmaw Zug Asme (Rohmatullah 3g) WPQDocumento4 pagine167 Gmaw Zug Asme (Rohmatullah 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- BMP (Class 14 - Class-17) WeldingDocumento24 pagineBMP (Class 14 - Class-17) WeldingAsesh PramanikNessuna valutazione finora

- DrawingDocumento1 paginaDrawingM Tommy AdamsNessuna valutazione finora

- MASHOP 3 (New Curriculum) Topic: Electric Arc Welding: Prepared By: Engr. Emiliano P. Heraña JR Faculty, CME. OLFUDocumento41 pagineMASHOP 3 (New Curriculum) Topic: Electric Arc Welding: Prepared By: Engr. Emiliano P. Heraña JR Faculty, CME. OLFUBrianss AyangssNessuna valutazione finora

- PQR FormatDocumento2 paginePQR FormatBE GNessuna valutazione finora

- PrayerDocumento11 paginePrayerTrecita BacoNessuna valutazione finora

- LA02b - Soldering TechniqueDocumento24 pagineLA02b - Soldering TechniqueFairolizwan AbdullahNessuna valutazione finora

- Img 20200831 0001Documento1 paginaImg 20200831 0001Aung Naing Latt Aung100% (1)

- Weld Defects Incomplete Root PenetrationDocumento4 pagineWeld Defects Incomplete Root PenetrationMuhammed SulfeekNessuna valutazione finora