Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

412512sp10hw3 635731752264840564 PDF

Caricato da

Trường TùngDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

412512sp10hw3 635731752264840564 PDF

Caricato da

Trường TùngCopyright:

Formati disponibili

ChE 412-512 - Spring 2010

Polymer Materials Engineering

Homework Set #3 Ch 9,10 (80 pts)

due Tuesday, February 16

1. (15 pts) Condensation Polymerization

1 mole of hydroxybutyric acid (HO-(CH2)3-COOH) is placed in a reactor that reaches 50 %

conversion.

a. How many moles of unreacted COOH groups are left in the reactor? How many moles of

unreacted monomer are left in the reactor?

b. What are the average Mn, Mw, and PDI for the reaction mixture?

2. (10 pts) Calculate the gel point conversion (based on the limiting reactant) for reacting 3 mol

ethylene glycol (see p.21 D) with 1 mol butyl dianhydride (p.22 R - replace the ‘R’ group with

(CH2)4).

3. (10 pts) Work Rosen Chapter 9, Problem 10.

4. (20 pts) In a free radical polymerization, 1 mol of acrylic acid monomer CH2=C(H)(COOH) is

placed in a reactor with 0.001 mol of hydrogen peroxide.

In this problem, ignore volume shrinkage during polymerization, and assume no chain transfer

(no loss of radicals to anything except another monomer once a chain reaction has begun).

a. How much monomer remains at 75 % conversion?

b. If the initiator efficiency is 0.37, what is the average chain length in the reactor, including the

remaining monomer? (xn)

c. After the monomer is removed (by evaporation under vacuum), what is the average chain

length of PAA?

d. What is the number-average molecular weight of the PAA in part c?

e. How would you determine the polydispersity of PAA in part c?

5. (15 pts) Temperature-Dependence of Chain Length

For the same experiment discussed in Chapter 10, Example 3,

A. Determine the temperature required to run the free radical polymerization to obtain a polymer

with double the molecular weight of the polymer produced at 60 oC.

B. For the reaction temperature in A, find the rate of this reaction compared to 60 oC.

6. (10 pts) An initial experiment at Bausch and Lomb has produced poly(methyl methacrylate),

whose monomer is CH2=C(CH3)(COOCH3), (used in eyeglasses and hard contact lenses) with a

number average molecular weight of 143,000, by carrying out the reaction at 65 oC for 45

minutes. Since the product design group has determined that a molecular weight of 100,000 is

satisfactory, how fast can you speed up the production process and still achieve the desired

MW? The activation energies for each reaction step are: propagation = 7 kcal/mol, initiator

decomposition = 27 kcal/mol, and termination = 3 kcal/mol.

Potrebbero piacerti anche

- Nanoporous Catalysts for Biomass ConversionDa EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNessuna valutazione finora

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasDa EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNessuna valutazione finora

- Assignment Reaction EngineeringDocumento6 pagineAssignment Reaction Engineeringnur hidayatiNessuna valutazione finora

- Assignment CPP Jan 2020 PDFDocumento5 pagineAssignment CPP Jan 2020 PDFNur Afifah IINessuna valutazione finora

- Tutorial 2 QuestionDocumento3 pagineTutorial 2 Questionnur hidayatiNessuna valutazione finora

- Assignment 4Documento3 pagineAssignment 4Duy Do MinhNessuna valutazione finora

- Exercises in Polymer ChemistryDocumento34 pagineExercises in Polymer ChemistryShirish Maheshwari100% (1)

- Mta Che471 01052020Documento3 pagineMta Che471 01052020afifiNessuna valutazione finora

- In-Class Problem Set 3 - 2021Documento5 pagineIn-Class Problem Set 3 - 2021tanishka kucheriaNessuna valutazione finora

- CHEN 200 Mid Term Questions Spring 2015Documento2 pagineCHEN 200 Mid Term Questions Spring 2015Diana BeirutiNessuna valutazione finora

- CHP 2 Practice QuestionsDocumento1 paginaCHP 2 Practice QuestionsElif Deniz YeşilyaprakNessuna valutazione finora

- MTA QuestionDocumento3 pagineMTA QuestionArissa HaniNessuna valutazione finora

- 1415 Exam 1 (ICP) (EN)Documento5 pagine1415 Exam 1 (ICP) (EN)김하은Nessuna valutazione finora

- SKKK1113 Tutorial Assignment-04-ReactiveDocumento2 pagineSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194Nessuna valutazione finora

- 1415 Exam 1 Answers (ICP) (EN)Documento8 pagine1415 Exam 1 Answers (ICP) (EN)김하은Nessuna valutazione finora

- In CH O1999Documento5 pagineIn CH O1999CorneliaNessuna valutazione finora

- Assignment 4Documento3 pagineAssignment 4Đạt Trương MinhNessuna valutazione finora

- 2020 CHEE2001 Week 6 Tutorial SheetDocumento2 pagine2020 CHEE2001 Week 6 Tutorial SheetMuntaha ManzoorNessuna valutazione finora

- 99prepare SolDocumento53 pagine99prepare SolPopa ElenaNessuna valutazione finora

- Catalytic Conversion of Cyclohexylhydroperoxide ToDocumento20 pagineCatalytic Conversion of Cyclohexylhydroperoxide ToZhalaNessuna valutazione finora

- Assignment 06: CP 518: Polymer Science & EngineeringDocumento2 pagineAssignment 06: CP 518: Polymer Science & EngineeringAD D100% (1)

- Ch. 10 PDFDocumento20 pagineCh. 10 PDFDr.AhmedNessuna valutazione finora

- CKB 20104 - Reaction EngineeringDocumento9 pagineCKB 20104 - Reaction EngineeringNoor FatihahNessuna valutazione finora

- CBSE Class 12 Chemistry 2018Documento17 pagineCBSE Class 12 Chemistry 2018parv dhanoteNessuna valutazione finora

- 31 Prepare ThaiDocumento52 pagine31 Prepare ThaiHuyềnTrânCôngChúaNessuna valutazione finora

- Biotechnology Engineering 2019 SyllabusDocumento139 pagineBiotechnology Engineering 2019 SyllabusprarthanaNessuna valutazione finora

- CHT305 SyllabusDocumento8 pagineCHT305 SyllabusYuxin CasioNessuna valutazione finora

- Gujarat Technological UniversityDocumento4 pagineGujarat Technological UniversityMohit PatelNessuna valutazione finora

- Week 3 - Pre-Lecture Quiz (1%)Documento6 pagineWeek 3 - Pre-Lecture Quiz (1%)Winnie LimNessuna valutazione finora

- Instructions:: Write The Following Mathematical EquationsDocumento4 pagineInstructions:: Write The Following Mathematical EquationsDechenPemaNessuna valutazione finora

- 838 PDFDocumento8 pagine838 PDFAravind KumarNessuna valutazione finora

- Instructions For Students: Indian National Chemistry Olympiad Theory 2010Documento53 pagineInstructions For Students: Indian National Chemistry Olympiad Theory 2010Anubhuti GhaiNessuna valutazione finora

- CL 201 Tutorial 4 Time: 1 Hour Marks: 70 Oct 21, 2020: C C / (1 + KV/)Documento2 pagineCL 201 Tutorial 4 Time: 1 Hour Marks: 70 Oct 21, 2020: C C / (1 + KV/)Rishiraj KamdarNessuna valutazione finora

- Assignment ReactiveDocumento2 pagineAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Chemical Process Design 2009Documento4 pagineChemical Process Design 2009Priyam RamsokulNessuna valutazione finora

- 4sem Mid 3 PCE Set 1Documento1 pagina4sem Mid 3 PCE Set 1Sai Praneethtej SaspretNessuna valutazione finora

- CRE-Project 2324 Sem1Documento3 pagineCRE-Project 2324 Sem1MOHAMMAD KHAIRUL AKMAL BIN MOHD AZAM A21ET0094Nessuna valutazione finora

- HW1 QuestionsDocumento2 pagineHW1 QuestionsMohit MaluNessuna valutazione finora

- Homework 2-S15 (1) Chem E 178Documento1 paginaHomework 2-S15 (1) Chem E 178siegeddNessuna valutazione finora

- Some Useful ConstantsDocumento4 pagineSome Useful ConstantsAbdelfattah oufNessuna valutazione finora

- Che502 Mid Term Assessment May 2021 HimDocumento3 pagineChe502 Mid Term Assessment May 2021 HimLehbron JemsNessuna valutazione finora

- Alkanes, Alkenes, Alkynes and Their Alicyclic Couterparts: 1. What Is The IUPAC Name For CHDocumento17 pagineAlkanes, Alkenes, Alkynes and Their Alicyclic Couterparts: 1. What Is The IUPAC Name For CHEllaŠtrbac100% (1)

- Che505 t2 Dec 16Documento2 pagineChe505 t2 Dec 16AQou RekNessuna valutazione finora

- 2021 August CH204-HDocumento3 pagine2021 August CH204-HMidhunNessuna valutazione finora

- Hop AmDocumento4 pagineHop AmAnonymous 5lZJ470Nessuna valutazione finora

- Kinetic Investigations On The Esterification of Phthalic Anhydride With N-Heptyl, N-Nonyl or N-Undecyl Alcohol Over Sulfuric Acid CatalystDocumento7 pagineKinetic Investigations On The Esterification of Phthalic Anhydride With N-Heptyl, N-Nonyl or N-Undecyl Alcohol Over Sulfuric Acid CatalystVimal PatelNessuna valutazione finora

- R05320802chemicalreactionengineeringiiDocumento8 pagineR05320802chemicalreactionengineeringiiSanthosh KumarNessuna valutazione finora

- 5bfd1a25-a358-45a3-b994-02540a001a19Documento2 pagine5bfd1a25-a358-45a3-b994-02540a001a19Student KeekNessuna valutazione finora

- EXP Saponification in Batch Reactor-FinalDocumento36 pagineEXP Saponification in Batch Reactor-FinalMuhd Fadzli HadiNessuna valutazione finora

- Comparison of Fuel Cell and Internal Combustion Engine: CL 152-Choose Focus and Analyse ExerciseDocumento32 pagineComparison of Fuel Cell and Internal Combustion Engine: CL 152-Choose Focus and Analyse ExerciseRajiv SoniNessuna valutazione finora

- Mass Balance Tutorial 2 - 2021 Fin-StuDocumento2 pagineMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNessuna valutazione finora

- Assignment L01 (Thursday, 11.30 Am)Documento9 pagineAssignment L01 (Thursday, 11.30 Am)MawareNessuna valutazione finora

- Tute 3Documento4 pagineTute 3ArunNessuna valutazione finora

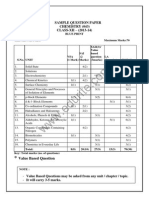

- Sample Question Paper CHEMISTRY (043) CLASS-XII - (2013-14) : Blue PrintDocumento17 pagineSample Question Paper CHEMISTRY (043) CLASS-XII - (2013-14) : Blue Printapi-243565143Nessuna valutazione finora

- CBSE Class 12 Question Paper 2018 Chemistry Set 1Documento12 pagineCBSE Class 12 Question Paper 2018 Chemistry Set 1jeffNessuna valutazione finora

- Exercise Chapter 2Documento22 pagineExercise Chapter 2yewhouNessuna valutazione finora

- Alkyl Halides, Alcohols, Ethers and Epoxides: 1. What Is The IUPAC Name For CHDocumento17 pagineAlkyl Halides, Alcohols, Ethers and Epoxides: 1. What Is The IUPAC Name For CHEllaŠtrbacNessuna valutazione finora

- Solution Manual Introduction To Chemical Processes Principles Analysis Synthesis 1st Edition Regina MurphyDocumento7 pagineSolution Manual Introduction To Chemical Processes Principles Analysis Synthesis 1st Edition Regina MurphyDaniela Andrea Vargas MedinaNessuna valutazione finora

- CIV1319 Final Exam 2020 FinalDocumento10 pagineCIV1319 Final Exam 2020 FinalSubhajit MondalNessuna valutazione finora

- Handbook of Coordination Catalysis in Organic ChemistryDa EverandHandbook of Coordination Catalysis in Organic ChemistryNessuna valutazione finora

- Ethylbenzene: You Could Be Exposed To Ethylbenzene ThroughDocumento2 pagineEthylbenzene: You Could Be Exposed To Ethylbenzene ThroughTrường TùngNessuna valutazione finora

- 344W11MidTermExamI Solution PDFDocumento22 pagine344W11MidTermExamI Solution PDFTrường TùngNessuna valutazione finora

- Ethylbenzene SDS US enDocumento17 pagineEthylbenzene SDS US enTrường TùngNessuna valutazione finora

- C. Guizani, F.J. Escudero Sanz, S. Salvador: SciencedirectDocumento11 pagineC. Guizani, F.J. Escudero Sanz, S. Salvador: SciencedirectTrường TùngNessuna valutazione finora

- Air Products Ar2018 PDFDocumento148 pagineAir Products Ar2018 PDFTrường TùngNessuna valutazione finora

- ECH 158A Economic Analysis and DesignDocumento36 pagineECH 158A Economic Analysis and DesignTrường TùngNessuna valutazione finora

- Homework 2 HUMG 2019 PDFDocumento3 pagineHomework 2 HUMG 2019 PDFTrường Tùng100% (1)

- Regeneration of Hydrotreating and FCC CatalystsDocumento58 pagineRegeneration of Hydrotreating and FCC CatalystsTrường TùngNessuna valutazione finora

- 37 - 446411061 - EthylBenzene CASNO 100 41 4 MSDS PDFDocumento7 pagine37 - 446411061 - EthylBenzene CASNO 100 41 4 MSDS PDFTrường TùngNessuna valutazione finora

- Chapter 14 - Kinetics: Additional Practice ProblemsDocumento5 pagineChapter 14 - Kinetics: Additional Practice ProblemsTrường TùngNessuna valutazione finora

- Midterm2 PDFDocumento3 pagineMidterm2 PDFTrường TùngNessuna valutazione finora

- Ep 15168928 Nwa 1Documento11 pagineEp 15168928 Nwa 1Trường TùngNessuna valutazione finora

- 37 - 446411061 - EthylBenzene CASNO 100 41 4 MSDS PDFDocumento7 pagine37 - 446411061 - EthylBenzene CASNO 100 41 4 MSDS PDFTrường TùngNessuna valutazione finora

- Problem Set 2 KEY PDFDocumento5 pagineProblem Set 2 KEY PDFTrường TùngNessuna valutazione finora

- Chemical Economics Handbook BrochureDocumento4 pagineChemical Economics Handbook BrochureTrường Tùng100% (1)

- Carbon/Epoxy CompositeDocumento1 paginaCarbon/Epoxy CompositeTrường TùngNessuna valutazione finora

- HUMG / Advance Program in Chemical EngineeringDocumento2 pagineHUMG / Advance Program in Chemical EngineeringTrường TùngNessuna valutazione finora

- Exp 9Documento10 pagineExp 9June Angela BacayNessuna valutazione finora

- Angew Chem Int Ed - 2020 - Holmberg Douglas - Regioselective Arene C H Alkylation Enabled by Organic Photoredox CatalysisDocumento5 pagineAngew Chem Int Ed - 2020 - Holmberg Douglas - Regioselective Arene C H Alkylation Enabled by Organic Photoredox Catalysiszhang quanNessuna valutazione finora

- 385 2Documento5 pagine385 2ThulileLimamaNessuna valutazione finora

- 4 5816516579378071204Documento60 pagine4 5816516579378071204Daniel PadillaNessuna valutazione finora

- MSDS New CAUSTIC SODADocumento6 pagineMSDS New CAUSTIC SODAAlves EdattukaranNessuna valutazione finora

- Corrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, IndiaDocumento76 pagineCorrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, Indiadeviprasadh.a100% (3)

- Neutralization ReactionDocumento4 pagineNeutralization ReactionNor Ashikin Ismail67% (3)

- Jan 2022 Chem Unit 3 QPDocumento20 pagineJan 2022 Chem Unit 3 QPSyeda SadiaNessuna valutazione finora

- Recycling of Plastics Using SolventDocumento65 pagineRecycling of Plastics Using SolventTeddy Ekubay GNessuna valutazione finora

- Enargite Leaching Under Ammoniacal MediaDocumento10 pagineEnargite Leaching Under Ammoniacal MediaEnrique QuezadaNessuna valutazione finora

- Lecture 4: Adsorption: The Islamic University of Gaza-Environmental Engineering Department Water Treatment (EENV - 4331)Documento45 pagineLecture 4: Adsorption: The Islamic University of Gaza-Environmental Engineering Department Water Treatment (EENV - 4331)Anuja Padole100% (1)

- Total Synthesis of Quercetin 3 SophorotriosideDocumento4 pagineTotal Synthesis of Quercetin 3 SophorotriosideRiskaNessuna valutazione finora

- Knowledge Sharing Session: Topic: AnodizingDocumento23 pagineKnowledge Sharing Session: Topic: AnodizingRaj Kumar GiriNessuna valutazione finora

- Physical IncompatibilityDocumento5 paginePhysical IncompatibilityTony Jr BalatongNessuna valutazione finora

- Portable Power - A Designer's Guide To Battery ManagementDocumento19 paginePortable Power - A Designer's Guide To Battery ManagementMedSparkNessuna valutazione finora

- Metalloenzymes: Function of Metal Ions in BiologyDocumento17 pagineMetalloenzymes: Function of Metal Ions in BiologyFhazzira AjahNessuna valutazione finora

- An Introduction To Physical Organic ChemistryDocumento92 pagineAn Introduction To Physical Organic ChemistrymichaelNessuna valutazione finora

- AGM 301 - After Mid Semester MaterialsDocumento63 pagineAGM 301 - After Mid Semester Materialsshubham100% (2)

- 1 - (Science) ReviewerDocumento5 pagine1 - (Science) Reviewerranulfo mayolNessuna valutazione finora

- FyQ Tema 3Documento14 pagineFyQ Tema 3Danyel Rodriguez RomeraNessuna valutazione finora

- Iit Jam Chemistry Core2014Documento8 pagineIit Jam Chemistry Core2014Mahendra GanuboyinaNessuna valutazione finora

- Chemistry Pre-U Chemistry Sem 1 Chap 5 PDFDocumento85 pagineChemistry Pre-U Chemistry Sem 1 Chap 5 PDFJIANHUI0160% (1)

- Ajib 9 (Q1)Documento8 pagineAjib 9 (Q1)NuriyahNessuna valutazione finora

- Methods of Samrling and Test For Paints, VarnishesDocumento9 pagineMethods of Samrling and Test For Paints, Varnishessingaravelan narayanasamyNessuna valutazione finora

- Food Fraud Compedium Food Packaging PDFDocumento20 pagineFood Fraud Compedium Food Packaging PDFjai soniNessuna valutazione finora

- Flashcards - CP3 Titration To Find The Concentration of A Solution of Hydrochloric Acid - Edexcel IAL Chemistry A-LevelDocumento35 pagineFlashcards - CP3 Titration To Find The Concentration of A Solution of Hydrochloric Acid - Edexcel IAL Chemistry A-LevelTravel UnlimitedNessuna valutazione finora

- Final-Yr-Thesis-Pdf Uet PeshawarDocumento137 pagineFinal-Yr-Thesis-Pdf Uet PeshawarHa M ZaNessuna valutazione finora

- A. Qureshi, Et AlDocumento11 pagineA. Qureshi, Et AlAr Kuldeep MalamNessuna valutazione finora

- Maizer Fertilizers CatalogueDocumento50 pagineMaizer Fertilizers CatalogueMaizerNessuna valutazione finora

- Chapter 12: Structures & Properties of CeramicsDocumento10 pagineChapter 12: Structures & Properties of Ceramics윤종현Nessuna valutazione finora