Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

S-265 Weld On Pivot Link

Caricato da

Sarfaraz KhanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

S-265 Weld On Pivot Link

Caricato da

Sarfaraz KhanCopyright:

Formati disponibili

Lifting Points

• Available in capacities from .5 to 3.2 metric tons

• Bail is Forged Alloy Steel – Quenched and Tempered J

• Bail swivels 360° degree

• Rated at 100% for 90 degree angle.

• Fatigue rated to 20,000 cycles at 1-1/2 times the Working Load Limit.

• Meets the Machinery Directive 2006/42/EC guidelines and is marked

with CE accordingly.

• Replaceable bolts available, including longer bolts.

• Bolt specification for metric bolt is Grade 10.9 alloy cap screw to ISO 898-1.

• Unique locking mechanism makes the lifting point well suited for quick

attachment to load surface. No need for tools.

• Features QUIC-CHECK® markings on bail to assist in knowing when

device is ready for lifting.

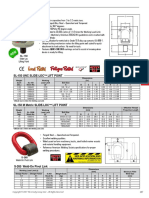

SL - 150

Slide-Loc

Lifting Point

® SEE APPLICATION AND

WARNING INFORMATION

On Page 215 -216

Para Español: www.thecrosbygroup.com

SL-150 UNC SLIDE-LOC™ LIFT POINT

Dimensions

Weight Working (in.) Effective Thread

Each SL-150 Load Limit Bolt Size Projection Length

(lbs.) Stock No. (t)* A B C E F H J T

0.30 1068407 0.50 3/8 - 16 x 1 1.40 2.09 1.10 0.33 1.11 1.77 0.60

0.53 1068416 0.75 1/2 - 13 x 1 - 1/4 1.67 2.47 1.30 0.41 1.30 2.13 0.79

1.10 1068425 1.50 5/8 - 11 x 1 - 5/8 2.17 2.98 1.46 0.52 1.46 2.50 1.01

2.05 1068434 2.30 3/4 - 10 x 2 2.71 3.59 1.72 0.63 1.72 2.98 1.26

2.16 1068443 2.30 7/8 - 9 x 2 2.71 3.61 1.72 0.63 1.72 2.98 1.23

3.73 1068452 3.20 1 - 8 x 2 - 1/2 3.25 4.33 2.08 0.76 1.93 3.59 1.59

*Ultimate load is 4 times the Working Load Limit.

SL-150 METRIC SLIDE-LOC™ LIFT POINT

Dimensions Effective Thread

Weight Working (mm) Projection

Each SL-150M Load Limit Bolt Size Length

(kg) Stock No. (t)* A B C E F H J T

.14 1068515 0.50 M10X1.5 X 25 35.5 53.0 28.0 8.5 27.8 45.0 14.6

.23 1068524 0.75 M12x1.75x30 42.5 62.6 33.0 10.5 32.9 54.0 18.3

.50 1068533 1.50 M16x2x40 55.0 75.7 37.0 13.2 37.0 63.4 24.5

.94 1068542 2.30 M20x2.5x50 68.8 91.1 43.9 16.0 43.6 75.6 31.0

1.60 1068551 3.20 M24x3x60 82.5 110.0 52.8 19.2 52.8 91.2 37.0

*Ultimate load is 4 times the Working Load Limit.

RIGGING ACCESSORIES

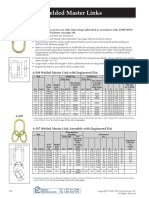

• Forged Steel — Quenched and Tempered.

• Excellent welding qualities.

• Widely used on farm machinery, trucks, steel hulled marine vessels

and material handling equipment.

• Reference American Welding Society specifications for proper

welding procedures.

SEE APPLICATION AND

S - 265 WARNING INFORMATION

Weld-On Pivot Link On Pages 208 -209

Para Español: www.thecrosbygroup.com

S-265 Weld-On Pivot Link

Dimensions

Working Load Limit (t)

(in.) Minimum Fillet

Design Factor Design Factor S-265 Weight Each Weld Size

5:1 4:1 Stock No (lbs.) A B C D F G H (in.)

1 1.2 1290740 .88 1.57 1.42 3.27 1.38 .51 2.60 1.65 3/32

2.5 3.2 1290768 1.32 1.77 1.73 3.90 1.65 .71 3.19 1.89 3/32

4.2 5.3 1290786 2.65 2.17 2.38 4.84 1.93 .87 3.90 2.24 1/4

6.4 8 1290802 5.29 2.76 2.52 5.67 2.52 1.02 4.80 2.64 1/4

12 15 1290820 13.01 3.82 3.54 7.60 3.39 1.34 6.50 3.70 5/16

Copyright © 2016 The Crosby Group LLC All Rights Reserved 187

Potrebbero piacerti anche

- Lifting Points: Slide-Loc Lifting PointDocumento1 paginaLifting Points: Slide-Loc Lifting PointAnonymous hHWOMl4FvNessuna valutazione finora

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocumento1 paginaCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNessuna valutazione finora

- Crosby Grade 100 Chain FittingsDocumento1 paginaCrosby Grade 100 Chain FittingsKonstantinos SynodinosNessuna valutazione finora

- Gancho de Ojo Fijo Con Seguro YOKE 0.75 Ton en PROCARGADocumento1 paginaGancho de Ojo Fijo Con Seguro YOKE 0.75 Ton en PROCARGAJhoules FgNessuna valutazione finora

- Crosby® Grade 100 SHUR-LOC® HooksDocumento1 paginaCrosby® Grade 100 SHUR-LOC® HooksleoNessuna valutazione finora

- Crosby - S-279 Machinery Shoulder Eye Bolts SpecsDocumento3 pagineCrosby - S-279 Machinery Shoulder Eye Bolts SpecsHarwi HarwiNessuna valutazione finora

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocumento1 paginaCrosby Grade 100 Clevis Sling Hooks: J AA R LYOGESH GOPALNessuna valutazione finora

- Crosby Hoisting RingDocumento1 paginaCrosby Hoisting RingI-SignNessuna valutazione finora

- Eye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchDocumento1 paginaEye Hook Clevis Hook: S-1316 Eye Hook Shur-Loc Hook Series With Positive Locking LatchKonstantinos SynodinosNessuna valutazione finora

- SBPT Catalogue DC CouplingDocumento11 pagineSBPT Catalogue DC CouplingEserNessuna valutazione finora

- Catalogo Crosby ShacklesDocumento1 paginaCatalogo Crosby Shacklesinternet.casa149Nessuna valutazione finora

- Hook Shur LocDocumento1 paginaHook Shur LocCall Wirvin FalcãoNessuna valutazione finora

- Axial Plug-In, Maintenance-Free, Torsionally Rigid: Bowex Fle-Pa - Dimensions/Nominal Dimension To SaeDocumento2 pagineAxial Plug-In, Maintenance-Free, Torsionally Rigid: Bowex Fle-Pa - Dimensions/Nominal Dimension To SaeglobalindosparepartsNessuna valutazione finora

- lt1000d6 PDFDocumento3 paginelt1000d6 PDFJo Ferry0% (1)

- Latch Kit CrosbyDocumento1 paginaLatch Kit CrosbyRodolfo Garduño ColínNessuna valutazione finora

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Documento14 pagineWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNessuna valutazione finora

- Ezydek 44 Profile - DimensionsDocumento2 pagineEzydek 44 Profile - DimensionsAnirban BhattacharjeeNessuna valutazione finora

- Electric Chain Hoist Eha TypeDocumento3 pagineElectric Chain Hoist Eha TypePhan Van LoiNessuna valutazione finora

- Crosby 198Documento1 paginaCrosby 198oscar_jfrNessuna valutazione finora

- FR-4.0 Conventional FR-4 and Bonding Prepreg FeaturesDocumento2 pagineFR-4.0 Conventional FR-4 and Bonding Prepreg FeaturesNOUREDDINE ELHAMRINessuna valutazione finora

- Property of Polyfelt TS Nonwoven GeotextilesDocumento1 paginaProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Tiavs UdDocumento2 pagineTiavs UdgeigerNessuna valutazione finora

- Bee08e1 01 PDFDocumento319 pagineBee08e1 01 PDFanggie100% (1)

- K-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederDocumento2 pagineK-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederselvaNessuna valutazione finora

- Team Corporation R 10 Rotary ActuatorDocumento4 pagineTeam Corporation R 10 Rotary Actuatortojazlodziej2Nessuna valutazione finora

- TSCS 0033Documento8 pagineTSCS 0033Ranjan ShankarNessuna valutazione finora

- Button Spelter Sockets Mooring Spelter SocketsDocumento1 paginaButton Spelter Sockets Mooring Spelter SocketshoiNessuna valutazione finora

- Closed Swage Sockets National Swage ButtonsDocumento1 paginaClosed Swage Sockets National Swage ButtonshoiNessuna valutazione finora

- GCC Scales - Floor Scales WH7620 01Documento1 paginaGCC Scales - Floor Scales WH7620 01kevinNessuna valutazione finora

- Item:130ST Series Servo Motor: SpecificationsDocumento4 pagineItem:130ST Series Servo Motor: Specificationsn13t0314Nessuna valutazione finora

- HR-100 Pivot Hoist Rings Coil ThreadsDocumento1 paginaHR-100 Pivot Hoist Rings Coil ThreadsYAKUBU A. AROGENessuna valutazione finora

- Blow Off Calculation Rev.1Documento4 pagineBlow Off Calculation Rev.1Ankit AgarwalNessuna valutazione finora

- MS25205GDocumento5 pagineMS25205GGülinNessuna valutazione finora

- Button Spelter SocketDocumento1 paginaButton Spelter SocketKonstantinos SynodinosNessuna valutazione finora

- BoWex 05 Flange Couplings BoWex FLE-PA PACDocumento13 pagineBoWex 05 Flange Couplings BoWex FLE-PA PACdobasNessuna valutazione finora

- Mitsubishi Guide Book 130116 R7 LowRes PDFDocumento120 pagineMitsubishi Guide Book 130116 R7 LowRes PDFIsmail Mohammad100% (1)

- Fer 52 01 037 2006Documento5 pagineFer 52 01 037 2006Danielle SasongkoNessuna valutazione finora

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PDocumento1 paginaData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PrezaNessuna valutazione finora

- 2 - Premium Line (PDT) - SB-MB-HB 2006Documento14 pagine2 - Premium Line (PDT) - SB-MB-HB 2006Cristian LuqueNessuna valutazione finora

- Air Blower FPZ DSB K 03 Ms Mor Ie2 en 15-02 r1Documento2 pagineAir Blower FPZ DSB K 03 Ms Mor Ie2 en 15-02 r1semih degirmenciNessuna valutazione finora

- AC Servo Motor and Driver Designation and SpecificationsDocumento39 pagineAC Servo Motor and Driver Designation and SpecificationsAnes BelNessuna valutazione finora

- Main Control Valve Especificações 320D and 323D ExcavatorsDocumento17 pagineMain Control Valve Especificações 320D and 323D Excavatorsdaniel lacerdaNessuna valutazione finora

- Trox DiffusersDocumento6 pagineTrox Diffusersසිරිමල් අයියාNessuna valutazione finora

- Angular Contact Bearing SwivelsDocumento1 paginaAngular Contact Bearing SwivelsmeromikhaNessuna valutazione finora

- ZF25ADocumento4 pagineZF25A1380485Nessuna valutazione finora

- Forged Machinery Eye Bolts: See Application and Warning InformationDocumento1 paginaForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunNessuna valutazione finora

- T 1-2 - 1 - en - 2 Disc Valves LvsDocumento6 pagineT 1-2 - 1 - en - 2 Disc Valves LvsIvanNessuna valutazione finora

- T Series CouplingsDocumento4 pagineT Series CouplingsiradocajNessuna valutazione finora

- 13 - SSR 1 1 50 - 001 - eDocumento21 pagine13 - SSR 1 1 50 - 001 - edrop9721Nessuna valutazione finora

- Torsion Testing SystemDocumento3 pagineTorsion Testing Systemsrinath.gajapathy5478Nessuna valutazione finora

- Air-Cooled and Water-Cooled Screw CompressorsDocumento2 pagineAir-Cooled and Water-Cooled Screw CompressorsMichaelNessuna valutazione finora

- Load Swivel CrosbyDocumento1 paginaLoad Swivel CrosbyDwiki RamadhaniNessuna valutazione finora

- MasterlinkDocumento1 paginaMasterlinkAndreyNessuna valutazione finora

- New DPD350T ManualDocumento36 pagineNew DPD350T Manualequipadojacob796Nessuna valutazione finora

- 150 QS001G en P PDFDocumento16 pagine150 QS001G en P PDFHanks EpphNessuna valutazione finora

- High Cycle - TWHC: Torque WrenchDocumento4 pagineHigh Cycle - TWHC: Torque WrenchAlaa saidNessuna valutazione finora

- CANAN Steel Deck Catalogue - 2023Documento48 pagineCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersDa EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersValutazione: 5 su 5 stelle5/5 (2)

- Zone Map - UpWork QueryDocumento19 pagineZone Map - UpWork QuerySarfaraz KhanNessuna valutazione finora

- Zone Map - UpWork QueryDocumento19 pagineZone Map - UpWork QuerySarfaraz KhanNessuna valutazione finora

- Improving Tolerance Control On Modular Construction Project With 3D Laser ScanningDocumento21 pagineImproving Tolerance Control On Modular Construction Project With 3D Laser ScanningSarfaraz KhanNessuna valutazione finora

- MIT18 330S12 Chapter6Documento19 pagineMIT18 330S12 Chapter6kliouliouNessuna valutazione finora

- 04 Nonlinear Equations PDFDocumento9 pagine04 Nonlinear Equations PDFSau L.Nessuna valutazione finora

- Gasket Contact Surface FlatnessDocumento2 pagineGasket Contact Surface FlatnessSarfaraz KhanNessuna valutazione finora

- Cousera Convergence Study - Guided Project #2Documento6 pagineCousera Convergence Study - Guided Project #2Sarfaraz KhanNessuna valutazione finora

- Methods For Ordinary Differential Equations: 5.1 Initial-Value ProblemsDocumento20 pagineMethods For Ordinary Differential Equations: 5.1 Initial-Value Problemsupasana9Nessuna valutazione finora

- Ring Joint Gaskets: RTJ Gasket ProfilesDocumento9 pagineRing Joint Gaskets: RTJ Gasket ProfilesSarfaraz KhanNessuna valutazione finora

- Plate With Hole AnnotatedDocumento8 paginePlate With Hole AnnotatedSarfaraz KhanNessuna valutazione finora

- Plate With Hole AnnotatedDocumento8 paginePlate With Hole AnnotatedSarfaraz KhanNessuna valutazione finora

- 07 Spectral Interpolation, Differentiation, Quadrature PDFDocumento18 pagine07 Spectral Interpolation, Differentiation, Quadrature PDFSau L.Nessuna valutazione finora

- CFDDocumento28 pagineCFDShantiswarup MahapatraNessuna valutazione finora

- Handout 4.3 Laminar WithNotesDocumento9 pagineHandout 4.3 Laminar WithNotesDaniel GómezNessuna valutazione finora

- MIT18 330S12 Chapter3 PDFDocumento16 pagineMIT18 330S12 Chapter3 PDFJuan David Valderrama ArtunduagaNessuna valutazione finora

- Handout 4.1 Fluids Big Ideas WithoutNotes PDFDocumento7 pagineHandout 4.1 Fluids Big Ideas WithoutNotes PDFHarshanaLaknathNessuna valutazione finora

- 02 Integrals As Sums and Derivatives As Differences PDFDocumento9 pagine02 Integrals As Sums and Derivatives As Differences PDFSau L.Nessuna valutazione finora

- Handout 4.3 Laminar WithNotesDocumento9 pagineHandout 4.3 Laminar WithNotesDaniel GómezNessuna valutazione finora

- Laminar Pipe Flow: Fluent Solution Outline: Problem SpecificationDocumento3 pagineLaminar Pipe Flow: Fluent Solution Outline: Problem SpecificationSarfaraz KhanNessuna valutazione finora

- Handout 3.2 Bolted NoPicturesDocumento10 pagineHandout 3.2 Bolted NoPicturesAnonymous 7MdZQn1Nessuna valutazione finora

- 2D Steady Heat Conduction Block ProblemDocumento6 pagine2D Steady Heat Conduction Block ProblemIrtiza ZafarNessuna valutazione finora

- 2D Steady Heat Conduction Block ProblemDocumento6 pagine2D Steady Heat Conduction Block ProblemIrtiza ZafarNessuna valutazione finora

- Handout 2.2 Bike Crank WithNotesDocumento8 pagineHandout 2.2 Bike Crank WithNotesJuan Emanuel VenturelliNessuna valutazione finora

- Handout 4.1 Fluids Big Ideas WithoutNotes PDFDocumento7 pagineHandout 4.1 Fluids Big Ideas WithoutNotes PDFHarshanaLaknathNessuna valutazione finora

- Handout 2.2 Bike Crank WithNotesDocumento8 pagineHandout 2.2 Bike Crank WithNotesJuan Emanuel VenturelliNessuna valutazione finora

- HandoutDocumento9 pagineHandoutElijah NormanNessuna valutazione finora

- CFDDocumento28 pagineCFDShantiswarup MahapatraNessuna valutazione finora

- Wes Mosler The Piping and Tubing Design Guide For SolidWorks Routing 2011 2011Documento1 paginaWes Mosler The Piping and Tubing Design Guide For SolidWorks Routing 2011 2011andredurvalandrade0% (1)

- Handout Module 5 Turbulence WithoutNotesDocumento9 pagineHandout Module 5 Turbulence WithoutNotesSarfaraz KhanNessuna valutazione finora

- (Asme) Asme - Asme B30-14-Pipe Layers or Side Boom TractorsDocumento61 pagine(Asme) Asme - Asme B30-14-Pipe Layers or Side Boom TractorsBorislav VulićNessuna valutazione finora

- Rock ClimbingDocumento11 pagineRock ClimbingDaria TurdalievaNessuna valutazione finora

- Balzac and the Little Chinese Seamstress: A Journey During the Cultural RevolutionDocumento4 pagineBalzac and the Little Chinese Seamstress: A Journey During the Cultural RevolutionRogona 123Nessuna valutazione finora

- TiONA 592 PDS - ENDocumento1 paginaTiONA 592 PDS - ENQuang VANessuna valutazione finora

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocumento4 paginePSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNessuna valutazione finora

- Linear Programming Models: Graphical and Computer MethodsDocumento91 pagineLinear Programming Models: Graphical and Computer MethodsFaith Reyna TanNessuna valutazione finora

- Albert PikeDocumento6 pagineAlbert Pikeapi-302575383Nessuna valutazione finora

- Ubc 2015 May Sharpe JillianDocumento65 pagineUbc 2015 May Sharpe JillianherzogNessuna valutazione finora

- MATH Concepts PDFDocumento2 pagineMATH Concepts PDFs bNessuna valutazione finora

- Land-Use PlanningDocumento15 pagineLand-Use PlanningCiara MaryNessuna valutazione finora

- 3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2Documento24 pagine3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2CHARLYN JOY SUMALINOGNessuna valutazione finora

- Intro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODDocumento45 pagineIntro - S4HANA - Using - Global - Bike - Slides - MM - en - v3.3 MODMrThedjalexNessuna valutazione finora

- Hong Kong A-Level Chemistry Book 3ADocumento69 pagineHong Kong A-Level Chemistry Book 3AMARENG BERNABENessuna valutazione finora

- EJC H2 Math P1 With Solution PDFDocumento23 pagineEJC H2 Math P1 With Solution PDFKipp SohNessuna valutazione finora

- Lake Isle of Innisfree Lesson Plan BV ZGDocumento4 pagineLake Isle of Innisfree Lesson Plan BV ZGapi-266111651100% (1)

- IntegrityDocumento5 pagineIntegrityPritam Kumar100% (1)

- Absolute Value - WikipediaDocumento10 pagineAbsolute Value - WikipediaVenu GopalNessuna valutazione finora

- Vernacular Architecture: Bhunga Houses, GujaratDocumento12 pagineVernacular Architecture: Bhunga Houses, GujaratArjun GuptaNessuna valutazione finora

- Amity Online Exam OdlDocumento14 pagineAmity Online Exam OdlAbdullah Holif0% (1)

- Uc 3525 ADocumento17 pagineUc 3525 AespaguetesNessuna valutazione finora

- Inclusive E-Service or Risk of Digital Divide The Case of National ICT Policy 2018 of BangladeshDocumento11 pagineInclusive E-Service or Risk of Digital Divide The Case of National ICT Policy 2018 of BangladeshInternational Journal of Innovative Science and Research Technology100% (1)

- Graphs & Charts SummariesDocumento20 pagineGraphs & Charts SummariesMaj Ma Salvador-Bandiola100% (1)

- Philosophy of Disciple Making PaperDocumento5 paginePhilosophy of Disciple Making Paperapi-665038631Nessuna valutazione finora

- Mitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedDocumento5 pagineMitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedJohn Osborne100% (1)

- Transistor Amplifier Operating ParametersDocumento21 pagineTransistor Amplifier Operating ParametersReddyvari VenugopalNessuna valutazione finora

- Solution Manual For Illustrated Guide To The National Electrical Code 7th Edition Charles R MillerDocumento24 pagineSolution Manual For Illustrated Guide To The National Electrical Code 7th Edition Charles R MillerHenryJohnsonaswek97% (39)

- Defender 90 110 Workshop Manual 5 WiringDocumento112 pagineDefender 90 110 Workshop Manual 5 WiringChris Woodhouse50% (2)

- Applied Physics Mini Launcher Lab ReportDocumento12 pagineApplied Physics Mini Launcher Lab ReportTalharashid RamzanNessuna valutazione finora

- 42U System Cabinet GuideDocumento68 pagine42U System Cabinet GuideGerman AndersNessuna valutazione finora

- Ragavendhar Seeks Entry Software JobDocumento2 pagineRagavendhar Seeks Entry Software JobfferferfNessuna valutazione finora

- Internal auditing multiple choice questionsDocumento4 pagineInternal auditing multiple choice questionsSantos Gigantoca Jr.Nessuna valutazione finora