Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 09 Procedures and Laboratory Equipment (

Caricato da

محمد أحمد عبداللطيفCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 09 Procedures and Laboratory Equipment (

Caricato da

محمد أحمد عبداللطيفCopyright:

Formati disponibili

WATER-BASED DRILLING

PROCEDURES AND FLUIDS

LABORATORY

EQUIPMENT

(NON INHIBITING)

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 1

INTRODUCTION

• The American Petroleum Institute (API) recommends standardized methods for

laboratory and rig site tests which can be found in their publications.

• Recommended Practice: Standard Procedure for Field Testing Water-Based (Oil-

Based)

• Drilling Fluids, API RP 13B-1, 13 B2.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 2

FLUID DENSITY (or MUD DENSITY)

INSTRUMENTS

The density, commonly called “mud weight” is checked with a mud balance whose

precision has a margin of error of 0.1 lb/gal. (10 gr/l).

The density is defined as weight per unit of volume.

The weight of mud may be expressed as density in: lb/gal or lb/ft3 or Specific Gravity

(SG)

lb/gal lb/ft 3 g kg

SG = or or or

8.345 62.3 cm3 litre

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 3

MUD BALANCE

Description

Balance for mud

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 4

CALIBRATION

9 Fill the cup with pure or distilled water.

9 Put the graduated bar of the balance down with care so that it is in equilibrium on

the fulcrum.

9 The level-bubble should be centred when the reader is set on 1 g./cm2 or 8.33

lb/gal. If not, it will be necessary to carry out an adjustment on the calibration

screw situated at the end of the same bar.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 5

PROCEDURE

1. Fill the vessel with a sample of mud to check its weight.

2. Put the cap on again, rotate it several times to ensure that no solids are in its seat.

3. Rinse all and dry with a cloth.

4. Put the graduated bar of the balance down with care in equilibrium on the fulcrum.

5. Move the slider until the bubble of air is in the centre.

6. Read, near the cursor, the weight (or density) of the mud.

7. Write the weight, according to the system of measure desired, both in lb/gal, lb/ft3,

psi/1,000 ft of depth or Specific Gravity (SG).

8. If the balance in use does not have the system desired, the following equations

may be used.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 6

MUD GRADIENT

psi/ft = 0.052 x lb/gal

= 0.4333 x SG

= 0.00695 x lb/ft3

kg/cm2/m = SG / 10

SG a 60°F (15.6°C) = (141.5) / (131.5 + °API)

Where: °API = American Petroleum Institute gravity

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 7

VISCOSITY

INSTRUMENTS

The Marsh Funnel is used in the rig site to measure the viscosity. The Fann V-G

viscosimeter is used when complete information on rheology is necessary(Plastic

viscosity, yield point and gels).

Marsh Funnel and graduated cup

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 8

MARSH FUNNEL

Description

The Marsh Funnel is 6 inch. In diameter at the top and 12 inch long. At the bottom is has

a 2 inch smooth-bore tube having an insider diameter of 3/16 inch.

Calibration

Fill the funnel till the bottom of the screen (1,500 cm3) with fresh water at

70±5°F. The time to flow of 1 qt (946 ml) should be 26 sec ±0.5 sec.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 9

MARSH FUNNEL

Procedure

9 Collect a fresh mud sample

9 Hold the funnel erect with a finger over the outlet tube, and pour the mud into the

funnel through the screen until the mud level reaches the bottom of the screen (The

screen will filter out the larger particles that could clog the outlet tube)

9 Quickly remove the finger from the outlet tube, and at the same time, begin timing the

mud outflow

9 Allow one quart of gallon (946 cc) of mud to drain from the Marsh Funnel into a

graduated container

9 Record the number of seconds it takes for the quart of mud to flow out of the funnel,

and report this value as the Marsh Funnel Viscosity. Also record the temperature of

the mud sample in degrees F or C.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 10

ROTATIONAL VISCOSIMETER

With a Rotational Viscosimeter it is possible to

measure the rate/shear stress of a drilling fluid

and you can calculate the Bingham PV and YP

parameters. With the same data it is possible to

use other rheological models. The Rotational

Viscosimeter is also used to measure the

thyxotropic properties and gel strength

Description

The Rotational Viscosimeter offers a direct

reading and functions electrically.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 11

SPECIFICATIONS: DIRECT READING

VISCOSIMETER

Rotor sleeve (external cylinder)

Internal diameter 1.450 in. (36.83 mm)

Total length 3.425 in. (87.00 mm)

Reference line 2.30 in. (58.4 mm) above the bottom of the cylinder.

Two rows of 1.8-in. (3.18-mm) holes spaced of 120 degrees (2.09 radiants)

around the rotor just below the reference line.

Bob (internal cylinder)

Diameter 1.358 in. (34.49 mm)

Cylinder length 1.496 in. (38.00 mm)

The BOB is closed with a flat base.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 12

SPECIFICATIONS: DIRECT READING

VISCOSIMETER

Constant spring torsion

386 dyne-cm/degrees defletion

High 600 RPM

Rotor Speeds:

Low 300 RPM

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 13

SPECIFICATIONS: DIRECT READING

VISCOSIMETER

The following types of viscosimeters are normally used to test the fluids:

¾A handle viscosimeter has a speed of 300 and 600 RPM. A control situated at the point

of the speed change lever is used to determine the gel strength.

¾The electrical motor type (12-volt) has a speed of 300 and 600 RPM. A “governor-

release” type switch allows a strong agitation before the determination of the

measurement, then a hand wheel is used to determine the gel strength.

¾The electrical motor type, 115-volt, allows two synchronized speeds in the range

between 600, 300, 200, 100, 6 and 3 RPM. The speed of 3-RPM is used to determine

the gel strength.

¾At variable speed (115- or 240-volt with electrical motor) it allows variable speed from

625 to 1 RPM. The speed of 3-RPM is used to determine the gel strength.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 14

PROCEDURE TO DETERMINE APPARENT

VISCOSITY, PLASTIC VISCOSITY AND YIELD POINT

¾ Shake the sample then pour it, into the thermocup until the level reaches the

appropriate line of the rotor.

¾ Increase or decrease the temperature of the sample to 59°C (120°F). Stir slowly

during the calibration of the temperature.

¾ Start the motor rotating with the knob on high speed and the gear level at the

bottom. Wait for a stabilized reading and report the reading at 600 RPM. Change

the ratio only when the motor is working.

¾ Select a rotation speed of 300-RPM. When the value is stabilized report the

reading at 300-RPM.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 15

PROCEDURE TO DETERMINE APPARENT

VISCOSITY, PLASTIC VISCOSITY AND YIELD POINT

• Plastic Viscosity in centipoise = Reading at 600 RPM – Reading at 300 RPM (see

figure below)

• Yield Point in lb/100 ft2 = reading at 300 RPM less the plastic viscosity in

centipoise.

• Apparent Viscosity in centipoise = reading at 600 RPM divided by 2.

Typical “flow curve” of a drilling fluid.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 16

PROCEDURE TO DETERMINE THE GEL

STRENGTH (AT 10” AND AT 10’)

¾ Shake the sample of mud at 600 RPM for approximately 15 sec and raise the gear

lever to the neutral position.

¾ Step 1: stop the motor and wait for 10” sec.

¾ Step 2: move the switch to low speed and report the unit of maximum deflection in

lb/100 ft2. If the indication of the instrument should not return to zero do not

reposition it.

¾ Repeat step 1 and 2, wait 10’ minutes then position the lever on low speed and

read the unit of maximum deflection. Report the temperature measured.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 17

FILTRATION

DESCRIPTION

The filtration, or capacity of a mud to constitute a filter cake is determined by the filter

press. The test defines the Ratio with which a fluid is forced through the filter press.

This API Fluid Loss test must be carried out in specific conditions of duration,

temperature and pressure that according to the API Recommended Practice are

surface temperature, 100 psi and recorded as the number of millimeters lost in 30

minutes.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 18

INSTRUMENTS

Cell

Graduated

cylinder

Carbon dioxide

Example of Filter Press

cartridges

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 19

API FLUID LOSS

Procedure

1. Pressure availability at 100 psi with gas or air.(7 Kg/cm2).

2. Remove the cap from the bottom of the cleaned and dried cell. Install the O-ring to

check that its seat is not damaged, then turn the cell upside down for the filling.

Any mechanical imperfection can compromise the seal. Close the inlet hole with a

finger.

3. Fill the cell with mud up to ¼ inch from the housing of the O-ring. Put the filter

paper (Whatman No. 50 or equivalent) over the O ring. Put the cap on the filter

paper with its flanges between those of the cell, then turn in a clockwise direction

and close by hand. Turn the cell upside down and insert the cell body into the

bottom of the mud chamber of the filter press and turn in either direction to lock

the closure.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 20

API FLUID LOSS

4. Put a graduated cylinder under the drain tube.

5. Open the valve to pressurize the cell. You will immediately notice a fluctuation of

the needle of the manometer which will indicate higher pressures during the

pressurization and then, it stabilizes at 100 psi.

6. The API duration for this test is 30 minutes. When the test is finished, close the

valve to stop the pressure at the source. The purge will occur automatically.

Remove the cell.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 21

API FLUID LOSS

7. Report the fluid loss in millilitres.

8. Disassemble the cell, remove the mud and carefully remove the filter of paper in

order to avoid any minimum damaging to the mud cake. Wash the cake and

remove the mud in excess. Measure the thickness of the cake and report it in 32

nds of an inch.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 22

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

HTHP Filter Press

MB style (API #II) HTHP filter press

Description

The instrument consists of a heating

jacket with thermostat, cell plate

assembly, primary pressure assembly

and back-pressure receiver. The

capacity of the mud cell is 160 ml with

a filter area of 3.5 in.2.

Filtrate receiver holds 15 ml, and up to

100 psi backpressure can use a glass

tube. If a higher back pressure is to be

used, a stainless-steel tube should

replace the glass.

A routine test can be conducted at

300°F and 500 psi differential pressure.

High-temperature fluid loss is recorded

as double the number of milliliters lost

in 30 min.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 23

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

Procedure

1. Turn on the heating and wait for the instrument to reach the pre-heating

temperature. Put the thermometer in its housing and control the thermostat to

reach a temperature higher than the desired one of 10 °F.

2. Close the inlet valve of the cell and invert the cell.

3. Take the mud from the flow line. Pour it inside the vessel up to 0.2” below the

housing of the O-ring and wait for the expansion.

4. Put a filter of paper in the appropriate housing and put over it the O-ring. Use a

Watman filter No. 50 or equivalent.

5. Put the cover above the filter of paper and block it.

6. Shut the caps with strength and close the bleeding valve.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 24

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

7. With the cap of the cell at the bottom, put the cell inside the heater making sure

that all valves are closed. Transfer the thermometer to its location.

8. Install the cylinder of CO2 in its seat and turn it clockwise until the cover is opened.

The controller and the purge valve must be closed.

9. Keeping the lock ring raised, insert the primary unit of pressure in the upper

housing, and turn the lock ring to close.

10. Introduce a pressure of 100 psi against the valve, then open it to pressurize the

unit. This pressure will minimize the boiling during the heating of the sample.

11. Always use a container to prevent the vaporization of the filtrate if the test

temperature will reach or exceed the boiling temperature. Install and activate the

cylinder of CO2 in the purge unit.

12. Install the purge unit in the proper housing.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 25

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

13. Apply a pressure of 100 psi. at the lower unit while the valve is still closed.

14. Once you have reached the desired temperature (300°F), as indicated by the

thermometer, increase the pressure of the controller in the upper cell from 100 to

600 psi to make the pressure increase, keeping 100 psi with the lower controller.

Open the lower cell valve by one turn and start the test.

15. Keep a pressure of 100 psi on the receiver during the test. If the pressure raises,

discharge some of the filtrate and keep a differential of 500 psi. Keep the

temperature at ±5°F.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 26

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

16. After 30 min., close the valve of the lower cell and then the higher one.

17. Loosen either T-screws in the controller and discharge the pressure from either

controllers.

18. Discharge the filtrate in the graduated cylinder and read the volume. Double the

reading in the ratio. Remove the receiver.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 27

HIGH-TEMPERATURE, HIGH-PRESSURE (HTHP)

FILTRATION (High Pressure High Temperature)

19. Disconnect the primary unit of pressure raising the blocking ring and taking off the

unit. CAUTION: The cell is pressurized.

20. Hold the cell erect and leave cooling at ambient temperature, then discharge the

pressure; the mud must not pass through the valve.

21. Invert the cell, then loosen the screen of the cup. (If necessary, use an hexagonal

key) and disassemble. Clean and dry the various parts.

22. Visually observe and note the condition of the filter cake. It can be measured in

1/32 of an inch.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 28

API #I Filterpress HTHP

Tests at 300°F (149°C) or lower temperatures

Vapours pressure and expansion of the water volume between 212° and 450°F

Coefficient of the Expansion Volume of External pressure

Treating temperature Water vapours pressure

water at a Saturation Pressure suggested

°F °C kPa psi kPa psi

212 100 101 14.7 1.04 689 100

250 121 207 30 1.06 689 100

300 149 462 67 1.09 689 100

350 177 931 135 1.12 1104 160

400 205 1703 247 1.16 1898 275

450 232 2917 422 1.21 3105 450

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 29

API #I Filterpress HTHP

Tests at 300°F (149°C) or lower temperatures

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 30

TEST AT TEMPERATURE BETWEEN 300 AND

400°F (149 to 233°C)

The same procedures are used, except the following cases, where the 500-ml cell is

suggested, manifold pressurization with azote:

1. During the heating of the sample, pressurize either units with 450 psi. At the

beginning of the test, the higher pressure raises at 950 psi while the lower pressure

is kept at 450 psi.

2. With temperatures between 350 and 400°F, a porous stainless steel disk (Dynalloy

X5 or equivalent) is preferred . (see API RP 13B-1 and 13B-2).

3. Heating time should not exceed 1 hour.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 31

FILTER-CAKE COMPRESSIBILITY

For this test, the same procedure compared to 300°F (149°C) is applied, but there’s

a difference infact, 200 psi are applied to the cell and 100 psi to the receiver at the

bottom. The differential values regarding 100 and 500 psi are then compared.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 32

SAND CONTENT

INSTRUMENTS

KIT FOR SAND CONTENT

The Sand Content Kit determines the volume percent of sand-sized particles in the

drilling fluid. API defines sand-sized particles as any material larger than 74 microns

(200 mesh) in size. This test can be performed on low solids fluids as well as on

weighted fluids. The kit consists of a glass tube graduated to read percent (%) by

volume, a funnel, and a 200-mesh sieve contained in a cylindrical-shaped holder.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 33

SAND CONTENT

Procedure

1. Fill the glass vessel to the indicated mark with mud. Add water to the next mark.

Close the mouth of the vessel and shake vigorously

2. Pour the mixture onto the screen, add more water to the vessel shake and again

pour onto the screen. Repeat until water will be clear. Wash the sand remained on

the screen

3. Put the funnel over the mouth of the vessel. Insert the tip of the funnel into the

mouth of the glass vessel. Wash the sand on the screen by spraying a fine spray

of water. Allow the sand to settle, from the graduate on the tube, read the volume

percent of the sand.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 34

SAND CONTENT KIT

200 Mesh

screen

"Mud"

line

Funnel

"Water"

line

Sand %

graduation

Elutriometer

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 35

SOLIDS AND LIQUIDS CONTENT

INSTRUMENTS

The distillation of the mud through the heating can define the quantity of liquids and

solids in the mud. A sample of mud (distillers available 10, 20 or 50 cm3), is placed

in the cup and it is heated until the liquid components have been vaporized. Then,

they are pressed through a condenser and collected in a percent graduated cylinder.

The volume of liquid (oil and water) is measured directly in percent. The solids, both

suspended and dissolved, are determined by subtracting from 100%. The distiller is

also called Ministil and/or Retort.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 36

KIT FOR OIL AND MUD DISTILLATION

Retort Condenser

Retort Stem

Retort Cody

Retort Assembly

Steel Wool Condenser

Discharge

Lid

Retort Cup Liquid

Receiver

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 37

DISTILLER DESCRIPTION

Procedure

1. Allow the mud to cool down to ambient temperature.

2. Disassemble the distiller and lubricate the threads of the cup with grease for high

temperature. Fill in the sample cup with the mud till the edge. Put on the cap, make

a firm rotation and let pour out the fluid in excess. The correct volume of mud, which

can be 10, 20 or 50 cm3, is defined. Dry any possible trace of mud.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 38

DISTILLER DESCRIPTION

3. Fill the upper expansion chamber with a steel wool which will trap the boiling

solids. Hold all erect so that the mud cannot flow into the drain tube.

4. Insert, or screw the drain tube in the hole situated at the end of the

condenser. The graduated cylinder, which is calibrated in order to allow the

reading of the percentage, will be then arranged in the condenser.

5. Connect to the electrical network and keep the current till the completion of the

distillation. This could require 25 minutes, according to the characteristics of

the oil, water and the content of solids.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 39

DISTILLER DESCRIPTION

6. Allow the distillate to cool down to ambient temperature

7. Read the % of water, oil and solids. A couple of drops of aerosol solution will help

the definition of the oil-water interface, after the reading of the solids percentage.

8. Once you have finished the test, cool the distiller then clean and dry it .

9. Run a pipe cleaner through condenser hole and retort drain tube to maintain full

openings.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 40

METHYLENE BLUE CAPACITY

It is the field procedure to define cation exchange capacity (for Shales)

Equipment

1. Syringe, 3 cm3, burette 10 cm3.

2. Micropipette, 0.5- cm3.

3. Erlenmeyer flask (graduated), 250- cm3 with a gum plug.

4. Burette or pipette, 10- cm3.

5. Graduated cylinder, 50- cm3.

6. Mixer vane.

7. Hot plate.

8. Filter paper: diametre 11 cm, Whatman No. 1 or equivalent.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 41

METHYLENE BLUE CAPACITY

Reagents

1. Methylene blue solution:

1 cm3 = 0.01 milliequivalents

3.74 g of methylene blue, USP degree

(C16H18N3SCl•3H2O) per litre.

2. Hydrogen peroxide, solution at 3%.

3. Sulphuric acid solution 5 N.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 42

METHYLENE BLUE CAPACITY

PROCEDURE

1) Add 2 ml of muds to 10 ml of water in the E. Flask. Add 15 ml of 3% hydr.

Peroxide and 0.5 ml of 5N sulfuric acid solution and mix. Boil gently for 10 min.

(this initial treatment is to remove the organic materials like CMC,

lignosulfonate…). Dilute to about 50 ml with water.

2) Add Methylene Blue Solution 0,5 ml at time, and shake for 30 sec. after each

addition. While the solids are still suspended, remove 1 drop from the flask with a

glass rod and place on filter paper. The end point of the titration is needed when

the dye appears as a greenish-blue ring surrounding the dyed solids.

3) Record the ml of methylene blue solution used.

MBC of mud in lbs/bbl = (cm3 of methylene blue/cm3 of mud used) x 5

MBC of mud in kg/m3 (cm2 of methylene blue/cm3 of mud used) x 14

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 43

HYDROGEN IONS CONCENTRATION (pH)

AIM

Mud (or filtrate) pH surveys and pH adjustments, are fundamental in order to control

the drilling fluid. Interactions of the clay, solubility of the various components and the

effectiveness of the additives depend on the pH, as well as the control of the

corrosion caused by acids and sulphates. Th pH is used to describe the acidity or

basicity of solutions. The pH value is defined as the negative logarithm of the

hydrogen ion concentration: pH = - log [H+].

Low pH value corresponds to acids and high pH values correspond to basic solution.

The range of pH is 0 to 14.

7 is neutral (water).

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 44

pH INDICATOR STICKS

Description

These pH indicators sticks are coated with indicators whose colour is dependent on the

ph of the fluid in which the stick is placed. Standard colour charts are supplied for

comparison with the test stick, allowing estimation of pH to 0.5 pH units. (from 0 to 14).

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 45

pH METERS

Description

The pH meter, equipped with a glass electronic electrode is the recommended method

for measuring the pH in drilling fluids. Surveys are highly accurate, easy and auto-

adapting to the temperature variations.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 46

pH METERS Equipment

• A portable pH meters consists of a

probe and an electronic indicator. The

probe consists of:

• A glass Electrode

• An Electro standard reference

• Temperature detector (optional)

Portable pH meters

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 47

pH METER

The recommended procedure to detect the pH is as follows:

Measurements consist of:

9 Instrument calibration.

9 pH survey from a sample.

9 Cleaning and storage of the probe.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 48

CHEMICAL ANALYSIS OF WATER

IN THE MUD

INTRODUCTION

Alkalinity Titrations define OH-, HCO3- and CO3-- concentrations, by measuring the

amount of acid required to reduce the pH.

Phenolphtalein Alkalinity (P) is reported as the number of millimeters of 0.02 N H2SO4

required to titrate a ml of filtrate (Pf) or mud (Pm), reducing the pH at 8.3.

The methyl orange filtrate alkalinity Mf measures the acid (H2SO4) required to reduce the

pH at 4.3.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 49

CHEMICAL ANALYSIS OF WATER IN THE MUD

Alkalinity (Pf, Pm, Mf and lime content)

Equipment

The following materials and products are necessary in order to define the alkalinity of

the mud and lime:

1. Standard acid solution, 0.02 N (N/50); nitric or sulphuric acid (as an alternative, It is

also possible to use an acid solution 0.1N(N/10). However, it must be converted to

the equivalent of ml 0.02 N multiplied 5).

2. Phenolphtalein indicator solution.

3. Methyl orange indicator solution.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 50

CHEMICAL ANALYSIS OF WATER

IN THE MUD

4. Vessel for titration, from 100 to 150 cm3, preferably white.

5. Graduated pipettes: one 1 cm3 and one 10 cm3.

6. Stirring rod.

7. One syringe from 1 cm3.

8. pH meter with glass electrode. (optional but suggested)

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 51

PROCEDURE FOR THE ALKALINITY OF THE FILTRATE

(PF AND MF)

1. Measure 1 cm3 of filtrate in the vessel for titration, then add 5 cm3 of deionized

water (distilled water).

2. Add 2 or more drops of phenolphtalein indicator. The solution turns pink.

3. Add acid N/50 drop by drop while stirring, until the pink colour just disappears. If

the colour of the sample cannot be defined because of its intensity, the end point

must be surveyed when the pH drops to 8.3, as measured with the pH meter. (The

sample can be diluted with distilled water.)

4. Report the Phenolphtalein Alkalinity of the filtrate, Pf, as the number of cm3 of

0.02 of N acid required for every cm3 of filtrate to reach the end point.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 52

PROCEDURE FOR THE ALKALINITY

OF THE FILTRATE (Pf and Mf)

5. To the same sample used to measure the Pf, add 3 to 4 drops of Methyl orange.

The reaction will give a green colour

6. Titrate with 0.02 N acid until a yellow colour is obtained. This will happen when a

pH = 4.3. is reached

7. The Mf is reported as the number of millilitre of acid used for the Pf plus this last

titration.

Example:

If you use 0.5 cm3 of acid to titrate the final point of the phenolphtalein the Pf is 0.5.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 53

PROCEDURE - MUD ALKALINITY (Pm)

1. Measure 1 cm3 of mud into the vessel using the syringe. Dilute the sample with 25

cm3 of distilled water. Add 5 drops of Phenolphtalein Indicator, and while stirring,

titrate with 0.02 of acid N or with 0.1 of acid N until the pink colour just disappears.

N/50 or N/10 Sulphuric acid.

2. If the intensity of the colour cannot define the change, the end-point is reported

when the pH drops at 8.3, as measured with pH meter.

3. Report the phenolphtalein alkalinity of the mud, Pm, as the number of cm3 of acid

0.02 N (N/50) required per cm3 of mud. If the acid 0.1 N is used, Pm = 5 x cm3 of

0.1 acid N for cm3 of mud.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 54

PROCEDURE FOR LIME CONTENT

After having defined the Pf and Pm, determine the volume fraction of water in the mud,

Fw, using the value from retort test. Report the lime content of the mud in lb/bbl

calculated as follows:

Lime (lb/bbl) = 0.26 x (Pm – Fw x Pf)

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 55

CHLORIDES (Cl–)

Aim

Chloride test is very important in those areas where salt can contaminate the mud.

The content of the chloride ion is an excellent detector for example, when

stratigraphic levels of salt and salt water areas are crossed during the drilling,

Moreover, the chloride test check the quality of industrial water.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 56

CHLORIDES (Cl–)

Equipment

The following equipment is required for the determination of the chloride ion

concentration in the filtrate.

1. Silver nitrate solution, 0.0282N or 0.282N (strong) AgNO3, in an opaque bottle.

Italy ENI : 0,1N and 1N.

2. Potassium Chromate indication solution.

3. Sulfuric or nitric acid 0.02.

4. Distilled water.

5. Two graduated pipettes: one 1- cm3 and one 10- cm3.

6. Titration dish from 100 to 150 cm3, preferably white.

7. Stirring rod

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 57

CHLORIDES (Cl–)

PROCEDURE

1. Measure 1 cm3 into the titration dish.

2. Add the amount of acid required in the Pf titration.

3. Add 25 ml of distilled water and 10 drops of potassium chromate solution. Stir

continuously and titrate with standard silver nitrate solution, drop by drop until the

colour changes from yellow to orange-red and persists for 1 minute.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 58

CHLORIDES (Cl–)

4. Report the number of cm3 of silver nitrate solution needed to reach the colour

change point:

Cl– (mg/l) = cm3 of 0.0282 N silver nitrate x 1,000 / cm3 of filtrate if a concentrate

silver nitrate solution is used (0.282 N): Cl- (mg/l) = cm2 0.282 Silv. Nitr. X 10.000/cm3

of filtrate.

Any normal silver nitrate or 0,1N (frequent for ENI):

Cl– (mg/l) = (N x 35,000 x cm3 used) / (cm3 of the sample filtrate)

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 59

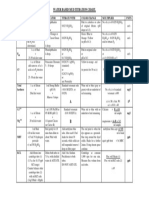

CHLORIDES TITRATION

Chlorides Titration

Chlorides (Cl-) – Tinge colour filtrates

Chemical

analysis Column 1 Column 2

Sample 1 cm3 filtrate 1 cm3 filtrate

Deionized water No 25-50 cm3

Buffer No No

Colour Indicator 2-3 Phenolphtalein drops 8-10 drops of Potassium Chromate

0.02 (N/50) 0.028N AgNO3

Titrate with: H2SO4 (sulphuric acid) or 0.282N AgNO3

(Titolatore)

* (silver nitrate)

Colour change Filtrate, from pink to original From Yellow to Red-Orange

Record No (cm3 of 0.0282 N AgNO3 x 1,000) / cm3 of filtrate

or

(cm3 of 0.282 N AgNO3 x 10,000 ) / cm3 of filtrate

*Chlorides : 10,000 mg/l

See col. 2 If < use: 0.0282 N AgNO3

Note:

If > use: 0.282 N AgNO3

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 60

CALCIUM - QUALITATIVE

Aim

When water has a high content of mineral salts in particular calcium and magnesium,

is called “hard water”. The evidence of hardness in water at home is the difficulty in

producing a lather with soap.

When the water used to mix the mud is hard, drilling clays have low yields. Bentonite

must be used in greater amount to make a satisfactory thixotropy.

It is often economical to treat the water to reduce the hardness.

Calcium may also arrive from drilling out cement or gypsum or anhydrite levels.

Calcium contamination can increase gels and filtrate valve. The high hardness in the

mud reduces the effectiveness of the majority of the polymeric products.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 61

CALCIUM AND MAGNESIUM TOGETHER –

QUANTITATIVE

Equipment

1. Standard Versenate Solution (EDTA) 0.01 M (1 ml = 400 mg Ca++ or 1,000 mg

CaCO3).

2. Buffer Hardness Solution (ammonium hydroxide/ammonium chloride).

3. Versenate solution as hardness indicator (Clamagite Indicator Solution).

4. Titration dish, 100 to 150 cm3, preferably white.

5. Three graduated pipettes: 1 cm3 , 5 cm3 ,10 cm3.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 62

CALCIUM AND MAGNESIUM TOGETHER –

QUANTITATIVE

7. Graduated Cylinder, 50 cm3.

8. Distilled water.

9. Stirring rod.

10. NaOH, 8N solution or KOH.

11. Calcon Indicator Calver II

12. Porcelain Spatula.

13. Masking Agent: tritalonamine mixture at 1:1:2

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 63

CALCIUM AND MAGNESIUM TOGETHER –

QUANTITATIVE

Procedure (total hardness)

Add 50 cm3 of deionized water to the titration dish; add 2 cm3 (20 drops) of

versenate buffer solution (base NH4OH).

Add 10 drops of Versenate Hardness Indicator Solution (nero eriocromo t). If

calcium and/or Magnesium is present in the deionized water, a wine red-colour will

develop otherwise the solution will keep the blue colour.

During the stirring titrate with standard versenate (EDTA) unitl the colour turns

from red-wine to blue. Do not pass the colour change point.

Note: The steps 1-3 remove hardness from deionized water.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 64

CALCIUM AND MAGNESIUM TOGETHER –

QUANTITATIVE

Procedure (total hardness)

Add to the deionized water 1 cm3 of filtrate. If there’s calcium and/or magnesium

a red-wine colour will develop. During the stirring, titrate (drop by drop) until the

colour turns from red-wine to blue.

Note the number of cm3 of versenate used (if magnesium is measured according

to procedures report the value as “A” cm3.) and calculate the hardness in mg/l.

A = total hardness; B = calcium hardness ;A-B = magnesium hardness.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 65

CALCIUM AND MAGNESIUM TOGETHER –

QUANTITATIVE

Calculation

Total Hardness as Ca++ (mg/l) = (cm3 versenate x 400) / (cm3 sample)

CaCO3 (mg/l) = (cm3 versenate x 1,000) / (cm3 sample)

Occasionally, the dark colour filtrate could not be easily visible at the end point as a

consequence, it is difficult to define the total hardness. For a better definition of the

end point, the following mehtod is suggested.

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 66

TOTAL HARDNESS TITRATION

Total Hardness Titration

Total Hardness

Chemical analysis Column 1 Column 2

Sample No 1 cm3 of filtrate

Deionized Water 50 cm3 No

Buffer 2 cm3 Buffer Versenate hardness No

Colour Indicator 10 gocce Versenate Hardness indicator No

Titrate with: Standard Versenate Standard Versenate

Red-wine to blue

Change Colour Do not pass the end point Wine-red colour to blue

(cm3 of versenate x 400)/ (cm3 of

Record No the sample)

Note: Pass to column 2

Well Area Operations

Agip KCO Drilling Supervisors Training Course

Drilling Muds RPW2021A 67

Potrebbero piacerti anche

- Fundamentals and Applications of Bionic Drilling FluidsDa EverandFundamentals and Applications of Bionic Drilling FluidsNessuna valutazione finora

- Drilling Fluids Lab FinalDocumento24 pagineDrilling Fluids Lab FinalHameed Bin AhmadNessuna valutazione finora

- ContaminationDocumento30 pagineContaminationSofiane KharchiNessuna valutazione finora

- Section 4 - Basic Pilot Testing and ContaminationDocumento25 pagineSection 4 - Basic Pilot Testing and ContaminationEjaz ul Haq kakar100% (1)

- Chapter 05 Spacers PDFDocumento14 pagineChapter 05 Spacers PDFLeonardo Barrios CarreraNessuna valutazione finora

- Linear Swell TestDocumento3 pagineLinear Swell TestAhmer AkhlaqueNessuna valutazione finora

- Cementing Proposal Programs TFT-473 - TP-211 PDFDocumento25 pagineCementing Proposal Programs TFT-473 - TP-211 PDFAmine MimoNessuna valutazione finora

- Drilling Fluids SelectionDocumento16 pagineDrilling Fluids SelectionRashid Ali SheikhNessuna valutazione finora

- Settling Plug Mixing ProcedureDocumento8 pagineSettling Plug Mixing ProcedureKamel TouahriaNessuna valutazione finora

- Well Engineering Guidlines For Hole CleaningDocumento13 pagineWell Engineering Guidlines For Hole CleaningWilliam100% (1)

- ch5 - Drilling FluidsDocumento66 paginech5 - Drilling FluidsMahmoud NassarNessuna valutazione finora

- 5 Effect of High Temp On MudsDocumento8 pagine5 Effect of High Temp On Mudsgplese0Nessuna valutazione finora

- Rilling Ngineering Course (2 Ed.)Documento43 pagineRilling Ngineering Course (2 Ed.)MarcoNessuna valutazione finora

- Chap - 21 Drill-In FluidsDocumento46 pagineChap - 21 Drill-In FluidspaimanNessuna valutazione finora

- Sect-2 Diff StickDocumento13 pagineSect-2 Diff StickAbderrahim HaciniNessuna valutazione finora

- DF Prod & Sys SEADocumento103 pagineDF Prod & Sys SEApaimanNessuna valutazione finora

- Annular Velocity TheoryDocumento2 pagineAnnular Velocity TheoryMohitTagotraNessuna valutazione finora

- Field Fluids QaqcDocumento38 pagineField Fluids QaqcscrbdgharaviNessuna valutazione finora

- Pilot Test: ScientificDocumento12 paginePilot Test: ScientificHomam MohammadNessuna valutazione finora

- Baroid Fluids Handbook EZ-MudDocumento3 pagineBaroid Fluids Handbook EZ-MudKinni ShenoldNessuna valutazione finora

- RA Casing CementingDocumento66 pagineRA Casing CementingAnonymous 9AZe3w0% (1)

- Completion Fluids Displacement and Cementing SpacersDocumento18 pagineCompletion Fluids Displacement and Cementing SpacersAnonymous JMuM0E5YONessuna valutazione finora

- Several Tests For Drilling Fluid in FieldDocumento9 pagineSeveral Tests For Drilling Fluid in FieldMufti Ghazali100% (1)

- Well InterventionDocumento83 pagineWell InterventionJosue FishNessuna valutazione finora

- OBM Syntethic PDFDocumento23 pagineOBM Syntethic PDFzahid latifNessuna valutazione finora

- Performax Brochure 0810Documento6 paginePerformax Brochure 0810dchyNessuna valutazione finora

- Drilling Fluid QuestionsDocumento2 pagineDrilling Fluid QuestionsMunsef AL-juroshyNessuna valutazione finora

- Chapter 14 - Drilling Fluids For ERD, Horizontal WellsDocumento14 pagineChapter 14 - Drilling Fluids For ERD, Horizontal WellsAbbas AlkhudafiNessuna valutazione finora

- Mud ContaminantDocumento16 pagineMud ContaminantCiputra 'Boy' Tampubolon0% (1)

- Lost Circulation - 2020Documento54 pagineLost Circulation - 2020JohnNessuna valutazione finora

- WarpDocumento12 pagineWarpGT GuidoNessuna valutazione finora

- Drilling Fluid 2 (C5)Documento44 pagineDrilling Fluid 2 (C5)jibriilmustafa5Nessuna valutazione finora

- Salt TableDocumento25 pagineSalt TableHappiness ImuetinyanNessuna valutazione finora

- Part VII Deepwater Drilling PDFDocumento31 paginePart VII Deepwater Drilling PDFSlim.BNessuna valutazione finora

- Turbochem BrochureDocumento8 pagineTurbochem BrochureSameer KhanNessuna valutazione finora

- Drilling Fluids and Drilling Waste Management PDFDocumento8 pagineDrilling Fluids and Drilling Waste Management PDFkenny haekaseNessuna valutazione finora

- Drilling FluidDocumento48 pagineDrilling FluidNasih AhmadNessuna valutazione finora

- Drilling Fluid Drilling Fluid Drilling Fluid Drilling Fluid Contaminants ContaminantsDocumento51 pagineDrilling Fluid Drilling Fluid Drilling Fluid Drilling Fluid Contaminants ContaminantsAmine BiroukNessuna valutazione finora

- CementingDocumento43 pagineCementingMax SinghNessuna valutazione finora

- The Use and Misuse of Centrifuges PDFDocumento4 pagineThe Use and Misuse of Centrifuges PDFChandrasekar Srinivas MohanNessuna valutazione finora

- 3 Mud Additives & TreatmentDocumento28 pagine3 Mud Additives & TreatmentyasirismNessuna valutazione finora

- All About MudDocumento91 pagineAll About MudRomadona Yoga PutratamaNessuna valutazione finora

- Mud EngineeringDocumento151 pagineMud EngineeringLuis RomeroNessuna valutazione finora

- BARKLNFLDocumento2 pagineBARKLNFLgplese0Nessuna valutazione finora

- Oil Based Mud ThinnerDocumento2 pagineOil Based Mud ThinnerjangriNessuna valutazione finora

- Mud Engineers HandbookDocumento29 pagineMud Engineers HandbookWasif KarimNessuna valutazione finora

- Low Viscosity Drilling Fluid, LSRVDocumento8 pagineLow Viscosity Drilling Fluid, LSRVMohitTagotraNessuna valutazione finora

- 14 Contaminants - Part 2 NEWDocumento26 pagine14 Contaminants - Part 2 NEWLuis CarrilloNessuna valutazione finora

- WBM ObmDocumento27 pagineWBM ObmMygroup 5544Nessuna valutazione finora

- Cementing Design Liner GeneralDocumento5 pagineCementing Design Liner GeneralnkhamidyNessuna valutazione finora

- Ultra High Temperature Aqueous and Non Aqueous Drilling FluidsDocumento20 pagineUltra High Temperature Aqueous and Non Aqueous Drilling FluidspostingidsgNessuna valutazione finora

- Oil Based Mud or Fluids (OBM)Documento7 pagineOil Based Mud or Fluids (OBM)mmohsinaliawanNessuna valutazione finora

- Water Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sDocumento1 paginaWater Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sjamesNessuna valutazione finora

- SPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterDocumento19 pagineSPE-116364-Entrance Pressure of Oil Based Mud Into Shale Effect of Shale, WaterwjawichNessuna valutazione finora

- Rheliant Plus Brochure PDFDocumento8 pagineRheliant Plus Brochure PDF2591995Nessuna valutazione finora

- 45-Mud Hole CleaningDocumento11 pagine45-Mud Hole CleaningFreddy Quintero100% (1)

- Liner Cementing GuidelinesDocumento2 pagineLiner Cementing GuidelineszapspazNessuna valutazione finora

- Drilling Fluid CompressibilityDocumento1 paginaDrilling Fluid CompressibilityLuisA.HarCórNessuna valutazione finora

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDa EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNessuna valutazione finora

- 55Documento12 pagine55محمد أحمد عبداللطيفNessuna valutazione finora

- Swab No Report Well No O2Documento5 pagineSwab No Report Well No O2محمد أحمد عبداللطيفNessuna valutazione finora

- Paper Subject Oil, Water and Gas) : (SaturationDocumento9 paginePaper Subject Oil, Water and Gas) : (Saturationمحمد أحمد عبداللطيفNessuna valutazione finora

- PRPP 2013 Crude Oil PropertiesDocumento7 paginePRPP 2013 Crude Oil PropertiesMohamed AlaaNessuna valutazione finora

- Main 17Documento11 pagineMain 17محمد أحمد عبداللطيفNessuna valutazione finora

- Paper Subject Oil, Water and Gas) : (SaturationDocumento9 paginePaper Subject Oil, Water and Gas) : (Saturationمحمد أحمد عبداللطيفNessuna valutazione finora

- Ana FoxDocumento2 pagineAna Foxمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 11 Polymers ChemistryDocumento37 pagineChapter 11 Polymers Chemistryمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 07 Clays ChemistryDocumento39 pagineChapter 07 Clays Chemistryمحمد أحمد عبداللطيفNessuna valutazione finora

- Circulation Losses and Spot Pills - Rev4Documento63 pagineCirculation Losses and Spot Pills - Rev4محمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 15 Drill-In FluidsDocumento13 pagineChapter 15 Drill-In Fluidsمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 14 Solids RemovalDocumento38 pagineChapter 14 Solids Removalمحمد أحمد عبداللطيفNessuna valutazione finora

- Drilling Fluids CourseDocumento1 paginaDrilling Fluids CourseKevin LealNessuna valutazione finora

- Drilling Fluids CourseDocumento79 pagineDrilling Fluids Courseمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 13 Oil Based MudsDocumento65 pagineChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 10 Water - Based Drilling Fluids Non-InhDocumento12 pagineChapter 10 Water - Based Drilling Fluids Non-Inhمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 12 Inhibiting Water Based MudsDocumento63 pagineChapter 12 Inhibiting Water Based Mudsمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 01 Drilling Fluids Functions (4Documento70 pagineChapter 01 Drilling Fluids Functions (4محمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 07 Mud DisplacementDocumento34 pagineChapter 07 Mud Displacementمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 07 Mud DisplacementDocumento19 pagineChapter 07 Mud Displacementمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 07 Mud DisplacementDocumento19 pagineChapter 07 Mud Displacementمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 08 Gas MigrationDocumento21 pagineChapter 08 Gas Migrationمحمد أحمد عبداللطيفNessuna valutazione finora

- Chapter 02 Basic ChemistryDocumento67 pagineChapter 02 Basic ChemistryKevin LealNessuna valutazione finora

- Diesel Fuel Cetane NumberDocumento2 pagineDiesel Fuel Cetane NumbermdchetrNessuna valutazione finora

- Chapter 01 Drilling Fluids Functions (4Documento70 pagineChapter 01 Drilling Fluids Functions (4محمد أحمد عبداللطيفNessuna valutazione finora

- Drilling Fluid FunctionsDocumento28 pagineDrilling Fluid FunctionsChristian Olascoaga MoriNessuna valutazione finora

- Drilling Fluid FunctionsDocumento28 pagineDrilling Fluid FunctionsChristian Olascoaga MoriNessuna valutazione finora

- Chapter 03 Basic Chemistry and Chemical ReactionDocumento16 pagineChapter 03 Basic Chemistry and Chemical Reactionمحمد أحمد عبداللطيفNessuna valutazione finora

- Uop 987Documento11 pagineUop 987pramod23septNessuna valutazione finora

- Water Permeability of Geotextiles by Permittivity: Standard Test Methods ForDocumento6 pagineWater Permeability of Geotextiles by Permittivity: Standard Test Methods ForLupita RamirezNessuna valutazione finora

- CS TheoryDocumento403 pagineCS TheoryAnonymous scnl9rHNessuna valutazione finora

- Landing GearDocumento6 pagineLanding GearMureithi SamNessuna valutazione finora

- Rubber World HNBR Article - Therban AT PDFDocumento9 pagineRubber World HNBR Article - Therban AT PDFAnusha Rajagopalan100% (1)

- +M - MDocumento6 pagine+M - MRitesh SonawaneNessuna valutazione finora

- Research Note On Aluminium Alloy Property PDFDocumento80 pagineResearch Note On Aluminium Alloy Property PDFpenghzNessuna valutazione finora

- Determination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationDocumento6 pagineDetermination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationHeidi HughesNessuna valutazione finora

- Numerical Methods in Quantum MechanicsDocumento108 pagineNumerical Methods in Quantum MechanicsMichel Marcondes100% (1)

- What Are The Properties of Air Entrained ConcreteDocumento2 pagineWhat Are The Properties of Air Entrained ConcretesuryakantameNessuna valutazione finora

- E3877 Optics FormulasDocumento6 pagineE3877 Optics FormulasKaran DoshiNessuna valutazione finora

- Training Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine ServicesDocumento42 pagineTraining Session 5: Gas Turbine Repair: by Scott Hastie / Liburdi Turbine Serviceskp pkNessuna valutazione finora

- Conexion BlueDocumento32 pagineConexion Bluecesardario90Nessuna valutazione finora

- Advanced Packaging TechnologiesDocumento5 pagineAdvanced Packaging TechnologiesSam HongNessuna valutazione finora

- AbrasionDocumento18 pagineAbrasionNiño Bryan Talibong AceroNessuna valutazione finora

- Unconventional Manufacturing ProcessesDocumento8 pagineUnconventional Manufacturing ProcessestfortazNessuna valutazione finora

- 015 - NH - 1003 Thermal and Acoustic InsulationDocumento26 pagine015 - NH - 1003 Thermal and Acoustic InsulationSaif AhmedNessuna valutazione finora

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Documento9 pagine09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- B 91 - 12Documento5 pagineB 91 - 12phaindikaNessuna valutazione finora

- Us 20130000370Documento9 pagineUs 20130000370japerezle23Nessuna valutazione finora

- Analysis of Dynamic Load Capacity of The Top Drive of Drilling Rigs.Documento8 pagineAnalysis of Dynamic Load Capacity of The Top Drive of Drilling Rigs.NestorMenesesPintoNessuna valutazione finora

- Hydration of C3A With Calcium Sulfate Alone and in The Presence of Calcium SilicateDocumento154 pagineHydration of C3A With Calcium Sulfate Alone and in The Presence of Calcium SilicatememorphNessuna valutazione finora

- 10 1016@j Jclepro 2019 03 260Documento10 pagine10 1016@j Jclepro 2019 03 260Rose BleueNessuna valutazione finora

- BioEx.D.Foam Anglais Web PDFDocumento2 pagineBioEx.D.Foam Anglais Web PDFhectorNessuna valutazione finora

- Rotogravure Printing Learn MoreDocumento15 pagineRotogravure Printing Learn Moreumangashling100% (1)

- Gaussian 03 Winodws TutorialDocumento4 pagineGaussian 03 Winodws Tutorialfernandojardim12Nessuna valutazione finora

- Etil Acetate Total Production RDDocumento6 pagineEtil Acetate Total Production RDJuan Camilo Rodriguez SandovalNessuna valutazione finora

- Apoptosis ManualDocumento174 pagineApoptosis Manualbibeksd796Nessuna valutazione finora

- The Language of Quantum MechanicsDocumento7 pagineThe Language of Quantum Mechanicslaura HernandezNessuna valutazione finora