Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Root Cause Chart PII R6 Complimentary 11x17

Caricato da

Gustavo GustavoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Root Cause Chart PII R6 Complimentary 11x17

Caricato da

Gustavo GustavoCopyright:

Formati disponibili

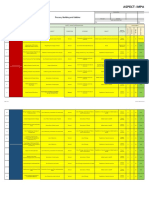

Start here with each causal factor

Root Cause Chart™ Equipment Personnel Natural Sabotage/

Other Difficulty

Difficulty 5

Difficulty 5 Phenomena 5 Horseplay 6 6

Design Equipment Administrative/ Human Factors Immediate

Input/Output Reliability Management Procedures Engineering Training Communication Fitness for Duty

Systems Supervision

7 Program 7 7 8 8 8 8 9 9

Design Input NI 11 Preparation NI 52 Sensory/

• Design Input Overall Program Equipment/ Reliability Program 14 Reliability Task 14 Perceptual 60

NI 14 Reliability 14 • No Preparation 53

Cannot Be Met 12 Implementation NI Execution NI Capabilities NI

Records NI • Job Plan NI 53

• Design Input • No Program 15 • Equipment Missing • Reactive/Corrective Personal Stress

• Equipment from Reliability Maintenance NI 19 • Instructions to Workers NI

Obsolete 12

• Procedure for 53 ID/management

Design Records System 17 • Preventive • Walkthrough NI 53 system NI 60

• Design Input Not Determining • Scheduling NI 54

Correct 12 Needs for NI 16

• Selection of Type of Maintenance NI 19 Motor/Physical

Equipment NI 15 • Equipment Task NI 17 • Predictive • Worker Selection/ Capabilities NI 60

• Necessary

Design Input Not Operating/ • Task Frequency/ Maintenance NI 19 Assignment NI 54

• Risk Acceptance Substance Abuse

Available 12 Criteria NI Reliability History Trigger Identification • Proactive Supervision During Issue 61

15 NI

Design Output NI 11 16 or Adjustment NI 17 Maintenance NI 19 Work NI 52

• Allocation of Rest/Sleep NI

• Scope 13 Resources NI 15 • Task Initiation NI 18 • Failure Finding • No Supervision 55 (Fatigue) 61

• Tracking/Closure of Maintenance NI 20

• Design Output • Supervision NI 55 Illness/Medication

Not Clear 13 Task NI 18 • Routine Equipment Problems 61

Rounds NI 20

• Design Output

Not Correct 13

• Inconsistent

Design Output 13

No Communication or Misunderstood Work/Shift

• Design Input Not Not Timely 56 Communication 56

Addressed in Turnover NI 56

Design Output 13 • Method Not Available • Standard • Communication

or NI 57 Terminology Not Within Shifts NI 59

• Communication Between Used 58 • Communication

Work Groups NI 57 • Verification/ Between Shifts NI 59

1 • Communication Between Repeat-back Not

Shift Workers and Used 58

Standards, Standards, Safety/Hazard/Risk Problem Product/Material Procurement Control Document and

Policies, or Policies, or Review NI 22 Identification, Control NI 22 NI 23 Configuration Management NI 57 • Long Message 58

Administrative Administrative Investigation, and Control NI 23 • Communication with • Speech

• Risk Review NI 27 • Handling NI 29 • Product Acceptance Interference 58

Controls (SPACs) Controls (SPACs) Control NI 22 • Change Not Contractors NI 57

NI 22 Not Used 22 • Not Performed 27 • Storage NI 29 Requirements Do Not

• Problem Reporting • Communication with

• Recommendations • Packaging NI 29 Match Design Identified or

• No SPACs 24 • Communication of NI 28 Reviewed 32 Customers NI 57

Not Yet • Shipping NI 29 Requirements 30

• Not Strict Enough 24 SPACs NI 26 • Problem • Control (and

Implemented 27 • Shelf Life • Control of Changes to

• Confusing or • Recently Changed 26 Investigation/ 29 verfication) of No Training 47 Training Records Training NI 47

• Risk Acceptance Exceeded Procurement System NI 47

Incomplete 24 • Enforcement NI 26 Analysis NI 28 Design/Field • Decision Not to • Job/Task Analysis

Criteria NI 27 • Unauthorized Specifications/

• Technical Error 24 • Difficult to Changes NI Train 48 • Training Records NI 50

• Review Procedure • Corrective Action NI Product/Material Purchase Orders NI 31

• Responsibility for Implement 26 28 (No PSSR) 32 • Training Incorrect 49 • Program Design

or Leader Training • Corrective Action Substitution 30 • Fabricated Item Does

Item/Activity Not • Documentation Requirements Not • Training Records NI 50

NI 27 Not Yet • Product/Material Not Meet Specs 31

Adequately Not Up-to-Date Identified 48 Not Up-to-Date 49 • Training

Implemented 28 Inspections NI 30 • Incorrect Item 32

Defined 25 • Control of Objectives NI 50

Received 31

• Contradictory Documents NI • Lesson Content

• Product/Service 32

Requirements 25 NI 50

Accept. Req. NI 31

• Scheduling/ Shape Description Workplace Layout Work Environment Workload NI 39 Intolerant System 39 • On-the-Job

Tracking System NI 39 NI 39 • Knowledge-based • Errors Not Training NI 50

NI 25 Procedure Not Misleading/Confusing 33 Wrong/Incomplete 33

• Qualification

Used 33 • Controls NI 40 • Housekeeping NI 42 Decision Required 44 Detectable 46

• Employee Causal Factor Type • Typographical Error 38

• Format Confusing or NI 35 • Displays NI 40 • Climate NI 42 • Excessive Control • Errors Not Testing NI 50

Screening/ • Not Available or • More Than One Action per Step • Sequence Wrong 38 • Continuing

35 • Control/Display • Lighting NI 42 Action Required 44 Recoverable 46

Selection NI 25 Inconvenient to • No Checkoff Space Provided but • Facts Wrong/ Training NI 51

Root Cause Category Integration NI 40 • Excessive Noise 42 • Unrealistic

Obtain 34 Should Be Requirements Not • Training Support

35 • Conflicting • PPE NI 43 Monitoring

• Procedure Difficult • Inadequate Checklist 35 Correct 38 Equipment NI 51

Layouts 41 • Other Required 45

Bold Near Root Cause to Use 34 • Wrong Revision Used 38

• Graphics NI 35 • Reach or Visual Environmental • Excessive Mental • Instructor

• Use Not Required • Inconsistency

• Ambiguous or Confusing Envelope NI 41 Stressors NI 43 Math, Memory, Qualifications NI 51

Root Cause but Should Be 34 Between 38

Instructions/Requirements 36 • Labeling NI 41 Logic Required 45 • Training on New

• No Procedure for • Data/Computations Wrong/ Requirements Work Methods NI 51

Note: Node numbers correspond to the Task 34 Incomplete 36 • Incomplete/Situation • Abnormal Events/

matching page numbers in PII's Root Cause

• Equipment Identification NI 36 Not Covered 38 Emergency

Coding Guide. There are typically more than

one node per page • Excessive References 36 Training NI 51

• Multiple Area References 36 • Qualifications

• Identification of Revised Steps Standard NI 51

Note: NI = Needs Improvement NI 37

US • Presentation of Limits NI

37

Copyrighted by: Process Improvement Institute, 2003; Rev.6, April 2009. Adapted from

DOE Root Cause Coding Tree and supplemented by User’s Guide for Reactor Incident Root

Cause Coding Tree, revision five, DPST-87-209, E.I. duPont de Nemours, Savannah River

Laboratory, 1986. www.piii.com wbridges@piii.com

Potrebbero piacerti anche

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesDocumento4 pagineAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenNessuna valutazione finora

- Toshiba QEHS ManualDocumento113 pagineToshiba QEHS ManualSubhi El Haj SalehNessuna valutazione finora

- D152: Demo of Iso 45001:2018 Document KitDocumento10 pagineD152: Demo of Iso 45001:2018 Document KitTFattahNessuna valutazione finora

- The End of SilosDocumento15 pagineThe End of SilosN. AndradeNessuna valutazione finora

- 5S Checklist - Area: 5S Check Item Guidance RatingDocumento5 pagine5S Checklist - Area: 5S Check Item Guidance RatingUğur SAYILINessuna valutazione finora

- Pub 100427Documento5 paginePub 100427Engr Nabeel AhmadNessuna valutazione finora

- Chapter 9. Failure Root Cause PreventionDocumento23 pagineChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNessuna valutazione finora

- FMEA Template and RankingsDocumento43 pagineFMEA Template and RankingsBeste Ardıç ArslanNessuna valutazione finora

- Simptww PSV C208Documento4 pagineSimptww PSV C208Vijay RajaindranNessuna valutazione finora

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDocumento2 pagineJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranNessuna valutazione finora

- STUD BOLT TO NUT CHARTDocumento1 paginaSTUD BOLT TO NUT CHARTPrathap Kumar NNessuna valutazione finora

- (SOP09) LUS-HSE-SP2-442-001.02 - HSE Training ProcedureDocumento8 pagine(SOP09) LUS-HSE-SP2-442-001.02 - HSE Training ProceduregiovadiNessuna valutazione finora

- Hazard Prmopt List - Sample 2 PDFDocumento2 pagineHazard Prmopt List - Sample 2 PDFDen PamplonaNessuna valutazione finora

- Machine Faults and Percentage Breakdown ReportDocumento6 pagineMachine Faults and Percentage Breakdown ReportMuhammad Irfan ArshadNessuna valutazione finora

- Iso 45001Documento32 pagineIso 45001Rajeev kapoorNessuna valutazione finora

- Schedule Check Report Analysis and RecommendationsDocumento3 pagineSchedule Check Report Analysis and RecommendationstopriyeshppNessuna valutazione finora

- X, Ems For Die Cast IndustryDocumento216 pagineX, Ems For Die Cast IndustryAMINNessuna valutazione finora

- SOP For Hydra RepairingDocumento13 pagineSOP For Hydra RepairingMD AbdullahNessuna valutazione finora

- 09200-En-30 Process Facility Site Change ManagementDocumento6 pagine09200-En-30 Process Facility Site Change ManagementfernandoNessuna valutazione finora

- Business Risk Management Risk Assessment Tool: To Get StartedDocumento19 pagineBusiness Risk Management Risk Assessment Tool: To Get StartedaslamsiddiqNessuna valutazione finora

- Asset Management Research Report SlidesDocumento22 pagineAsset Management Research Report SlidesBobyNessuna valutazione finora

- HSE MS Training Feb 2019Documento17 pagineHSE MS Training Feb 2019Tatak Bay AhmedNessuna valutazione finora

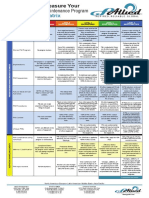

- Maturity Matrix: Preventive Maintenance ProgramDocumento2 pagineMaturity Matrix: Preventive Maintenance ProgramAnonymous OuY6oAMggx100% (1)

- Failure Mode Effects and Criticality Analysis PDFDocumento2 pagineFailure Mode Effects and Criticality Analysis PDFMacNessuna valutazione finora

- CLS Root Cause Analysis Tool2Documento2 pagineCLS Root Cause Analysis Tool2mouataz elsherbinyNessuna valutazione finora

- THE BASICS OF FAILURE MODE AND EFFECT ANALYSIS (FMEADocumento32 pagineTHE BASICS OF FAILURE MODE AND EFFECT ANALYSIS (FMEApsrajjNessuna valutazione finora

- GENSET Inventory ListDocumento16 pagineGENSET Inventory ListNiten GuptaNessuna valutazione finora

- 5S ChecklistDocumento4 pagine5S ChecklistMohdAzhanBinIshakNessuna valutazione finora

- Effectiveness of Safety Incentives in ConstructionDocumento14 pagineEffectiveness of Safety Incentives in ConstructionAndre MarsNessuna valutazione finora

- Assessment of Human Factors On Oil SpillsDocumento53 pagineAssessment of Human Factors On Oil SpillsflouzanNessuna valutazione finora

- Hot Weather Safety PresentationDocumento10 pagineHot Weather Safety Presentationkashifbutty2kNessuna valutazione finora

- P5 - Anrpod - Productivity CycleDocumento19 pagineP5 - Anrpod - Productivity CycleNicko Nur RakhmaddianNessuna valutazione finora

- RISK Mba 17Documento22 pagineRISK Mba 17Cecily Sandra100% (1)

- TOR 2014 02202 Root Cause Investigation Best Practices GuideDocumento110 pagineTOR 2014 02202 Root Cause Investigation Best Practices GuideOCangaceiro100% (1)

- CEMP Audit ChecklistDocumento6 pagineCEMP Audit ChecklistNash C. UsopNessuna valutazione finora

- ISO 45001 2018 Incident Investigation and Reporting Procedure SampleDocumento5 pagineISO 45001 2018 Incident Investigation and Reporting Procedure SampleAmr EssamNessuna valutazione finora

- Environmental Management System: SANS/ISO 14001:2015Documento6 pagineEnvironmental Management System: SANS/ISO 14001:2015Kevin RamanNessuna valutazione finora

- Map ISO 55001 asset management requirements to Plant Wellness Way processesDocumento34 pagineMap ISO 55001 asset management requirements to Plant Wellness Way processesFrank SerranoNessuna valutazione finora

- 7 Keys To STO Success Introduction PDFDocumento28 pagine7 Keys To STO Success Introduction PDFEzomar UzcáteguiNessuna valutazione finora

- TSF Emergency Responce Plan 2020Documento24 pagineTSF Emergency Responce Plan 2020chrisNessuna valutazione finora

- Risk Register 2017 - Final - 0Documento52 pagineRisk Register 2017 - Final - 0Arif MazlanNessuna valutazione finora

- 8 APEX MANUAL Industrial Gases CompanyDocumento33 pagine8 APEX MANUAL Industrial Gases CompanyNowfal HabeebNessuna valutazione finora

- Resume of Judy HuntDocumento3 pagineResume of Judy Huntapi-12295621Nessuna valutazione finora

- Initial Stages of EvolutionDocumento5 pagineInitial Stages of EvolutionVivek MulchandaniNessuna valutazione finora

- AutoCAD Drawing TemplateDocumento1 paginaAutoCAD Drawing TemplatedipenstarNessuna valutazione finora

- Hiradc KNB - Esd and WorkshopDocumento13 pagineHiradc KNB - Esd and WorkshopsnadiahNessuna valutazione finora

- Understanding The New International Standard For OH&SDocumento12 pagineUnderstanding The New International Standard For OH&SNarasimharaghavanPuliyurKrishnaswamyNessuna valutazione finora

- IAF Code Table for Industry SectorsDocumento1 paginaIAF Code Table for Industry SectorsAuditoria SMSNessuna valutazione finora

- Iso 14001 Case StudiesDocumento6 pagineIso 14001 Case StudiesAlexandra RomeroNessuna valutazione finora

- Cardone Industries Et. Al. v. BBB IndustriesDocumento22 pagineCardone Industries Et. Al. v. BBB IndustriesPriorSmartNessuna valutazione finora

- TPMDocumento85 pagineTPManggaNessuna valutazione finora

- Ge700 2020 Ga01Documento1 paginaGe700 2020 Ga01LucianNessuna valutazione finora

- Literaturhinweise Literaturhinweise: E DIN EN 61703:2013-11 E DIN EN 61703:2013-11Documento57 pagineLiteraturhinweise Literaturhinweise: E DIN EN 61703:2013-11 E DIN EN 61703:2013-11Arian NjNessuna valutazione finora

- OH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsDocumento1 paginaOH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsdnmuleNessuna valutazione finora

- BIS Application FormDocumento15 pagineBIS Application FormJagannath Majhi80% (5)

- What Is A Vehicle InspectionDocumento3 pagineWhat Is A Vehicle InspectionFranz Martinez100% (1)

- Fme (C) ADocumento4 pagineFme (C) AMurat IslamNessuna valutazione finora

- Asset Management A Complete Guide - 2020 EditionDa EverandAsset Management A Complete Guide - 2020 EditionNessuna valutazione finora

- Root Cause MapDocumento2 pagineRoot Cause Mapamevaluaciones100% (1)

- 250 Lit 001aDocumento1 pagina250 Lit 001aGustavo GustavoNessuna valutazione finora

- Jam Detection PDFDocumento1 paginaJam Detection PDFGustavo GustavoNessuna valutazione finora

- MOC and PSSER ProcedureDocumento21 pagineMOC and PSSER ProcedureGustavo GustavoNessuna valutazione finora

- Preventive Maintenance Maturity MatrixDocumento2 paginePreventive Maintenance Maturity MatrixGustavo Gustavo100% (2)

- Main 83 397370618Documento6 pagineMain 83 397370618Gustavo GustavoNessuna valutazione finora

- Sensor VibraciónDocumento25 pagineSensor VibraciónGustavo GustavoNessuna valutazione finora

- Sensor VibracionDocumento2 pagineSensor VibracionGustavo GustavoNessuna valutazione finora

- Ba Sar2!07!16 Norm enDocumento52 pagineBa Sar2!07!16 Norm enjromero_rpgNessuna valutazione finora

- Accuracy Graph Sheet Rev.1Documento1 paginaAccuracy Graph Sheet Rev.1Gustavo GustavoNessuna valutazione finora

- Management of Change (MOC) & Pre-Startup Safety Review (PSSERDocumento37 pagineManagement of Change (MOC) & Pre-Startup Safety Review (PSSERGustavo GustavoNessuna valutazione finora

- RCM Manual Feb02Documento26 pagineRCM Manual Feb02Gustavo GustavoNessuna valutazione finora

- Autovac HD User Manual Rev 7Documento32 pagineAutovac HD User Manual Rev 7Gustavo GustavoNessuna valutazione finora

- DeltaV ConfigurationDocumento518 pagineDeltaV ConfigurationGustavo Gustavo93% (15)

- Fieldbus - FISCO HPTDocumento7 pagineFieldbus - FISCO HPTGustavo GustavoNessuna valutazione finora

- Life Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity JointDocumento244 pagineLife Model For Rolling Contact, Applied To The Optimization of A Tripode Constant Velocity Jointbee140676Nessuna valutazione finora

- Risk in Clean RoomDocumento9 pagineRisk in Clean RoomABEERNessuna valutazione finora

- 3.dummy VariablesDocumento25 pagine3.dummy VariablesUnushka ShresthaNessuna valutazione finora

- Grade 3 Unit 3 (English)Documento1 paginaGrade 3 Unit 3 (English)Basma KhedrNessuna valutazione finora

- TableDocumento9 pagineTableShamlakan elghaoucheNessuna valutazione finora

- Telescopic sight basics and reticle typesDocumento18 pagineTelescopic sight basics and reticle typesKoala LumpurNessuna valutazione finora

- Plagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Documento7 paginePlagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Rostyslav SKLYAR, Dr. (Eng)Nessuna valutazione finora

- ACL-PDC-01 - Rev01 (Procurement Document Control)Documento3 pagineACL-PDC-01 - Rev01 (Procurement Document Control)Mo ZeroNessuna valutazione finora

- Grade-3-DLL MATHEMATICS-3 Q1 W4Documento3 pagineGrade-3-DLL MATHEMATICS-3 Q1 W4Jonathan Corveau IgayaNessuna valutazione finora

- Examining Oral Communication FunctionsDocumento5 pagineExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaNessuna valutazione finora

- Alvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreDocumento11 pagineAlvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreLeilane AlvesNessuna valutazione finora

- DX DiagesDocumento36 pagineDX DiagesBpbd Kota BengkuluNessuna valutazione finora

- Paper 2 Answer SPMDocumento12 paginePaper 2 Answer SPMSylarkNessuna valutazione finora

- Fta-500 A (03-20-08) PDFDocumento8 pagineFta-500 A (03-20-08) PDFOrlando Vazquez PuertaNessuna valutazione finora

- 2219 Aluminium Alloy - WikipediaDocumento2 pagine2219 Aluminium Alloy - WikipediaVysakh VasudevanNessuna valutazione finora

- Microsoft Word - JOB DESCRIPTION Staff AccountantDocumento2 pagineMicrosoft Word - JOB DESCRIPTION Staff Accountantanon-634050100% (3)

- Chapter 2 Planning Business MessagesDocumento15 pagineChapter 2 Planning Business MessagesNuriAisyahHikmahNessuna valutazione finora

- Mechanics of FlightDocumento1 paginaMechanics of FlightMoh Flit25% (4)

- Diagrama Montacargas AlmacenDocumento8 pagineDiagrama Montacargas AlmacenMiguel Gutierrez100% (1)

- Research Proposal of SheepDocumento37 pagineResearch Proposal of SheepDabalo Garama67% (3)

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocumento2 pagineMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgNessuna valutazione finora

- Elements of TQM: Dr. Sanjay MahalingamDocumento7 pagineElements of TQM: Dr. Sanjay Mahalingamuday saiNessuna valutazione finora

- Register for a WordPress account in 5 easy stepsDocumento5 pagineRegister for a WordPress account in 5 easy stepsPutriNessuna valutazione finora

- Gases and Gas LawDocumento5 pagineGases and Gas LawMaria mercedesNessuna valutazione finora

- Phil of DepressDocumento11 paginePhil of DepressPriyo DjatmikoNessuna valutazione finora

- High Current Transistor SpecsDocumento5 pagineHigh Current Transistor SpecsamernasserNessuna valutazione finora

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDocumento33 pagineKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaNessuna valutazione finora

- SUCHANA EANV SANCHAR PRAUDYOGIK (I.C.T.) AADHARIT SHIKSHAN ADHIGAM VYUV RACHANA KA MADHYAMIK STAR PAR ADHYAYANRAT GRAMIN EANV SHAHARI PARIVESH KE VIDHYARTHITON KI GANIT UPLABDHI PAR PRABHAV KA ADHYAYANDocumento9 pagineSUCHANA EANV SANCHAR PRAUDYOGIK (I.C.T.) AADHARIT SHIKSHAN ADHIGAM VYUV RACHANA KA MADHYAMIK STAR PAR ADHYAYANRAT GRAMIN EANV SHAHARI PARIVESH KE VIDHYARTHITON KI GANIT UPLABDHI PAR PRABHAV KA ADHYAYANAnonymous CwJeBCAXpNessuna valutazione finora

- CH 07Documento40 pagineCH 07Ambreen31Nessuna valutazione finora

- Textbook List for Sri Kanchi Mahaswami Vidya Mandir 2020-21Documento13 pagineTextbook List for Sri Kanchi Mahaswami Vidya Mandir 2020-21drsubramanianNessuna valutazione finora