Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Modeling Using HYSYS NGL Fractionation Train

Caricato da

NasroTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Modeling Using HYSYS NGL Fractionation Train

Caricato da

NasroCopyright:

Formati disponibili

Process Modeling Using HYSYS NGL Fractionation Train

NGL Fractionation Train

©2005 AspenTech. All Rights Reserved. 1 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Workshop

Recovery of natural-gas liquids (NGL) from natural gas is quite

common in natural gas processing. Recovery is usually done to:

• Produce transportable gas (free from heavier hydrocarbons

which may condense in the pipeline)

• Meet a sales gas specification

• Maximize liquid recovery (when liquid products are more

valuable than gas)

HYSYS can model a wide range of different column configurations. In

this simulation, an NGL Plant will be constructed, consisting of three

columns:

• De-Methanizer (operated and modeled as a Reboiled Absorber

column)

• De-Ethanizer (Distillation column)

• De-Propanizer (Distillation column)

Learning Objectives

Once you have completed this section, you will be able to:

• Add columns using the Input Experts

• Add extra specifications to columns

Prerequisites

Before beginning this module you need to complete modules 1, 2, and

3.

©2005 AspenTech. All Rights Reserved. 2 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

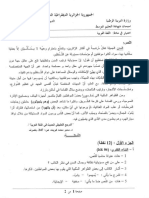

Process Overview

©2005 AspenTech. All Rights Reserved. 3 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

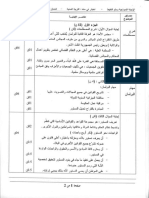

Column Overviews

DC1: De-Methanizer

©2005 AspenTech. All Rights Reserved. 4 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

DC2: De-Ethanizer

DC3: De-Propanizer

©2005 AspenTech. All Rights Reserved. 5 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Building the Simulation

Defining the Simulation Basis

1. Start a new case.

2. Select the Peng Robinson EOS.

3. Add the components: N2, CO2, C1 - C8.

4. Enter the Simulation Environment.

Adding the Feed Streams

Add a Material Stream with the following data:

In this cell... Enter...

Name Feed1

Temperature -95°C (-140°F)

Pressure 2275 kPa (330 psia)

Flowrate 1620 kgmole/h (3575 lbmole/hr)

Component Mole Fraction

N2 0.0025

CO2 0.0048

C1 0.7041

C2 0.1921

C3 0.0706

i-C4 0.0112

n-C4 0.0085

i-C5 0.0036

n-C5 0.0020

C6 0.0003

C7 0.0002

C8 0.0001

©2005 AspenTech. All Rights Reserved. 6 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

2. Add a Material Stream with the following data:

In this cell... Enter...

Name Feed2

Temperature -85°C (-120°F)

Pressure 2290 kPa (332 psia)

Flowrate 215 kgmole/h (475 lbmole/hr)

Component Mole Fraction

N2 0.0057

CO 2 0.0029

C1 0.7227

C2 0.1176

C3 0.0750

i-C 4 0.0204

n-C 4 0.0197

i-C 5 0.0147

n-C 5 0.0102

C6 0.0037

C7 0.0047

C8 0.0027

Adding the Unit Operations

De-Methanizer

The De-Methanizer is modelled as a reboiled absorber operation, with

two feed streams and an energy stream feed, which represents a side

heater on the column.

1. Add an Energy stream with the following values:

In this cell... Enter...

Name Ex Duty

Energy Flow 2.1e+006 kJ/h (2.0e+06Btu/hr)

Reboiled Absorber 2. Double-click the Reboiled Absorber icon on the Object Palette.

Column icon The first Input Expert view appears.

©2005 AspenTech. All Rights Reserved. 7 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

3. Complete the view as shown below:

The Input Exports

provide the new user

with step by step

instruction for defining

a column.

4. Click the Next button to proceed to the next page.

5. Supply the following information to the Pressure Estimates page. If

you are using field units, the values will be 330 psia and 335 psia,

for the Top Stage Pressure and Reboiler Pressure, respectively.

The Next button is only

available when all of

the necessary

information has been

supplied.

6. Click the Next button to proceed to the next page.

©2005 AspenTech. All Rights Reserved. 8 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

7. Enter the temperature estimates shown below. In field units, the

top stage temperature estimate will be -125°F, and the reboiler

temperature estimate will be 80°F.

Temperature estimates are

not required for the

column to solve but they

will aid in convergence.

8. Click the Next button to continue.

9. For this case, no information is supplied for the Boil-up Ratio on

the last page of the Input Expert, so click the Done button.

The basic Reboiled

Absorber has a single

DOF.

When you click the Done button, HYSYS will open the Column

property view. Access the Monitor page on the Design tab.

©2005 AspenTech. All Rights Reserved. 9 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Before you converge the column, make sure that the specifications are

as shown above. You will have to enter the value for the Ovhd Prod

Rate specification. The specified value is 1338 kgmole/h (2950

lbmole/hr).

10. Click the RUN button to run the column.

What is the mole fraction of Methane in DC1 Ovhd?

Although the column is converged, it is not always practical to have

flow rate specifications. These specifications can result in columns that

cannot be converged or that produce product streams with undesirable

properties if the column feed conditions change.

An alternative approach is to specify either component fractions or

component recoveries for the column product streams.

1. Go to the Specs page on the Design tab of the Column property

view.

©2005 AspenTech. All Rights Reserved. 10 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

2. Click the Add button in the Column Specifications group to create

a new specification.

3. Select Column Component Fraction from the list that appears.

4. Click the Add Spec(s) button.

5. Complete the spec as shown in the following figure.

6. When you have finished, close the view.

The Monitor page of the Column property view shows 0 Degrees of

Freedom even though you have just added another specification. This

©2005 AspenTech. All Rights Reserved. 11 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

is due to the fact that the specification was added as an estimate, not as

an active specification.

7. Go to the Monitor page. Deactivate the Ovhd Prod Rate as an

active specification and activate the Comp Fraction specification

(C1 in Overhead) which you created.

What is the flowrate of the overhead product, DC1 Ovhd? .

Once the column has converged, you can view the results on the

Performance tab.

©2005 AspenTech. All Rights Reserved. 12 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Adding a Pump

The pump is used to move the De-Methanizer bottom product to the

De-Ethanizer.

Install a pump and enter the following information:

Pump icon In this cell... Enter...

Connections

Inlet DC1 Btm

Outlet DC2 Feed

Energy P-100-HP

Worksheet

DC2 Feed Pressure 2790 kPa (405 psia)

De-Ethanizer

The De-Ethanizer column is modeled as a distillation column, with 16

stages, 14 trays in the column, plus the reboiler and condenser. It

operates at a pressure of 2760 kPa (400 psia). The objective of this

column is to produce a bottom product that has a ratio of ethane to

propane of 0.01.

1. Double-click the Distillation Column button on the Object Palette

Distillation Column

and enter the following information.

icon

In this cell... Enter...

Connections

Name DC2

No. of Stages 14

Inlet Stream/Stage DC2 Feed/6

Condenser Type Partial

Overhead Vapour Product DC2 Ovhd

Overhead Liquid Product DC2 Dist

Bottoms Liquid Outlet DC2 Btm

Reboiler Duty Energy Stream DC2 Reb Q

Condenser Duty Energy Stream DC2 Cond Q

Pressures

Condenser 2725 kPa (395 psia)

Condenser Delta P 35 kPa (5 psi)

Reboiler 2792 kPa (405 psia)

©2005 AspenTech. All Rights Reserved. 13 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Temperature Estimates

Condenser -4°C (25°F)

Reboiler 95°C (200°F)

Specifications

320 kgmole/h (700

Overhead Vapour Rate

lbmole/hr)

Distillate Rate 0 kgmole/h

Reflux Ratio 2.5 (Molar)

2. Click the Run button to run the column.

What is the flowrate of C2 and C3 in DC2 Btms?

C2 , C3 , Ratio of C2/C3 .

3. On the Specs page, click the Add button to create a new

specification.

4. Select Column Component Ratio as the Column Specification

Type and provide the following information:

In this cell... Enter...

Name C2/C3

Stage Reboiler

Flow Basis Mole Fraction

Phase Liquid

Spec Value 0.01

Numerator Ethane

Denominator Propane

5. On the Monitor tab, deactivate the Ovhd Vap Rate specification

and activate the C2/C3 specification that you created.

What is the flowrate of DC2 Ovhd? .

©2005 AspenTech. All Rights Reserved. 14 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Adding a Valve

A valve is required to reduce the pressure of the stream DC2 Btm

before it enters the final column, the De-Propanizer.

Add a Valve operation and provide the following information:

In this cell... Enter...

Valve icon Connections

Inlet DC2 Btm

Outlet DC3 Feed

Worksheet

DC3 Feed Pressure 1690 kPa (245 psia)

De-Propanizer

The De-Propanizer column is represented by a distillation column

consisting of 25 stages, 24 trays in the column plus the reboiler. (Note

that a total condenser does not count as a stage). It operates at 1620

kPa (235 psia). There are two process objectives for this column. One

is to produce an overhead product that contains no more than 1.50

mole percent of i-C4 and n-C4 and the second is that the concentration

Distillation

of propane in the bottom product should be less than 2.0 mole percent.

Column icon

1. Add a distillation column and provide the following information:

In this cell... Enter...

Connections

Name DC3

No. of Stages 24

Inlet Streams/Stage DC3 Feed/11

Condenser Type Total

Ovhd Liquid Outlet DC3 Dist

Bottom Liquid Outlet DC3 Btm

Reboiler Duty Energy Stream DC3 Reb Q

Condenser Duty Energy Stream DC3 Cond Q

Pressures

Condenser 1585 kPa (230 psia)

Condenser Delta P 35 kPa (5 psi)

Reboiler 1655 kPa (240 psia)

Temperature Estimates

Condenser 38°C (100°F)

©2005 AspenTech. All Rights Reserved. 15 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Reboiler 120°C (250°F)

Specifications

Liquid Rate 110 kgmole/h (240 lbmole/hr)

Reflux Ratio 1.0 Molar

2. Run the column.

What is the mole fraction of C3 in the overhead and bottoms products?

and .

3. Create two new Component Fraction specifications for the column.

In this cell... Enter...

i-C4 and n-C4 in Distillate

Name iC4 and nC4

Stage Condenser

Flow Basis Mole Fraction

Phase Liquid

Spec Value 0.015

Components i-C4 and n-C4

C3 in Reboiler Liquid

Name C3

Stage Reboiler

Flow Basis Mole Fraction

Phase Liquid

Spec Value 0.02

Component C3

4. Deactivate the Distillate Rate and Reflux Ratio specifications.

5. Activate the iC4, nC4, and C3 specifications that you created.

Optional

©2005 AspenTech. All Rights Reserved. 16 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Advanced Modeling

The column is a special type of sub-flowsheet in HYSYS. Sub-

flowsheets contain equipment and streams, and exchange information

with the parent flowsheet through the connected streams. From the

main environment, the column appears as a single, multifeed

multiproduct operation. In many cases, you can treat the column in

exactly that manner.

The column subflowsheet provides a number of advantages:

• Isolation of the Column Solver. The Column Build

Environment allows you to make changes and focus on the

column without the re-calculation of the entire flowsheet.

• Optional use of different fluid packages. HYSYS allows you

to specify a unique (different from the main environment) fluid

package for the column subflowsheet. This is useful when a

different fluid package is better suited to the column (Gas Plant

using PR may contain an Amine Contactor that needs to use

the Amines Property Package), or the column does not use all

of the components used in the main flowsheet and so by

decreasing the number of components in the column you may

speed up column convergence.

• Construction of custom templates. In addition to the default

column configurations which are available as templates, you

may define column setups with varying degrees of complexity.

Complex custom columns and multiple columns may be

simulated within a single subflowsheet using various

combinations of subflowsheet equipment. Custom column

examples include, replacement of the standard condenser with

a heat exchanger, or the standard kettle reboiler with a

thermosyphon reboiler.

• Ability to solve multiple towers simultaneously. The column

subflowsheet uses a simultaneous solver whereby all

operations within the subflowsheet are solved simultaneously.

The simultaneous solver permits the user to install multiple

interconnected columns within the subflowsheet without the

need for recycle blocks.

You can enter the column subflowsheet by clicking the Column

Environment icon on the Column property view. Once inside the

column environment, you can return to the parent environment by

Enter Parent clicking either the Parent Environment button on the Column runner

Simulation view or the Enter Parent Simulation Environment icon in the tool

Environment

icon

bar.

©2005 AspenTech. All Rights Reserved. 17 Aspen Technology, Inc.

Process Modeling Using HYSYS NGL Fractionation Train

Exploring the Simulation

Challenge

After simulating your DeMethanizer, you have to use HYSYS to

determine the UA for the DeMethanizer Reboiler. Assume that you

have 1000 kgmole/h of saturated 100 psi steam available for the shell

The presence of the side and there is a 5 psi pressure drop on the steam side. Your

green “Up Arrow”

overhead Methane spec of 0.96 (mole) must still be met.

icon in the tool bar and

the Environment: Remember, you will need to add water to your component list. Instead

Name (COL1) of changing the configuration of the column (changing the solver type

indicates that you are

in the column

to Modified HYSIM Inside-Out), you can create an internal stream (on

subflowsheet. the Flowsheet tab). This stream represents the liquid that flows from

the bottom tray to the reboiler, which can then be added to a heat

exchanger in the Main Flowsheet. Use steam to exchange heat with the

process stream.

©2005 AspenTech. All Rights Reserved. 18 Aspen Technology, Inc.

Potrebbero piacerti anche

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- 03 Refrigerated Gas PlantDocumento23 pagine03 Refrigerated Gas Plantmiguel100% (1)

- Statistics for Process Control Engineers: A Practical ApproachDa EverandStatistics for Process Control Engineers: A Practical ApproachNessuna valutazione finora

- The HYSYS SpreadsheetDocumento10 pagineThe HYSYS SpreadsheetSyed Muzamil AhmedNessuna valutazione finora

- Amine Sweetening With DEADocumento14 pagineAmine Sweetening With DEARoza SavitriNessuna valutazione finora

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationDa EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNessuna valutazione finora

- HYSYS Simulation BasisDocumento527 pagineHYSYS Simulation BasisAbdallah FEKKAINessuna valutazione finora

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsDa EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsValutazione: 2 su 5 stelle2/5 (1)

- Build A Propane Refrigeration Loop Workshop: ObjectiveDocumento24 pagineBuild A Propane Refrigeration Loop Workshop: ObjectivePauü ReinaNessuna valutazione finora

- AspenHYSYSUpstreamV7 3 OptDocumento304 pagineAspenHYSYSUpstreamV7 3 Opti786zzyNessuna valutazione finora

- Training CaseDocumento15 pagineTraining CaseThái Xuân QuangNessuna valutazione finora

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodDa EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNessuna valutazione finora

- Unique Advantages Of: PipenetDocumento27 pagineUnique Advantages Of: PipenetruzlaNessuna valutazione finora

- Enhanced Recycle Split VapourDocumento19 pagineEnhanced Recycle Split VapourMaythee SaisriyootNessuna valutazione finora

- Steam CoilDocumento6 pagineSteam CoilMyung Ho SynNessuna valutazione finora

- PROII 8.1 Getting Started GuideDocumento139 paginePROII 8.1 Getting Started Guidekingcobra008100% (2)

- Dewatering Column AA Grade MethanolDocumento15 pagineDewatering Column AA Grade MethanolIrma BrennanNessuna valutazione finora

- Distillation1 AdeyabDocumento17 pagineDistillation1 AdeyabSrihari Kodimela0% (1)

- Flare Sweep GasDocumento5 pagineFlare Sweep GasChem.EnggNessuna valutazione finora

- HMB Latest Stream ReporterDocumento20 pagineHMB Latest Stream ReporterConnor SailorNessuna valutazione finora

- 06 GasGatheringDocumento18 pagine06 GasGatheringChristian Chinedu0% (1)

- Crude Tower Simulation-HYSYS v8.6Documento42 pagineCrude Tower Simulation-HYSYS v8.6EstrellaNessuna valutazione finora

- Hysys Training To Link Hysys Valve To ExcelDocumento4 pagineHysys Training To Link Hysys Valve To ExcelVarada Radjou CNessuna valutazione finora

- Treat LPGs With AminesDocumento12 pagineTreat LPGs With Amineskaaskopdawie5755Nessuna valutazione finora

- Acid Gas Sweetening Case StudyDocumento16 pagineAcid Gas Sweetening Case Studyome solNessuna valutazione finora

- Anaerobic Digestion of Cow Dung For Biogas Production: Baba Shehu Umar Ibn Abubakar and Nasir IsmailDocumento4 pagineAnaerobic Digestion of Cow Dung For Biogas Production: Baba Shehu Umar Ibn Abubakar and Nasir IsmailanantriNessuna valutazione finora

- Liquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessDocumento8 pagineLiquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessHaru MasaNessuna valutazione finora

- Natural Gas Liquids Recovery Processes in Natural Gas ProcessingDocumento27 pagineNatural Gas Liquids Recovery Processes in Natural Gas ProcessingVictor Ali MentaNessuna valutazione finora

- Rate-Based Modeling For CO2 AbsorptionDocumento10 pagineRate-Based Modeling For CO2 AbsorptiongoingtohellwithmeNessuna valutazione finora

- Inprocess-BP Lingen Project ArticleDocumento3 pagineInprocess-BP Lingen Project Articlejrz85Nessuna valutazione finora

- Sulphur Recovery, HYSYS, GPSA-Conversion ReactorsDocumento3 pagineSulphur Recovery, HYSYS, GPSA-Conversion ReactorsBindu joglekarNessuna valutazione finora

- AspenHYSYSRefiningV7 2 OpsDocumento478 pagineAspenHYSYSRefiningV7 2 Opsnguyennha1211100% (1)

- Volume 3-The Origins of ProtreatDocumento2 pagineVolume 3-The Origins of ProtreatIbhar Santos MumentheyNessuna valutazione finora

- Column EfficiencyDocumento8 pagineColumn Efficiencynebulakers100% (1)

- A-Extensions in HYSYSDocumento4 pagineA-Extensions in HYSYSSyed Muzamil AhmedNessuna valutazione finora

- 4528.07.R380.02 ShellDocumento26 pagine4528.07.R380.02 ShellAnil B YadavNessuna valutazione finora

- Kulkarni 2010Documento11 pagineKulkarni 2010Amirullah AbdiNessuna valutazione finora

- Liquefaction Process EvaluationDocumento15 pagineLiquefaction Process Evaluationapi-3715370100% (1)

- Section 03 - Basic Data PDFDocumento27 pagineSection 03 - Basic Data PDFChakerZagroubaNessuna valutazione finora

- IntroKGTowerV2 0 PDFDocumento14 pagineIntroKGTowerV2 0 PDFrasyid93Nessuna valutazione finora

- UniSim Design Tutorial 2Documento63 pagineUniSim Design Tutorial 2solo66Nessuna valutazione finora

- Dynamic Depressuring PDFDocumento16 pagineDynamic Depressuring PDFAsimNessuna valutazione finora

- Furnace Heater DesignDocumento7 pagineFurnace Heater DesignAaAaA_88Nessuna valutazione finora

- Pro II Tutorial - Rev 9Documento15 paginePro II Tutorial - Rev 9Manikandan SubramanianNessuna valutazione finora

- Fractionation and Absorption For The Process Man PDFDocumento70 pagineFractionation and Absorption For The Process Man PDFWilliam SandersNessuna valutazione finora

- AT 03609 WP Dehydration With Aspen HYSYS PDFDocumento25 pagineAT 03609 WP Dehydration With Aspen HYSYS PDFVictor Miguel Diaz JimenezNessuna valutazione finora

- LPG Energy IntegrationDocumento6 pagineLPG Energy IntegrationBandaru KiranNessuna valutazione finora

- 08 - Column Pressure ReliefDocumento10 pagine08 - Column Pressure ReliefjeedanNessuna valutazione finora

- HYSYS PROII Converter - V1.5 PDFDocumento28 pagineHYSYS PROII Converter - V1.5 PDFzubair1951Nessuna valutazione finora

- Auto Thermal Reactor:: Secondary ReformerDocumento6 pagineAuto Thermal Reactor:: Secondary ReformerAtif MehfoozNessuna valutazione finora

- 12-Modelling For Capture of Carbon Dioxide Using Aqueous Ammonia From Flue Gases of A Brick KilnDocumento8 pagine12-Modelling For Capture of Carbon Dioxide Using Aqueous Ammonia From Flue Gases of A Brick KilnWARP-World Academy of Research and PublicationNessuna valutazione finora

- Aspen Plus Model For Entrained Flow Coal Gasifier PDFDocumento35 pagineAspen Plus Model For Entrained Flow Coal Gasifier PDFSumit KaushikNessuna valutazione finora

- UOP Ortloff NGL LPG and Sulfur Recovery Technologies Tech PresentationDocumento30 pagineUOP Ortloff NGL LPG and Sulfur Recovery Technologies Tech PresentationAlfredo Ledezma100% (1)

- At-04304-Aspen ELearning Catalog 0918Documento57 pagineAt-04304-Aspen ELearning Catalog 0918jimmNessuna valutazione finora

- Pipephase 9.1: User's GuideDocumento104 paginePipephase 9.1: User's GuideGabi AraujoNessuna valutazione finora

- Nitrogeoin Rejection Technology For Abu DhabiDocumento10 pagineNitrogeoin Rejection Technology For Abu DhabiBeshuoNessuna valutazione finora

- Aspen Estimating Physical PropertiesDocumento12 pagineAspen Estimating Physical PropertiesStheh Ka NkosiNessuna valutazione finora

- Process Modeling Using HYSYS Getting StartedDocumento34 pagineProcess Modeling Using HYSYS Getting StartedNasroNessuna valutazione finora

- Process Modeling Using HYSYS Getting StartedDocumento34 pagineProcess Modeling Using HYSYS Getting StartedNasroNessuna valutazione finora

- Process Modeling Using HYSYS Propane Refrigeration LoopDocumento22 pagineProcess Modeling Using HYSYS Propane Refrigeration LoopsekharbhattaNessuna valutazione finora

- Electrical Design & Detailed Engineering 1Documento391 pagineElectrical Design & Detailed Engineering 1Nasro100% (2)

- Bem2011 ArabicDocumento2 pagineBem2011 ArabicNasroNessuna valutazione finora

- Bem2011 Civic CorrectionDocumento2 pagineBem2011 Civic CorrectionNasroNessuna valutazione finora

- Fonctions Logiques PDFDocumento2 pagineFonctions Logiques PDFNasroNessuna valutazione finora

- Post-Installed Rebars Design and Analysis: Singapore, 11.03.2016Documento44 paginePost-Installed Rebars Design and Analysis: Singapore, 11.03.2016SewGuanNessuna valutazione finora

- LEM 91-161 Fla E 0612Documento13 pagineLEM 91-161 Fla E 0612Julen IturriozNessuna valutazione finora

- Philippine Airlines Reservation New Timings Dep - 230314 - 193643Documento7 paginePhilippine Airlines Reservation New Timings Dep - 230314 - 193643sophia buiserNessuna valutazione finora

- Annals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskDocumento13 pagineAnnals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskIdmNessuna valutazione finora

- Factory Program Library List v1.0Documento9 pagineFactory Program Library List v1.0Ronaldo DamattaNessuna valutazione finora

- Type of TrucksDocumento8 pagineType of TrucksYojhan VelezNessuna valutazione finora

- Gas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusDocumento12 pagineGas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusCinthiaCevallosNessuna valutazione finora

- Unit II Construction PracticesDocumento61 pagineUnit II Construction PracticesiploguNessuna valutazione finora

- Therelek - Heat Treatment ServicesDocumento8 pagineTherelek - Heat Treatment ServicesTherelek EngineersNessuna valutazione finora

- Thermal Analysis of Polymers - 2008 - Menczel - FrontmatterDocumento8 pagineThermal Analysis of Polymers - 2008 - Menczel - FrontmatterBABLI GUPTANessuna valutazione finora

- HorticultureDocumento12 pagineHorticultureवरुण राठीNessuna valutazione finora

- Dense Ball PackingDocumento334 pagineDense Ball PackingLucas RibeiroNessuna valutazione finora

- Esthetics and Shade Communication: A Practical Approach: Clinical ApplicationDocumento21 pagineEsthetics and Shade Communication: A Practical Approach: Clinical Applicationcatalin_adinaNessuna valutazione finora

- WST Macros Add-In FeaturesDocumento1 paginaWST Macros Add-In FeaturesTrader CatNessuna valutazione finora

- Essentials of o Ste 00 DaveDocumento112 pagineEssentials of o Ste 00 DaveGeki Iovan100% (1)

- 9trffi&hpr.! Ni-: Use E EDocumento2 pagine9trffi&hpr.! Ni-: Use E ERafi ZulfiNessuna valutazione finora

- Smart City Scheme GuidelinesDocumento48 pagineSmart City Scheme GuidelinesKarishma Juttun100% (1)

- 6 Chapter 6 9781786393814Documento41 pagine6 Chapter 6 9781786393814yunicenjeNessuna valutazione finora

- N100 Rle Back MassageDocumento24 pagineN100 Rle Back MassagerlinaoNessuna valutazione finora

- Listening DictationDocumento3 pagineListening DictationThảo ĐinhNessuna valutazione finora

- Advanced Automatic ControlDocumento26 pagineAdvanced Automatic Controlabdullah 3mar abou reashaNessuna valutazione finora

- Methodology of Static Pile Load TestDocumento33 pagineMethodology of Static Pile Load Testraju_420034520100% (1)

- Compressed Air Pressure Drop DiagramDocumento4 pagineCompressed Air Pressure Drop DiagramycemalNessuna valutazione finora

- 3 RVDocumento8 pagine3 RVDivaruzNessuna valutazione finora

- Street Design Manual NYCDocumento312 pagineStreet Design Manual NYCgonleoNessuna valutazione finora

- Nursing Practice Skills: Adult Intensive Care Unit PatientsDocumento10 pagineNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- En 13757 3 2018 04Documento104 pagineEn 13757 3 2018 04Hélder Vieira100% (1)

- Dave Graham Literature CatalogDocumento640 pagineDave Graham Literature CatalogPierce PetersonNessuna valutazione finora

- At Your Service: Affordable LandscapingDocumento1 paginaAt Your Service: Affordable LandscapingDamaris HigginsNessuna valutazione finora

- Video Wall, Digital Signage & C'Type Serial NumberDocumento8 pagineVideo Wall, Digital Signage & C'Type Serial NumberAbhijit BarmanNessuna valutazione finora