Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Renyson Resume

Caricato da

Don0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

29 visualizzazioni4 paginecvb

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentocvb

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

29 visualizzazioni4 pagineRenyson Resume

Caricato da

Doncvb

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

#714 Southern Main Phone 1-868-374-6048

Road, e-mail:

Chinese Village, renysonharcharan@ya

La Brea, hoo.com

Trinidad W.I.

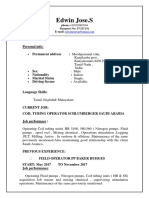

Renyson Vernlyn Harcharan

Date of birth 31st July 1978

Nationality Trinidadian

Key Skills and Acting Shift Supervisor (LNG)

Experience Coaching and mentoring technicians in safe and competent operational

practices.

Monitoring and optimizing the day to day operations and maintenance

activities of the facility.

Participates in PHAs, P&ID HAZOP reviews, operator training.

Leads commissioning, shutdowns/startups and plant turnarounds.

Education 2004 - 2008 University of The West Indies/University of

Trinidad and Tobago.

Course: Bachelor of Technology Degree in Mechanical

Engineering

1996 - 1999 San Fernando Technical Institute

Course: Mechanical Engineering Technician

Applied Mathematics

Theory Of Machines And Basic Machine Design

Plant Technology

Industrial Management

Strengths Of Materials And Mechanics Of Solids

Materials Technology

Professional 10/99 – 10/00 Air Caribbean Ltd. Piarco International Airport.

Experience Aircraft mechanic

Assembly and disassembly of YS –11A, Boeing 737 Nose wheels and

main wheels.

General preventative maintenance of above aircraft engines example; oil

change, visual inspection, changing of igniter plug, cleaning of burner cans,

oil check of CSD, oil check of engine, changing of filters,

Carry out wheel change, brake disc change, brake pox change on aircraft.

Lubrication of landing gears, flaps, slats.

Inspection of hydraulic components and systems.

Assist in general mechanical maintenance wherever necessary.

11/00 – 3/01 United Engineering Services Ltd. Point Lisas.

QA/QC (Electrical installation on a water plant)

Testing of electrical cables before installation.

Inspection of conduits, fittings and ensuring the electrical systems are put

in place as per drawing specifications.

Develop forms and record test results for client.

Preparation and presentation of quality control documents to clients on

completion of projects.

3/01 – 3/02 ONYX Resources Trinidad Ltd. Point Fortin.

Mechanical Technician (Offshore Oil Pumping Facility)

Perform preventative maintenance checks on running equipment such as

cranes, diesel engines, water pumps, crude oil pumps and process

equipments.

Changing oil on diesel engine driven generators and fire water pumps,

ensuring proper coolant level, inspect for leaks, loose mechanical or

electrical parts and excessive vibration.

Checking serviceability of pressure relief valves and other safety systems

on high pressure equipment.

Remove, replace and troubleshooting of process equipment.

3/02 – 2017 Atlantic LNG Co. Point Fortin

Operator Technician (2002 – 2008)

Senior Operator Technician (2008 – 2017)

Ensuring process parameters are maintained for safe, optimal plant

performance and equipment reliability.

Ensuring guidelines of the permit system and plant safety polices are

adhered to when maintenance activities are carried out on the facility.

Mentoring and training of junior operations personnel.

Certified in all aspects of LNG production and cargo shipping:

1. Utilities; Power generation, demineralized water production, firewater

system, instrument air/nitrogen generation system and waste water/oil

package.

2. Inlet gas treatment; Acid gas removal, feed gas dehydration, mercury

removal and natural gas liquids processing.

3. Gas liquefaction; Propane and ethylene refrigeration.

4. Compressor Controls; Turbine and process compressor control and

monitoring.

5. Shipping; LNG cargo shipping operations.

6. DCS Panel; Panel operations.

Acting Shift Supervisor (Intermittently since 2008)

Coaching and mentoring technicians in safe and competent operational

practices.

Coordinating operator assignment roles within the team.

Management of staffing requirements for the team where team members

require leave.

Coordinating with various operation support services such as engineering,

maintenance and planning groups for successful plant turnarounds and

daily maintenance activities.

Develop operational procedures for safe isolation of equipment for

maintenance activities.

Approves low level risk assessments and aid in the development of high

level assessments for maintenance duties.

Participates in PHAs, P&ID HAZOP reviews, operator training,

commissioning and startup preparation.

Trained in major emergency management.

Trained in supervisory skills development.

Interests and Building Construction / Welding and Fabrication.

activities

Potrebbero piacerti anche

- DCS/CCR Operator: Sri Ramraj.GDocumento4 pagineDCS/CCR Operator: Sri Ramraj.GDonNessuna valutazione finora

- Control Room Operator: J.Bala DineshDocumento5 pagineControl Room Operator: J.Bala DineshDonNessuna valutazione finora

- Magesh.M OPTDocumento3 pagineMagesh.M OPTDonNessuna valutazione finora

- Mechanical Technician - Bala DineshDocumento4 pagineMechanical Technician - Bala DineshDonNessuna valutazione finora

- Dine EshDocumento11 pagineDine EshDonNessuna valutazione finora

- C.Babu: Production OperatorDocumento4 pagineC.Babu: Production OperatorDonNessuna valutazione finora

- District Wise College Detrails With Phone NumberDocumento15 pagineDistrict Wise College Detrails With Phone NumberDonNessuna valutazione finora

- M.S.Kirubhananth: Senior Instrument TechnicianDocumento4 pagineM.S.Kirubhananth: Senior Instrument TechnicianDonNessuna valutazione finora

- Antony Vikas: Phone: + 965 69968427, + 91 9994863918Documento3 pagineAntony Vikas: Phone: + 965 69968427, + 91 9994863918DonNessuna valutazione finora

- Curriculum Vitae: Sivanath. N Email: Mob: +91 9500931501 ,+91 9003667677Documento5 pagineCurriculum Vitae: Sivanath. N Email: Mob: +91 9500931501 ,+91 9003667677DonNessuna valutazione finora

- Antony Vikas: Phone: + 965 69968427, + 91 9994863918Documento3 pagineAntony Vikas: Phone: + 965 69968427, + 91 9994863918DonNessuna valutazione finora

- Vibin Raja CVDocumento5 pagineVibin Raja CVDonNessuna valutazione finora

- Curriculam VitaeDocumento3 pagineCurriculam VitaeDonNessuna valutazione finora

- Babu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDocumento9 pagineBabu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDonNessuna valutazione finora

- Swaminathan CVDocumento6 pagineSwaminathan CVDonNessuna valutazione finora

- SVZDFHDocumento3 pagineSVZDFHDonNessuna valutazione finora

- APPLYING FOR Coil Tubing Operator: Antony Arul RogerDocumento4 pagineAPPLYING FOR Coil Tubing Operator: Antony Arul RogerDonNessuna valutazione finora

- APPLYING FOR Coil Tubing Operator: Antony Arul RogerDocumento4 pagineAPPLYING FOR Coil Tubing Operator: Antony Arul RogerDonNessuna valutazione finora

- 3 Phase Separator BrochureDocumento6 pagine3 Phase Separator BrochureRandy SooknananNessuna valutazione finora

- Antony Vikas: Phone: + 965 69968427, + 91 9994863918Documento3 pagineAntony Vikas: Phone: + 965 69968427, + 91 9994863918DonNessuna valutazione finora

- Arul Alex CVDocumento3 pagineArul Alex CVDonNessuna valutazione finora

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocumento27 pagineNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- Babu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDocumento9 pagineBabu.P.V: Coiled Tubing Service Supervisor - Pumping SupervisorDonNessuna valutazione finora

- Turbine Operational ProblemsDocumento35 pagineTurbine Operational Problemsna2011100% (1)

- SWT Book03B2 PDFDocumento117 pagineSWT Book03B2 PDFbuat unduhNessuna valutazione finora

- Gheewala SAUDI Recrutment Interview 3rd Week 2018 at ChennaiDocumento7 pagineGheewala SAUDI Recrutment Interview 3rd Week 2018 at ChennaiImthiyas MohamedNessuna valutazione finora

- WT Training ManualDocumento429 pagineWT Training Manualbilmard100% (4)

- Choke Manifold PDFDocumento2 pagineChoke Manifold PDFluciano_ferreira_80Nessuna valutazione finora

- IHS Fekete Software Installation GuideDocumento26 pagineIHS Fekete Software Installation GuideDonNessuna valutazione finora

- Derrick Anthony Das: Career ObjectivesDocumento1 paginaDerrick Anthony Das: Career ObjectivesDonNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pgurl 2679036134142300Documento4 paginePgurl 2679036134142300Barbara VasquezNessuna valutazione finora

- Sikaceram - 288 MyDocumento4 pagineSikaceram - 288 MyKenji TanNessuna valutazione finora

- Nov1994 Paper3 ChemistryDocumento11 pagineNov1994 Paper3 ChemistrydhsNessuna valutazione finora

- Historical Steelwork HandbookDocumento80 pagineHistorical Steelwork HandbookÉmilie Riverin100% (1)

- Gamma Monitoring Systems EngDocumento73 pagineGamma Monitoring Systems Engnmtan17Nessuna valutazione finora

- Solution To Problem 503 - Flexure FormulaDocumento23 pagineSolution To Problem 503 - Flexure FormulaLara GatbontonNessuna valutazione finora

- Geo PolymerizationDocumento19 pagineGeo PolymerizationAhmed EssamNessuna valutazione finora

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocumento187 pagineThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic Schematicsaa100% (1)

- Constitutive Equation For AISI4140 Steel Applicable To A Wide Range of Strain Rates at Elevated TemperaturesDocumento6 pagineConstitutive Equation For AISI4140 Steel Applicable To A Wide Range of Strain Rates at Elevated TemperaturesWinston SequeiraNessuna valutazione finora

- Engine Lubrication SystemsDocumento8 pagineEngine Lubrication SystemsMentsnot GetuNessuna valutazione finora

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Documento22 pagineGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- News From Vietnam Chemical DatabaseDocumento3 pagineNews From Vietnam Chemical DatabasequýNessuna valutazione finora

- Homework-5 2Documento3 pagineHomework-5 2Dorothy CastilloNessuna valutazione finora

- Viva QuestionDocumento4 pagineViva QuestionBarathkannan Lakshmi PalanichamyNessuna valutazione finora

- Muscles Revision QuestionsDocumento20 pagineMuscles Revision QuestionsalexdarcyNessuna valutazione finora

- Science Water Cycle HydrosphereDocumento3 pagineScience Water Cycle Hydrosphereapi-254658342Nessuna valutazione finora

- 12 0436 Quick Connected Steel Pipe System ALL121101 enDocumento52 pagine12 0436 Quick Connected Steel Pipe System ALL121101 enSorin Tzuri Clim100% (1)

- The State of MixingDocumento6 pagineThe State of MixingNico RobinNessuna valutazione finora

- Chemistry C8A Aanotes SDocumento26 pagineChemistry C8A Aanotes SQuan YingNessuna valutazione finora

- N-Containing Secondary CompoundsDocumento16 pagineN-Containing Secondary CompoundsNasiha el KarimaNessuna valutazione finora

- Glinka Problems in General Chemistry MirDocumento290 pagineGlinka Problems in General Chemistry MirMaurizio D'IppolitoNessuna valutazione finora

- Fat ManDocumento18 pagineFat ManYasir Khan0% (1)

- TikZ Package - Overleaf, Editor de LaTeX OnlineDocumento13 pagineTikZ Package - Overleaf, Editor de LaTeX OnlinechkornarosNessuna valutazione finora

- Biotech Fourth QuarterDocumento4 pagineBiotech Fourth QuarterRodge BuereNessuna valutazione finora

- FLS Coal FeederDocumento17 pagineFLS Coal Feedertrung2iNessuna valutazione finora

- Gates Uk PDFDocumento293 pagineGates Uk PDFZMCONTROLNessuna valutazione finora

- Astm F 1140-07Documento5 pagineAstm F 1140-07jsiddh30100% (2)

- Ni CDDocumento13 pagineNi CDMohamed MeeranNessuna valutazione finora

- Voluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Documento17 pagineVoluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Mauricio Riquelme100% (2)