Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kiln Scan

Caricato da

NabilBouabanaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Kiln Scan

Caricato da

NabilBouabanaCopyright:

Formati disponibili

> Maintenance of Rotary Kilns

KILNSCAN

Kilnscan

KILN SHELL TEMPERATURE MONITORING

THERMAL SCANNING TO EXTEND KILN LIFETIME

Kilnscan infrared scanner monitors rotary kiln shell temperature,

continuously, in real-time, with a high thermal sensitivity and

definition. By providing early warning of failures, Kilnscan

improves kiln efficiency and its long-term reliability. It contributes

to increasing production rates, reducing operating costs, improving

the burning process, and saving energy.

HIGH-RESOLUTION DIAGNOSTIC SYSTEM

With the highest spatial and thermal resolution, Kilnscan keeps > Kilnscan scanner head

permanent surveillance on each individual refractory. It tracks hot

spots, tyre slippage, rings formation, brick losses, thermal warp, to

prevent irreversible damage. With more than 1000 units in operation

around the world, HGH thermal scanners are used in most cement

plants to warn of potential failures and trigger preventive actions.

FEATURES

• High spatial resolution to detect single brick failure

• High thermal sensitivity to warn of any suspect temperature

change

• Automatic calibration with internal blackbody: no drift over time

• Unique scan angle, up to 140°, to scan long shell

• Unique external reference blackbody for unsurpassed accuracy in

adverse weather conditions

• Fibre optic link to the control room to avoid electromagnetic

interferences

• Rugged system, designed for demanding environments > Kilnscan in operation

BENEFITS

• Continuous full temperature map, with a true one-brick

resolution

• Hot spots early warning, before damage

• Monitoring and extension of refractory lifetime

• Reliable preventive maintenance scheduling

• Solution adapted to any requirement

(multiple shadows – long kiln – free space limited)

• Scanner data directly linked to Plant

Control System

> Preserving kiln shell lifetime

WWW.HGH.FR

Kilnscan

KILN SHELL TEMPERATURE MONITORING

KILNSCAN

ref: KS-Len-ac1

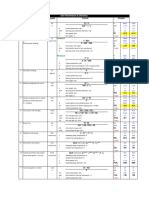

> Kiln monitoring with Kilnscan software > Scanner installation

KILNSCAN SOFTWARE

On control room screens and maintenance team workstations, Kilnscan software takes

advantage of Kilnscan very accurate measurements, to display at a glance all necessary

information to preserve kiln shell integrity. In addition, thanks to valuable unique features,

Kilnscan software enables analysis on long-term basis and reliable trend drawing.

• Real-time 3D thermal profile

• Brick and coating thickness

• Advanced refractory management

• Kiln rotating speed

• Tyre slip monitoring

• Heat loss calculation

• Unique thermal warp monitoring, a must for predictive maintenance

• OPC server & client configurations

• Multiple alarms management, with cooling fans control

• Automatic data recording

• Historical data management, to monitor events evolution

EXPERT SERVICES – TRAINING & COMMISSIONING

Our team of highly qualified engineers has been internationally recognized for

years as experts in infrared technologies. We are proud to deliver cutting-edge

products, high-end solutions to extend kiln lifetime. Our commitment is to ensure

that you can maximize the profit from your equipment, as fast as possible, and

for years.

> HGH service - Training&commissioning

conception: www.agencegalilee.com

Above information is subject to changes without notice

HGH SYSTEMES INFRAROUGES

10 rue Maryse Bastié

91430 IGNY - FRANCE

TEL: +33 1 69 35 47 70 - FAX: +33 1 69 35 47 80

E-MAIL: HGH@HGH.FR

WWW.HGH.FR

Potrebbero piacerti anche

- GS-TS02 Tyre Slip Monitoring System-Operation ManualDocumento8 pagineGS-TS02 Tyre Slip Monitoring System-Operation Manualvsrikala68Nessuna valutazione finora

- Cement Plant VIPDocumento51 pagineCement Plant VIPengr kazamNessuna valutazione finora

- Colour Codes, Notes & FAQ: WBCSD Cement Sustainability Initiative CO2 Emissions Inventory Protocol, Version 2.0Documento33 pagineColour Codes, Notes & FAQ: WBCSD Cement Sustainability Initiative CO2 Emissions Inventory Protocol, Version 2.0Rodrigo DíazNessuna valutazione finora

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Documento5 pagineVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuNessuna valutazione finora

- 1.4878 Eng PDFDocumento3 pagine1.4878 Eng PDFRoberto_PrrNessuna valutazione finora

- Chemical Composition of Portland Cement 9Documento2 pagineChemical Composition of Portland Cement 9Jorge CabreraNessuna valutazione finora

- 09.work Instruction For Operation of Additive Ball MillDocumento9 pagine09.work Instruction For Operation of Additive Ball MillRahul VermaNessuna valutazione finora

- Thermos Design of Rotary Kiln For Reduction of Radiation Losses-10Documento17 pagineThermos Design of Rotary Kiln For Reduction of Radiation Losses-10Madhav Krishna MNessuna valutazione finora

- Ball Mill GrindingDocumento6 pagineBall Mill GrindingShyanu Udeshika WijerathnaNessuna valutazione finora

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocumento51 pagineEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhNessuna valutazione finora

- Assignment On Fundamental Analysis Acc CompanyDocumento5 pagineAssignment On Fundamental Analysis Acc CompanyDevika SuvarnaNessuna valutazione finora

- AETHER Cement - ECRA Barcelona PresentationDocumento23 pagineAETHER Cement - ECRA Barcelona PresentationGilsayan100% (1)

- Kiln Paper1Documento5 pagineKiln Paper1mmkattaNessuna valutazione finora

- Heat Balance Cement IndustryDocumento1 paginaHeat Balance Cement IndustryMin ZayarNessuna valutazione finora

- Paper Darab Cement Kiln SealDocumento11 paginePaper Darab Cement Kiln Sealomid1302Nessuna valutazione finora

- Comparison of Different Methods For Enhancing Reactivity of Pozzolans PDFDocumento6 pagineComparison of Different Methods For Enhancing Reactivity of Pozzolans PDFArtemia Loayza ArguellesNessuna valutazione finora

- Finance Project On ACC CEMENTDocumento87 pagineFinance Project On ACC CEMENTShilpan Shah80% (5)

- (Grate Cooler Assessment) June 2012Documento13 pagine(Grate Cooler Assessment) June 2012Phillip007Nessuna valutazione finora

- Kiln Eval Line IDocumento1 paginaKiln Eval Line IRaji SuriNessuna valutazione finora

- Bypass SystemDocumento9 pagineBypass SystemirfanNessuna valutazione finora

- Ercom Brief ProfileDocumento57 pagineErcom Brief ProfileKarthik DhayalanNessuna valutazione finora

- BypassDocumento4 pagineBypassm4a1_2Nessuna valutazione finora

- Flat Slide Valve: Machine Manual En-23261.001-EDocumento32 pagineFlat Slide Valve: Machine Manual En-23261.001-ERahmat YusufNessuna valutazione finora

- Waste CFB CombustionDocumento15 pagineWaste CFB CombustionmihugirNessuna valutazione finora

- Mechanical OperationDocumento116 pagineMechanical OperationNomee PatelNessuna valutazione finora

- Turbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnerDocumento4 pagineTurbu-Flex Burner: A World First. Effortlessly Adapt To Different Fuels With One BurnermsvprasadNessuna valutazione finora

- Clinker GrindingDocumento7 pagineClinker Grindingdoxa mariaNessuna valutazione finora

- 08 A Critical Review of Grinding Design Procedures For The 21st CenturyDocumento3 pagine08 A Critical Review of Grinding Design Procedures For The 21st CenturyAbhay BodhmageNessuna valutazione finora

- Grindability of Commercial Clinkers With High MgO LevelDocumento7 pagineGrindability of Commercial Clinkers With High MgO LevelAnonymous NxpnI6jCNessuna valutazione finora

- Executive Summary: Delhi Pollution Control CommitteeDocumento26 pagineExecutive Summary: Delhi Pollution Control CommitteeparthNessuna valutazione finora

- VB 29 - 10Documento5 pagineVB 29 - 10Kenny RuizNessuna valutazione finora

- Ball Mill Volume LoadingDocumento2 pagineBall Mill Volume LoadingThaigroup CementNessuna valutazione finora

- Flames and Fuel Preparation: What You Need To KNOW!Documento27 pagineFlames and Fuel Preparation: What You Need To KNOW!Suhail ahmadNessuna valutazione finora

- Cement Kiln Co-ProcessingDocumento11 pagineCement Kiln Co-ProcessingflukemonsterNessuna valutazione finora

- Review No.145: Keystone S Cross-OverDocumento7 pagineReview No.145: Keystone S Cross-Overbasavaraju535Nessuna valutazione finora

- Cement Manufacturing at A GlanceDocumento2 pagineCement Manufacturing at A GlancelokeshkrjainNessuna valutazione finora

- Energy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Documento28 pagineEnergy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Sarah FrazierNessuna valutazione finora

- Lafarge Ravena Modernization FEISDocumento97 pagineLafarge Ravena Modernization FEISLafargeRavenaFactsNessuna valutazione finora

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDocumento12 pagineStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationNessuna valutazione finora

- AG and SAG Mill Circuit Selection and Design by SimulationDocumento22 pagineAG and SAG Mill Circuit Selection and Design by Simulationbob2341Nessuna valutazione finora

- Department of Chemical EngineeringDocumento19 pagineDepartment of Chemical EngineeringPandia RajanNessuna valutazione finora

- S.No. Particulars Units FLS: Performance Guarantees Pyro-Processing PlantDocumento2 pagineS.No. Particulars Units FLS: Performance Guarantees Pyro-Processing Plantrashmiranjan1110Nessuna valutazione finora

- Outlet Apparatus: Machine Manual En-23122.102-ADocumento16 pagineOutlet Apparatus: Machine Manual En-23122.102-ARahmat YusufNessuna valutazione finora

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Documento1 paginaAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNessuna valutazione finora

- Pozzolana ReportDocumento1 paginaPozzolana ReportGeorge OparNessuna valutazione finora

- Graphic Symbol 39701-01-2.2: Instruction ManualDocumento17 pagineGraphic Symbol 39701-01-2.2: Instruction ManualmkpqNessuna valutazione finora

- SikaGrind For Vertical Roller Mills PDFDocumento8 pagineSikaGrind For Vertical Roller Mills PDFEduardo RojasNessuna valutazione finora

- Better Burner Specifications PDFDocumento4 pagineBetter Burner Specifications PDFAbdul HayyeNessuna valutazione finora

- Chapter 1 Final A5 Edit PDFDocumento10 pagineChapter 1 Final A5 Edit PDFkINGNessuna valutazione finora

- Fan Build Up ControlDocumento2 pagineFan Build Up ControlSafrin SangiaNessuna valutazione finora

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocumento2 pagineBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNessuna valutazione finora

- Comparative Studies of Quality and Standards of Cement ManuifacturedDocumento103 pagineComparative Studies of Quality and Standards of Cement ManuifacturedAbdulkadir AdamNessuna valutazione finora

- Assiut Cement PlantDocumento17 pagineAssiut Cement PlantMahmoud RashadNessuna valutazione finora

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignDocumento13 paginePaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980Nessuna valutazione finora

- Engineering: General CatalogDocumento37 pagineEngineering: General CatalogzsmithNessuna valutazione finora

- Kiln Tyre WobblingDocumento3 pagineKiln Tyre WobblingPrashant Kumar mishraNessuna valutazione finora

- Ball Mill Inspection - Chap 1Documento6 pagineBall Mill Inspection - Chap 1Min MCLNessuna valutazione finora

- ABC Cooler InletDocumento4 pagineABC Cooler InletNaelNessuna valutazione finora

- Kilnscan: Kiln Shell Temperature MonitoringDocumento2 pagineKilnscan: Kiln Shell Temperature MonitoringAhmad NilNessuna valutazione finora

- Kilnscan Brochure HGHDocumento2 pagineKilnscan Brochure HGHVikas JainNessuna valutazione finora

- S7 Bit LogicDocumento15 pagineS7 Bit LogicNabilBouabanaNessuna valutazione finora

- Compressed Air System: by Raj PrabhakarDocumento21 pagineCompressed Air System: by Raj PrabhakarNabilBouabanaNessuna valutazione finora

- S7 Counter InstructionsDocumento12 pagineS7 Counter InstructionsNabilBouabanaNessuna valutazione finora

- S7 Jump InstructionsDocumento10 pagineS7 Jump InstructionsNabilBouabanaNessuna valutazione finora

- S7 Timer InstructionsDocumento16 pagineS7 Timer InstructionsNabilBouabanaNessuna valutazione finora

- S7 PLC Data & MemoryDocumento19 pagineS7 PLC Data & MemoryNabilBouabanaNessuna valutazione finora

- Spare Parts For Erection, Precommissioning, Commissioning and Start-UpDocumento6 pagineSpare Parts For Erection, Precommissioning, Commissioning and Start-UpNabilBouabana100% (4)

- S7 DefinitionDocumento5 pagineS7 DefinitionNabilBouabanaNessuna valutazione finora

- Elec Cold Test - Smdb-Roof AtkinsDocumento2 pagineElec Cold Test - Smdb-Roof AtkinsNabilBouabanaNessuna valutazione finora

- 01234567Documento4 pagine01234567NabilBouabanaNessuna valutazione finora

- Test Run No. Date: Total Yield: Price/ Kg. - Total Cost: - Activities Monitoring Tools Standards Observations Corrective ActionsDocumento2 pagineTest Run No. Date: Total Yield: Price/ Kg. - Total Cost: - Activities Monitoring Tools Standards Observations Corrective ActionsNabilBouabanaNessuna valutazione finora

- Guidelines For Bar Code Symbol PlacementDocumento96 pagineGuidelines For Bar Code Symbol PlacementNabilBouabanaNessuna valutazione finora

- Testing and CommitioningDocumento11 pagineTesting and CommitioningNabilBouabanaNessuna valutazione finora

- Commissioning GuideDocumento78 pagineCommissioning GuideNabilBouabanaNessuna valutazione finora

- 3 Using Deep Learning To DetectDocumento6 pagine3 Using Deep Learning To DetectNabilBouabanaNessuna valutazione finora

- Tees Valley 2 Commissioning Plan Rev0Documento22 pagineTees Valley 2 Commissioning Plan Rev0NabilBouabanaNessuna valutazione finora

- Cover Sheet: - To Record Overall Project and Assessment DetailsDocumento62 pagineCover Sheet: - To Record Overall Project and Assessment DetailsNabilBouabanaNessuna valutazione finora

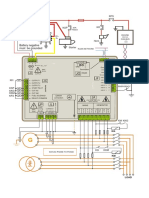

- Diesel Generator Control Panel Wiring Diagrampdf - CompressDocumento1 paginaDiesel Generator Control Panel Wiring Diagrampdf - CompressNabilBouabana100% (1)

- RVM X3: (Pet, Can & Glass)Documento2 pagineRVM X3: (Pet, Can & Glass)NabilBouabanaNessuna valutazione finora

- Diesel Generator Control Panel Wiring Diagram BeK3Documento1 paginaDiesel Generator Control Panel Wiring Diagram BeK3NabilBouabana100% (3)

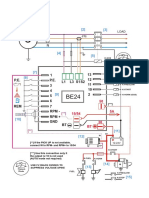

- Control Panel Circuit Diagram PDFDocumento3 pagineControl Panel Circuit Diagram PDFNabilBouabana75% (4)

- Diesel Generator Control Panel Wiring Diagram Be24Documento1 paginaDiesel Generator Control Panel Wiring Diagram Be24NabilBouabana100% (3)

- Making Things Right ... The First Time: Process Instrumentation Start Up and Commissioning ServicesDocumento2 pagineMaking Things Right ... The First Time: Process Instrumentation Start Up and Commissioning ServicesNabilBouabanaNessuna valutazione finora

- ACS880 Benefits - RevbDocumento14 pagineACS880 Benefits - RevbNabilBouabanaNessuna valutazione finora

- HP Compaq nx6110Documento2 pagineHP Compaq nx6110NabilBouabanaNessuna valutazione finora

- Tiles ProcessDocumento7 pagineTiles Processinkera - HRNessuna valutazione finora

- PREVIEW The Architecture of Ramses WissDocumento13 paginePREVIEW The Architecture of Ramses WissaldesNessuna valutazione finora

- Cadbg 09 Freemium 1Documento34 pagineCadbg 09 Freemium 1Stefan Van Cleemput100% (2)

- BricksDocumento34 pagineBricksShubhi Sonal100% (1)

- 6 BricksDocumento59 pagine6 BricksMian Afzaal 72Nessuna valutazione finora

- The+Potter IndustryDocumento7 pagineThe+Potter Industryaishwarya.koli25Nessuna valutazione finora

- Supply Chain Management Professional (SCMP) National Exam Supply Chain Canada - 2021Documento18 pagineSupply Chain Management Professional (SCMP) National Exam Supply Chain Canada - 2021Purnima VermaNessuna valutazione finora

- Manufacturing of Burnt Clay BricksDocumento16 pagineManufacturing of Burnt Clay BricksRohit BhamareNessuna valutazione finora

- CWHR Presentation of BricksDocumento75 pagineCWHR Presentation of BricksFayyaz Ahmad KhanNessuna valutazione finora

- Chapter 1: Introduction: 1.1 Background of Tile IndustryDocumento12 pagineChapter 1: Introduction: 1.1 Background of Tile Industrysohraf100% (1)

- Volume 3 Burning WorkshopDocumento59 pagineVolume 3 Burning WorkshopmkpqNessuna valutazione finora

- Intensiv Filter 15th Arab 08Documento25 pagineIntensiv Filter 15th Arab 08Zahir KhiraNessuna valutazione finora

- A. Introduction: 3. Poor LimeDocumento28 pagineA. Introduction: 3. Poor LimeYenNessuna valutazione finora

- MALAYSIA Small-Scale Brick ManufacturingDocumento22 pagineMALAYSIA Small-Scale Brick ManufacturingMohammad Joseph ZuhriNessuna valutazione finora

- VSBK Presentation SameerDocumento20 pagineVSBK Presentation SameerIwan TirtaNessuna valutazione finora

- Field Visit ReportDocumento10 pagineField Visit ReportNiroj Mote100% (2)

- Paper ClayDocumento51 paginePaper ClayThao Ngoc Do100% (2)

- BS 1041 - 7-Temperature MeasureDocumento19 pagineBS 1041 - 7-Temperature MeasuregadNessuna valutazione finora

- Internship Report On Simpolo CeramicsDocumento46 pagineInternship Report On Simpolo CeramicsChintan RamnaniNessuna valutazione finora

- Mathematical Model To Analyze The Heat Transfer in Tunnel Kilns For Burning of CeramicsDocumento137 pagineMathematical Model To Analyze The Heat Transfer in Tunnel Kilns For Burning of CeramicsJudy Ann BoseNessuna valutazione finora

- Rural Technology S.khuntiaDocumento12 pagineRural Technology S.khuntiaSURENDRA KHUNTIANessuna valutazione finora

- Selected Bibliography On Brickmaking in Developing CountriesDocumento4 pagineSelected Bibliography On Brickmaking in Developing CountriesRobert PetrutNessuna valutazione finora

- Clay PowerpointDocumento21 pagineClay PowerpointGopal N. Suthar100% (1)

- Electric KilnsDocumento13 pagineElectric KilnsLisa LuethyNessuna valutazione finora

- Truyền Nhiệt Trong Lò NungDocumento8 pagineTruyền Nhiệt Trong Lò Nungmap vitcoNessuna valutazione finora

- Casting Slip ControlDocumento20 pagineCasting Slip ControlGayathri Surya100% (2)

- 01-ASTM C113 (2002) Test Method PDFDocumento3 pagine01-ASTM C113 (2002) Test Method PDFSreekumar K SNessuna valutazione finora

- Firing Deformation in Large Size Porcelain Tiles. Effect of Compositional and Process VariablesDocumento15 pagineFiring Deformation in Large Size Porcelain Tiles. Effect of Compositional and Process Variablesmap vitcoNessuna valutazione finora

- DHBB Chy (ĐĐX) 2019 L10Documento25 pagineDHBB Chy (ĐĐX) 2019 L10Tuyền Nguyễn Thị ÚtNessuna valutazione finora

- Article FS999 Instructions 8 23 2017Documento2 pagineArticle FS999 Instructions 8 23 2017ChomikNessuna valutazione finora