Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Article JBF Top Down Lapide

Caricato da

MaFe Cifuentes PuertoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Article JBF Top Down Lapide

Caricato da

MaFe Cifuentes PuertoCopyright:

Formati disponibili

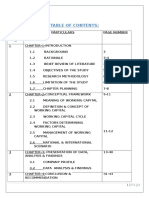

TOP-DOWN & BOTTOM-UP

FORECASTING IN S&OP

By Larry Lapide

(This is an ongoing column in quantitatively based statistical forecast rapidly changing business environment.

The Journal, which is intended methods are becoming less effective in More market intelligence now needs to be

capturing all that is happening in today’s incorporated during the development of

to give a brief view on a potential forecasts.

topic of interest to practitioners of

business forecasting. Suggestions This means that effective collaborative

on topics that you would like to see environments are necessary to solicit input

covered should be sent via email to from a wider group of people within a

company who have some understanding of

llapide@mit.edu). where a business might be going. This has

T

his May I was invited by my led to greater adoption and interest in the

colleagues at the University of use of S&OP (a process that I have recently

Tennessee to give a presentation on found myself discussing and writing more

the importance of Top-Down & Bottom- about). This is a cross-functional process

Up forecasting in the Sales and Operations that brings together teams of individuals on

Planning (S&OP) process. The last time a routine basis to plan for where businesses

I had covered this type of forecasting in are going on a tactical basis. Each team

one of my columns was eight years ago member brings to the process a specific

in the Summer 1998 issue of The Journal perspective during the development of

of Business Forecasting (JBF). Its title supply and demand plans/forecasts.

was “A Simple View of Top-Down Versus

Bottom-Up Forecasting.” When I wrote In this regard, each S&OP team member

that piece, I felt I had given the topic the may have to generate, review, and revise

LARRY LAPIDE demand forecasts that reflect the aspects of a

coverage it needed for a very long time.

However, having to prepare for this year’s business with which they are most familiar.

Dr. Lapide is a Research Director at This requires leveraging Top-Down &

presentation opened my eyes to the fact that, MIT’s Center for Transportation &

since I wrote that article eight years ago, Bottom-Up forecasting in the process more

Logistics where he manages its Supply than that required eight years ago. The

much has changed. The topic of Top-Down Chain 2020 Project focused on supply

& Bottom-Up forecasting has become even remainder of this article discusses Top-

chain management of the future and Down & Bottom-Up forecasting in terms

more important. its demand management research of what it is, how it supports accountability

initiatives. He has extensive business and commitment in the S&OP process,

The expanding globalization of business, experience in industry, consulting,

the continuing move from push to pull and the use of forecasting hierarchies as

and research, and has a broad range enablers.

manufacturing, and the rise in consumer- of forecasting experiences. He was a

oriented economies, have led to a much more forecaster in industry for many years,

complex forecasting and planning world. has led forecasting-related consulting

Forecasters and planners are being asked projects for clients across a variety of

WHAT IS TOP-DOWN &

to create plans for expanding geographies, industries, and has taught forecasting in BOTTOM-UP FORECASTING?

increased numbers of sales channels, a college setting. In addition, for seven

and broader, more diverse, and shorter years he was a leading market analyst Top-down forecasting is extremely

life cycle product lines. This complexity in the research of forecasting and supply useful for improving the accuracy of

means that markets are more dynamic and chain software. detailed forecasts. As depicted in Figure

THE JOURNAL OF BUSINESS FORECASTING, SUMMER 2006 1

1, aggregated demand is less volatile than

its individual components, so on a relative FIGURE 1

basis a forecast of the aggregate is more

AGGREGATED DEMAND IS RELATIVELY LESS

accurate than the forecasts of its individual

components. This is due to the phenomenon VOLATILE THAN ITS INDIVIDUAL

of compensating errors where random errors COMPONENTS

and variations tend to cancel each other out.

This is the principle behind the concept of

Top-Down forecasting where, rather than Aggregate Group

Demand

forecasting each component separately, it is

better to first forecast the aggregated group

Time

and then disaggregate the resulting forecast

to derive the forecasts of the individual

components. The good news is that this

principle can be leveraged for any type of

Entity 1 Entity 2 Entity 3

aggregation, such as aggregations across

products, sales channels (e.g., stores),

Demand

Demand

Demand

geographies, and even time itself.

However, as discussed in my Summer Time Time Time

1998 JBF column, one of the things to be

careful about is that Top-Down forecasting

only makes sense when a top-level

sales to remain flat, while the Top-Down of the accuracy that can be achieved from

aggregated group is made up of components

forecast predicts it to grow by 10%, then using both types in conjunction with each

that have similar patterns of variation.

the correction factor to apply to the bottom- other. For example, brand-level forecasts

That is because component forecasts are

level forecasts would be 1.1). Thus, Top- may be most accurately generated at the

frequently derived by breaking down the

Down in conjunction with Bottom-Up, and brand level, and SKU-level forecasts might

top-level forecast using the proportions

even Middle-Out is recommended. best be derived from disaggregating the

that the individual components represent of

brand-level forecasts using Top-Down

the total. When this is done, the pattern of

forecasting. In turn, product group forecasts

variation of the aggregated group would be

assumed for the individual components—

THEIR USE IN THE S&OP might best be derived by aggregating the

brand-level forecasts using Bottom-Up

and this may not always hold. PROCESS forecasting.

The use of Bottom-Up forecasting is There are two ways in which Top-

better for situations where the individual Down & Bottom-Up forecasting is useful The S&OP process also involves refining

components have different patterns of during S&OP, a process that is predicated the supply and demand plans, as well as the

variation. Under the concept of Bottom-Up on developing consensus-based demand baseline-demand forecast. The resulting

forecasting, one forecasts the individual and supply plans. Cross-function teams consensus-based supply and demand plans

components separately and then adds the comprised of members from the supply developed during the process require

forecasts up to get the forecast for the chain, operations, marketing, sales, and accountability and commitment from each

aggregated group. finance organizations meet to discuss of the stakeholder organizations involved

their plans for generating and satisfying to ensure each will execute as close as

Generally, Top-Down or Bottom-Up used customer demand. The process is driven possible to what is embodied in the plans. In

on an exclusive basis is not the best way by a baseline demand forecast that reflects order to get this type of buy-in and increase

to forecast. Often the aggregate group’s the demand expected from the marketing forecast accuracy, each organization needs

Bottom-Up forecast can be improved by and sales plans, which in turn drives the to participate in the development of the

replacing it with a Top-Down forecast. The supply plans reflecting the future activities forecasts in terms of reviewing and revising

individual Bottom-Up component forecasts of the operations, manufacturing, logistics, them as necessary.

can be then improved by adjusting each using and procurement organizations. Thus, the

correction factors derived from looking at first (obvious) way in which Top-Down & This is best accomplished by translating

the aggregated group’s Bottom-Up versus Bottom-Up forecasting is useful in the S&OP and representing the demand forecasts in

its Top-Down forecast. (For example, if process is during the development of the a form in which each organization is used

the Bottom-Up forecast predicts aggregate baseline forecast, in order to take advantage to dealing with. If marketing’s approach to

2 THE JOURNAL OF BUSINESS FORECASTING, SUMMER 2006

planning, for example, focuses on revenues

generated by product groups and brands FIGURE 2

rather than by unit-based Stock-Keeping- A FORECAST HIERARCHY CREATES SPECIAL

Units (SKUs), then any unit-based SKU VIEWS FOR EACH S&OP PARTICIPANT

demand forecasts needs to be aggregated to

these product levels on a dollar basis before Financial Views

Marketing could effectively review and Demand-side Views Supply-side Views

revise the forecasts. Meanwhile, if Sales Com

pan

m

Co ny

Com

pan

m

Co ny

Com

pan

Ye

ar

pa pa y

is most familiar with dealing with sales (in

y y

R eg t Wa Div rs

ions duc

Pro gories

reho n ts is

BUs ions/ arte

uses Pla Qu

dollars) by customer accounts and/or sales Acc

Cate

ds

Ship

Loc -to duc

tion Ope

eks

oun n Pro Lines Unit rating

districts and channels, then demand forecasts Bra

ts atio

ns We

Sale

sV g L og urin

g Bud s

ie rke

tin is act geta

($) w Vie tics nuf w e

Ma View s) (Re Units ry Tim nues

needs to be aggregated, disaggregated, and ($ , U nit

(Un w

Cas its,

es)

Ma Vie its)

(Un

v

Ma enues

rgin &

ve

(Re & s)

s $) rgin

translated into these account groupings Ma

before Sales can usefully play its role in

the S&OP process. Similarly, Supply Chain forecasting levels. Also embedded in the leveraged within an S&OP process. The

managers are most comfortable dealing hierarchy are the rules used to aggregate improvement is due to three underlying

with forecasts that reflect unit-based SKU and disaggregate the numbers needed when principles: 1) aggregated entities experience

and case-level demand, for example; while generating various views of the forecasts. lower relative volatility than their individual

Finance relates best to forecasts that are components, 2) marketing intelligence can

aggregated into budgetary units in terms of I’ve often referred to the technology be incorporated more effectively, which

revenues, costs, and margins. needed to support a forecasting hierarchy improves accuracy and 3) this results in

as a “slicer and dicer” engine because it has greater accountability and commitment

Thus to get the requisite accountability to aggregate and break-down numbers in to consensus-based plans. All these can

and commitment from all the organizations any number of ways, while at the same time be achieved only if all the participants in

involved in the S&OP process requires that keeping them consistent and synchronized. the S&OP process collaborate during the

forecasts be aggregated and disaggregated A forecast revised by Sales for a very large development of demand forecasts. However,

(and possibly translated) to various levels national account, for example, can percolate much of the potential for improvement with

to be reviewed and revised by each one, in up and down to all SKU-level, brand-level, Top-Down & Bottom-Up forecasting cannot

terms they best understand. This represents channel-level, warehouse-level, and plant- be fully achieved unless a formal forecast

another way in which Top-Down & Bottom level forecasts, and the resulting changes to hierarchy is being leveraged to support the

Up forecasting is useful to the S&OP them need to be as consistent as possible S&OP process.

process. For example, if an organization with revisions made to them by other

revises a demand forecast at an aggregated organizations. And these are points I never recognized

level, then the revision needs to percolate or discussed in my first column on the topic

up and down, using Top-Down, Bottom- Figure 2 depicts an example of a forecast eight years ago—yet they are extremely

Up, and Middle-Out forecasting methods. hierarchy that creates special views for important in planning for today’s more

each S&OP participant. It has two supply uncertain and dynamic markets.

and two demand-side aggregated views, as

HIERARCHY AS AN S&OP

well as a financial roll-up view. As can be

ENABLER seen from it, Marketing, Sales, Logistics,

Manufacturing, and Finance need to

A forecasting hierarchy is an important generate, review, and revise forecasts in

element of the S&OP process that is often very different ways, as represented on the

overlooked in its design, yet it is needed faces of the pyramids. All views on the faces

for effective leveraging of Top-Down & need to be consistent with the lowest, most

Bottom-Up forecasting. As discussed earlier, detailed forecasts, as well as be consistent

forecasts need to be generated, reviewed, among each other.

and revised at various levels of aggregation

and disaggregation. To do this, a pre-

established and formal set of relationships SUMMARY

embodied within a forecast hierarchy is

required. The hierarchy maps and translates In summary, Top-Down & Bottom-Up

all the levels among themselves to the forecasting is extremely useful to improve

highest, the lowest, and the most detailed the accuracy of forecasts and plans when

THE JOURNAL OF BUSINESS FORECASTING, SUMMER 2006 3

Potrebbero piacerti anche

- Translating Strategy into Shareholder Value: A Company-Wide Approach to Value CreationDa EverandTranslating Strategy into Shareholder Value: A Company-Wide Approach to Value CreationNessuna valutazione finora

- (Article) Sales and Operations Planning Part I - The Process (2004)Documento3 pagine(Article) Sales and Operations Planning Part I - The Process (2004)M YazdkhastiNessuna valutazione finora

- # (Article) How To Use What-If Analysis in Sales and Operations Planning (2013)Documento9 pagine# (Article) How To Use What-If Analysis in Sales and Operations Planning (2013)AbusamraMousaNessuna valutazione finora

- GUIDE TO AFP. FP&A Systems - Linking People and Processes FP&A Guide Series. Issue 2 PDFDocumento26 pagineGUIDE TO AFP. FP&A Systems - Linking People and Processes FP&A Guide Series. Issue 2 PDFDaveNessuna valutazione finora

- Using Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingDocumento2 pagineUsing Six Steps, Not Your Sixth Sense: No More Crystal-Ball ForecastingAshok MuthuswamyNessuna valutazione finora

- Lucidchart Content Team (2019) : How To DoaDocumento6 pagineLucidchart Content Team (2019) : How To DoaAaquib KapadiaNessuna valutazione finora

- A Synopsis Report ON A Study On Capital Budgeting AT L&TDocumento19 pagineA Synopsis Report ON A Study On Capital Budgeting AT L&TMohmmedKhayyum100% (1)

- Forecasting Is The Process of Estimation in Unknown Situations. Prediction IsDocumento26 pagineForecasting Is The Process of Estimation in Unknown Situations. Prediction IsMehul RasadiyaNessuna valutazione finora

- Isitbettertobe Aggressiveor Conservativein Managing WCDocumento12 pagineIsitbettertobe Aggressiveor Conservativein Managing WCMargarette LumaynoNessuna valutazione finora

- # (Article) Benchmarking Forecasting Processes (2007)Documento7 pagine# (Article) Benchmarking Forecasting Processes (2007)M YazdkhastiNessuna valutazione finora

- SOP Principles - The Foundation For SuccessDocumento6 pagineSOP Principles - The Foundation For SuccessUchenna 'Bonex' OgbonnaNessuna valutazione finora

- Executive S&OP: Managing To Achieve Consensus: January 2010Documento6 pagineExecutive S&OP: Managing To Achieve Consensus: January 2010crackendNessuna valutazione finora

- AFP GUIDE TO FP&A Organizational Structure - Trends and Best Practices. FP&A Guide Series. Sponsored By. Issue 5 PDFDocumento19 pagineAFP GUIDE TO FP&A Organizational Structure - Trends and Best Practices. FP&A Guide Series. Sponsored By. Issue 5 PDFDave100% (1)

- Module 2 - ForecastingDocumento9 pagineModule 2 - ForecastingALMIRA LOUISE PALOMARIANessuna valutazione finora

- WC in Kotak MahindraDocumento28 pagineWC in Kotak MahindraHemant ReddyNessuna valutazione finora

- Job of Working Capital The Board in Productivity Thinking About The Association Among Bookkeeping and MoneyDocumento6 pagineJob of Working Capital The Board in Productivity Thinking About The Association Among Bookkeeping and MoneyAjay MahawerNessuna valutazione finora

- Thinking About Composite ForecastingDocumento3 pagineThinking About Composite ForecastingNguyen NguyenNessuna valutazione finora

- Lesson 4Documento3 pagineLesson 4Mikaela Dela CruzNessuna valutazione finora

- Intermediate Financial Management 12th Edition Brigham Solutions ManualDocumento31 pagineIntermediate Financial Management 12th Edition Brigham Solutions Manuallendablefloordpq7r100% (28)

- Book Review: Sales & Operations Planning-Best Practices, Trafford Publishing, 6E-2333Documento2 pagineBook Review: Sales & Operations Planning-Best Practices, Trafford Publishing, 6E-2333M YazdkhastiNessuna valutazione finora

- 1 ForecastingDocumento29 pagine1 ForecastingDirar AribkusumaNessuna valutazione finora

- RRL MatrixDocumento4 pagineRRL MatrixMarcelita AlasNessuna valutazione finora

- Forecasting PDFDocumento37 pagineForecasting PDFRomel MedenillaNessuna valutazione finora

- Working Capital On WIPRO ITCDocumento50 pagineWorking Capital On WIPRO ITCB Swaraj100% (1)

- Suitable Techniques of Capital Budgeting in Growing or Distressed BusinessDocumento8 pagineSuitable Techniques of Capital Budgeting in Growing or Distressed BusinessAnonymous qAegy6GNessuna valutazione finora

- TYBBA FinanceDocumento40 pagineTYBBA FinancePhalit GuptaNessuna valutazione finora

- The Rise of S&OEDocumento5 pagineThe Rise of S&OEpcokoroigweNessuna valutazione finora

- Firm Characteristics and Financial Performance Evidence From Quoted Manufacturing Firms in NigeriaDocumento14 pagineFirm Characteristics and Financial Performance Evidence From Quoted Manufacturing Firms in NigeriaEditor IJTSRDNessuna valutazione finora

- Bank Loan Loss AccountingDocumento11 pagineBank Loan Loss AccountingSanjay PotterNessuna valutazione finora

- Final Project Antanas Capskis X20147503.Documento13 pagineFinal Project Antanas Capskis X20147503.Antanas CapskisNessuna valutazione finora

- How Companies Should Prepare Thier ForecastsDocumento6 pagineHow Companies Should Prepare Thier ForecastsAhmed KhubaibNessuna valutazione finora

- A Review On Working Capital ManagementDocumento5 pagineA Review On Working Capital ManagementAnonymous izrFWiQ0% (1)

- Evolution of The Forecasting Function: Applications by Spyros Makridakis andDocumento3 pagineEvolution of The Forecasting Function: Applications by Spyros Makridakis andmuskan_0Nessuna valutazione finora

- Intermediate Financial Management 13th Edition Brigham Solutions ManualDocumento33 pagineIntermediate Financial Management 13th Edition Brigham Solutions Manualcuongamandan4c100% (37)

- Leveling Up S&OP: For A Well-Orchestrated Supply ChainDocumento6 pagineLeveling Up S&OP: For A Well-Orchestrated Supply ChainSilvia CastilloNessuna valutazione finora

- Steps in Forecasting With Seasonal Regression A Ca PDFDocumento10 pagineSteps in Forecasting With Seasonal Regression A Ca PDFIZZATI32Nessuna valutazione finora

- Review Literature Ratio Analysis ProjectDocumento6 pagineReview Literature Ratio Analysis Projectggsmsyqif100% (1)

- How To Evaluate CapitalDocumento15 pagineHow To Evaluate Capitalkumarashish21Nessuna valutazione finora

- Discounted Cash Flow DCF As A Measure of Startup FDocumento24 pagineDiscounted Cash Flow DCF As A Measure of Startup FRavi SinghNessuna valutazione finora

- " Bhubaneswar: A Project Report Submitted For The Partial Fulfillment of Post Graduate Diploma in ManagementDocumento4 pagine" Bhubaneswar: A Project Report Submitted For The Partial Fulfillment of Post Graduate Diploma in ManagementPrakash SinghNessuna valutazione finora

- Article - How Do CFOs Make Capital Budgeting and Capital Structure DecisionsDocumento16 pagineArticle - How Do CFOs Make Capital Budgeting and Capital Structure DecisionsmssanNessuna valutazione finora

- 1252am - 140.EPRA Journals - 4180Documento7 pagine1252am - 140.EPRA Journals - 4180Kishore ThirunagariNessuna valutazione finora

- Solventure Whitepaper 4 Demand PlanningDocumento14 pagineSolventure Whitepaper 4 Demand Planningarijit16Nessuna valutazione finora

- Lecture 3.3 - SlidesDocumento21 pagineLecture 3.3 - Slidessfalcao91Nessuna valutazione finora

- Business Forecasting: 4 Revitalize Your S&OPDocumento9 pagineBusiness Forecasting: 4 Revitalize Your S&OPcrackendNessuna valutazione finora

- Acc JACF How Do CFOs Make Capital Budgeting and Capital Structure Decisions?Documento18 pagineAcc JACF How Do CFOs Make Capital Budgeting and Capital Structure Decisions?Herleif HaavikNessuna valutazione finora

- S&OECoE WhitePaperDocumento9 pagineS&OECoE WhitePaperAlejandro Aguilar LanasNessuna valutazione finora

- Effect of Financial Gearing and Financial Structure On Firm's Financial Performance Evidence From PakistanDocumento13 pagineEffect of Financial Gearing and Financial Structure On Firm's Financial Performance Evidence From PakistanInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Liquidity Management and Corporate Performance Evidence From Quoted Oil and Gas Sector Firms in NigeriaDocumento7 pagineLiquidity Management and Corporate Performance Evidence From Quoted Oil and Gas Sector Firms in NigeriaInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Research Report On Financial Analysis On Ford Motor CoDocumento101 pagineResearch Report On Financial Analysis On Ford Motor CoANKIT100% (4)

- Running Head: Financial Analysis 1: Case Study-A Financial Analyst at A Large Automobile CorporationDocumento5 pagineRunning Head: Financial Analysis 1: Case Study-A Financial Analyst at A Large Automobile CorporationBest EssaysNessuna valutazione finora

- 830pm 50.epra Journals-5705Documento7 pagine830pm 50.epra Journals-5705DedipyaNessuna valutazione finora

- Best Practices in Financial Planning and Analysis: White PaperDocumento8 pagineBest Practices in Financial Planning and Analysis: White PaperManikantan NatarajanNessuna valutazione finora

- Pe Ratio Research PaperDocumento6 paginePe Ratio Research Paperkxmwhxplg100% (1)

- The Future of Strategy Is Leadership. Eng VerDocumento5 pagineThe Future of Strategy Is Leadership. Eng VerPratiwi AprilyaNessuna valutazione finora

- SM 725Documento7 pagineSM 725Noah GunnNessuna valutazione finora

- Investment Appraisal Literature ReviewDocumento6 pagineInvestment Appraisal Literature Reviewgvxphmm8100% (1)

- Instant Download Ebook PDF Fundamentals of Corporate Finance 2 Asia Global Edition PDF ScribdDocumento42 pagineInstant Download Ebook PDF Fundamentals of Corporate Finance 2 Asia Global Edition PDF Scribdlauryn.corbett387100% (43)

- S&OP Part I The Process Larry Lapide PDFDocumento3 pagineS&OP Part I The Process Larry Lapide PDFOmar Enrique Gonzalez RozoNessuna valutazione finora

- BSDDocumento26 pagineBSDEunnicePanaliganNessuna valutazione finora

- Percentage and Profit & Loss: Aptitude AdvancedDocumento8 paginePercentage and Profit & Loss: Aptitude AdvancedshreyaNessuna valutazione finora

- Flowrox Valve Solutions Catalogue E-VersionDocumento16 pagineFlowrox Valve Solutions Catalogue E-Versionjavier alvarezNessuna valutazione finora

- 2011-11-09 Diana and AtenaDocumento8 pagine2011-11-09 Diana and AtenareluNessuna valutazione finora

- Hydraulics and PneumaticsDocumento6 pagineHydraulics and PneumaticsRyo TevezNessuna valutazione finora

- Datos Adjuntos Sin Título 00013Documento3 pagineDatos Adjuntos Sin Título 00013coyana9652Nessuna valutazione finora

- Cpar ReviewerDocumento6 pagineCpar ReviewerHana YeppeodaNessuna valutazione finora

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Documento82 pagineGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbNessuna valutazione finora

- Managemant PrincipleDocumento11 pagineManagemant PrincipleEthan ChorNessuna valutazione finora

- IPS PressVest Premium PDFDocumento62 pagineIPS PressVest Premium PDFLucian Catalin CalinNessuna valutazione finora

- DevOps Reference CardDocumento2 pagineDevOps Reference CardIntizarchauhanNessuna valutazione finora

- Friday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDocumento3 pagineFriday 25 Mar 12:15 AM Friday 25 Mar 5:30 AM: Emirates CGK DXBDONI ARTANessuna valutazione finora

- What Are The Advantages and Disadvantages of UsingDocumento4 pagineWhat Are The Advantages and Disadvantages of UsingJofet Mendiola88% (8)

- Economizer DesignDocumento2 pagineEconomizer Designandremalta09100% (4)

- Design Practical Eden Swithenbank Graded PeDocumento7 pagineDesign Practical Eden Swithenbank Graded Peapi-429329398Nessuna valutazione finora

- Catalogue of Archaeological Finds FromDocumento67 pagineCatalogue of Archaeological Finds FromAdrinaNessuna valutazione finora

- Ariba Collaborative Sourcing ProfessionalDocumento2 pagineAriba Collaborative Sourcing Professionalericofx530Nessuna valutazione finora

- Example of Flight PMDG MD 11 PDFDocumento2 pagineExample of Flight PMDG MD 11 PDFVivekNessuna valutazione finora

- Marieb ch3dDocumento20 pagineMarieb ch3dapi-229554503Nessuna valutazione finora

- Sodexo GermanyDocumento13 pagineSodexo GermanySandeep Kumar AgrawalNessuna valutazione finora

- 1 Prof Chauvins Instructions For Bingham CH 4Documento35 pagine1 Prof Chauvins Instructions For Bingham CH 4Danielle Baldwin100% (2)

- Beamng DxdiagDocumento22 pagineBeamng Dxdiagsilvioluismoraes1Nessuna valutazione finora

- Jurnal 1 Ieevee LPF PDFDocumento4 pagineJurnal 1 Ieevee LPF PDFNanda SalsabilaNessuna valutazione finora

- The History of Music in Portugal - Owen ReesDocumento4 pagineThe History of Music in Portugal - Owen ReeseugenioamorimNessuna valutazione finora

- Chestionar 2Documento5 pagineChestionar 2Alex AndruNessuna valutazione finora

- Risha Hannah I. NazarethDocumento4 pagineRisha Hannah I. NazarethAlpaccino IslesNessuna valutazione finora

- IbmautomtiveDocumento38 pagineIbmautomtiveMeltz NjorogeNessuna valutazione finora

- ISO-3046-4-2009 (Gobernador de Velocidad)Documento8 pagineISO-3046-4-2009 (Gobernador de Velocidad)David GastelumNessuna valutazione finora

- Dance Terms Common To Philippine Folk DancesDocumento7 pagineDance Terms Common To Philippine Folk DancesSaeym SegoviaNessuna valutazione finora

- Qualitrol 900 910Documento6 pagineQualitrol 900 910chennupati999Nessuna valutazione finora