Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spatial Fashioned Knitted Fabrics Flechage

Caricato da

Laura AquinoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spatial Fashioned Knitted Fabrics Flechage

Caricato da

Laura AquinoCopyright:

Formati disponibili

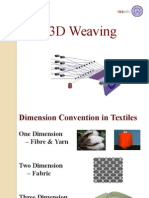

Spatial fashioned knitted fabrics

The 3D knitted performs started to be developed in the ’90, mainly based on the

development of electronic flat knitting machines and CAD/CAM systems. Even if there is

significant progress in this domain, there are a lot of aspects that need addressed in order

for the spatial knitted fabrics to become industrially feasible.

The spatial fashioning of the knitted fabrics is based on the need to produce fabrics with

complex shapes that are similar to the shape of the final product. Even if a certain degree of

spatial geometry can be obtained by using modules of structures with different patterns or

by dynamic stitch length, the technique of spatial fashioning is the only one that has no

limitations with regard to the shape complexity and dimensions. This technique (also

known as ‘flechage’) is based on knitting courses on all working needles and courses on a

variable number of needles, determining zones with different amount of stitches. The zones

with the highest amount of stitches will have in the end a spatial geometry.

A classification of the spatial fashioned fabrics must take into consideration the 3D shape of

the product, defined geometrically as a 3D body. These bodies can be divided in solids of

revolution, such as tubes (cylinders), spheres and hemispheres, cones and frustum of cones,

ellipsoids, hyperboloids, and polyhedrons, such as tetrahedrons, pyramids, parallelepipeds,

etc. Apart from these simple bodies, other bodies can be considered: bodies obtained from

composing simple bodies or bodies with irregular shape.

The fabric 2D plan is a rectangular area where are positioned fashioning lines that define the

final 3D shape of the product. Such a 3D fabric is obtained by placing more fashioning lines

with certain characteristics, forming repeating geometric basic forms within the plan or not

(as is the case for parallelepiped forms).

The fashioning lines can be defined as the zones where the knitting will be carried out on a

variable number of needles, these zones generating the spatial geometry. The lines have two

components, corresponding to decreasing the number of working needles and the other to

increasing them. In the fabric, these two lines become one, the actual fashioning line, as

presented in Fig. 14.

Tejidos de punto de fantasía

El 3D realiza de punto comenzaron a desarrollarse en el '90, basada principalmente en el

desarrollo de las máquinas de tejer planos electrónicos y sistemas CAD / CAM. Incluso si hay

avances significativos en este ámbito, hay una gran cantidad de aspectos que deben abordarse con el fin

para los tejidos de punto espaciales para convertirse industrialmente factible.

La hechura espacial de los tejidos de punto se basa en la necesidad de producir telas con

formas complejas que son similares a la forma del producto final. Aunque un cierto grado de

geometría espacial se puede obtener mediante el uso de módulos de estructuras con diferentes patrones o

por longitud de puntada dinámica, la técnica de modelar espacial es el único que no tiene

limitaciones con respecto a la complejidad forma y dimensiones. Esta técnica (también

conocido como 'flechage') se basa en cursos de tejer en todas las agujas de trabajo y cursos sobre una

número variable de agujas, la determinación de zonas con diferente cantidad de puntos de sutura. las zonas

con la mayor cantidad de puntos de sutura tendrá al final una geometría espacial.

Una clasificación de los tejidos espaciales de moda debe tener en cuenta la forma 3D de

el producto, definida geométricamente como un cuerpo 3D. Estos organismos se pueden dividir en los sólidos

de revolución, tales como tubos (cilindros), esferas y hemisferios, conos y conos de cono truncado,

elipsoides, hiperboloides, y poliedros, como tetraedros, pirámides, paralelepípedos,

etc Aparte de estos cuerpos simples, otros organismos pueden ser considerados: cuerpos obtienen a partir de

la composición de los órganos u organismos con forma irregular simples.

El plan de 2D tela es un área rectangular donde se coloca la configuración de las líneas que definen el

forma 3D final del producto. Dicha tela 3D se obtiene mediante la colocación de más líneas Fashioning

con ciertas características, que forman la repetición de formas geométricas básicas dentro del plan o no

(Como es el caso de las formas de paralelepípedo).

Las líneas Fashioning se pueden definir como las zonas en que se lleve a cabo el tricotado en una

número variable de agujas, estas zonas que generan la geometría espacial. Las líneas tienen dos

componentes, que corresponde a la disminución del número de agujas de trabajo y el otro a

aumentarlos. En la tela, estas dos líneas se convierten en uno, la línea de hechura real, como

presentado en la Fig. 14.

Higo.

Traductor de Google para empresas:Google Translator ToolkitTraductor de sitios webGlobal Market Finder

The sandwich fabrics presented are characterised by constant thickness and rectangular

form in cross section. There are three major ways to diversify these fabrics and to obtain

structures with complex shape (Ciobanu, 2003):

• The use of connection layers with different length

• The use of connection layers with variable form (the fashioning/flechage technique)

• The use of exterior fashioned separate fabrics

Sandwich fabrics with connecting layers of different length

The simple variation of the layer length will modify the cross-section of the fabric. The

shape is created by the specific position of the separate fabrics between the consecutive

layers. Two possibilities can be mentioned. One takes into consideration a specified

sequence of layers with different length, as illustrated in Fig. 26. The different length of the

layers will determine an inclined geometry for the exterior fabrics.

Fig. 26. Sandwich fabric with connecting layers of variable length

The other possibility refers to a sequence of two layers with predetermined (different)

length, combined with an according number of courses in the separate fabric(s) that

generates a corner effect (position at 900). It is the case of fabrics with L and T shapes,

presented in Fig. 27 and Fig. 28.

Fig. 27. Sandwich fabric with L shape

www.intechopen.com

Development of 3D Knitted Fabrics for Advanced Composite Materials

179

Fig. 28. Sandwich fabric with T shape

Sandwich fabrics with shaped layers (variable courses technique)

In this case the shape is determined directly by the shape of the layers, obtained through the

variable courses technique. The technique is based on knitting on only a part of the needles

producing the layer, in certain rows, while the others are missing. One example (knitting

programme, Sirix) is presented in Fig. 29.

Fig. 29. Knitting sequence for a shaped layer (SIRIX, Stoll)

The fabric cross section given by the connecting layers is controlled through these layers.

Different shapes can be therefore produced, as exemplified in Fig. 30. The layers are

emphasised in red, while the separate fabrics are lined; the arrows are indicating the

knitting direction. Two main types of shaped layers can be identified: with integral shape

(the yarn guide is feeding continuously, even if on only a variable number of needles), as in

Fig. 30.a. and b. and with divided shape (the evolution is split on distinct groups of needles,

requiring separate feeding), as in the case of the fabric presented in Fig. 30.c.

www.intechopen.com

Advances in Composites Materials - Ecodesign and Analysis

180

a) Sandwich fabric with trapezoidal cross section

b) Sandwich fabric with elliptical cross section

c) Sandwich fabric with complex cross section

Fig. 30. Examples of sandwich fabrics with shaped connecting layers

Sandwich fabrics with fashioned exterior fabric

The fully-fashioning of the separate fabrics is obtained by narrowing and enlargement

technique the number of working needles of the fabrics, using stitch transfer and racking.

Fig. 31 illustrates one such possibility.

www.intechopen.

Potrebbero piacerti anche

- Shop Manual Mustang 65Documento25 pagineShop Manual Mustang 65SAúl Guth N40% (5)

- Textile Structures For Technical TextilesDocumento10 pagineTextile Structures For Technical TextilesRajesh DwivediNessuna valutazione finora

- CuttingDocumento38 pagineCuttingSaloni Dubey100% (4)

- Jisung Hydrahulic Breaker Operation & Maintenance ManualDocumento56 pagineJisung Hydrahulic Breaker Operation & Maintenance ManualMilton Hernandez Pérez100% (4)

- Translation Corpse Bride MovieDocumento12 pagineTranslation Corpse Bride Movieseong sooNessuna valutazione finora

- Descriptive EssayDocumento1 paginaDescriptive Essayapi-262142985100% (1)

- Special Knitting StructureDocumento4 pagineSpecial Knitting StructureYared Fikre100% (2)

- Fabric Science 3Documento8 pagineFabric Science 3Anurag VermaNessuna valutazione finora

- Weaving of 3D Fabrics: A Critical AppreciationDocumento59 pagineWeaving of 3D Fabrics: A Critical AppreciationGarmentLearnerNessuna valutazione finora

- 3d WeavingDocumento14 pagine3d WeavingRashique Ul LatifNessuna valutazione finora

- 3-Dimensional Weaving: B K Behera & Rajesh MishraDocumento14 pagine3-Dimensional Weaving: B K Behera & Rajesh MishraTiara YurizalNessuna valutazione finora

- Keywords: 3d-Fabric, 2d-Weaving, Noobing: 2.0 Classification of 3D FabricsDocumento3 pagineKeywords: 3d-Fabric, 2d-Weaving, Noobing: 2.0 Classification of 3D FabricsdasmousumiNessuna valutazione finora

- Virtual Garments: A Fully Geometric Approach For Clothing DesignDocumento10 pagineVirtual Garments: A Fully Geometric Approach For Clothing DesignAndreea DinuNessuna valutazione finora

- Textile Composite Production MethodsDocumento8 pagineTextile Composite Production MethodsHassan Al MamunNessuna valutazione finora

- 3D Fabrics: Review: A TechnologicalDocumento12 pagine3D Fabrics: Review: A TechnologicalomiNessuna valutazione finora

- Three-Dimensional Simulation of Warp Knitted Structures Based On Geometric Unit Cell of Loop YarnsDocumento9 pagineThree-Dimensional Simulation of Warp Knitted Structures Based On Geometric Unit Cell of Loop YarnsKUNAL MANDALNessuna valutazione finora

- Shedding Mechanism: Advanced Weaving Technologies For High-Performance FabricsDocumento19 pagineShedding Mechanism: Advanced Weaving Technologies For High-Performance FabricsMễro ĢANessuna valutazione finora

- 3D Woven FabricDocumento9 pagine3D Woven FabricAmit MadhuNessuna valutazione finora

- Basic Garment Modeling 3 D Cad DigitizerDocumento11 pagineBasic Garment Modeling 3 D Cad Digitizergebo_manNessuna valutazione finora

- 3D Woven FabricDocumento9 pagine3D Woven FabricCrystal NewmanNessuna valutazione finora

- Innovation in 3D Braiding Technology and Its ApplicationsDocumento21 pagineInnovation in 3D Braiding Technology and Its ApplicationsDiego BetancourtNessuna valutazione finora

- Pattern Remaking System of Dress Shirt Using 3D Shape MeasurementDocumento8 paginePattern Remaking System of Dress Shirt Using 3D Shape MeasurementasimnazirNessuna valutazione finora

- 3D Simulation of Warp Knitted Spacer Fabric StructureDocumento5 pagine3D Simulation of Warp Knitted Spacer Fabric StructuretempofaltuNessuna valutazione finora

- Parametrized Garment Pattern Manipulation For The Men's SuitDocumento4 pagineParametrized Garment Pattern Manipulation For The Men's SuitkleberttoscanoNessuna valutazione finora

- Cloth Simulation and Collision Detection Using Geometry ImagesDocumento10 pagineCloth Simulation and Collision Detection Using Geometry ImagesOm PatriNessuna valutazione finora

- Effect of Machine Parameters On Knit Fabric SpecificationsDocumento5 pagineEffect of Machine Parameters On Knit Fabric SpecificationsGarmentLearnerNessuna valutazione finora

- Jetavat D 2D-3D Braiding TechniquesDocumento30 pagineJetavat D 2D-3D Braiding TechniquesJesus Guillermo Rodriguez Cardenas100% (1)

- ASSIGMENT 1 Advanced Woven ManufacturingDocumento25 pagineASSIGMENT 1 Advanced Woven ManufacturingYared FikreNessuna valutazione finora

- 3d Pletenine 1Documento10 pagine3d Pletenine 1wiktor991Nessuna valutazione finora

- CAD CAM UNIT 2 (Compatibility Mode)Documento21 pagineCAD CAM UNIT 2 (Compatibility Mode)muhamed ademNessuna valutazione finora

- Geometric ModellingDocumento138 pagineGeometric ModellingSandeela NaveedNessuna valutazione finora

- Parsing Sewing Patterns into 3D GarmentsDocumento11 pagineParsing Sewing Patterns into 3D GarmentsDebopriyo BanerjeeNessuna valutazione finora

- Textiles and FashionDocumento8 pagineTextiles and FashionangelamNessuna valutazione finora

- CuttingDocumento39 pagineCuttingDaniela JakimovaNessuna valutazione finora

- Modelling of Textile Structure For Advanced ApplicationsDocumento10 pagineModelling of Textile Structure For Advanced Applicationsmamint74Nessuna valutazione finora

- SL Modelling Micro-Mech Textiles Paper PDFDocumento10 pagineSL Modelling Micro-Mech Textiles Paper PDFГЕННАДИЙ МИХАЙЛОВИЧ РЕЗНИЧЕНКОNessuna valutazione finora

- Computers in Industry: C.K. Au, Y.-S. MaDocumento8 pagineComputers in Industry: C.K. Au, Y.-S. MaAfnur Saputri YsNessuna valutazione finora

- Computers in Industry: C.K. Au, Y.-S. MaDocumento8 pagineComputers in Industry: C.K. Au, Y.-S. MaGabi KuhnenNessuna valutazione finora

- Microstructure Simulation of Virtual Woven Filter MediaDocumento8 pagineMicrostructure Simulation of Virtual Woven Filter MediaDIEGO ALEJANDRO PARRA GARRIDONessuna valutazione finora

- 3D Knitted TextilesDocumento20 pagine3D Knitted TextilesProfessorTextechNessuna valutazione finora

- 3D Fabrics-01Documento36 pagine3D Fabrics-01Zuhaib AhmadNessuna valutazione finora

- M3 - 3D Fabrics-01 Lec-3Documento36 pagineM3 - 3D Fabrics-01 Lec-3Shahan AkhtarNessuna valutazione finora

- FABRIC GEOMETRY-WPS OfficeDocumento23 pagineFABRIC GEOMETRY-WPS OfficeHemaNessuna valutazione finora

- Lab 4 - 3d Angle Interlock - Hannan HamimiDocumento15 pagineLab 4 - 3d Angle Interlock - Hannan HamimiHannan HamimiNessuna valutazione finora

- Gaussian Vault Geometry Digital Design and Fabrication of Scaled PrototypesDocumento10 pagineGaussian Vault Geometry Digital Design and Fabrication of Scaled PrototypesSofia GambettaNessuna valutazione finora

- 3D Weaving Mechanism and Applications ExplainedDocumento35 pagine3D Weaving Mechanism and Applications ExplainedYared FikreNessuna valutazione finora

- 3D Weaving OverviewDocumento70 pagine3D Weaving OverviewVijay KhoiwalNessuna valutazione finora

- Knit 3Documento189 pagineKnit 3adnan100% (1)

- Modtech 2012 IonesiDocumento6 pagineModtech 2012 IonesiZHARFAN ASYKUR YULIANTONessuna valutazione finora

- Vignan University Fabric Structure AssignmentDocumento2 pagineVignan University Fabric Structure AssignmentMohammad Vaseem ChavhanNessuna valutazione finora

- X-Direction and Y-Direction Z-Direction: The Manufacture of Fibre FabricDocumento3 pagineX-Direction and Y-Direction Z-Direction: The Manufacture of Fibre Fabricaditya singhNessuna valutazione finora

- Fabric-Construction-Methods (Questions) PDFDocumento6 pagineFabric-Construction-Methods (Questions) PDFTamer Farouk Khalifa67% (3)

- Bridges2011 217Documento8 pagineBridges2011 217Luca FaraldiNessuna valutazione finora

- Bending Properties of Three-Dimensional Honeycomb Sandwich Structure Composites: Experiment and Finite Element Method SimulationDocumento8 pagineBending Properties of Three-Dimensional Honeycomb Sandwich Structure Composites: Experiment and Finite Element Method SimulationhawNessuna valutazione finora

- Computational Meshing For CFD SimulationsDocumento31 pagineComputational Meshing For CFD SimulationsEduardo Antonio Burgos RuidíasNessuna valutazione finora

- Seamless Garment TechnologyDocumento6 pagineSeamless Garment Technologyspringstar100% (2)

- Pattern MakingDocumento10 paginePattern MakingChaitanya Krishna100% (1)

- Development in The Multiaxis 3D Weaving TechnologyDocumento16 pagineDevelopment in The Multiaxis 3D Weaving TechnologyIsmail BayraktarNessuna valutazione finora

- GAN-based Garment Generation PDFDocumento23 pagineGAN-based Garment Generation PDFTechnical SpecificationsNessuna valutazione finora

- Weaving Report, MolefeDocumento12 pagineWeaving Report, MolefesecuuulNessuna valutazione finora

- Theory of Silk Weaving: A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsDa EverandTheory of Silk Weaving: A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsNessuna valutazione finora

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsDa EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsValutazione: 3 su 5 stelle3/5 (1)

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsDa EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNessuna valutazione finora

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterDa EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterValutazione: 4 su 5 stelle4/5 (3)

- AFSOC Special Operations Security Forces DAGRE Qualification CourseDocumento2 pagineAFSOC Special Operations Security Forces DAGRE Qualification Coursemandagifamily3770Nessuna valutazione finora

- Master Run SheetDocumento8 pagineMaster Run Sheetapi-538676793Nessuna valutazione finora

- Nift BookDocumento133 pagineNift BookIftikhar Hussain ChangaziNessuna valutazione finora

- Eastern Influence On Polish ArmsDocumento39 pagineEastern Influence On Polish ArmsGreg RyanNessuna valutazione finora

- Halloween Int PDFDocumento11 pagineHalloween Int PDFAdrian Cockings100% (1)

- 6th Grade Vocabulary & Grammar PracticeDocumento50 pagine6th Grade Vocabulary & Grammar PracticeKate KupenovaNessuna valutazione finora

- Aurangabad's vision for industrial growth by 2020Documento31 pagineAurangabad's vision for industrial growth by 2020Khushi KalikarNessuna valutazione finora

- Alyssa Brooks - Dragon's DesireDocumento52 pagineAlyssa Brooks - Dragon's Desired4d42937100% (2)

- Alle V-Infos EnglischDocumento43 pagineAlle V-Infos EnglischMohamed Rashed50% (2)

- Angol B2 SzituációkDocumento5 pagineAngol B2 SzituációkzsoieNessuna valutazione finora

- Kaizen Project Brief Ver 1.1 - AdidasDocumento6 pagineKaizen Project Brief Ver 1.1 - Adidasthulasi ramanNessuna valutazione finora

- The Portrait of A KissDocumento4 pagineThe Portrait of A KissDelta CoveNessuna valutazione finora

- Charlie and The Chocolate FactoryDocumento14 pagineCharlie and The Chocolate FactoryAlexandre RodriguesNessuna valutazione finora

- Christmas Cuties Collection Vol 2 - Jen Mitchell - Nellas CottageDocumento31 pagineChristmas Cuties Collection Vol 2 - Jen Mitchell - Nellas CottageFatima Borque100% (2)

- Coulisse Journal 4 PDFDocumento52 pagineCoulisse Journal 4 PDFDenis MenaceNessuna valutazione finora

- Modal VerbsDocumento17 pagineModal VerbsNgarczNessuna valutazione finora

- Oda Nobuna No Yabou 2Documento218 pagineOda Nobuna No Yabou 2Alexander Hendrik SNessuna valutazione finora

- True20-Legends of Excalibur-Arthurian Adventures PDFDocumento84 pagineTrue20-Legends of Excalibur-Arthurian Adventures PDFShane Colon100% (2)

- ST-18 The Ape Girl by Author UnknownDocumento56 pagineST-18 The Ape Girl by Author Unknownsorin61100% (2)

- Appendix JDocumento20 pagineAppendix JAdeRatihIspandiariNessuna valutazione finora

- Basketball England - National Basketball League Regulations 2014-15Documento40 pagineBasketball England - National Basketball League Regulations 2014-15JayNessuna valutazione finora

- Primark's PESTLE and SWOT AnalysisDocumento7 paginePrimark's PESTLE and SWOT AnalysisIsa JoeNessuna valutazione finora

- Caswell ScarfDocumento1 paginaCaswell ScarfArashi KenseiNessuna valutazione finora

- 108 Sodium CarbonateDocumento6 pagine108 Sodium Carbonateeng20072007Nessuna valutazione finora

- NikeDocumento71 pagineNikeJeff LooNessuna valutazione finora

- Home Fun Booklet 5 KeysDocumento32 pagineHome Fun Booklet 5 KeysMarta PavelNessuna valutazione finora