Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Creating Larger Forces With Differential Roller Screws: Carlos Gonzalez

Caricato da

fbahsiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Creating Larger Forces With Differential Roller Screws: Carlos Gonzalez

Caricato da

fbahsiCopyright:

Formati disponibili

CARLOS GONZALEZ | Technology Editor

carlos.gonzalez@penton.com

Creating Larger

Forces with

Differential

Roller Screws

P

ower density is one of the primary reasons gears by forming (rolling), rather than undergo the

why design engineers and manufacturers time-consuming and expensive grinding process typi-

rely on hydraulics when they want their cally used to manufacture traditional roller screws.

machines to move something. Hydraulic Schaeffler’s PWG is characterized by very high pow-

systems offer very high force density in a compact, er density. The PWG’s large number of contact points

relatively economical design. But inherent drawbacks between the planets and spindle enable it to achieve

to hydraulics are leading design engineers and manu- very high axial load-carrying capacity. Applications

facturers to consider an electromechanical system as for the PWG include power tools, sheet-metal bend-

an alternative to its hydraulic counterpart. One way to ing machines, locking cylinders for plastic-injection-

do this is by replacing the hydraulic cylinder with an molding machines, and riveting and cutting devices.

actuator and screw driven by an electric motor. The PWG is currently in volume-production use in

The roller screw’s ability to generate two to five times automotive clutch actuators.

the force of an equivalent

ball screw makes it an

excellent replacement for

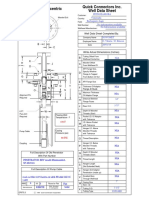

a hydraulic system. How- Spacer disc

ever, due to the precise

Nut half I

grinding tolerances need-

ed to achieve the load-

sharing properties, roller Planetary disc

screws can be expensive. Nut half II

Retaining ring

To address this issue,

Schaeffler (www.schaef-

Planets

fler.com) recently devel-

Spindle

oped the PWG differen-

tial roller screw, which

offers the high forces of a

traditional roller screw at

a price point closer to that

of a ball screw.

The key to the PWG’s

affordability is Schaef- Schaeffler’s PWG differential roller screw—whose spindle and planets are manufactured

fler’s ability to manufac- using forming, instead of traditional grinding, methods—is characterized by a very high power

ture its spindle and planet density. (Image courtesy of Schaeffler)

1 MACHINEDESIGN.COM

Potrebbero piacerti anche

- Why Consider Roller Screw TechnologyDocumento2 pagineWhy Consider Roller Screw Technologyryasa1Nessuna valutazione finora

- HeliCoil NPT Inserts 8UNDocumento4 pagineHeliCoil NPT Inserts 8UNAce Industrial SuppliesNessuna valutazione finora

- Dimensional Analysis, Similitude and Hydraulic ModelsDocumento6 pagineDimensional Analysis, Similitude and Hydraulic Modelskasandra01Nessuna valutazione finora

- Stock Compression Spring CatalogDocumento548 pagineStock Compression Spring CatalogRatno WijayaNessuna valutazione finora

- Surface Finish Chart PDFDocumento1 paginaSurface Finish Chart PDFTueNessuna valutazione finora

- How To Analyze Gear Failures - Machinery LubricationDocumento15 pagineHow To Analyze Gear Failures - Machinery LubricationJorgNessuna valutazione finora

- TYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsDocumento6 pagineTYPE 1604/2609/3609: First Edition API 682 Type C Sealol Metal Bellows SealsKapa KamalakarNessuna valutazione finora

- 2.mechanical Seal - 02Documento26 pagine2.mechanical Seal - 02AmrMashhourNessuna valutazione finora

- E04 Using Kalsi Seals in Washpipe AssembliesDocumento17 pagineE04 Using Kalsi Seals in Washpipe AssembliesSuresh Kumar MittapalliNessuna valutazione finora

- EB878G Gate Valves Trim Cross-ReferenceDocumento4 pagineEB878G Gate Valves Trim Cross-Referencejose eduardoNessuna valutazione finora

- Drill Tap Chart Inch MetricDocumento2 pagineDrill Tap Chart Inch Metricnate anantathatNessuna valutazione finora

- Acme & Stub Acme LoadDocumento4 pagineAcme & Stub Acme Loadraseen pNessuna valutazione finora

- Spring Design: Prepared and Presented By: Manoj AdhikariDocumento21 pagineSpring Design: Prepared and Presented By: Manoj AdhikariDhiraj NayakNessuna valutazione finora

- Lee Spring Catalog 2019Documento391 pagineLee Spring Catalog 2019StephenNessuna valutazione finora

- Acme Screw Data PDFDocumento4 pagineAcme Screw Data PDFAnggit PrakasaNessuna valutazione finora

- Model 500 GV CatalogDocumento4 pagineModel 500 GV CatalogYuda100% (1)

- Friction and Wear of Ptfe Comp at Cry TempDocumento10 pagineFriction and Wear of Ptfe Comp at Cry Tempa100acomNessuna valutazione finora

- P3000-2 Data Sheet Rev.1Documento1 paginaP3000-2 Data Sheet Rev.1Omar Alexander PerazaNessuna valutazione finora

- Data Sheet For Positive Displacement Pumps Reciprocating S 728Dv2020 08Documento10 pagineData Sheet For Positive Displacement Pumps Reciprocating S 728Dv2020 08roronoa_zorro11Nessuna valutazione finora

- Product Overview LIGHTNINDocumento34 pagineProduct Overview LIGHTNINNguyen Quang HungNessuna valutazione finora

- Camesa TechBulletin-022Documento1 paginaCamesa TechBulletin-022FauzanNessuna valutazione finora

- Threaded Fasteners CH 10Documento37 pagineThreaded Fasteners CH 10sarath6725Nessuna valutazione finora

- Dura - Product CatalogDocumento245 pagineDura - Product CatalogPedro Antonio Mejia SuarezNessuna valutazione finora

- SPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaDocumento10 pagineSPE - 22559 Advancements in Dynamic-Kill Calculations For Blowout Wells - G E KoubaAsahel NuñezNessuna valutazione finora

- Grove g4n Gate Valve BrochureDocumento24 pagineGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Tricocat PDFDocumento44 pagineTricocat PDFJuan PabloNessuna valutazione finora

- How To Analyze Gear FailuresDocumento12 pagineHow To Analyze Gear FailuresOuld EulerNessuna valutazione finora

- k10 GeothermalDocumento1 paginak10 GeothermalshegateNessuna valutazione finora

- Thrust CalculationsDocumento2 pagineThrust CalculationsshahqazwsxNessuna valutazione finora

- Chanjot ReportDocumento18 pagineChanjot ReportKumud BadoniNessuna valutazione finora

- Electric Linear Actuators and Controls Full enDocumento51 pagineElectric Linear Actuators and Controls Full ensaleemut3Nessuna valutazione finora

- Metallurgical Factors Influencing The Machinability of Inconel 718 - SchirraDocumento12 pagineMetallurgical Factors Influencing The Machinability of Inconel 718 - SchirraAntonioNessuna valutazione finora

- A Theory of Tesla Disc Turbines: Sayantan Sengupta and Abhijit GuhaDocumento14 pagineA Theory of Tesla Disc Turbines: Sayantan Sengupta and Abhijit GuhahatemNessuna valutazione finora

- Design and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working FluidDocumento6 pagineDesign and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working Fluidbillthegunm0% (1)

- Formato Caja de ChokeDocumento1 paginaFormato Caja de ChokeDaniel Camargo PérezNessuna valutazione finora

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocumento15 paginePiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNessuna valutazione finora

- Mil R 83248CDocumento20 pagineMil R 83248C이형주Nessuna valutazione finora

- 2020 Style 688 Split SealtekDocumento8 pagine2020 Style 688 Split SealtekdiamsamNessuna valutazione finora

- Power Calculations For Tesla TurbineDocumento10 paginePower Calculations For Tesla TurbineNajam Ul QadirNessuna valutazione finora

- Shear Force For SBRDocumento14 pagineShear Force For SBRnjava1978Nessuna valutazione finora

- ESP Centrifugal PumpDocumento7 pagineESP Centrifugal PumpRaidan AbdoNessuna valutazione finora

- Variseal enDocumento88 pagineVariseal enAzhar KhanNessuna valutazione finora

- COUPLINGDocumento11 pagineCOUPLINGabduallah rabahNessuna valutazione finora

- Gerotor 3Documento14 pagineGerotor 3Jean-Philippe GauthierNessuna valutazione finora

- Pumptools - BOP CanDocumento1 paginaPumptools - BOP Cancasda73Nessuna valutazione finora

- Stray Current Corrosion in Submersible PumpsDocumento5 pagineStray Current Corrosion in Submersible PumpsMachineryengNessuna valutazione finora

- Rupture Disk FUL-FLO Sampler: HalliburtonDocumento2 pagineRupture Disk FUL-FLO Sampler: Halliburtonsaeed65Nessuna valutazione finora

- Fea SR CouplingsDocumento67 pagineFea SR CouplingsAna Isabel Aguilar ReyesNessuna valutazione finora

- Seal Friction Parker SealsDocumento6 pagineSeal Friction Parker SealsChristian MavarezNessuna valutazione finora

- Product Catalogue - 0417ST (Print)Documento54 pagineProduct Catalogue - 0417ST (Print)Ivan GutierrezNessuna valutazione finora

- PumpDocumento7 paginePumpYohanis DabesaNessuna valutazione finora

- Baker 2 Phase FlowDocumento2 pagineBaker 2 Phase FlowLind D. QuiNessuna valutazione finora

- CamesaEMC Catalog 12-2013 7Documento1 paginaCamesaEMC Catalog 12-2013 7Gerardo LizardoNessuna valutazione finora

- Camesa Cable SpecDocumento1 paginaCamesa Cable SpecShashank Anand MishraNessuna valutazione finora

- Hevvy Hns Brocuhre enDocumento11 pagineHevvy Hns Brocuhre enJacobo MartínezNessuna valutazione finora

- BR MiningDocumento12 pagineBR MiningSteven TremolNessuna valutazione finora

- Co2 Injection Wells.009Documento11 pagineCo2 Injection Wells.009Shio WenzanNessuna valutazione finora

- IECEx CML 14.0047X 0 PDFDocumento7 pagineIECEx CML 14.0047X 0 PDFINSTECH ServicesNessuna valutazione finora

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965Da EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNessuna valutazione finora

- Heat Transfer Analysis Of: Compact Heat Exchangers Using Standard CurvesDocumento4 pagineHeat Transfer Analysis Of: Compact Heat Exchangers Using Standard CurvesfbahsiNessuna valutazione finora

- Tekstil Ve Mühendis (Journal of Textiles and Engineer) : Bu Makaleye Atıf Yapmak Için (To Cite This Article)Documento9 pagineTekstil Ve Mühendis (Journal of Textiles and Engineer) : Bu Makaleye Atıf Yapmak Için (To Cite This Article)fbahsiNessuna valutazione finora

- AdvancesinMetalsPaveWaytoLighterVehicles PDFDocumento6 pagineAdvancesinMetalsPaveWaytoLighterVehicles PDFfbahsiNessuna valutazione finora

- Wall Slip of Molten High Density Polyethylene. I. Sliding Plate Rheometer StudiesDocumento27 pagineWall Slip of Molten High Density Polyethylene. I. Sliding Plate Rheometer StudiesfbahsiNessuna valutazione finora

- Determination of Zero-Shear Viscosity of Molten PolymersDocumento69 pagineDetermination of Zero-Shear Viscosity of Molten PolymersfbahsiNessuna valutazione finora

- Computational and Experimental Evaluation of Two Models For The Simulation of Thermoplastics Injection MoldingDocumento128 pagineComputational and Experimental Evaluation of Two Models For The Simulation of Thermoplastics Injection MoldingfbahsiNessuna valutazione finora

- THE Ancient Life-History OF The Earth: Page V PREFACEDocumento339 pagineTHE Ancient Life-History OF The Earth: Page V PREFACEGutenberg.org100% (1)

- Rose Cross Over The Baltic - ToCDocumento3 pagineRose Cross Over The Baltic - ToCBobby Black0% (1)

- Pluto, Son of Saturn and Ops, Assisted JupiterDocumento3 paginePluto, Son of Saturn and Ops, Assisted JupiterKeyshia Languita BomedianoNessuna valutazione finora

- Gravitational Waves and Their MathematicsDocumento15 pagineGravitational Waves and Their MathematicscibercafejavaNessuna valutazione finora

- Different Planets in Sixth House - Anoop Astrology SutraDocumento4 pagineDifferent Planets in Sixth House - Anoop Astrology SutraSamar VaishampayanNessuna valutazione finora

- What Is GPSDocumento4 pagineWhat Is GPSGen RabliNessuna valutazione finora

- Navigation 1Documento37 pagineNavigation 1Piche Parcon Dayatan100% (1)

- Rising Sign Is in 23 Degrees Pisces - Aries - TaurusDocumento2 pagineRising Sign Is in 23 Degrees Pisces - Aries - TaurusLafidan Rizata FebiolaNessuna valutazione finora

- Model DiffDocumento418 pagineModel DiffYeye Dash100% (1)

- Technology Lesson PlanDocumento5 pagineTechnology Lesson PlanalyssaleroseNessuna valutazione finora

- Vortices in Super Uid: TheoryDocumento20 pagineVortices in Super Uid: Theoryfernando4talaveraNessuna valutazione finora

- Amco+Spelling+Bee+2016 Word+ListsDocumento32 pagineAmco+Spelling+Bee+2016 Word+ListsKevin Lique67% (3)

- Realmspace RevisitedDocumento18 pagineRealmspace RevisitedAndrey Loginov100% (3)

- Chp13 p395 413Documento19 pagineChp13 p395 413Nik Nazri Nik Ghazali100% (3)

- Fact and Opinion Switch It Up PDFDocumento2 pagineFact and Opinion Switch It Up PDFRamsha Tjw50% (2)

- Can SETI Succeed Carl Sagan and Ernst Mayr Debate. (From Planetary Society's Bio Astronomy News, 1995.)Documento16 pagineCan SETI Succeed Carl Sagan and Ernst Mayr Debate. (From Planetary Society's Bio Astronomy News, 1995.)joymoraNessuna valutazione finora

- STS-51D Press KitDocumento27 pagineSTS-51D Press KitBob AndrepontNessuna valutazione finora

- Sepher Raziel (Sl. 3846)Documento70 pagineSepher Raziel (Sl. 3846)John Walter WojcikNessuna valutazione finora

- Kala Vedic Astrology SoftwareDocumento13 pagineKala Vedic Astrology Softwareasd dsaNessuna valutazione finora

- Planetary RelationshipsDocumento3 paginePlanetary RelationshipsLokuliyanaNessuna valutazione finora

- Cartesian To GeodeticDocumento25 pagineCartesian To GeodeticAndırıs PörtülgenNessuna valutazione finora

- Lab 03 EM Lines-1Documento12 pagineLab 03 EM Lines-1Mehul JoshiNessuna valutazione finora

- Historical Eclipses and Earth RotationDocumento574 pagineHistorical Eclipses and Earth Rotationpecinta dakwah IslamNessuna valutazione finora

- CarringtonDocumento29 pagineCarringtonTaryn Lee AverittNessuna valutazione finora

- Astronomy ExamDocumento3 pagineAstronomy ExamHaRu HaRuNessuna valutazione finora

- QuranDocumento2 pagineQuranapi-442727279100% (1)

- KP Methodology For Chart AnalysisDocumento4 pagineKP Methodology For Chart AnalysispjpropraveenssNessuna valutazione finora

- Admiralty Manual of Navigation, 1914Documento500 pagineAdmiralty Manual of Navigation, 1914andresmejia68100% (3)

- Earth Science SHS 2.1 The Origin of Planet EarthDocumento17 pagineEarth Science SHS 2.1 The Origin of Planet EarthSophia RomanaNessuna valutazione finora

- Prenatal EclipsesDocumento10 paginePrenatal EclipsesAnahiti Atena100% (3)