Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AW60

Caricato da

Fitra VertikalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AW60

Caricato da

Fitra VertikalCopyright:

Formati disponibili

EXTRUSION ALUMINIUM ALLOY

EN AW-6060

The alloy type EN AW-6060 is the most popular alloy on the European market, thanks to its high deformation

speed under heat.

It is used to produce sections, even with complex cross sections, that include many hollows and groves, so

that the design of the extruded piece is as near as possible to the finished article and to reduce intermediary

processes.

Physical characteristics

Thermal in state O:

3 2,09 W / cm °K

Volume mass : 2,70 g / cm conductivity at in state T6:

1,75 W / cm °K

20°C

Lower melting point: 605 °C -6

Specific heat between 0° and Linear thermal - 20°C - 100°C: 23,0⋅ 10 1 / °K

-6

100°C:

890 J/Kg °K expansion - 20°C - 200°C: 24,0 ⋅ 10 1 / °K

-6

2 coefficient - 20°C - 300°C: 25,0 ⋅ 10 1 / °K

Linear modulus of elasticity E: 69000 N / mm

Electrical µΩ ⋅ cm

Tangential modulus of elasticity 2 in state O: 3,14

26000 N/ mm resistivity at

G: in state T6: 3,25 µΩ ⋅ cm

20°C

Chemical composition according to European Standard EN 573.3

Others

Si Fe Cu Mn Mg Cr Zn Ti Each Total

Al

0,30 0,10 0,35

0,10 0,10 0,05 0,15 0,10 0,05 0,15

EN AW-6060 ÷ ÷ max max ÷ max max max max max

rest

0,60 0,30 0,60

Minimum mechanical properties, according to European Standard EN 755.2

Tensile Limit elasticity

Diameter D [mm] for rods

Types of

strength Rm load Rp0.2 [MPa] Elongation

profile

(1) Temper or thickness TH [mm] for bars

[MPa]

state or thickness of walls and for

sections A % A50mm %

min max min max

min min

T4 (*) D ≤ 150 S ≤ 150 120 - 60 - 16 14

D ≤ 150 S ≤ 150

Full bars

T5 160 - 120 - 8 6

T6 (*) D ≤ 150 S ≤ 150 190 - 150 - 8 6

T64 (*) D ≤ 50 S ≤ 50 180 - 120 - 12 10

T66 (*) D ≤ 150 S ≤ 150 215 - 160 - 8 6

T4 (*) 120 - 60 - 16 14

Extruded

T5 160 - 120 - 8 6

pipe

T6 (*) e ≤ 15 190 - 150 - 8 6

T64 (*) 180 - 120 - 12 10

T66 (*) 215 - 160 - 8 6

T4 (*) e ≤ 25 120 - 60 - 16 14

e ≤5 160 - 120 - 8 6

T5

5 < e < 25 140 - 100 - 8 6

Sections

e ≤3 190 - 150 - 8 6

T6 (*)

3 < e < 25 170 - 140 - 8 6

T64 (*) e ≤ 15 180 - 120 - 12 10

T66 (*) e ≤3 215 - 160 - 8 6

3 < e < 25 195 - 150 - 8 6

NOTE (*) for state F the values of the characteristics are just written as an indication

(1) see chart related to: “Description of the treatments and of the metallurgic states adopted in standard production”

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Product Catalog AluminiuDocumento32 pagineProduct Catalog AluminiusnoofsnoofNessuna valutazione finora

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDa EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesValutazione: 4.5 su 5 stelle4.5/5 (7)

- Cosmos Alminium-Technical - Specifications PDFDocumento2 pagineCosmos Alminium-Technical - Specifications PDFmindsopenNessuna valutazione finora

- Physical Electronics: Handbook of Vacuum PhysicsDa EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNessuna valutazione finora

- 30 CR Ni Mo 8Documento2 pagine30 CR Ni Mo 8Amy GriffinNessuna valutazione finora

- CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)Documento4 pagineCLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)PeterWayNessuna valutazione finora

- CR Mo 4Documento2 pagineCR Mo 4Mohsen ParpinchiNessuna valutazione finora

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDa EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresValutazione: 4 su 5 stelle4/5 (1)

- Tehnicke Karakteristike Asistal Alu OkapnicaDocumento2 pagineTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNessuna valutazione finora

- CuZn33 CatalogueDocumento9 pagineCuZn33 CataloguefedericoNessuna valutazione finora

- C2700Documento6 pagineC2700Andrew TanNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Tempering Conditions For 30CrNiMo8Documento2 pagineTempering Conditions For 30CrNiMo8madyeNessuna valutazione finora

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Documento1 paginaAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaNessuna valutazione finora

- T Work9000Documento2 pagineT Work9000Maike SongNessuna valutazione finora

- Cu-ETP: C11000 Industrial RolledDocumento4 pagineCu-ETP: C11000 Industrial Rolledsrsivaraman81Nessuna valutazione finora

- Stainless Steels 410: MartensiticDocumento2 pagineStainless Steels 410: MartensiticKiranNessuna valutazione finora

- 90 MN CR V8Documento1 pagina90 MN CR V8arunajay724Nessuna valutazione finora

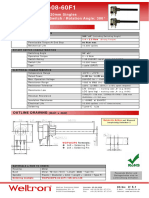

- Bedienungsanleitung 441128 Weltron 002045038962 Wcip20cips 08 60f1 4k7 20 Lin Dreh Potentiometer Mit Schalter Mono 04 W 47 K 1 STDocumento2 pagineBedienungsanleitung 441128 Weltron 002045038962 Wcip20cips 08 60f1 4k7 20 Lin Dreh Potentiometer Mit Schalter Mono 04 W 47 K 1 STEanBombingNessuna valutazione finora

- 310 Data SheetDocumento10 pagine310 Data SheetAbdullrahman AlzahraniNessuna valutazione finora

- 36NiCrMo16 PDFDocumento2 pagine36NiCrMo16 PDFAmy GriffinNessuna valutazione finora

- Datenblatt 441445 Weltron 002045039180 Wsfa202 A2 08 30f1 100k 20 Lin Dreh Potentiometer Mit Drehschalter Mono 04 W 100 K 1 STDocumento2 pagineDatenblatt 441445 Weltron 002045039180 Wsfa202 A2 08 30f1 100k 20 Lin Dreh Potentiometer Mit Drehschalter Mono 04 W 100 K 1 STEanBombingNessuna valutazione finora

- AmuDocumento2 pagineAmuavinashchauhan2695Nessuna valutazione finora

- CuZn30 PDFDocumento2 pagineCuZn30 PDFavinashchauhan2695Nessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Martin DuarteNessuna valutazione finora

- 34 CR Ni Mo 6Documento2 pagine34 CR Ni Mo 6hp_vijaykNessuna valutazione finora

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Documento4 pagineSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNessuna valutazione finora

- C1990-EH(HC)ver 1 0英文Documento6 pagineC1990-EH(HC)ver 1 0英文顏健軒Nessuna valutazione finora

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocumento10 pagineSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNessuna valutazione finora

- 102 CR 6Documento2 pagine102 CR 6ceca nikolicNessuna valutazione finora

- Nedal Alloy Datasheet en AW 6060Documento1 paginaNedal Alloy Datasheet en AW 6060ankur panwarNessuna valutazione finora

- Quenched and Tempered Alloyed Engineering Steel DINDocumento2 pagineQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNessuna valutazione finora

- 42crmo6 : Steel GradeDocumento2 pagine42crmo6 : Steel GradeYonas Dwiananta YuwonoNessuna valutazione finora

- 316 TiDocumento3 pagine316 TiRajeev ChandelNessuna valutazione finora

- Kme STOL76 C19010 enDocumento1 paginaKme STOL76 C19010 enMattia Terri TerrandoNessuna valutazione finora

- Cuzn37 Industrial RolledDocumento6 pagineCuzn37 Industrial RolledcvgfgNessuna valutazione finora

- 42 CR Mo 4Documento2 pagine42 CR Mo 4ElMacheteDelHuesoNessuna valutazione finora

- M.M.A. Welding ElectrodeDocumento1 paginaM.M.A. Welding ElectrodecwiksjNessuna valutazione finora

- Electrode ComparisionDocumento1 paginaElectrode ComparisionAnilNessuna valutazione finora

- Copper Cu-Dhp / Sf-Cu: Page 1/2Documento2 pagineCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNessuna valutazione finora

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocumento3 pagineProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNessuna valutazione finora

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Documento3 pagineHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNessuna valutazione finora

- M.M.A. Welding Electrode: Classifications & ApprovalsDocumento1 paginaM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNessuna valutazione finora

- SINOXX 4006 Steel: Designation by StandardsDocumento3 pagineSINOXX 4006 Steel: Designation by StandardsKiranNessuna valutazione finora

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Documento1 paginaAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNessuna valutazione finora

- Stainless Steel 1.4404 316lDocumento3 pagineStainless Steel 1.4404 316lDilipSinghNessuna valutazione finora

- Stainless Steel 1.4404 316lDocumento3 pagineStainless Steel 1.4404 316lDilipSinghNessuna valutazione finora

- Cu-HCP: C10300 Industrial RolledDocumento7 pagineCu-HCP: C10300 Industrial RolledpierocarnelociNessuna valutazione finora

- NIC Components NTL SeriesDocumento4 pagineNIC Components NTL SeriesNICCompNessuna valutazione finora

- Stainless Steels 430F: MartensiticDocumento2 pagineStainless Steels 430F: MartensiticRavindra ErabattiNessuna valutazione finora

- 34 CR Mo 4Documento2 pagine34 CR Mo 4Stefan GhNessuna valutazione finora

- Quality 1.4021 Chemical Composition: Lucefin GroupDocumento2 pagineQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNessuna valutazione finora

- D5sba10 D5sba60Documento2 pagineD5sba10 D5sba60Dimitris DimitriadisNessuna valutazione finora

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Documento4 pagineCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayNessuna valutazione finora

- CuETP PDFDocumento2 pagineCuETP PDFlovelyshreeNessuna valutazione finora

- Class Presentation M FG 318999 Sidney Shaol ADocumento28 pagineClass Presentation M FG 318999 Sidney Shaol AFitra VertikalNessuna valutazione finora

- LOUDEN Series 600 and 700 Monorail Track Fittings and Switches Installation Operation Maintenance and Parts ManualDocumento92 pagineLOUDEN Series 600 and 700 Monorail Track Fittings and Switches Installation Operation Maintenance and Parts ManualFitra VertikalNessuna valutazione finora

- Class Hand Out Im 473672 Demir AliDocumento23 pagineClass Hand Out Im 473672 Demir AliFitra VertikalNessuna valutazione finora

- Virtual Commissioning in The Factory: Learning ObjectivesDocumento25 pagineVirtual Commissioning in The Factory: Learning ObjectivesFitra VertikalNessuna valutazione finora

- Cq2 Z-Locking CylinderDocumento208 pagineCq2 Z-Locking CylinderFitra VertikalNessuna valutazione finora

- 2016E 00 Full PDFDocumento168 pagine2016E 00 Full PDFFitra VertikalNessuna valutazione finora

- It's STILL All in The Details - Tips & Tricks of Detailing in InventorDocumento22 pagineIt's STILL All in The Details - Tips & Tricks of Detailing in InventorFitra VertikalNessuna valutazione finora

- Class Presentation Im 322995 Florian Wegman NDocumento68 pagineClass Presentation Im 322995 Florian Wegman NFitra VertikalNessuna valutazione finora

- Cyclo 6000 Exploded ViewDocumento1 paginaCyclo 6000 Exploded ViewFitra VertikalNessuna valutazione finora

- Kissof Manual PDFDocumento1.017 pagineKissof Manual PDFFitra Vertikal100% (1)

- Automation Studio P6 Brochure PDFDocumento28 pagineAutomation Studio P6 Brochure PDFFitra VertikalNessuna valutazione finora

- Tutorial Week 3c - MECH3361 Workbench Guide PDFDocumento12 pagineTutorial Week 3c - MECH3361 Workbench Guide PDFVijendraAgarNessuna valutazione finora

- Ceiling Mounted CycloDocumento3 pagineCeiling Mounted CycloFitra VertikalNessuna valutazione finora

- Qlight Simple Catalogue (En)Documento59 pagineQlight Simple Catalogue (En)Anonymous MDkp0hnb3lNessuna valutazione finora

- 2 Fluid CouplingDocumento25 pagine2 Fluid CouplingFitra VertikalNessuna valutazione finora

- Development of Wall Jib Crane Design Systembased On Visual: Zhuli Liu, Zhuxinwang, Wei LiDocumento5 pagineDevelopment of Wall Jib Crane Design Systembased On Visual: Zhuli Liu, Zhuxinwang, Wei LiFitra VertikalNessuna valutazione finora

- Pulley Assembly 2015Documento1 paginaPulley Assembly 2015Fitra VertikalNessuna valutazione finora

- Bolt Nut Locking and Knock Pin Installation PDFDocumento3 pagineBolt Nut Locking and Knock Pin Installation PDFFitra VertikalNessuna valutazione finora

- Bolt Nut Locking and Knock Pin Installation PDFDocumento3 pagineBolt Nut Locking and Knock Pin Installation PDFFitra VertikalNessuna valutazione finora

- Robotics Guide enDocumento45 pagineRobotics Guide enFitra VertikalNessuna valutazione finora

- Bearing, Shear, and Tear-Out Stress?: What's The Difference BetweenDocumento2 pagineBearing, Shear, and Tear-Out Stress?: What's The Difference BetweenFitra VertikalNessuna valutazione finora

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Documento7 pagine0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanNessuna valutazione finora

- C ATILIVERDocumento8 pagineC ATILIVERFitra VertikalNessuna valutazione finora

- Fischer RM IIDocumento4 pagineFischer RM IIFitra VertikalNessuna valutazione finora

- Strength of Materials: (SI Units)Documento11 pagineStrength of Materials: (SI Units)Fitra VertikalNessuna valutazione finora

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Documento7 pagine0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanNessuna valutazione finora

- Bearing, Shear, and Tear-Out Stress?: What's The Difference BetweenDocumento2 pagineBearing, Shear, and Tear-Out Stress?: What's The Difference BetweenFitra VertikalNessuna valutazione finora

- Bucket For A Bucket ElevatorDocumento8 pagineBucket For A Bucket ElevatorFitra VertikalNessuna valutazione finora

- Orthoman OkDocumento156 pagineOrthoman OkFitra VertikalNessuna valutazione finora

- 2015 - KOBELCO - Arc Welding of High Tensile Strength SteelDocumento170 pagine2015 - KOBELCO - Arc Welding of High Tensile Strength SteelNhan vo vanNessuna valutazione finora

- Corporation Law Syllabus With Assignment of CasesDocumento4 pagineCorporation Law Syllabus With Assignment of CasesMarilou AgustinNessuna valutazione finora

- How To Use The R Software: July 2019Documento28 pagineHow To Use The R Software: July 2019Paul GokoolNessuna valutazione finora

- Murugan Temple of North America: Ahkpuf F Gankd - FZGJP JizDocumento8 pagineMurugan Temple of North America: Ahkpuf F Gankd - FZGJP JizOurMuruganTempleNessuna valutazione finora

- 2019 Specimen Paper 3 Mark SchemeDocumento6 pagine2019 Specimen Paper 3 Mark SchemeProjeck HendraNessuna valutazione finora

- Cisa 2Documento6 pagineCisa 2Ahmad MaaytahNessuna valutazione finora

- However, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To PrescriptionDocumento7 pagineHowever, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To Prescriptionkemsue1224Nessuna valutazione finora

- Rubric AutocadDocumento2 pagineRubric Autocadros maria100% (6)

- CS8792 CNS Unit5Documento17 pagineCS8792 CNS Unit5024CSE DHARSHINI.ANessuna valutazione finora

- Ashik KP - Windows Engineer - 6 00 - Yrs - Bangalore LocationDocumento4 pagineAshik KP - Windows Engineer - 6 00 - Yrs - Bangalore LocationmanitejaNessuna valutazione finora

- Property DigestDocumento9 pagineProperty DigestJoy OrenaNessuna valutazione finora

- Violence Against NursesDocumento22 pagineViolence Against NursesQuality Assurance Officer Total Quality ManagementNessuna valutazione finora

- Solar Smart Irrigation SystemDocumento22 pagineSolar Smart Irrigation SystemSubhranshu Mohapatra100% (1)

- From 1-73Documento95 pagineFrom 1-73Shrijan ChapagainNessuna valutazione finora

- Workflows in RUP PDFDocumento9 pagineWorkflows in RUP PDFDurval NetoNessuna valutazione finora

- Gendex 9200 enDocumento204 pagineGendex 9200 enArturo Jimenez Terrero80% (5)

- W01 358 7304Documento29 pagineW01 358 7304MROstop.comNessuna valutazione finora

- GT Reading Test 5, 2Documento2 pagineGT Reading Test 5, 2Muzammel Hossian MatinNessuna valutazione finora

- Allison at 500, at 1500 Series Parts Catalog: 2 1 See Section 10Documento7 pagineAllison at 500, at 1500 Series Parts Catalog: 2 1 See Section 10amin chaabenNessuna valutazione finora

- Scope: Manufacture of High Precision and CloseDocumento1 paginaScope: Manufacture of High Precision and CloseAnuranjanNessuna valutazione finora

- 2013 CATALOG - WebDocumento20 pagine2013 CATALOG - WebDevin ZhangNessuna valutazione finora

- Asus P8Z68-V PRO GEN3 ManualDocumento146 pagineAsus P8Z68-V PRO GEN3 ManualwkfanNessuna valutazione finora

- Optimizing The Office.: Transforming Business ProcessesDocumento10 pagineOptimizing The Office.: Transforming Business ProcessesNOSHEEN MEHFOOZNessuna valutazione finora

- BEVERAGE SERVICE INDUSTRY Lesson 1Documento18 pagineBEVERAGE SERVICE INDUSTRY Lesson 1milyn maramagNessuna valutazione finora

- Case Study: PointDocumento1 paginaCase Study: PointprasadzinjurdeNessuna valutazione finora

- Siningbayan Field Book PDFDocumento232 pagineSiningbayan Field Book PDFnathaniel zNessuna valutazione finora

- Appendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIDocumento20 pagineAppendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIhhbeckNessuna valutazione finora

- Isuzu 4be1 Engine Manual KolesooreDocumento5 pagineIsuzu 4be1 Engine Manual KolesooreRaymart Dealca75% (8)

- Cameron Residences - Official Project Brief - 080719Documento47 pagineCameron Residences - Official Project Brief - 080719neil dNessuna valutazione finora

- Key GroupsDocumento11 pagineKey GroupsJose RodríguezNessuna valutazione finora

- Privatization of ExtensionDocumento49 paginePrivatization of ExtensionLiam Tesat67% (3)