Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ISMR February 2015

Caricato da

Suresh GandikotaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ISMR February 2015

Caricato da

Suresh GandikotaCopyright:

Formati disponibili

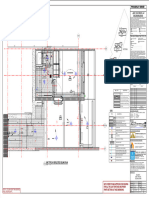

FOCUS ON CAD/CAM

After thorough testing, Fontana Pietro selected

AutoForm-ProcessDesignerforCATIA software for Fontana Group

its internal product development process With its claim “where ideas take

shape”, Fontana Pietro is

considered the ‘technological

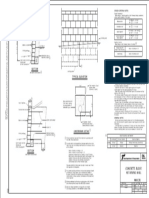

Addendum creation tailor’ of sports cars for its

DIE DESIGN

(Boundary Editor, Connect Editor) expertise in turning challenging

ideas into feasible and

extraordinary shapes.

Founded in 1956 as a

workshop for mechanical and

IN CATIA

trimming jobs, it is now divided

into three divisions: engineering,

manufacturing and assembling

of steel and aluminum parts for

Body-in-White. Its head office in

Calolziocorte (LC) manages two

factories in Italy, one in Turkey

and one in Romania.

ISMR SAYS : It is now a global leader,

employing 700 people, 60 of

“The creation of surfaces is becoming a critical aspect in this whom work in the engineering

complex market where the competitive edge is timing” department alone. Constantly

Development of flanges

on addendum (Flange oriented towards innovation and

Editor, Develop Flange) continuous improvement,

Fontana Group actively

S

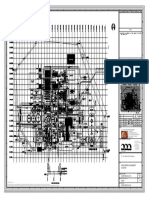

heet metal forming involves the creation Trim plan definition AutoForm-DieDesignerplus. These surfaces “Our objective”, continued Cavenago, “is to collaborates with universities

of surfaces which, depending upon their (Trim Segment Editor) were not easy to handle within CAD. It became use AutoForm-ProcessDesignerforCATIA with any and research centres. The

own complexity, enable adjustments to clear that this procedure was slow, complex of our customers’ files. We hope to create an Fontana Group uses tools and

be made at the right time and to the desired and, above all, time-consuming for the creation even closer connection between AutoForm- technologies that include

level of precision and quality. This is a key of CAD quality surfaces which could be DieDesignerplus and AutoForm- AutoForm software and, in

concern for the technicians working for the immediately used in CNC machining,” added ProcessDesignerforCATIA to reproduce the particular, AutoForm-

engineering department at Fontana Pietro. Riccardo Brivio, R&D Engineer, Fontana Pietro. parameters already defined during simulation ProcessDesignerforCATIA for the

Fontana Group activities encompass AutoForm-ProcessDesignerforCATIA software is on surfaces or drawbeads.” rapid creation of high quality

engineering; die design and construction; what AutoForm itself terms ‘the strategic In accordance with customer requirements, CAD surfaces.

car body production and interior design missing link which enables the user to create a better integration is required with even more www.fontana-group.com

construction. Fontana Pietro is the Group’s die layout, which includes not only the drawing targeted features to make these procedures

headquarters in Italy and has been the but also all secondary operations, without having faster and more efficient. AutoForm AutoForm Engineering GmbH

domestic and international reference point for to leave the CATIA environment’. The software, Engineering has already planned a new market AutoForm offers software

the design and manufacture of stamping dies says AutoForm, fulfils these requirements and release to make some of these functions solutions for the die-making and

in sheet metal forming for over 50 years. It offers significant benefits in terms of time available. This release will be an update, to be sheet metal forming industries

serves well known, prestigious automotive reduction and fewer mistakes made. followed by others, that will make the software along the entire process chain.

www.autoform.com

OEMs around the world. faster and immediately effective, even when

To meet the needs of its customers in terms From theory implemented with other software systems.

of lead time, precision and quality of surfaces, to practice

Fontana Pietro started testing the features To assess the operating potential and Quality in focus

offered by AutoForm-ProcessDesignerforCATIA in adaptability of AutoForm-ProcessDesignerforCATIA, “The positive feedback received on the

2013. This software is dedicated to the rapid the engineering department carried out performance of AutoForm-ProcessDesignerforCATIA few, very powerful features which enable easy

creation of high quality CAD surfaces. Engineering to investigate the benefits offered does not offer solutions for those working in thorough tests on a designated project of one has convinced Fontana Pietro to extend the use and rapid surface design. A comprehensible

Following positive feedback, the software was by the AutoForm-ProcessDesignerforCATIA the design and manufacture of stamping dies production line. At the same time, two further of it to other departments within the company, data structure simplifies the usage of these

bought and implemented internally within its software. From the very beginning, it has and, more importantly, it does not fulfil our projects were carried out implementing the such as in its Die Process Engineering new features and improves collaboration

product development process to optimise the demonstrated the potential to meet our needs.” specific needs,” pointed out Giuseppina Milani, strategies currently in use. department. The die process engineer’s job is internally. The surfaces created are

methodologies and strategies already in place. AutoForm-ProcessDesignerforCATIA, one of the Die Surfaces Coordinator, Fontana Pietro. “Each of the three projects”, explained facilitated, especially when elaborating the early characterised by a significantly reduced

software products which AutoForm offers for The creation of surfaces is becoming a Cavenago, “employed the same work phases. product development phase, thanks to the number of control elements and appropriate

Staying in the die-making and sheet metal forming critical aspect in this complex market where We noticed that, when applying the features of validity and speed of analysis. What is significant surface continuity. These high quality surfaces

the CATIA industries, connects competence in sheet metal the competitive edge is timing. The AutoForm-ProcessDesignerforCATIA, the are the benefits and advantages that include the can immediately be used for further

environment forming with the effective design functionalities engineering department at Fontana required a designated project clearly showed relevant re-use and reproducibility of data, the efficient operations, such as over-crowning,

“We are satisfied”, said Valentina of CATIA V5. This software enables company- direct connection, not a manual transition, time savings.” exchange of data (internally among departments compensation or CNC machining.”

Cavenago, Senior Die Surfaces wide workflow standardisation and a significant between the conceptual creation of surfaces When compared to a CATIA license, the and externally among OEMs and their suppliers) “Over-crowning,” concluded Guglielmo

Technician, Fontana Pietro, “with reduction in the time needed to create high carried out by engineers and the creation of software can be used during the running and the rapid creation of a die layout that Oleari, R&D Engineer, Fontana Pietro, “will be

this collaboration with AutoForm quality CAD surfaces. surfaces which can be immediately used for session by adding the AutoForm- includes drawing as well as all secondary the object of further and future operating

“CATIA has been used in our engineering CNC machining. ProcessDesignerforCATIA license every time it is operations,” added AutoForm. strategies by our company. Rules will be

Valentina Cavenago, Senior Die Surfaces department for over 25 years. Although it is “We had a fast and efficient simulation required. At the same time, the software “The various sketches and construction generated to further reduce the time needed to

Technician at Fontana Pietro certainly a powerful system, it unfortunately method based on surfaces created with allows for a high quality level of data update. elements used in CATIA V5 are assembled in a develop surfaces.” ■

36 | sheetmetalplus.com | ISMR February 2015 ISMR February 2015 | sheetmetalplus.com | 37

Potrebbero piacerti anche

- Instant Assessments for Data Tracking, Grade K: MathDa EverandInstant Assessments for Data Tracking, Grade K: MathNessuna valutazione finora

- TOGAF Poster Series 12 Models and ArchitectureDocumento1 paginaTOGAF Poster Series 12 Models and ArchitectureIan JaredNessuna valutazione finora

- Leica iCON Build Construction Layout BRO PDFDocumento2 pagineLeica iCON Build Construction Layout BRO PDFAPRWSEA WGNessuna valutazione finora

- MAG'Impact: The High-Performance Impactor: Cubicity and SimplicityDocumento5 pagineMAG'Impact: The High-Performance Impactor: Cubicity and SimplicityPrekelNessuna valutazione finora

- Dilworth's New Fire Hall PlansDocumento7 pagineDilworth's New Fire Hall PlansMelissa Van Der StadNessuna valutazione finora

- Mind MapDocumento1 paginaMind Mapapi-552131457Nessuna valutazione finora

- Lighting Electrical layout-EP-04Documento1 paginaLighting Electrical layout-EP-04Madelo, Allysa Mae, M.Nessuna valutazione finora

- ACCA F1 Chapter 2 - MuralDocumento1 paginaACCA F1 Chapter 2 - Muraltrường giangNessuna valutazione finora

- Cs4 5000 Brochure Uk Intec 020714 PrintDocumento2 pagineCs4 5000 Brochure Uk Intec 020714 PrintFrederik NeytNessuna valutazione finora

- Namahn 2004posterDocumento1 paginaNamahn 2004posterSumit KumawatNessuna valutazione finora

- Strip o Ce Façade: Converted Building Vacant o Ce Building Unit Design Construction in StepsDocumento3 pagineStrip o Ce Façade: Converted Building Vacant o Ce Building Unit Design Construction in StepsBruno MeloNessuna valutazione finora

- BOXiQ Jumeriah Park ConceptDocumento42 pagineBOXiQ Jumeriah Park ConceptEmili NoyaNessuna valutazione finora

- NX CAD CAM CAE - Bundle - Quick Reference (Jun2020)Documento2 pagineNX CAD CAM CAE - Bundle - Quick Reference (Jun2020)Thanakorn VichiensamuthNessuna valutazione finora

- (EN) Prezentare Evo DesignDocumento14 pagine(EN) Prezentare Evo DesignMarius NicNessuna valutazione finora

- Down Twon 7-1-2023Documento1 paginaDown Twon 7-1-2023Ayman MohdNessuna valutazione finora

- Command Line The Computer-Aided Office PDFDocumento1 paginaCommand Line The Computer-Aided Office PDFMukul GuptaNessuna valutazione finora

- Poster PA 2015 en A1Documento1 paginaPoster PA 2015 en A1Dalat TigonNessuna valutazione finora

- Report Rapid Manufacturing in Facade DesignDocumento113 pagineReport Rapid Manufacturing in Facade DesignSai SrimanthNessuna valutazione finora

- Neighbor'S Plot - : Sheet No Rev No R0Documento1 paginaNeighbor'S Plot - : Sheet No Rev No R0jibeesh cmNessuna valutazione finora

- Product Focus PMJ02 PropositionsDocumento24 pagineProduct Focus PMJ02 PropositionsPieter Van LijsebettenNessuna valutazione finora

- Simulation of Fan Blade Out Event in A Gas Turbine Engine: Devendra Singh BhatiDocumento12 pagineSimulation of Fan Blade Out Event in A Gas Turbine Engine: Devendra Singh BhatiDevendra SinghNessuna valutazione finora

- Reinforced Walls Design ManualDocumento17 pagineReinforced Walls Design ManualNANA ADDONessuna valutazione finora

- The Sustainable Concrete Guide: Andrea J. Schokker, EditorDocumento183 pagineThe Sustainable Concrete Guide: Andrea J. Schokker, EditorDaniel ReynoldsNessuna valutazione finora

- Detail ADocumento1 paginaDetail ASardar DwivediNessuna valutazione finora

- B103015019 葉米亞Documento1 paginaB103015019 葉米亞文件資料Nessuna valutazione finora

- CCDC NTL Ar Una1 RCP 01Documento1 paginaCCDC NTL Ar Una1 RCP 01ericka.mir401Nessuna valutazione finora

- Aiag Vda - d and P-fmea表格英文版Documento22 pagineAiag Vda - d and P-fmea表格英文版isolongNessuna valutazione finora

- Section Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignDocumento1 paginaSection Piping General Arrangment: Hi - Tech Carbon RCC Stack DesignAbhijeet OundhakarNessuna valutazione finora

- Project Report On Customer Satisfaction Regarding Mahindra BoleroDocumento76 pagineProject Report On Customer Satisfaction Regarding Mahindra BoleroTarun Kathiriya100% (1)

- Fundamentals of Creating A Great UI - UXDocumento31 pagineFundamentals of Creating A Great UI - UXMd Rodi Bidin100% (4)

- Plano Eléctrico d7r TractorDocumento4 paginePlano Eléctrico d7r TractorCarlos Andres Ávila PuertaNessuna valutazione finora

- Mechanics of Metal CuttingDocumento23 pagineMechanics of Metal CuttingDr-Bharath Vedashantha MurthyNessuna valutazione finora

- Proiect C&a PDFDocumento8 pagineProiect C&a PDFCristian PaladeNessuna valutazione finora

- Curs de Desen Tehnic IndustrialDocumento25 pagineCurs de Desen Tehnic IndustrialValentin PetrescuNessuna valutazione finora

- The Nigerian Society of Engineers April 2013 Professional Examination Summary of Candidaes Performance, Warri CentreDocumento4 pagineThe Nigerian Society of Engineers April 2013 Professional Examination Summary of Candidaes Performance, Warri CentreAnonymous jlLBRMAr3ONessuna valutazione finora

- Floor Plan and Wall Treatment Mechanical Electrical Plan: LegendDocumento1 paginaFloor Plan and Wall Treatment Mechanical Electrical Plan: LegendSilvia PratiwiNessuna valutazione finora

- 23opt17682-001-A1L DWGDocumento1 pagina23opt17682-001-A1L DWGJames Hampton GreenieNessuna valutazione finora

- Aykut TeknikDocumento3 pagineAykut TeknikMurat SuakNessuna valutazione finora

- SpeedhumpDocumento1 paginaSpeedhumpCarlos MakheleNessuna valutazione finora

- Goldfields-Esperance Key In-Print & Online Advertising ApprovalDocumento1 paginaGoldfields-Esperance Key In-Print & Online Advertising ApprovalJO JONessuna valutazione finora

- Appendix B2 S - CurveDocumento1 paginaAppendix B2 S - CurveSushant Raje BhosaleNessuna valutazione finora

- Utilities Substation Construction and Maintenance WorkflowDocumento1 paginaUtilities Substation Construction and Maintenance WorkflowmanhNessuna valutazione finora

- Modular MD: State-of-the-Art ICU Facilities For Rapid Medical ResponseDocumento2 pagineModular MD: State-of-the-Art ICU Facilities For Rapid Medical ResponseakinravNessuna valutazione finora

- 02 ISA-Skill MatrixDocumento6 pagine02 ISA-Skill MatrixJack LaksmanaNessuna valutazione finora

- Interior Office Lobby Concept View: Interior Lobby Elevation 2 - West Side Shown, East Side Is SimilarDocumento1 paginaInterior Office Lobby Concept View: Interior Lobby Elevation 2 - West Side Shown, East Side Is Similartito_matrixNessuna valutazione finora

- 0000gf Also AsloaDocumento1 pagina0000gf Also AsloaAhmadjakwarNessuna valutazione finora

- Basic Engineering Design Data: Studi Tecnologie Progetti S.P.ADocumento1 paginaBasic Engineering Design Data: Studi Tecnologie Progetti S.P.ATAHIR MAHMOODNessuna valutazione finora

- Performance Manage MenDocumento1 paginaPerformance Manage MenmariaaltammamNessuna valutazione finora

- 9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)Documento1 pagina9946Z - 0657-SP-SL-PL-C-G20-001 (P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNessuna valutazione finora

- Product Focus PMJ14 Product MarketingDocumento24 pagineProduct Focus PMJ14 Product MarketingBarry IbrahimaNessuna valutazione finora

- ETEEAP BS ME Project Management - 2022-2023-2Documento8 pagineETEEAP BS ME Project Management - 2022-2023-2Roderick P. ManaigNessuna valutazione finora

- RW Tew 22Documento1 paginaRW Tew 22Yong TonghannNessuna valutazione finora

- Huot Henglong - Shop DrawingDocumento21 pagineHuot Henglong - Shop Drawinghuothenglong.sdh231Nessuna valutazione finora

- REM - Building For Life Booklet, Part 2Documento7 pagineREM - Building For Life Booklet, Part 2malehaleNessuna valutazione finora

- RW CB 22Documento1 paginaRW CB 22Yong TonghannNessuna valutazione finora

- Department of Architecture Faculty of Civil Engineering and PlanningDocumento1 paginaDepartment of Architecture Faculty of Civil Engineering and PlanningMuhammad Wildan SahidillahNessuna valutazione finora

- Instant Assessments for Data Tracking, Grade 2: MathDa EverandInstant Assessments for Data Tracking, Grade 2: MathNessuna valutazione finora

- Instant Assessments for Data Tracking, Grade 5: MathDa EverandInstant Assessments for Data Tracking, Grade 5: MathNessuna valutazione finora

- SMIT TEXTILE Awarded For Product InnovationDocumento2 pagineSMIT TEXTILE Awarded For Product InnovationgomzielpNessuna valutazione finora

- Final SubmissionDocumento17 pagineFinal Submissionapi-3486299090% (1)

- Food Product Innovation PDFDocumento35 pagineFood Product Innovation PDFDidik HariadiNessuna valutazione finora

- New Product Development of PepsiDocumento1 paginaNew Product Development of Pepsisamirather100% (1)

- JNTUH MBA R17 III Semester SyllabusDocumento16 pagineJNTUH MBA R17 III Semester SyllabusNandhiniNessuna valutazione finora

- OPS/571 Week 1 Quiz 100% AnswersDocumento4 pagineOPS/571 Week 1 Quiz 100% AnswersStephanie YeagerNessuna valutazione finora

- MetricsGuidebook 1995-0725Documento143 pagineMetricsGuidebook 1995-0725waste33Nessuna valutazione finora

- Bikano Project ReportDocumento74 pagineBikano Project ReportGurpal Singh100% (1)

- Ford MotorDocumento3 pagineFord MotorSwarupa KudaleNessuna valutazione finora

- Documentation Matrix DS-QMS-00-R2 PDFDocumento19 pagineDocumentation Matrix DS-QMS-00-R2 PDFDhinakaranNessuna valutazione finora

- Radical Innovation at Philips Lighting: ©2009 Dorothea Seebode, Gerard Harkin and John BessantDocumento30 pagineRadical Innovation at Philips Lighting: ©2009 Dorothea Seebode, Gerard Harkin and John BessantMuhammad Ammar YasirNessuna valutazione finora

- New Product Development WorksheetDocumento3 pagineNew Product Development WorksheetMian Aamir IlyasNessuna valutazione finora

- 100 Best-Selling Cases, 2008 EditionDocumento30 pagine100 Best-Selling Cases, 2008 EditionGaurav BasnyatNessuna valutazione finora

- Assignment of PoonamDocumento73 pagineAssignment of PoonamPinky ChowdhuryNessuna valutazione finora

- MGT301 MIDTERM Solved PDFDocumento69 pagineMGT301 MIDTERM Solved PDFAli BhattiNessuna valutazione finora

- Lecture02 - MEMS Design FlowDocumento16 pagineLecture02 - MEMS Design FlowMohamed El SheikhNessuna valutazione finora

- Quality ControlDocumento3 pagineQuality ControlAnkit0% (2)

- Book Reviews: Book Review Editor: Teresa Jurgens-KowalDocumento4 pagineBook Reviews: Book Review Editor: Teresa Jurgens-KowalAndrew S. FarmNessuna valutazione finora

- NPD Ent600 - NPD - Guidelines - Template - AmendmentDocumento6 pagineNPD Ent600 - NPD - Guidelines - Template - AmendmentIrfan SyafiqNessuna valutazione finora

- SMEs HEIs Automotive and South AfricaDocumento32 pagineSMEs HEIs Automotive and South Africachrissy2011Nessuna valutazione finora

- Marketing q2 - Clas1 - PRODUCT-STRATEGYDocumento10 pagineMarketing q2 - Clas1 - PRODUCT-STRATEGYaraNessuna valutazione finora

- Eco Design ManualDocumento4 pagineEco Design Manualacampos2012Nessuna valutazione finora

- General Manager Sales Operations in San Diego CA Resume Mike PerkinsDocumento2 pagineGeneral Manager Sales Operations in San Diego CA Resume Mike PerkinsMikePerkins3Nessuna valutazione finora

- Dyson Appliances Innovation AuditDocumento15 pagineDyson Appliances Innovation AuditJatin Satija0% (1)

- Nivea (A)Documento2 pagineNivea (A)sukriti guptaNessuna valutazione finora

- EG ArtiosCAD EG PDFDocumento5 pagineEG ArtiosCAD EG PDFTEBIBNessuna valutazione finora

- Hill 8e Basic Ch04Documento32 pagineHill 8e Basic Ch04Adnan Ahmad Al-NasserNessuna valutazione finora

- Test Bank Ch. 8 Developing New Product-1Documento5 pagineTest Bank Ch. 8 Developing New Product-1Hạ XuânNessuna valutazione finora

- 2013 FDM 1Documento21 pagine2013 FDM 1Aizrul ShahNessuna valutazione finora

- Tourism Sector Market System AnalysisDocumento31 pagineTourism Sector Market System AnalysisDhimiterTola100% (1)