Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mooring and Unmooring: PPE To Be Used

Caricato da

tonyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mooring and Unmooring: PPE To Be Used

Caricato da

tonyCopyright:

Formati disponibili

Mooring and unmooring

This ARBO chapter is part of the

Health and Safety Index for the

shipping industry.

This chapter contains the measures that must be taken to ensure the safe

It is intended to help employers to mooring and unmooring and to minimise potential hazards.

comply with the requirements of

health and safety legislation. It may be

used as a checklist by employees.

It contains the necessary measures to PPE to be used

be taken in order to safely carry out

certain work-related activities.

Compliance with these regulations, or

alternative regulations offering an

equivalent level of protection, is

essential.

This chapter contains health and

safety regulations to ensure safe Various factors in mooring/unmooring

mooring and unmooring procedures.

vessels:

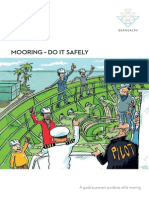

In order to safely moor/unmoor seagoing ships, a number of factors will

Employees’ checklist have to be taken into consideration. In addition, equipment, experience

and on-board organisation are vital in ensuring smooth

■ Always use an adequate mooring/unmooring:

number of crew when Availability of sufficient (experienced) crew

mooring/unmooring Mutual supervision

Preparation

■ Make each other aware of Communication

unsafe situations Sound division of labour and appropriate supervision

Maintenance of all equipment

■ Familiarise yourself with the

equipment used in order to be

able to spot any wear and tear Be vigilant

at an early stage In many instances accidents do not happen because of the complicated

nature of a manoeuvre, but rather because of lack of care and attention

■ Provide supervision at stem whilst carrying out a (simple) job:

and stern whilst You have a legal obligation to point out unsafe routines and/or

mooring/unmooring incorrect usage of protective equipment to the people you work

with.

■ Has the mooring plan been

discussed?

■ Use well-working

communication equipment

■ Do not carry out more than

one aspect of the job at any

one time (like manning winch

and handling ropes)

1

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

Organisation and safety

✓Communication equipment has been tested and agreement has been

reached on the division of labour; the crew has been briefed on the

mooring plan.

✓All supervising officers are familiar with the nature of the equipment

used. Experience and vigilance are vital in the prevention of accidents

Supervising officers shall have a working knowledge of:

• The characteristics of the ropes, springs and warps used

• The ropes’ breaking strength

• The criteria for condemning ropes, springs and warps

• Operating winches

• Communication

• Holding power brake band

• Winches’ self tensioning properties

• Winches’ heavingpower

• The mooring plan

• The location of capstans and hawsoles and the correct handling

of mooring ropes along them

• The work to be carried out

• The snap-back zones (see schedule of danger zones)

✓ Supervision over and operation of winches and capstans should be in

the hands of experienced crew.

✓ Officers in charge should have an overall picture of the situation at all

times

✓ Preparation of the work space is vital to safety at work.

✓ Work should only be carried out by authorised persons.

Equipment

✓ All tools and equipment used should be inspected and maintained

regularly.

✓ All of the mooring gears movable parts should be current.

✓The surfaces of all hawsoles, fairleads, cable guides, bollards and

warping ends should be kept clean and in good working order

✓ Ropes and warps should be in good condition and should have been

inspected

2

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

By being familiar with the danger zones on deck,

crew members will become aware of

the potential hazards present.

Marked zones: snap-back zones.

✓ Care, control and maintenance are of prime importance, however,

always be aware that ropes may snap at any time.

✓ Lay-out and equipment –and therefore the mooring plan too– are

different on every ship. For that reason make sure to study a ship’s lay-

out on boarding.

✓ The operational direction will have been clearly marked, both on the

drum and the handle

✘ Unclear workspaces increase the risk of accidents.

Mooring and unmooring

✓An adequate number of experienced crew will be available

✓Whilst moored, regular checks should be carried out to ensure that the

vessel is still alongside safely (“mooring rounds”)

✓Crew will take into account the effects of:

• The wind

• The current

• Suction from passing ships

• Waves and swell

• The tide

• The ships movements as a result of cargo operations

✓Always maintain a safe distance from warping ends/drums to prevent

becoming trapped. (keep hands and fingers free)

3

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

✓Sound communication between ship and shore (and tug if and when

applicable) is of the essence

✓Wear stout protective gloves to ensure a strong grip as rope burns and

steel cables have burrs

✓Be vigilant of observers whilst mooring and unmooring: ropes may snap

at any time

✘ Do not ever lay ropes and warps around sharp corners. When using a

winch, the angle to the hawsole should be as large as possible.

✘ Do not ever stand close to taut ropes or warps and stay clear of the

snap-back zone.

✘ As much as possible, stand behind the warping end when handling

ropes; avoid the side of the taut rope.

✘ Do not ever stand inside a bend or loop of any rope or warp.

✘ Stay clear of moving parts.

✘ Beware of heaving lines being thrown aboard from tugs or shore

Stopping and belaying ropes

✓ For preference, do not just belay a rope by using figures-of-eight:

instead first hitch it twice around the lower side of the bollard (see

picture)

✓ Using a winch to handle ropes and warps should never be done by one

single person.

✓ Level out stress on ropes as much as possible

✓ Be aware of the different elasticity of the various materials

✘ Do not leave stoppers attached to rope after use (see picture)

4

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

Some options for stopping ropes

5

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

✘ Avoid too many turns on the drum (picture)

✘ Steel cables must not be belayed on top of ropes.

✘ When using ‘split drum’ never allow a double layer on the working part

to avoid fouling and/or trapping/damaging ropes.

Steel cables

✓ Steel cables must be stopped with chain stoppers which should run in

the opposite direction to that of the cable in question.

✓ Steel cables must not kink whilst being ran out or heaved up

✓ Only special shackles should be used to connect steel cables to ropes

(e.g. Tonsberg)

✘ Beware of burrs: use stout leather gloves.

Physical strain

✓ When using mooring gear, the availability of sufficient manpower to

reduce physical strain is vital

✘ Avoid manual pulling on ropes as much as possible to avoid straining –

and possibly injuring – the back.

Storage

✓ After use, ropes should be stored clear of the deck (picture)

6

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

Further information / documentation used

✓ Arbeidsomstandighedenbesluit en beleidsregels

(Netherlands’ Labour Conditions Decree and Policy Rules)

✓ “Dat is juist / Safety first”

✓ IMCASF P&I publications Jan 2009 Mooring incidents

✓ Effective Mooring (OCIMF)

✓ Mooring Equipment guidelines Sec edition 1997 OCIMF

✓ MCA Code of Safe Working Practice for Merchant Seamen

7

Printed and Published by www.arbocatalogus.com, www.kvnr.nl, www.nautilusnl.org

English Version 0.2

Potrebbero piacerti anche

- Mooring and UnmooringDocumento7 pagineMooring and UnmooringDnv Bailey0% (1)

- SEAM 1 WK 9 12Documento104 pagineSEAM 1 WK 9 12Jayren Abdul BakarrNessuna valutazione finora

- Basket 2Documento1 paginaBasket 2Bilal tahirNessuna valutazione finora

- Q4 2017 Ship-To-Ship-Operation-LetDocumento14 pagineQ4 2017 Ship-To-Ship-Operation-LetNigel SionoNessuna valutazione finora

- Safety Letter 02-16Documento68 pagineSafety Letter 02-16Marius-Cristian GindacNessuna valutazione finora

- Marine Operations RevisionDocumento36 pagineMarine Operations RevisionCacc BacNessuna valutazione finora

- Anchor Handling and Towing OperationsDocumento37 pagineAnchor Handling and Towing OperationsRomi Oktavianus67% (3)

- Capstan (OSRV) SOPDocumento7 pagineCapstan (OSRV) SOPakbar muslimNessuna valutazione finora

- Concrete Bucket Safety2 PDFDocumento3 pagineConcrete Bucket Safety2 PDFMuhammad Hamzah Habibburrahman100% (2)

- SSB 16 2020eDocumento3 pagineSSB 16 2020eCharalampos ChatzivasileiouNessuna valutazione finora

- Course: MTEC 102 Period: PRELIM Week: 2 Session: 1 Topic: Procedures For Safe Mooring-Deployment and Monitoring of Moorings For Cargo ShipDocumento14 pagineCourse: MTEC 102 Period: PRELIM Week: 2 Session: 1 Topic: Procedures For Safe Mooring-Deployment and Monitoring of Moorings For Cargo ShipMeljorin LayeseNessuna valutazione finora

- Marine Notice 04 2022 Safe Hatch HandlingDocumento1 paginaMarine Notice 04 2022 Safe Hatch Handlingreynold deepakNessuna valutazione finora

- BSEE Safety Alert 468 - Red Zone Hazards Pose Increased Risk To Personnel During Lifting OperationsDocumento3 pagineBSEE Safety Alert 468 - Red Zone Hazards Pose Increased Risk To Personnel During Lifting OperationsmakramNessuna valutazione finora

- Lashing It Down!: Guidance On The Correct Use of Lashings Systems On Container VesselsDocumento2 pagineLashing It Down!: Guidance On The Correct Use of Lashings Systems On Container VesselsJosé PintoNessuna valutazione finora

- Crane OperationDocumento40 pagineCrane OperationZeeshan Javaid WarraichNessuna valutazione finora

- Avoiding "Death Traps On Ships" - Understanding Dangers of Mooring OperationDocumento9 pagineAvoiding "Death Traps On Ships" - Understanding Dangers of Mooring OperationSubbu JsrNessuna valutazione finora

- Crane SafetyDocumento8 pagineCrane SafetyRaghu Dev Hosur100% (1)

- Instructions For The Safe Use Of: Flat Woven Webbing SlingsDocumento2 pagineInstructions For The Safe Use Of: Flat Woven Webbing SlingsMontadhar SaeedNessuna valutazione finora

- Anchoring, Mooring/BerthingDocumento13 pagineAnchoring, Mooring/BerthingLiviu VladNessuna valutazione finora

- Mooring Operation and Safety For Cadets 56 Batch 2021Documento10 pagineMooring Operation and Safety For Cadets 56 Batch 2021sadmannoor56Nessuna valutazione finora

- Wire Rope Slings SI 2.3Documento2 pagineWire Rope Slings SI 2.3reda mesbahNessuna valutazione finora

- Instructions For The Safe Use of Flat Woven Webbing SlingsDocumento4 pagineInstructions For The Safe Use of Flat Woven Webbing SlingsavisheklochunNessuna valutazione finora

- QMF 123 Instructions For The Use of Wedge SocketsDocumento2 pagineQMF 123 Instructions For The Use of Wedge Socketsmanglesh1Nessuna valutazione finora

- Deck Seamanship and Shipboard Safety: NS 101 Captain N. A. ReedDocumento14 pagineDeck Seamanship and Shipboard Safety: NS 101 Captain N. A. Reedibrafeeu83% (6)

- Safety Alert - ConveyorsDocumento2 pagineSafety Alert - ConveyorsHIPAPNessuna valutazione finora

- Instructions For The Safe Use Of: Fibre Rope SlingsDocumento2 pagineInstructions For The Safe Use Of: Fibre Rope SlingsMontadhar SaeedNessuna valutazione finora

- Anchor Handling EquipmentDocumento33 pagineAnchor Handling EquipmentJayvee Bongon Galos89% (9)

- MooringDocumento1 paginaMooringmarwin violagoNessuna valutazione finora

- Cabin Operations Planned Ditching - Unplanned DitchingDocumento12 pagineCabin Operations Planned Ditching - Unplanned DitchingHung NguyenNessuna valutazione finora

- SOP-13-Loading and Offloading Casings With CraneDocumento7 pagineSOP-13-Loading and Offloading Casings With CraneDQE040 HSSENessuna valutazione finora

- Concrete Basket 2-3Documento2 pagineConcrete Basket 2-3Bilal tahirNessuna valutazione finora

- Material Basket TrainingDocumento2 pagineMaterial Basket TrainingBilal tahirNessuna valutazione finora

- Wire Rope Slings Si 2 - 2 EmmDocumento2 pagineWire Rope Slings Si 2 - 2 EmmheppyfaebanffNessuna valutazione finora

- Why Master Standing Instructions Is Important??Documento11 pagineWhy Master Standing Instructions Is Important??Владислав Комаров100% (1)

- DOCK Top of Containers On Board ShipDocumento5 pagineDOCK Top of Containers On Board ShipVignesh KmNessuna valutazione finora

- Proper Procedure For Anchoring and Mooring: - Group 2Documento45 pagineProper Procedure For Anchoring and Mooring: - Group 2Jerry Flores100% (2)

- Safe Mooring and AnchoringDocumento51 pagineSafe Mooring and AnchoringAhmad Imran100% (1)

- 7A. Crane & Hoist SafetyDocumento2 pagine7A. Crane & Hoist SafetySantos RexNessuna valutazione finora

- Cargo SafetyDocumento6 pagineCargo SafetyGaurav MaithilNessuna valutazione finora

- LEEA - Instruction For Safe Use of Flat Woven Webbing SlingsDocumento2 pagineLEEA - Instruction For Safe Use of Flat Woven Webbing Slingsdonnyars1979Nessuna valutazione finora

- Lecture 3. TOWINGDocumento3 pagineLecture 3. TOWINGFlint KNessuna valutazione finora

- Working Safely: Around Overhead CranesDocumento2 pagineWorking Safely: Around Overhead CranesParth PatelNessuna valutazione finora

- Crane Safety: Stability and Tipping: Remember ThisDocumento2 pagineCrane Safety: Stability and Tipping: Remember Thismiraç burak navruzNessuna valutazione finora

- Century t500 Parts 55145Documento482 pagineCentury t500 Parts 55145Luis OrellanaNessuna valutazione finora

- Quickmooringsafetyalert - 24 04 05Documento1 paginaQuickmooringsafetyalert - 24 04 05d_damnNessuna valutazione finora

- Code of Safe Working Practices: Objectives & ContentsDocumento8 pagineCode of Safe Working Practices: Objectives & Contentssidadams2Nessuna valutazione finora

- Anchor ProcedureDocumento5 pagineAnchor ProcedureRahulChoudharyNessuna valutazione finora

- Craneblock WulDocumento2 pagineCraneblock WulZachNessuna valutazione finora

- STCI /TF-CM/CVF-18 Rev. No. 00 Issued: 6-20-12 Approved: RTDDocumento99 pagineSTCI /TF-CM/CVF-18 Rev. No. 00 Issued: 6-20-12 Approved: RTDRolando DumelodNessuna valutazione finora

- Ship Towage Guidelines MedwayDocumento17 pagineShip Towage Guidelines MedwayMichael Pascual100% (2)

- Unsafe Working Practices While Working Aloft and Over The SideDocumento2 pagineUnsafe Working Practices While Working Aloft and Over The SideDaniel Edd BaccolNessuna valutazione finora

- 5 Rack Safety Training ModuleDocumento7 pagine5 Rack Safety Training ModuleBhaskar ShuklaNessuna valutazione finora

- Hazards in Port and Docks Info SheetDocumento6 pagineHazards in Port and Docks Info SheetAidanNessuna valutazione finora

- Chapter 1Documento22 pagineChapter 1GustiRadhenIchwan100% (1)

- B TC Installation 2Documento19 pagineB TC Installation 2TanveerNessuna valutazione finora

- Chain Slings SI 1.3Documento2 pagineChain Slings SI 1.3reda mesbahNessuna valutazione finora

- Deck Watchkeeping - Basic PrinciplesDocumento50 pagineDeck Watchkeeping - Basic Principlesneo miala100% (3)

- RFPNW Handouts PDFDocumento64 pagineRFPNW Handouts PDFIan Denver Sotero100% (1)

- Safety Guide - ENG - FinalDocumento52 pagineSafety Guide - ENG - FinalSuresh DevarakondaNessuna valutazione finora

- Confident Powerboating: Mastering Skills and Avoiding Troubles AfloatDa EverandConfident Powerboating: Mastering Skills and Avoiding Troubles AfloatNessuna valutazione finora

- Ni 617 July 2014 PDFDocumento46 pagineNi 617 July 2014 PDFTi AnnelNessuna valutazione finora

- Towing Winch Emergency Release Systems-Cu Aplicare Din 2020Documento4 pagineTowing Winch Emergency Release Systems-Cu Aplicare Din 2020tonyNessuna valutazione finora

- Section 8 Windlass Design and Testing: 8.1 GeneralDocumento3 pagineSection 8 Windlass Design and Testing: 8.1 GeneralANTON NEAGUNessuna valutazione finora

- SNDocumento113 pagineSNtonyNessuna valutazione finora

- Section 8 Windlass Design and Testing: 8.1 GeneralDocumento3 pagineSection 8 Windlass Design and Testing: 8.1 GeneralANTON NEAGUNessuna valutazione finora

- TugDocumento2 pagineTugtonyNessuna valutazione finora

- Proiectare Cuplajelor PermanenteDocumento160 pagineProiectare Cuplajelor PermanentetonyNessuna valutazione finora

- A2 Shipboard Fittings and Supporting Hull Structures Associated With Towing and Mooring On Conventional Vessels A2Documento6 pagineA2 Shipboard Fittings and Supporting Hull Structures Associated With Towing and Mooring On Conventional Vessels A2tonyNessuna valutazione finora

- Life Saving-Inland-2009-Rrr PDFDocumento12 pagineLife Saving-Inland-2009-Rrr PDFtonyNessuna valutazione finora

- Guide Application Directive 2006-42-Ec-2nd Edit 6-2010 enDocumento6 pagineGuide Application Directive 2006-42-Ec-2nd Edit 6-2010 entonyNessuna valutazione finora

- Cargo Securing Guidelines enDocumento208 pagineCargo Securing Guidelines enAndrejs Meļņikovs100% (2)

- SPM Rules E-July14Documento98 pagineSPM Rules E-July14Julio Fernando Asitimbay ChávezNessuna valutazione finora

- UE Guide Directive Machine 2006-42-CEDocumento406 pagineUE Guide Directive Machine 2006-42-CEvoltaredNessuna valutazione finora

- Panama Canal Regulations PDFDocumento114 paginePanama Canal Regulations PDFtony100% (1)

- Single Point Moorings 2018 KDocumento60 pagineSingle Point Moorings 2018 KtonyNessuna valutazione finora

- Exxonmobil Minimum Safety CriteriaDocumento40 pagineExxonmobil Minimum Safety Criteriakhaled116071% (7)

- Cargo Securing Manual CsmtesDocumento31 pagineCargo Securing Manual Csmtesreka1950Nessuna valutazione finora

- SVR Part 6 Jan 19 PDFDocumento268 pagineSVR Part 6 Jan 19 PDFsreeNessuna valutazione finora

- Abs-Equipment Condition Monitoring PDFDocumento101 pagineAbs-Equipment Condition Monitoring PDFShubhodeep SarkarNessuna valutazione finora

- 692D Guidelines Marine DesignersDocumento9 pagine692D Guidelines Marine Designerspapaki2Nessuna valutazione finora

- Importance of Surface Finish in The Design of Stainless SteelDocumento2 pagineImportance of Surface Finish in The Design of Stainless SteelPostolache ValentinNessuna valutazione finora

- 692D Guidelines Marine DesignersDocumento9 pagine692D Guidelines Marine Designerspapaki2Nessuna valutazione finora

- Mooring Do It Safely - 2013-08-09 PDFDocumento45 pagineMooring Do It Safely - 2013-08-09 PDFjuricic2100% (1)

- Design Verification of Winch For Offshore Cranes PDFDocumento4 pagineDesign Verification of Winch For Offshore Cranes PDFtonyNessuna valutazione finora

- Winch AnalysisDocumento21 pagineWinch Analysisvarshasdm19870% (1)

- Spring Design HandbookDocumento199 pagineSpring Design Handbooklakshmanakumarr97% (31)

- Electropalan-Verificarea Motorului ElectricDocumento28 pagineElectropalan-Verificarea Motorului ElectrictonyNessuna valutazione finora

- Deck Machineries: Windlass & Winches Onboard Offshore and AshoreDocumento30 pagineDeck Machineries: Windlass & Winches Onboard Offshore and AshoreAlexEcnom100% (3)

- Fundamentals of Pulley and WinchesDocumento62 pagineFundamentals of Pulley and WinchesvikasgahlyanNessuna valutazione finora

- Jacks Winches 2014 Hire CatalogueDocumento32 pagineJacks Winches 2014 Hire CatalogueMohd Zuhdi IsmailNessuna valutazione finora

- Harbor Freight Tools & Equipment Replacement Parts ListDocumento319 pagineHarbor Freight Tools & Equipment Replacement Parts ListBenjamin DoverNessuna valutazione finora

- Product Catalogue: Proudly Representing The Global Lifting GroupDocumento228 pagineProduct Catalogue: Proudly Representing The Global Lifting GroupSanjeeb SinhaNessuna valutazione finora

- Checklist For Equipment Inspection Winch MachineDocumento2 pagineChecklist For Equipment Inspection Winch MachineIdada EzekielNessuna valutazione finora

- Mooring of Ships - ForcesDocumento168 pagineMooring of Ships - ForcesAnonymous NGXdt2Bx100% (2)

- Winch OperationsDocumento9 pagineWinch Operationsdsn_sarmaNessuna valutazione finora

- Assemblies Arv t72Documento1 paginaAssemblies Arv t72stormbreakkr100% (1)

- Important Information:: Ingersoll-Rand Winch or Hoist. The Manual Form Numbers Are As FollowsDocumento73 pagineImportant Information:: Ingersoll-Rand Winch or Hoist. The Manual Form Numbers Are As FollowsMauricio GarciaNessuna valutazione finora

- Product Presentation - Oct 2016Documento143 pagineProduct Presentation - Oct 2016Dwi PutraNessuna valutazione finora

- Catalogo Hadef Product OverviewDocumento47 pagineCatalogo Hadef Product OverviewPedro MoralesNessuna valutazione finora

- Petronas Technical Standards: Offshore Crane - 12 TonsDocumento13 paginePetronas Technical Standards: Offshore Crane - 12 TonsBalkis FatihaNessuna valutazione finora

- Toyota 80 SeriesDocumento5 pagineToyota 80 Seriesaagi_dNessuna valutazione finora

- DNV ST 0377Documento285 pagineDNV ST 0377Chief Engineer100% (1)

- Checklist For The Inspection of Overhead Travelling CraneDocumento1 paginaChecklist For The Inspection of Overhead Travelling CraneMaged ObaidNessuna valutazione finora

- Model Dd800W Winch: Sheet 16Documento2 pagineModel Dd800W Winch: Sheet 16Cristian Andres Matamala TapiaNessuna valutazione finora

- Docdoss 5138Documento419 pagineDocdoss 5138naved ahmedNessuna valutazione finora

- Product Catalog: Winches Recovery Gear Accessories HubsDocumento44 pagineProduct Catalog: Winches Recovery Gear Accessories HubsDaniel VilchisNessuna valutazione finora

- K-WINCH 70ft SkyFoldDocumento1 paginaK-WINCH 70ft SkyFoldBrainsync MotorsportNessuna valutazione finora

- Loading Device With Telescopic ChuteDocumento130 pagineLoading Device With Telescopic ChuteBata ZivanovicNessuna valutazione finora

- Wire Rope - A Few Hints - RegDec94 - WireropeDocumento2 pagineWire Rope - A Few Hints - RegDec94 - WireropeMax BeeksNessuna valutazione finora

- Bergen Rolls Royce Old ProductsDocumento4 pagineBergen Rolls Royce Old ProductsHui ChenNessuna valutazione finora

- Eilbeck Catalogue 2013 WinchesDocumento15 pagineEilbeck Catalogue 2013 WinchesyaskawaNessuna valutazione finora

- KR-250H-V: Rough Terrain CraneDocumento10 pagineKR-250H-V: Rough Terrain CraneBanyuNessuna valutazione finora

- Section 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Documento12 pagineSection 8 Windlasses, Winches and Hydraulic Systems: Chapter 2, Section 8, B Chapter 2, Sec-Tion 8, B.3 B.4Suresh KumarNessuna valutazione finora

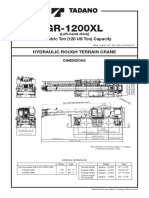

- GR-1200XL: Hydraulic Rough Terrain CraneDocumento16 pagineGR-1200XL: Hydraulic Rough Terrain Cranesrikanthc85Nessuna valutazione finora

- Mooring Winch Tests1Documento7 pagineMooring Winch Tests1RachitNessuna valutazione finora

- 420118-Gantry Crane ManualDocumento17 pagine420118-Gantry Crane ManualAndreyOsyaninNessuna valutazione finora

- Sany SCC 1500cDocumento21 pagineSany SCC 1500cYashwant R KamathNessuna valutazione finora

- Spec. For Pedestal CraneDocumento18 pagineSpec. For Pedestal Craneronny_fernandes363Nessuna valutazione finora