Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Importance of Side Stream Filtration

Caricato da

mishtinil0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

51 visualizzazioni4 pagineFilter

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFilter

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

51 visualizzazioni4 pagineImportance of Side Stream Filtration

Caricato da

mishtinilFilter

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 4

pep

The Importance of Side Stream

Filtration in Water and Energy

Conservation

By Kenn Latzer, Process Efficiency Products, Inc

ilding owners and those responsible for the design,

BB einer tain

‘ment often overlook the impact of cooling tower opera-

tion on their profit and loss picture. Tbs not unusual for a

large facility to spend hundreds of thousands of dollars in

energy costs for cooling, to which must be added additional

costs of equipment maintenance and downtime losses. Even a

small increase in efficieney and reduced maint squire

‘ments can result in savings of tens of thousands of dollars a

ar. Improving the quality of the water in these systems is the

simplest and most cost effective method of obtaining these

savings.

Several aspects of water quality

formance. Total dissolved solids (TDS), pH, alkalinity, hard-

ness and other chemical aspects of water quality can be pre-

dicted and controlled by comparing a chemical analysis of

makeup water to evaporation potential and calculating expect-

ed conditions. However, there is one variable that defies easy

prediction....the amount of particles (Total Suspended Solids)

in the water. ‘The air that is drawn through the fill of a eooling

tower inevitably contains particles of dust, soil, soot, organic

debris and numerous other materials. Th

tively scrubbed from the air by the cooling tower and concen-

trated in the water. Particle concentrations vary and are influ-

enced by constantly changing factors such as wind direction,

amount and type of traffic, and the activity of neighbors (

construction, plant operation cycles, etc.), among others. It is

not unusual for air over a Targe city to have upwards of

100,000 particles in each cubic centimeter of air. Clive

Broadbent's quote in the 1992 ASHRAE (American Society of

Heating, Refrigeration and Air-Conditioning Engineers) report

states, “a typical 200 ton cooling tower in a season, may

assimilate upwards of 600 pounds of particulate matter from

airborne dust and make-up water supply” (ASHRAB

Handbook, 1996)

particles are effec-

In addition, the system itself produces particles. These include

corrosion products, mineral precipitates (e.g. iron oxides, hard=

ness salts), microbiological colonies, aggregates of organic

chemicals and many others. Contamination by dissolved and

particulate materials leaking from the process side of hea

exchange equipment adds to the process by precipitating insol-

uble chemical products, providing nutrients for accelerated

biological growth, and accelerating corrosion and the forms

tion of corrosion products.

The particulates in cooling water, when bound together by pre

cipitation of scale-forming minerals, result in a greatly

inereased volume of scale and a thicker scale layer, Similarly,

particles bound together by development of a biological foul

se the foul volume and layer thickness. These

layers decrease heat transfer efficiency, reduce flow rate acros

heat exchange surfaces and encourages corrosion, resulting in

additional fouling. Slower flow allows more particles to settle

amplifying the problem and further reducing efficiency,

layer also incr

Benefits of Clean Water

Of the numerous water quality parameters that may affect per

formance, suspended solids are the most common and serious

culprit. ‘Therefore, the benefits of removing particles from the

system are numerous. They include

1. Reduced Energy Consumption

layer of foul or scale measuring 1/1000 ine thiek can

reduce heat transfer to

increase energy costs by

as much as 10 percent

The formula listed below

can be used to calculate

the energy cost per year

for an air-conditioning

system

ANC ton x kw/ton x load

factor x hours of operation/yr x costkwh = Energy Costs/Yeai

For example: 400 ton A\C x 0.65kw/ton x 0.7 load factor x

2500 operating hours

x $0.07/ kwh = $31,850 energy cost for one year

Consider the same 400 ton chiller operating 2500 hours a year

at $0.,07/kwh with a foul layer of 1/1000 inch thick will result

in $3,185 increased energy costs per year. A 10 percent

2. Improved Chemical

Performance

Particles consume chemi-

cals used to prevent scal

ing and comrosion. Asa

result, dirty water require

more chemicals and

rea leas effective

ie

‘treatment than clean water.

Biocides are also consumed by particles. In addition, particles

provide habitat and nutrients that bacteria and algae need to

thrive. A filtration system that removes suspended particles

allows the water treatment program to operate at maximum,

effectiveness with minimum chemical use. The result is

enhanced water quality at lower chemical costs

3. Lower Maintenance Cost

Traditional methods of

cleaning a cooling tower

include draining the tower

and shoveling sediment

from the sump. This incurs

costs for downtime. labor,

lost water and chemicals,

‘The savings obtained by

doing this mechanically with

a filtration system translates to substantial savings and is an

added bonus in recovering the cost of a filtration system.

4, Improved Productivity and Less Downtime

Fouling a cooling system can slow production. Five seconds

added to a plastic mold cooling rate can mean 25 fewer pants per

day, translating to less profit per machine. This is compounded

by the number of molding machines a plant may have, which can

significantly impact profits, In some cases, a water cleaning: sys-

tem may cost as little as a single day of downtime.

A successful water treatment

program will include steps 1

remove or reduce the volum

of particles that inevitably

collect in any eoolin

tem, Water inspec

cooling tower is easily

viewed! without system shut-

down and should be considered an indicator of total system con-

dition and cleanliness. Place your hi

dist and observe if the fill is clean. Any accumulation of dirt is 4

sign of future problems.

jon at the

1d in the basin, check for

The LEGIONELLA Problem

Today, anyone with a cooling tower must consider the growing

Legionella problem. ASHRAE Guideline 12-2000 presents basi

treatment recommendations for control and prevention of

Legionella in cooling towers, stating that a principal key to sue~

cess in Legionella control is system cleanliness. ‘The September

2000 issue of the ASHRAE Journal (pages 44-49) states,

“Conditions favorable for amplification of Legionella growth

includes water temperature of 77°F to 108 °F and presence of

scale, sediment and biofilm... generally Legionetia thrives in

diverse complex microbial communities because they require

nutrients and protection from the environment.” More simply,

maintaining low particle levels reduces the habitat surfaces and

nutrients required for Legionella geowth

This should be coupled with an

appropriate biocidal program of

proven effectiveness for control

of Legionelia. It is recommended

that a water treatment specialist

oversee the treatment program,

Further, to protect yourself from

egal exposure should someone

contract Legionellosis, il is ree~

‘ommended that your specifica-

tions require good record keeping

‘on the operation and maintenance

of the system. These records

should include manufacturer's

and maintenance manu-

als; description of the water treat-

ment program; dates and data of

all inspections and maintenance;

material safety data sheets for all

chemicals used; dates of any

repairs; records of system water

volume; names and duties of per-

son(s) responsible for system

start-up, operation and shut down,

Assuming steps have been taken

to keep your system clean, and

that you are employing an appro-

priate biocidal program, these

records will demonstrate that due

diligence has been performed. Al

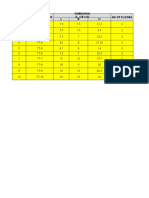

Sweeper Jet

Mode PS}250

Ip. of 20)

How Rate 5 gpm

CINECTREAM ECILTER INCTALI ATION

‘hat cane 56 dees tr eee the

public from contracting Legionellosis from the cooling tower

mist has been taken,

Filtration Selection Required for

Clean Water

Control of suspended particles is easily achieved by filtration.

‘This is not a new idea - your body uses kidneys to remove

impurities. 1 fact, the human body is far more tolerant of many

“impurities” contained in our water than are many industrial

applications that use water in the manufacturing process (i

your car has an oil filter to protect your engine). Hence, filtra

2 tower water is just as important,

Many think that filtration must treat the full system flow.

However, like your car’s oil filter that treats a small portion of

the oil at time, side stream filtration is most practical and effec~

tive in cooling towers. For example, a 400-ton cooling tower

hhas a flow rate of 1200 gpm, A filter large enough to treat this

entire flow would be 108 feet in diameter and would require it’s

own building. However, it has been found that a 5% side stream

flow through a filter is all that is needed to control suspended

solids, Five percent of 1200 gpm is 60 gpn

24-inch filter with a flow rate of 63 gpm.

ich requires a

Removal of particle as small as 5 to 10 microns is required for

effective Legionelfa control, since these small particles constitute

the bulk of particulate surface area for bacterial colonization and

are most easily incorporated in foul and scale. Many cooling,

tower operators use centrifugal separators to reduce particle load,

bbut these only remove relatively large (70 microns) or dense (sp.

gt 2.6) particles. In the September 2000 issue of Chemical

Engineering, W.C. Meyer states, “Centrifugal separators do not

remove very small or low density particles and are, therefore, not

appropriate for this purpose.”

‘There are several filtration technologies that can be used to

accomplish this goal. ‘They include:

Cartridge filters

Bag filters

Permanent Media filters

Cartridge and bag filters are relatively inexpensive, but their con-

sumable filter elements require regular replacement. The cost of

cartridges and bags and the associated labor required for their

continuous replacement results in high operating costs that over-

ride any savings made on the initial purchase. In comparison,

permanent media filters have a higher initial cost but much Tower

‘operating costs that make them more economical

Filtration Operations

Water entering a permanent media filter is evenly distributed

over the sand bed, achieving full penetration. As the particles

are removed they coat the surface of the media bed creating a

surface layer or “Schmutz Deck” of particles that increase the

effectiveness in removing the finer particles not easily filtered by

bag or cartridge filters. In other words, the dirt removed becomes

the filter media for removal of the next particle. When the per-

manent media becomes clogged, it is regenerated by backwash-

es a a cre cece

FILTRATION

MODE

FROM

SYSTEM

RETURN TO SYSTEM

BACKWASH

MODE

SveRoRAR

FROM

SYSTEM,

RETURN TO SYSTEM

FILTER OPERATION

attention and can use the same media for years, producing sub-

stantial savings in material and labor costs when compared to

other disposable filter technologies. Studies have shown that the

average permanent media filter will pay for itself in less than

two years.

Side stream permanent media filters can be installed in two

ways. An in-line filter taps (see page 4) the condenser cireula.

tion line where water is drawn off, filtered, and the clean water

returned to the circulation fine, Filter input and return lines

should be at least 10 feet apart to avoid registering the same

water. Sump/basin sidesteam filtration removes, filters and

returns clean water directly to the tower sump. This is the sys

tem of choice, since it allows use of sweeper jets to direct sedi

ment to the filter inlet to keep the basin free from debris. Today,

all three major manufacturers of cooling towers [BAC, Marley,

Evapco] offer sweeper jets as a factory option

Summary

As suggested by ASHRAE und confirmed by numerous industry

articles, there is one simple way to maximize the efficiency of

any cooling system. Obtain the best economic return on your

and protect against spreading disease

and the legal exposure this may incur

KEEP YOUR WATER CLEAN

Potrebbero piacerti anche

- Technical Specification of DamperDocumento2 pagineTechnical Specification of DampermishtinilNessuna valutazione finora

- Franc3D - Onramp 1: BITS PilaniDocumento21 pagineFranc3D - Onramp 1: BITS Pilaniraaspoy2007Nessuna valutazione finora

- Adjustable Louver Grill Volume ControlDocumento1 paginaAdjustable Louver Grill Volume ControlmishtinilNessuna valutazione finora

- Technical Specification of GrillsDocumento1 paginaTechnical Specification of GrillsmishtinilNessuna valutazione finora

- Pipe Estimation ps-1Documento9 paginePipe Estimation ps-1mishtinilNessuna valutazione finora

- TT Details - AdaniDocumento4 pagineTT Details - AdanimishtinilNessuna valutazione finora

- BasicsofACHEBrochure WebDocumento33 pagineBasicsofACHEBrochure WebTrần Tuấn VũNessuna valutazione finora

- Specification ChillerDocumento28 pagineSpecification Chillermishtinil100% (1)

- Chemical Storage Tanks Specifications Rev. 8-24-04Documento13 pagineChemical Storage Tanks Specifications Rev. 8-24-04Rahmi ArslanNessuna valutazione finora

- Mechanical Spec - Plain Water DSSDocumento9 pagineMechanical Spec - Plain Water DSSmishtinilNessuna valutazione finora

- Essential PDMS Commands for Piping, Equipment & StructuresDocumento12 pagineEssential PDMS Commands for Piping, Equipment & StructuresmishtinilNessuna valutazione finora

- Utility Write UpDocumento15 pagineUtility Write UpmishtinilNessuna valutazione finora

- Maximizing Energy Efficiency Through Utilization of By-Product GasesDocumento9 pagineMaximizing Energy Efficiency Through Utilization of By-Product GasesbalusmeNessuna valutazione finora

- Electrical Motor SpecificationDocumento6 pagineElectrical Motor SpecificationmishtinilNessuna valutazione finora

- Motor technical specificationsDocumento2 pagineMotor technical specificationsmishtinilNessuna valutazione finora

- Tech Spec For Misc. PumpsDocumento6 pagineTech Spec For Misc. PumpsmishtinilNessuna valutazione finora

- Accumulator Sizing For Water SystemDocumento5 pagineAccumulator Sizing For Water SystemmishtinilNessuna valutazione finora

- Plate With Surface Crack: BITS PilaniDocumento4 paginePlate With Surface Crack: BITS Pilaniraaspoy2007Nessuna valutazione finora

- Altroz India 01Documento1 paginaAltroz India 01KarniNessuna valutazione finora

- Revised - 02 Dry - Vent - Capacity - Selection - 10.05.10Documento34 pagineRevised - 02 Dry - Vent - Capacity - Selection - 10.05.10mishtinilNessuna valutazione finora

- Feeder List - R0 - CHPDocumento42 pagineFeeder List - R0 - CHPmishtinilNessuna valutazione finora

- Clarifications & DeliverablesDocumento4 pagineClarifications & DeliverablesmishtinilNessuna valutazione finora

- Different Type Air DryerDocumento9 pagineDifferent Type Air DryermishtinilNessuna valutazione finora

- Arvind Corotech BrochureDocumento11 pagineArvind Corotech BrochuremishtinilNessuna valutazione finora

- Storage Type Water-Cooler & Water Purifier Storage Type Water CoolerDocumento2 pagineStorage Type Water-Cooler & Water Purifier Storage Type Water CoolermishtinilNessuna valutazione finora

- A8ga 45240 65 DW 5039 - R3Documento1 paginaA8ga 45240 65 DW 5039 - R3mishtinilNessuna valutazione finora

- Assignment Seventh SemDocumento10 pagineAssignment Seventh SemmishtinilNessuna valutazione finora

- Garden City of IndiaDocumento20 pagineGarden City of IndiamishtinilNessuna valutazione finora

- Lab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIIDocumento12 pagineLab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIImishtinilNessuna valutazione finora

- Full Page PhotoDocumento1 paginaFull Page PhotomishtinilNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)