Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

031 - Engine - Igniter Circuit Malfunction (No. 1)

Caricato da

Ayun AhmCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

031 - Engine - Igniter Circuit Malfunction (No. 1)

Caricato da

Ayun AhmCopyright:

Formati disponibili

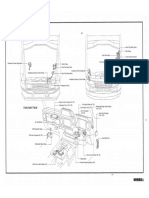

DI–109

DIAGNOSTICS – ENGINE

DI3HD–06

DTC P1300 Igniter Circuit Malfunction (No. 1)

DTC P1305 Igniter Circuit Malfunction (No. 2)

DTC P1310 Igniter Circuit Malfunction (No. 3)

DTC P1315 Igniter Circuit Malfunction (No. 4)

CIRCUIT DESCRIPTION

A Direct Ignition System (DIS) has been adopted. The DIS improves the ignition timing accuracy, reduces

high–voltage loss, and enhances overall reliability of the ignition system by eliminating the distributor.

The DIS is a 1–cylinder ignition system which ignites one cylinder with one ignition coil. In the 1–cylinder

ignition system, the spark plug is connected to the end of the secondary winding. High voltage generated

in the secondary winding is applied directly to the spark plug. The spark of the spark plug passes, from the

center electrode to the ground electrode.

The ECM determines ignition timing and outputs the ignition signals (IGT) for each cylinder. Based on IGT

signals, the power transistors in the igniter cuts off the current to the primary coil in the ignition coil supplied

to the spark plug connected to the end of the secondary coil. At the same time, the igniter also sends an

ignition confirmation signal (IGF) as a fail–safe measure to the ECM.

DTC No. DTC Detection Condition Trouble Area

S Ignition system

P1300

S Open or short in IGF and IGT circuit from ignition coil with

P1305

No IGF signal to ECM while engine is running igniter

P1310

S ignition coil with igniter

P1315

S ECM

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 273

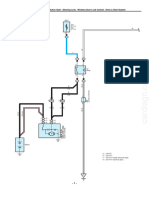

DI–110

DIAGNOSTICS – ENGINE

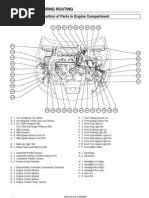

WIRING DIAGRAM

ECM

Spark Plug

B–R I2

1 No. 1 10

Ignition Coil B IGT1

E5

with Igniter 3

W–B B–Y

4 2

Spark Plug

From B–R I3

Terminal 3 of 1 No. 2 11

Ignition Coil L IGT2

IG2 Relay E5

(See page DI–132) with Igniter 3

W–B B–Y

B–R 4 2

Spark Plug

W–B B–Y

B–R I4

BC1 8 1 No. 3 12

Ignition Coil L–W IGT3

E5

with Igniter 3

W–B B–Y

4 2

B–R

Spark Plug

W–B B–Y

B–R B–R I5

1 No. 4 13

Ignition Coil L IGT4

E5

B–R with Igniter 3

W–B 25

1 4 2 B–Y B–Y IGF

N1 E5

Noise W–B

Filter

EC

A13057

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 274

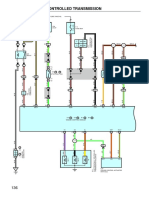

DI–111

DIAGNOSTICS – ENGINE

INSPECTION PROCEDURE

HINT:

S If DTC P1300 is displayed, check No. 1 ignition coil with igniter circuit.

S If DTC P1305 is displayed, check No. 2 ignition coil with igniter circuit.

S If DTC P1310 is displayed, check No. 3 ignition coil with igniter circuit.

S If DTC P1315 is displayed, check No. 4 ignition coil with igniter circuit.

S Read freeze frame data using TOYOTA hand–held tester or OBD II scan tool. Because freeze frame

records the engine conditions when the malfunction is detected. When troubleshooting, it is useful for

determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel

ratio was lean or rich, etc. at the time of the malfunction.

1 Check spark plug and spark (See page DI–63).

NG Go to step 4.

OK

2 Check for open and short in harness and connector in IGF and IGT signal circuit

between ECM and ignition coil with igniter (See page IN–28).

NG Repair or replace harness or connector.

OK

3 Disconnect ignition coil with igniter connector and check voltage between termi-

nals IGF of ECM connector and body ground.

ON PREPARATION:

(a) Disconnect the ECM with connector from body panel

(See page SF–62).

(b) Disconnect the ignition coil with igniter connector.

(c) Turn the ignition switch ON.

CHECK:

(+) (–)

Measure the voltage between terminals IGF of the ECM con-

IGF

BE6653 nector and body ground.

A11506

A12743 OK:

Voltage: 4.5 – 5.5 V

OK Replace ignition coil with igniter.

NG

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 275

DI–112

DIAGNOSTICS – ENGINE

Check and replace ECM (See page IN–28).

4 Check for open and short in harness and connector in IGT signal circuit between

ECM and ignition coil with igniter (See page IN–28).

NG Repair or replace harness or connector.

OK

5 Check voltage between terminals IGT1 – IGT4 of ECM connector and body

ground.

IGT4 IGT3 IGT2 IGT1 PREPARATION:

Disconnect the ECM with connector from body panel (See page

SF–62).

CHECK:

Measure the voltage between terminals IGT1 – IGT4 of the

(+) (–) ECM connector and body ground when the engine is cranked.

OK:

Voltage: More than 0.1 V and less than 4.5 V

A12547

IGT and IGFSsignal Waveforms

Reference: INSPECTION USING OSCILLOSCOPE

5 V/

During cranking or idling, check the waveform between termi-

Division nals IGT1 – IGT4 and E1, IGF and E1 of the ECM connector.

IGT

HINT:

GND Correct waveform appears as shown, with rectangle waves.

GND

IGF

20 msec./ Division A03401

NG Check and replace ECM (See page IN–28).

OK

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 276

DI–113

DIAGNOSTICS – ENGINE

6 Disconnect ignition coil with igniter connector and check voltage between termi-

nals IGT1 – IGT4 of ECM connector and body ground.

IGT4 IGT3 IGT2 IGT1 PREPARATION:

(a) Disconnect the ECM with connector from body panel

(See page SF–62).

(b) Disconnect the ignition coil with igniter connector.

CHECK:

(+) (–) Measure the voltage between terminals IGT1 – IGT4 of the

ECM connector and body ground when the engine is cranked.

OK:

A12547 Voltage: More than 0.1 V and less than 4.5 V

NG Check and replace ECM (See page IN–28).

OK

7 Check ignition coil with igniter power source circuit.

ON PREPARATION:

Disconnect the ignition coil with igniter connector.

1

CHECK:

START

Measure the voltage between terminal 1 of the ignition coil with

(–) (+)

igniter connector and body ground when ignition switch is

turned to ON and START position.

OK:

Voltage: 9 – 14 V

BE6653

A01761 A01861

NG Repair ignition coil with igniter power source

circuit.

OK

8 Check for open and short in harness and connector between ignition switch and

ignition coil with igniter (See page IN–28).

NG Repair or replace harness or connector.

OK

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 277

DI–114

DIAGNOSTICS – ENGINE

9 Check IG2 relay (Marking: IG2) (See page IG–7).

NG Replace IG2 relay.

OK

Replace ignition coil with igniter.

2000 MR2 (RM760U)

AuthorĂ: DateĂ: 278

Potrebbero piacerti anche

- Timing Diagrams PDFDocumento54 pagineTiming Diagrams PDFAlejandro Lira97% (32)

- SXE10 3S-GE - Engine Control Electrical Parts Location GuideDocumento13 pagineSXE10 3S-GE - Engine Control Electrical Parts Location GuideElvis Mantilla100% (2)

- Ignition Coil Diagnostic Codes for 1GR-FE EngineDocumento11 pagineIgnition Coil Diagnostic Codes for 1GR-FE Enginemike chenNessuna valutazione finora

- Toyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineDocumento5 pagineToyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineMark Anthony Fletcher100% (1)

- Toyota Trouble Code InfoDocumento6 pagineToyota Trouble Code InfoFrancis Azul Simalong50% (2)

- Ignition System: 1988 Toyota CelicaDocumento7 pagineIgnition System: 1988 Toyota CelicaToua Yaj100% (1)

- 3.3L 6-Cyl VinDocumento28 pagine3.3L 6-Cyl VingypsyshortNessuna valutazione finora

- 4WD ECU Connector DiagramDocumento1 pagina4WD ECU Connector Diagramcartronix2010Nessuna valutazione finora

- Engine Controls (2UZ-FE)Documento14 pagineEngine Controls (2UZ-FE)B1MNUSO B1MNUSONessuna valutazione finora

- Dellorto ManualDocumento34 pagineDellorto Manualmarkintosh44100% (16)

- A340E and A343E Automatic Transmissions: DescriptionDocumento8 pagineA340E and A343E Automatic Transmissions: DescriptionArda Billy24Nessuna valutazione finora

- Lubrication (2jz-Ge)Documento15 pagineLubrication (2jz-Ge)AlexendraNessuna valutazione finora

- BYD G3-Owner's Manual20110610-EN PDFDocumento160 pagineBYD G3-Owner's Manual20110610-EN PDFamer100% (1)

- 05ewd PDFDocumento251 pagine05ewd PDFWawan SatiawanNessuna valutazione finora

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocumento15 pagineElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- Engine Bay Relay Locations GuideDocumento82 pagineEngine Bay Relay Locations GuidelukasNessuna valutazione finora

- System CircuitsDocumento234 pagineSystem CircuitsEme Elibe Johnson EmestarNessuna valutazione finora

- Toyota Noah AmDocumento11 pagineToyota Noah AmArchibold MachenaNessuna valutazione finora

- 1jz-Gte InfoDocumento8 pagine1jz-Gte Info007jones007Nessuna valutazione finora

- Engine Immobiliser Push-Button Start Steering LockDocumento38 pagineEngine Immobiliser Push-Button Start Steering LockAliNessuna valutazione finora

- Five Nights at Freddy's The Ultimate Guide Five Nights at Freddy's Wiki FandomDocumento1 paginaFive Nights at Freddy's The Ultimate Guide Five Nights at Freddy's Wiki FandomAmto Hosima0% (1)

- Engine - 2uz-Fe EngineDocumento3 pagineEngine - 2uz-Fe EnginePablo PérezNessuna valutazione finora

- EFDocumento49 pagineEFsurya100% (1)

- Engine 2JZ-GEDocumento108 pagineEngine 2JZ-GEroy.cheong900% (1)

- 2jzgte Uk Spec Ecu PinoutDocumento2 pagine2jzgte Uk Spec Ecu PinoutWilliamNessuna valutazione finora

- JB-Det Overhaul ManualDocumento64 pagineJB-Det Overhaul ManualMohdYasirNessuna valutazione finora

- Electronically controlled transmission system overviewDocumento6 pagineElectronically controlled transmission system overviewOliver leal100% (1)

- Optimize Fuel System PerformanceDocumento14 pagineOptimize Fuel System Performanceservice_007100% (1)

- BGA ENG MATL TS 0006 Cathodic Protection Rev 02aDocumento26 pagineBGA ENG MATL TS 0006 Cathodic Protection Rev 02aGururaj P KundapurNessuna valutazione finora

- Ignition PDFDocumento17 pagineIgnition PDFtavi2meNessuna valutazione finora

- Fuse Box E120Documento3 pagineFuse Box E120Shahmeer AhmedNessuna valutazione finora

- Maintenance Handbook On Bonding Earthing For 25 KV AC Traction SystemsDocumento46 pagineMaintenance Handbook On Bonding Earthing For 25 KV AC Traction SystemsPavan100% (1)

- AE101 4AGE 20 Valve Pins 2019Documento5 pagineAE101 4AGE 20 Valve Pins 2019jorgeNessuna valutazione finora

- T1 Cam Trigger Instructions 1Documento10 pagineT1 Cam Trigger Instructions 1Initial_BG100% (1)

- G Electrical Wiring Routing: Position of Parts in Engine CompartmentDocumento8 pagineG Electrical Wiring Routing: Position of Parts in Engine CompartmentTec RomeroNessuna valutazione finora

- C 20 Series - Lubrication and Maintenance Schedule - 2010Documento22 pagineC 20 Series - Lubrication and Maintenance Schedule - 2010Centrifugal SeparatorNessuna valutazione finora

- Astm Peel TestDocumento2 pagineAstm Peel TestIvander GultomNessuna valutazione finora

- Toyota Allion / Premio 240 (2001-2007) : System Capacity (L) Type Lubrication (W Filter)Documento1 paginaToyota Allion / Premio 240 (2001-2007) : System Capacity (L) Type Lubrication (W Filter)Walakulu Arachchige Lasantha IndralalNessuna valutazione finora

- Toyota Hilux 1GR Fe Pin Out PDFDocumento9 pagineToyota Hilux 1GR Fe Pin Out PDFEfrán HernándezNessuna valutazione finora

- 3grfse 2 PDFDocumento20 pagine3grfse 2 PDFMarranNessuna valutazione finora

- BeltsDocumento89 pagineBeltszul100% (2)

- d2fee44ce3373b7c092a008235dbd2f5Documento153 pagined2fee44ce3373b7c092a008235dbd2f5Ovvc100% (2)

- 2UZTRDDocumento33 pagine2UZTRDJd BuzzNessuna valutazione finora

- 1gr-Fe Engine Control System4Documento7 pagine1gr-Fe Engine Control System4mike chenNessuna valutazione finora

- 09 ls460 Navigation PDFDocumento16 pagine09 ls460 Navigation PDFbob loblawNessuna valutazione finora

- 1mz Ecu Wiring DiagramDocumento7 pagine1mz Ecu Wiring Diagram12volt bayNessuna valutazione finora

- Toyota 1nz Trasnsmision AutomaticaDocumento3 pagineToyota 1nz Trasnsmision AutomaticaCristhian Cazas100% (2)

- Toytoa Wire DiagramDocumento8 pagineToytoa Wire Diagramspybot1331100% (1)

- 1 ZzfeDocumento8 pagine1 ZzfeScuderia Redin100% (1)

- Ignition PDFDocumento16 pagineIgnition PDFDoDuyBacNessuna valutazione finora

- Z18XE SCHDocumento3 pagineZ18XE SCHJan WolnyNessuna valutazione finora

- Terminals of Ecm: E4 E5 E6 E7 E8Documento3 pagineTerminals of Ecm: E4 E5 E6 E7 E8luisNessuna valutazione finora

- Diagnosing ABS Solenoid Relay IssuesDocumento3 pagineDiagnosing ABS Solenoid Relay IssuesAdasson BravoNessuna valutazione finora

- How To Use Electrical Wiring Diagram: Section 1Documento3 pagineHow To Use Electrical Wiring Diagram: Section 1benjie187100% (1)

- Abandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsDocumento1 paginaAbandoned 1992 Toyota AE101 Turbo Project Car for Sale with 3SGTE Engine ModsjaiusopNessuna valutazione finora

- Ci P0500Documento2 pagineCi P0500David BenazeraNessuna valutazione finora

- J3 Meter Removal Installation and Troubleshooting GuideDocumento32 pagineJ3 Meter Removal Installation and Troubleshooting GuideWaqar KhattakNessuna valutazione finora

- 2az-Fe Engine Control System Sfi SystemDocumento6 pagine2az-Fe Engine Control System Sfi SystemMarcelo DecimaNessuna valutazione finora

- Mazda 5 EngineDocumento143 pagineMazda 5 EngineAngel CastNessuna valutazione finora

- 2006 Toyota Camry Engine ControlDocumento11 pagine2006 Toyota Camry Engine Control35.Hoàng Xuân TânNessuna valutazione finora

- Data List For Active TestDocumento5 pagineData List For Active Testjeremih alhegnNessuna valutazione finora

- Enginecontrol VVTi EnglishDocumento13 pagineEnginecontrol VVTi EnglishSatrio Ongis NadeNessuna valutazione finora

- Biante SKYACTIV: Dimension & Weight Seating & TrimDocumento4 pagineBiante SKYACTIV: Dimension & Weight Seating & Trimyusransyah100% (1)

- 31 PDFDocumento6 pagine31 PDFAlejandro NarvaezNessuna valutazione finora

- Diagnostics EngineDocumento5 pagineDiagnostics EnginePablo B. SoaresNessuna valutazione finora

- Ignition Coil Diagnostics and Troubleshooting GuideDocumento6 pagineIgnition Coil Diagnostics and Troubleshooting GuideErln LimaNessuna valutazione finora

- Ignition Coil DiagnosticsDocumento5 pagineIgnition Coil Diagnosticsjorge rioboNessuna valutazione finora

- TRW Easycheck Operating Instructions 6.0.0 PDFDocumento210 pagineTRW Easycheck Operating Instructions 6.0.0 PDFAyun AhmNessuna valutazione finora

- Guidelines For Quality Control Testing For Digital CR DR Mammography V4Documento62 pagineGuidelines For Quality Control Testing For Digital CR DR Mammography V4khaerul0% (1)

- Piper Archer II Checklist GuideDocumento8 paginePiper Archer II Checklist GuideJosías GenemNessuna valutazione finora

- SolverTable HelpDocumento13 pagineSolverTable HelpM Ibnu Aji DwiyantoNessuna valutazione finora

- Manual CleviteDocumento180 pagineManual CleviteJacko JaraNessuna valutazione finora

- Imperial SugarDocumento44 pagineImperial SugargerardoNessuna valutazione finora

- IalDocumento24 pagineIalWMONTOYA4897Nessuna valutazione finora

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocumento213 pagineDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNessuna valutazione finora

- Special cables for hybrid vehiclesDocumento1 paginaSpecial cables for hybrid vehiclesVlado PetkovskiNessuna valutazione finora

- Software Prototyping: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 8 Slide 1Documento39 pagineSoftware Prototyping: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 8 Slide 1Prateek GuptaNessuna valutazione finora

- Factory Overhead Variances: Flexible Budget ApproachDocumento4 pagineFactory Overhead Variances: Flexible Budget ApproachMeghan Kaye LiwenNessuna valutazione finora

- EPC Civil06Documento6 pagineEPC Civil06MHanif ARNessuna valutazione finora

- Shahzeb Hassan: Career ObjectiveDocumento2 pagineShahzeb Hassan: Career ObjectiveomairNessuna valutazione finora

- Semantics-Based Image Retrieval by Region SaliencyDocumento9 pagineSemantics-Based Image Retrieval by Region SaliencyRazzougui SarahNessuna valutazione finora

- Application of PWM Speed ControlDocumento7 pagineApplication of PWM Speed ControlJMCproductsNessuna valutazione finora

- Recruitment of Junior Associates (Customer Support & Sales)Documento5 pagineRecruitment of Junior Associates (Customer Support & Sales)Revanth TallaNessuna valutazione finora

- Revision Sex Death and EpicsDocumento77 pagineRevision Sex Death and EpicsAshli KingfisherNessuna valutazione finora

- Cv-Sreenath (T&i)Documento5 pagineCv-Sreenath (T&i)sreenaths100% (1)

- D5 Novtek Premium Tile Adhesive TDSDocumento2 pagineD5 Novtek Premium Tile Adhesive TDSJILBERT DORIANessuna valutazione finora

- Catalog CabluriDocumento7 pagineCatalog CabluriAdrian OprisanNessuna valutazione finora

- Master The Five Remote Function CallDocumento25 pagineMaster The Five Remote Function Callntesla2009Nessuna valutazione finora

- Techrite Siemens Siemens Qra Uv Flame Detection 013060323409Documento14 pagineTechrite Siemens Siemens Qra Uv Flame Detection 013060323409Ali Hadi100% (1)

- 14.H Out of Specification ResultsDocumento10 pagine14.H Out of Specification Resultsعبدالعزيز بدرNessuna valutazione finora

- Investment Opportunities in OdishaDocumento28 pagineInvestment Opportunities in OdishaNiladri MandalNessuna valutazione finora

- SNMP Tutorial PDFDocumento24 pagineSNMP Tutorial PDFSrivignessh PssNessuna valutazione finora

- Single 460 MM (18") Subwoofer System Key Features:: SpecificationsDocumento2 pagineSingle 460 MM (18") Subwoofer System Key Features:: SpecificationsguerreroNessuna valutazione finora