Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet - Ball Float Trap UFT 15 25NB PDF

Caricato da

siddheshTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet - Ball Float Trap UFT 15 25NB PDF

Caricato da

siddheshCopyright:

Formati disponibili

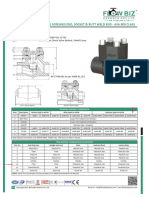

Ball Float Type Steam Trap

UFT-14/ UFT-20

UKL BALL FLOAT TYPE STEAM TRAP.

The enthalpy in the steam basically has two components :

The Latent heat and the Sensible heat. Whereas condensate

has only sensible heat. This condensate has to be removed

as soon as it is formed, because it hinders to efficient heat

transfer as well as leads to water hammer phenomenon as it

is hot water (having more Specific Gravity) that moves with

high velocity of steam (8 to 10 times higher than water),

carrying enough momentum to rupture pipes and which is

damaging to the plant pipelines as well as piping

equipments. Hence, need to remove condensate from steam

main and trap steam. This is done by steam trap.

UKL Ball Float Trap discharge condensate near to steam

saturation temperature, which works on the principle of

Buoyancy, [densities difference of Water and Steam].The

rising condensate level elevates the Float open the valve and

discharges the condensate. When the level of condensate

drops, the float falls down and the valve close the trap.

It is commonly used for most process heating applications.

Wherever steam is used for indirect heating application, the

trap to be used must be of mechanical design. It is a

continuous discharge type steam trap. This trap can handle

very high condensate loads and the discharge will be

proportional to the differential pressure across the trap.

There may be other similar process applications where the

heat load is small and a mechanical trap can handle small as

well as fluctuating loads.

This trap is provided with two optional features called

Steam Lock release (SLR) and Thermostatic Vent (TV).

The SLR is a manual operation to release steam that may

hamper free movement of the float on water level. The TV

will ensure that air and such un dissolved gases will be

automatically vented out when present in condensate.

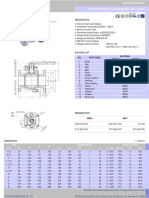

END CONNECTIONS:

MATERIAL OF CONSTRUCTION: UFT-14 CAST IRON MODEL

Threaded to NPT , BSP and BSPT.

CAST IRON MODEL UFT-20 CAST CARBON STEEL MODEL :-

UFT 14- CI – IS 210 FG260 Threaded to NPT , BSP and BSPT.

CAST CARBON STEEL MODEL Socket Weld to ASME B 16.11

UFT 20- CS- ASTM A216 Gr. WCB Flanged - #150/#300/#600

UKL-DS-UFT15-25-R00-MAY 2017

SIZES AVAILABLE:- INSTALLATION :-

UFT 14 Model: 15 NB, 20 NB and 25 NB Horizontal/Vertical position.

UFT 20 Model: 15 NB, 20 NB and 25 NB

OPTIONAL:-

IBR/Non-IBR

With Thermostatic Air vent

Inbuilt Strainer

.

UNI KLINGER LIMITED - AN ISO 9001:2008 COMPANY Page 1 of 4

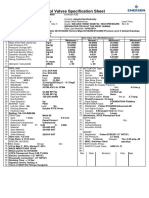

BILL OF MATERIAL:

UFT-14/UFT-20

Size- 15 NB/20 NB/25 NB 09 08 16 07 15 13 06 05 23 10

18

22

20

UNI KLINGER LTD.

PMA barg MODEL - UFT 20

TMA °C

TMO °C SIZE

P bar

21

19

01 14 04 12 03 11 02

UFT 20 Cast Steel Model UFT 14 Cast Iron Model

MATERIAL

No. PART NAME MATERIAL MATERIAL CODE MATERIAL

CODE

01 Body Cast Steel ASTM A 216 Gr WCB Cast Iron IS 210 FG 260

02 Cover Cast Steel ASTM A 216 Gr WCB Cast Iron IS 210 FG 260

03 Pivot Pin Stainless Steel AISI 304 Stainless Steel AISI 304

04 Valve Seat Stainless Steel AISI 304 Stainless Steel AISI 304

05 Pivot Bracket Stainless Steel AISI 304 Stainless Steel AISI 304

06 SLR Valve Seat Stainless Steel AISI 304 Stainless Steel AISI 304

07 Stem Stainless Steel AISI 304 Stainless Steel AISI 304

08 Stem Guide Stainless Steel AISI 304 Stainless Steel AISI 304

Stem Guide Lock

09 Stainless Steel AISI 304 Stainless Steel AISI 304

Nut

10# Float Stainless Steel AISI 304 Stainless Steel AISI 304

11 Lever Stainless Steel AISI 304 Stainless Steel AISI 304

12 Steel Ball Stainless Steel SS 440C Stainless Steel SS 440C

13# Cover Gasket CAF/ Non CAF CAF CAF CAF

14 Valve Seat Gasket Stainless Steel AISI 304 Stainless Steel AISI 304

SLR Valve Seat

Stainless Steel AISI 304 Stainless Steel AISI 304

15# Gasket

16 SLR Stem Gasket Graphite Graphite Graphite Graphite

17 Screws Stainless Steel AISI 304 Stainless Steel AISI 304

UKL-DS-UFT15-25-R00-MAY 2017

18 Cover Bolt (M10) Carbon Steel Gr. 8.8 Carbon Steel Gr. 8.8

19 Name Plate Stainless Steel AISI 304 Stainless Steel AISI 304

20 Rivets Alluminium --- Alluminium ---

ASTM A 106

21 Pipe

Carbon Steel ASTM A 106 Gr B Carbon Steel Gr B

22 Flanges- SWRF Carbon Steel ASTM A 105 Carbon Steel ASTM A 105

23 Strainer Stainless Steel AISI 304 Stainless Steel AISI 304

# AVAILABLE AS SPARES

UNI KLINGER LIMITED - AN ISO 9001:2008 COMPANY Page 2 of 4

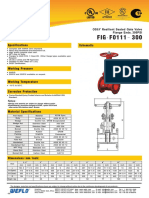

DIMENSIONS (mm) :-

B D

UNI KLINGER LTD.

PMA barg MODEL - UFT 20

TMA °C

TMO °C SIZE

P bar

A1 F E C

Screwed / Socket Weld End Connections

Size Diff Pressure A B C D E F Weight (kg)

15 NB 128 111 68 179 30 110 3.8

4.5/10/14 bar

20 NB 128 111 68 179 30 110 3.8

25 NB 153 111 75 202 30 130 5.3

Flanged End Connections

#150 #300

Size

A1 Weight(kg) A1 Weight(kg)

15 NB 278 4.5 278 5.1

20 NB 278 5.1 278 6.1

25 NB 303 7.0 303 8.0

Installation :-

The trap must be fitted with the float arm in a horizontal plane so that it rises and falls vertically. Hence the arrow on

the name plate must point downwards.

Traps will be generally supplied in horizontal connections with flow from left to right outlet (L-R) & horizontal

connections with flow R-L (rotating cover 180° w.r.t L-R ) or vertical connections with top inlet and bottom outlet

(rotating cover 90° w.r.t L-R) if specified.

The connection orientation can be changed from L-R and R-L in horizontal connections on site itself only by undoing

UKL-DS-UFT15-25-R00-MAY 2017

4 bolts and rotating the cover to required direction and then assembling.

The SLR has to be opened at the time of start up to avoid steam locking of the trap.

STORAGE

UNI KLINGER UFT and the respective spares should be stored only in enclosed dry rooms in a non-aggressive

atmosphere. Fully assembled Ball Float Traps must be stored as supplied by UNI KLINGER. Spare parts must be

handled with care and should be stored in their original packing.

UNI KLINGER LIMITED - AN ISO 9001:2008 COMPANY Page 3 of 4

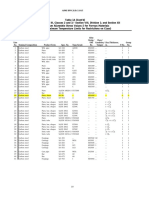

OPERATING CONDITIONS CAPACITY CHART

Max Diff.

Model PMO (Bar) Sat. Temp ⁰C

Pressure

UFT 14-4.5 4.5 Bar 14 193

UFT 14-10 10 Bar 14 193

UFT 14-14 14 Bar 14 193

UFT 20-4.5 4.5 Bar 32 237

UFT 20-10 10 Bar 32 237

UFT 20-14 14 Bar 32 237

UFT 20-21 21 Bar 32 237

UFT 20-32 32 Bar 32 237

For referring the capacity charts, please note

following:

• Select the model of UFT based on P/T range and MOC

• Select flow capacity on Y axis of the chart for selected

model.

• Work out actual differential pressure across the UFT.

• Consider all possible pressure losses in the lines.

• Select differential pressure on X axis.

• Move horizontally on Y axis & vertically on X axis.

• The point of cross section will give you the trap size

required.

MOST IMPORTANT:-

Before doing any maintenance on the trap it is necessary to isolate both supply and return lines and any pressure to

normalize to atmosphere pressure by opening SLR. Allow the trap to cool before doing any maintenance and clean all

sealing faces before assembling it.

How to order and Specify: SPARES AVAILABLE:

15 NB UKL UFT 14- 4.5 Bar, TV, Float Trap, Threaded SLR Assembly

BSP Float

Main controller assembly

Always order spares by stating the type and differential Cover Gasket

pressure, specify- Strainer

EXAMPLE :-

Controller Assembly- valve seat for 15 NB UFT14-4.5

Bar

UKL-DS-UFT15-25-R00-MAY 2017

Other Products : Cast / Forged Steel Piston Valves, Bellow seal valves, High Pressure valves (Gate/Globe) , Strainers – “Y” Type, ITVS

Steam Traps (Thermodynamic, Thermostatic, Ball Float Traps and IBT), Pressure Reducing Station, Condensate Recovery Products.

Level Gauges (Reflex, Transparent, Bicolor), Sight Glass, Hot Water Generation System, Safety and Relief Valves.

FSD Products : Compressed Asbestos / Non Asbestos Fiber Sheeting / Cut Gaskets, Spiral Wound Gaskets.

In view of technical progress design and dimensions are subjected to change without notice.

UNI KLINGER LIMITED

A joint venture of the Neterwala group of companies and KLINGER AG. Switzerland.

Central Sales Office & Pune Branch : SC1, 5th Fl., Kohinoor Est. Mumbai-Pune Highway, Kadaki, Pune-411 003. Tel.: +91-20-4102 3000 Fax.: (020) 4102 3001

e-mail : salescso@uniklinger.com, salespune@uniklinger.com, Website : www.uniklinger.com

Factory : C-37, M.I.D.C., Ahmednagar – 414 111, Maharashtra, Tel. : 0241 – 2777223 / 2777512 Fax : 0241 – 2777294, E-mail : fcdworks@uniklinger.com

Branch Offices :

Baroda : 102, 1st Floor, Oftel Towers-II R.C. Dutt Road, Baroda-390 005, Tel.: 91-0265-2312343 / 2340660, Fax.: 91-265-2341419. E-mail : salesbar@uniklinger.com

Chennai : East Coast Centre, 5th Floor, 553, Mount road, Teyanampet, Chennai - 600 018, Tel.: 91 - 44 - 24345707. Fax.: 91 - 44 - 24343960. E-mail : saleschen@uniklinger.com

Kolkata : 9, Chitrakoot, 8th Floor, 230 A, AJC Bose road, Kolkatta-700 020, Tel.: 91-33-22872510, Fax.: 91-33-22876494. E-mail : salescal@uniklinger.com

Mumbai : 22, 2nd Flr, Shreeji Arcade CHS, Almeda road, Thane-400 602, Tel.: 91-22-25421140 / 91-22-25440461, Fax.: 91-22-25440463. E-mail : salesmum@uniklinger.com

Delhi : 321, Ansal Chamber-II, 6, Bhikaji Cama Place, New Delhi-110 066, Tel.: 91-11-41658767 / 91-11-26193847 , Fax.: 91-11-41658768. E-mail : salesdel@uniklinger.com Page 4 of 4

Potrebbero piacerti anche

- Common Materials Welding CodesDocumento1 paginaCommon Materials Welding CodesLuttpiNessuna valutazione finora

- A105 A216 ComparisonDocumento10 pagineA105 A216 Comparisonprihartono_diasNessuna valutazione finora

- Equivalencia de AcerosDocumento8 pagineEquivalencia de AcerosTúlio Barata FrançaNessuna valutazione finora

- Data Sheet UFT 15-25NBDocumento4 pagineData Sheet UFT 15-25NBvipulsingh130Nessuna valutazione finora

- Data Sheet - Compressed Air Trap - UCA PDFDocumento4 pagineData Sheet - Compressed Air Trap - UCA PDFsiddheshNessuna valutazione finora

- Instruction Manual Ball Float Trap UFT PDFDocumento6 pagineInstruction Manual Ball Float Trap UFT PDFSaqib RaoufNessuna valutazione finora

- Trampa Tipo Balde JH7 TLVDocumento2 pagineTrampa Tipo Balde JH7 TLVAriel InsaurraldeNessuna valutazione finora

- Body & Bonnet / Cover Material: ASTM Specification Nominal/Designation ServiceDocumento2 pagineBody & Bonnet / Cover Material: ASTM Specification Nominal/Designation ServiceAntony MylvaganamNessuna valutazione finora

- MDT 2021 Bro Gtfe 10K FCDocumento1 paginaMDT 2021 Bro Gtfe 10K FCsuwono radukNessuna valutazione finora

- Nozasti Ventili Serije 200 (Knife Valves)Documento4 pagineNozasti Ventili Serije 200 (Knife Valves)Nenad NedeljkovicNessuna valutazione finora

- Steam Trap: P46SRN/P46SRM/P46SRWDocumento2 pagineSteam Trap: P46SRN/P46SRM/P46SRWGina FelyaNessuna valutazione finora

- 02.T Throttle Type Globe Valve Bonnetless: FeaturesDocumento1 pagina02.T Throttle Type Globe Valve Bonnetless: Featureskamal arabNessuna valutazione finora

- SS-E-04 - RID Air ToqueDocumento8 pagineSS-E-04 - RID Air ToqueagrovadoNessuna valutazione finora

- E ss1nh HPDocumento2 pagineE ss1nh HPRigobertoMedinaNessuna valutazione finora

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDocumento3 pagineCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9Nessuna valutazione finora

- FlowBiz Forged Steel Globe ValveDocumento14 pagineFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- FlowBiz Forged Steel Globe Valve Full BoreDocumento2 pagineFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- IPV - Vertical Indicator PostDocumento1 paginaIPV - Vertical Indicator PostAneesh ConstantineNessuna valutazione finora

- FlowBiz Forged Steel Globe Valve Reduced BoreDocumento2 pagineFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- FlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassDocumento2 pagineFlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassShakir AnsariNessuna valutazione finora

- 3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CDocumento5 pagine3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CAbigail Lupe Aguilar YapuraNessuna valutazione finora

- Hansun Tube Fitting - (S-LOK TYPE)Documento60 pagineHansun Tube Fitting - (S-LOK TYPE)qasim_maqboolNessuna valutazione finora

- RefBook Cashco ControlValvesDocumento24 pagineRefBook Cashco ControlValvesAksheyNessuna valutazione finora

- Automatic Air and Gas Vents For Liquid Systems - AE44Documento2 pagineAutomatic Air and Gas Vents For Liquid Systems - AE44Mohamed Osama El GendiNessuna valutazione finora

- BXX25 PGDocumento1 paginaBXX25 PGRam Prakash Durai RajanNessuna valutazione finora

- 10fco&fcos - 125fcoDocumento1 pagina10fco&fcos - 125fcoAndy SetyawanNessuna valutazione finora

- Ball Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsDocumento2 pagineBall Three Pieces Steel A105 / A216 WCB 1000 PSIG: Pressure Temperature RatingsAlicia MartinezNessuna valutazione finora

- Cast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KDocumento9 pagineCast Iron Gate Valves: OS& Y, Bolted Bonnet, JIS 10KSamuel GermatusNessuna valutazione finora

- Api and British Standard Trim DesignationsDocumento1 paginaApi and British Standard Trim DesignationsPOTDARNessuna valutazione finora

- Air ValveDocumento2 pagineAir ValveFAIYAZ AHMEDNessuna valutazione finora

- CMTOFTDocumento4 pagineCMTOFTagengfirstyanNessuna valutazione finora

- Steam & Condensate Manifold: M4/SM/CMDocumento2 pagineSteam & Condensate Manifold: M4/SM/CMBillal Al-ankarNessuna valutazione finora

- ISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFDocumento7 pagineISO Standard End-Suction Centrifugal Pumps NJK Series: PP-H PVDF Etfe PVDF CFRPVDFstar enggNessuna valutazione finora

- FlowBiz Forged Steel Globe Valve 1500 ClassDocumento2 pagineFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- Trim Numbers Nordic Pipe AbDocumento1 paginaTrim Numbers Nordic Pipe Abfer_2586Nessuna valutazione finora

- Kens Metal Brochure PDFDocumento40 pagineKens Metal Brochure PDFMike0% (1)

- Dual Filter: 20mm (/ ") - 200mm (8") Model OWDocumento4 pagineDual Filter: 20mm (/ ") - 200mm (8") Model OWJairo Andrés FANessuna valutazione finora

- ST - St. Wafer Butterfly Valve Jis10K/16KDocumento1 paginaST - St. Wafer Butterfly Valve Jis10K/16KCua TranNessuna valutazione finora

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Documento1 paginaOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNessuna valutazione finora

- Model: Heavy Duty Knife Gate ValveDocumento10 pagineModel: Heavy Duty Knife Gate Valveviki851Nessuna valutazione finora

- Caja Volante Manual Con EmbragueDocumento5 pagineCaja Volante Manual Con EmbragueNicolás FriasNessuna valutazione finora

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Documento5 pagineCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNessuna valutazione finora

- Safety Relief Valve VSEODocumento4 pagineSafety Relief Valve VSEOShashank HNessuna valutazione finora

- TLV SJ3FXDocumento2 pagineTLV SJ3FXÁlvaro Martínez FernándezNessuna valutazione finora

- Van bi inox lắp bích điều khiển khí nénDocumento1 paginaVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNessuna valutazione finora

- Carbon Steel Pipes: Application Pipe SpecificationsDocumento5 pagineCarbon Steel Pipes: Application Pipe SpecificationsFreddy Roa100% (1)

- Din 6314Documento2 pagineDin 6314Dule JovanovicNessuna valutazione finora

- A-36 - Pages From Section II Part D (Customary)Documento3 pagineA-36 - Pages From Section II Part D (Customary)siswantoNessuna valutazione finora

- TECVALDocumento8 pagineTECVALRamaswamy Neelakantan NNessuna valutazione finora

- FlowBiz Forged Steel Gate Valve Flanged End 150 ClassDocumento2 pagineFlowBiz Forged Steel Gate Valve Flanged End 150 ClassSHAKIR ANSARINessuna valutazione finora

- 각국 재질 비교표 (ASTM)Documento2 pagine각국 재질 비교표 (ASTM)Tommy Sung100% (1)

- Van bi inox tay gạt lắp bichDocumento1 paginaVan bi inox tay gạt lắp bichAutoma Viet NamNessuna valutazione finora

- 447 - en - CAAV - DAAV (CAAV0620S)Documento1 pagina447 - en - CAAV - DAAV (CAAV0620S)Mohammed NiqrisNessuna valutazione finora

- Bellow Seal Valves: AN ISO 9001:2000 COMPANYDocumento20 pagineBellow Seal Valves: AN ISO 9001:2000 COMPANYDeepak HishikarNessuna valutazione finora

- Check Ranurado RH84X MechDocumento1 paginaCheck Ranurado RH84X MechFLOW INDUSTRIAL SACNessuna valutazione finora

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Da EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Nessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Asme TDP-2006Documento38 pagineAsme TDP-2006ashdayashdayNessuna valutazione finora

- Elliott Upstream Solutions For Oil and Gas: Markets & ApplicationsDocumento8 pagineElliott Upstream Solutions For Oil and Gas: Markets & Applicationsyusuf alamerNessuna valutazione finora

- PSV Sizing TableDocumento14 paginePSV Sizing TablebadelitamariusNessuna valutazione finora

- Fire Water Demand PDFDocumento28 pagineFire Water Demand PDFOmar TocmoNessuna valutazione finora

- Pamphlet 9 - Edition 8 - Rev 1 January 2018 PDFDocumento48 paginePamphlet 9 - Edition 8 - Rev 1 January 2018 PDFArunkumar ChandaranNessuna valutazione finora

- NSFMW-2005-Technical-Papers FlowDocumento356 pagineNSFMW-2005-Technical-Papers FlowShakeel AhmedNessuna valutazione finora

- Electronic Timer Drain: Product FeaturesDocumento2 pagineElectronic Timer Drain: Product FeaturesdanielNessuna valutazione finora

- Turbine CommissioningDocumento36 pagineTurbine CommissioningAnonymous Ok9EVD2G100% (3)

- Flow After Flow Gas Wells Testing1Documento34 pagineFlow After Flow Gas Wells Testing1Rutwik BaradNessuna valutazione finora

- Oil IndiaDocumento445 pagineOil IndiaJayadevDamodaranNessuna valutazione finora

- Hazop - Net PDFDocumento9 pagineHazop - Net PDFPalash DeyNessuna valutazione finora

- Chapter 5: ParaffinDocumento37 pagineChapter 5: ParaffinjavierNessuna valutazione finora

- Delayed Coker Unit PinchDocumento28 pagineDelayed Coker Unit PinchPavel MarcinkovicNessuna valutazione finora

- Efficient Uses of Steam EnergyDocumento67 pagineEfficient Uses of Steam EnergytojinboNessuna valutazione finora

- Attach 1 - 9 PDFDocumento59 pagineAttach 1 - 9 PDFoperator produksiNessuna valutazione finora

- Polysep Oil Water SeparatorsDocumento4 paginePolysep Oil Water SeparatorsSAUL OSPINONessuna valutazione finora

- Pipe SpecDocumento84 paginePipe SpecAbdullahNessuna valutazione finora

- P103775-PC-FTD-003-r0.2 CONCEPTDocumento53 pagineP103775-PC-FTD-003-r0.2 CONCEPTErik ProchazkaNessuna valutazione finora

- Natural GAs Handbook CH-03Documento212 pagineNatural GAs Handbook CH-03yashin21100% (2)

- OlgaDocumento18 pagineOlgaSEEDEIG GROUPNessuna valutazione finora

- BIANCO Presentation PDFDocumento33 pagineBIANCO Presentation PDFnothing1aNessuna valutazione finora

- OMEGA AIR-Compressed Natural Gas Filtration - 950074Documento16 pagineOMEGA AIR-Compressed Natural Gas Filtration - 950074Junaid AhmedNessuna valutazione finora

- Integrated Management System: National Fertilizers LimitedDocumento48 pagineIntegrated Management System: National Fertilizers LimitedMK GandhiNessuna valutazione finora

- 1-Fisher Specification and Sizing Sheets - RevCDocumento3 pagine1-Fisher Specification and Sizing Sheets - RevCheikelNessuna valutazione finora

- DURI-GENTF14GN000-MEC-LST-PHR-2003-00 Rev 0A AFU Equipment List (For Issue)Documento10 pagineDURI-GENTF14GN000-MEC-LST-PHR-2003-00 Rev 0A AFU Equipment List (For Issue)Budi KamilNessuna valutazione finora

- Xe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableDocumento13 pagineXe-90M and Xe-145M Modbus Tables: R55 - R160 Fixed Speed Modbus TableAkun BaruNessuna valutazione finora

- Ball Float Steam TrapsDocumento22 pagineBall Float Steam TrapsManish SaraswatNessuna valutazione finora

- A869-6-44-0005 PMS For RevampDocumento950 pagineA869-6-44-0005 PMS For RevampMastram HatheshNessuna valutazione finora

- Adicomp TroubleshootingDocumento8 pagineAdicomp TroubleshootingM SohailNessuna valutazione finora

- API Tank DesignDocumento189 pagineAPI Tank DesignDD3NZ91% (11)