Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment2 of HMT ME 6003-1

Caricato da

Faraz KhanDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Assignment2 of HMT ME 6003-1

Caricato da

Faraz KhanCopyright:

Formati disponibili

IPS College of Technology & Management

An Institute of IPS Group of Colleges

PO: IPS College, Shivpuri Link Road, Gwalior. Ph-0751 3052400, Fax-3052447

ASSIGNMENT-II

HEAT AND MASS TRANSFER (ME-6003)

EXTENDED SURFACES (FINS) AND UNSTEADY HEAT CONDUCTION (UNIT-II)

Q.1 Drive the governing differential equation for temperature distribution of constant area extended surface.

Q.2 Define fin efficiency and fin effectiveness.

Q.3 What is lumped capacity analysis? What are assumptions for lumped capacity analysis?

Q.4 What do you understand by response of thermocouple? Also define time constant.

Q.5 In an indirect method of determining thermal conductivity of a material, a rod of 20mm diameter of this

material is kept with its one end inserted into a furnace, while the other end is kept projecting in air at 30 0C.

After steady state the temperature at two points 120mm apart are measured as 130 0C and 90 0C

respectively. Determine the thermal conductivity of the rod material, assuming heat transfer coefficient at

the rod surface as 20W/m2 k.

Q.6 An electronic semiconductor device generates heat equal to 480*10-3 W. In order to keep the surface

temperature at upper safe limit of 70 0C, the generated heat has to be dissipated to the surroundings which is

at 30 0C. To accomplish this task, aluminium fins of 0.7mm square size and 12mm long are attached to the

surface. The thermal conductivity of aluminium fins is 170 W/m K. If the heat transfer coefficient is 12W/m 2

k. Calculate the number of fins required. Assume no heat loss from the tip of the fins.

Q.7 A rod of 10mm square section and 160mm length with thermal conductivity of 50 W/m 0C protrudes

from a furnace wall at 200 0C and is exposed to air at 30 0C with convection coefficient 20 W/m2 0C.Make

calculations for the heat convected up to 80mm and 158mm lengths and comment on result. Adopt a long fin

model for the arrangement.

Q.8 Two long rods of the same diameter, one made of brass (K=85 W/m K) and the other made of copper

(K=375 W/m K) have one of their ends inserted into the furnace. Both of the rods are exposed to the same

environment. At a distance 10.5 cm away from the furnace end, the temperature of the brass rod is 120 0C.

At what distance from the furnace end the temperature would be reached in the copper rod?

Q.9 A turbine blade 6cm long and having a cross-sectional area 4.65cm2 and perimeter 12cm is made of

stainless steel (K=23.3 W/m K). The temperature at the root is 500 0C. The blade is exposed to a hot gas at

870 0C. The heat transfer coefficient between the blade surface and gas is 442 W/m 2 k. Determine the

temperature distribution and rate of heat flow at the root of the blade assuming the tip of the blade to be

insulated.

Q.10 The handle of a ladle used for pouring molten lead at 327 0C is 30cm long and is made of 2.5x1.5cm mild

steel bar stock(K=43 W/m K). In order to reduce the grip temperature, it is proposed to make hollow handle

of mild steel plate 1.5mm thick to the same rectangular shape. If the surface heat transfer coefficient is 14.5

W/m2 k and the ambient air is at 27 0C, estimate the inner surface of the hollow shape.

Q.11 A fin 5mm thick and 40mm long has its base on a plane plate which maintained at 130 0C. The ambient

temperature is 25 0C. The conductivity of fin material is 55 W/m 0C and the heat transfer coefficient is 145

W/m2 0C. Determine- (i) Temperature at the middle and at the end of the fin (ii) Heat dissipated by the fin

per meter width.

Q.12 The temperature distribution across a large concrete slab 500 mm thick heated from one side as

measured by thermocouples approximates to the following relation t=120-100x+24x2+40x3-30x4, where t is in

0C and x is in meters. Consider an area of 4m 2. Calculate- (i) The heat enters and leaves the slab in unit

time. (ii) The heat energy stored in unit time. (iii) The rate of temperature change at both sides of the slab.

(iv) The point where the rate of heating and cooling is maximum.

The properties for concrete are- K=1.2 W/m 0C, α=1.77x10-3 m2/hr.

Q.13 Discuss the criterion for lumped heat capacity analysis. A stainless steel rod of outer diameter 1.2cm

originally at a temperature of 350 0C is suddenly immersed in a liquid at 130 C for which the convective heat

transfer coefficient is 120 W/m2 k. Determine the time required for the rod to reach a temperature of 200 0C.

E-Mail ID: deanaa.ips@gmail.com, Website: http://www.ipsgwalior.org/

IPS College of Technology & Management

An Institute of IPS Group of Colleges

PO: IPS College, Shivpuri Link Road, Gwalior. Ph-0751 3052400, Fax-3052447

Q.14 A 50cm x 50cm brass slab 10 mm thick has a uniform temperature of 300 C. Its temperature is suddenly

lowered to 30 C. Calculate the time required for the plate to reach the temperature of 100 C. Take ρ =9000

kg/m3, CP=0.38 KJ/kg 0C ,K= 370 W/m 0C and h= 90 W/m2 0C.

Q.15 A steel ball of 5cm diameter, initially at 800 C exposed to still air at 30 C. Calculate- (i)

0

Temperature of ball after 30 seconds and (ii) Rate of cooling after 30 seconds( C/min). Take for steel– k= 40

W/m 0C, c=4200 J/kg K, ρ =7800 kg/m3 and for the surface of ball h= 20 W/m2 0C.

Q.16 One thousand spheres made of copper of diameter 10mm are annealed in the annealing furnace. Initial

temperature of the sphere=30 0C. Temperature of the annealing furnace=500 C. The properties of copper are

given as h= 30 W/m2 0C, CP=0.4 KJ/kg 0C, ρ =8200 kg/m3. Find the time required for the spheres to reach the

temperature of 300 0C.

Q.17 In heat treatment process, alloy steel balls of 12mm diameter are initially heated to 800 0C in a furnace.

Subsequently these are cooled to 100 0C by keeping them immersed in an oil bath at 35 0C with convection

coefficient 20 W/m2 0C. Find the time required for cooling process. Also calculate the value of convection

coefficient if it is desired to complete the cooling process in a period of 10 min. The thermo property of steel

balls are- ρ =7750 kg/m3 CP=520 J/kg 0C, k= 50 W/m 0C.

Q.18 A thermocouple junction of spherical form is to be used to measure the temperature of a gas stream.

The junction is initially at 20 0C and placed in gas stream which is at 200 0C. Make calculation for-(i) Junction

diameter needed for the thermocouple to have thermal time constant of one second (ii) Time required to

reach 197 0C for thermocouple assume the thermo physical properties as given below- ρ =8000 kg/m3, CP=0.4

kJ/kg 0C, k= 20 W/m 0C, h= 350 W/m2 0C.

Q.19 Calculate the junction diameter of a copper thermocouple, initially at 25 C, which when placed in a gas

stream at 200 C measures a temperature of 198 C in 5 seconds. For copper, ρ =8940 kg/m 3, CP=384 J/kg 0C, k=

390 W/m K and h= 350 W/m2 k.

E-Mail ID: deanaa.ips@gmail.com, Website: http://www.ipsgwalior.org/

Potrebbero piacerti anche

- HT Notes For ESEDocumento25 pagineHT Notes For ESEM BhurleNessuna valutazione finora

- Transient ConductionDocumento3 pagineTransient ConductionSanith RenjalNessuna valutazione finora

- Sheet 5Documento5 pagineSheet 5Mohamed AbdulazimNessuna valutazione finora

- Format For Declaration by InternsDocumento4 pagineFormat For Declaration by InternsNavya IshaNessuna valutazione finora

- Home Exam 1Documento3 pagineHome Exam 1htbd 1995Nessuna valutazione finora

- YYF - Tutorial 2 - CDB 2023 Conduction Heat Transfer - 120615Documento1 paginaYYF - Tutorial 2 - CDB 2023 Conduction Heat Transfer - 120615Tiger RaoNessuna valutazione finora

- 20ME111, Heat Transfer-Unit I II-Question BankDocumento7 pagine20ME111, Heat Transfer-Unit I II-Question BankR.MANIKANTHANessuna valutazione finora

- Tutorial 7 HTDocumento1 paginaTutorial 7 HTSahil GoyalNessuna valutazione finora

- Sheet 7Documento1 paginaSheet 7mkkNessuna valutazione finora

- Second AssignmentDocumento2 pagineSecond AssignmentNitish NehraNessuna valutazione finora

- 13 HT Assignment 01 2023 24 IisemDocumento2 pagine13 HT Assignment 01 2023 24 IisemrakiravaishuNessuna valutazione finora

- (An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaDocumento2 pagine(An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaMohammed Maaz100% (1)

- Heat and Mass Transfer Unit - I: 2 Conductivity 0 0Documento14 pagineHeat and Mass Transfer Unit - I: 2 Conductivity 0 0Christopher MillerNessuna valutazione finora

- Tutorial Sheet 3Documento2 pagineTutorial Sheet 3Mohammed MaazNessuna valutazione finora

- HMT Qp-IDocumento2 pagineHMT Qp-IPoyyamozhi Nadesan RanjithNessuna valutazione finora

- Sagar Group of Institutes, Bhopal: Subject: Heat& Mass Transfer CODE: ME-6003 Unit-IDocumento3 pagineSagar Group of Institutes, Bhopal: Subject: Heat& Mass Transfer CODE: ME-6003 Unit-IRiyasNessuna valutazione finora

- Heat Transfer AssignmentDocumento2 pagineHeat Transfer Assignmentdodo123dodo0% (1)

- Heat and Mass TransfgerDocumento15 pagineHeat and Mass TransfgerPeeyushiRaghavNessuna valutazione finora

- Heat Transfer - 012110043920 - 1Documento8 pagineHeat Transfer - 012110043920 - 1shweta_770587Nessuna valutazione finora

- HMT16 MarksDocumento12 pagineHMT16 MarkstagoreboopathyNessuna valutazione finora

- HMT Put Final 2018-18Documento2 pagineHMT Put Final 2018-18Vinod yadavNessuna valutazione finora

- Heat and Mass Transfer Practice Questions 1Documento2 pagineHeat and Mass Transfer Practice Questions 1Lucky 230503Nessuna valutazione finora

- Question Bank HTDocumento12 pagineQuestion Bank HTgreatrijuvanNessuna valutazione finora

- Tutorial - Transient ConductionDocumento2 pagineTutorial - Transient Conduction219016536Nessuna valutazione finora

- 9A03505 Heat TransferDocumento4 pagine9A03505 Heat TransfersivabharathamurthyNessuna valutazione finora

- Practice Set 19 (Fins)Documento2 paginePractice Set 19 (Fins)Nibir SahaNessuna valutazione finora

- BtechMech Heat TransferDocumento2 pagineBtechMech Heat TransferAdamsNessuna valutazione finora

- Mee40001 Thermodynamics 2 / Semester 2 2017 Assignment 1 DUE DATE: 25.09.2017 Mark: 5 % of Final Mark Answer All QuestionsDocumento1 paginaMee40001 Thermodynamics 2 / Semester 2 2017 Assignment 1 DUE DATE: 25.09.2017 Mark: 5 % of Final Mark Answer All QuestionsAndy NgoNessuna valutazione finora

- Super Drive Tut 3Documento4 pagineSuper Drive Tut 3Thebe Tshepiso MaitshokoNessuna valutazione finora

- 4th Sem.-ME 1251-HMTDocumento18 pagine4th Sem.-ME 1251-HMTPon ShanmugakumarNessuna valutazione finora

- PT1 AthtDocumento2 paginePT1 AthtFakkir MohamedNessuna valutazione finora

- Sheet 5 (Fins)Documento3 pagineSheet 5 (Fins)Rafi Mahmoud SulaimanNessuna valutazione finora

- UNIT-1: Question BankDocumento3 pagineUNIT-1: Question Bankdoddi.ajith2003Nessuna valutazione finora

- Heat and MassDocumento2 pagineHeat and Masssmg26thmayNessuna valutazione finora

- HeatDocumento1 paginaHeatM ANessuna valutazione finora

- Tutorial 3 HeatDocumento1 paginaTutorial 3 HeatBriana PalmerNessuna valutazione finora

- Tutorial One Heat Conduction: 5 2. A P M º N 0Documento7 pagineTutorial One Heat Conduction: 5 2. A P M º N 0kookoNessuna valutazione finora

- Week 1 TutorialsDocumento5 pagineWeek 1 TutorialsViliameNessuna valutazione finora

- HT ProblemsDocumento2 pagineHT ProblemsNipun SharmaNessuna valutazione finora

- 1,2,3 ProblemsDocumento25 pagine1,2,3 ProblemsWild BotNessuna valutazione finora

- Seatwork - Heat Transfer.Documento1 paginaSeatwork - Heat Transfer.BenNessuna valutazione finora

- Assignment 2Documento3 pagineAssignment 2Arjun AgarwalNessuna valutazione finora

- HMT5Documento9 pagineHMT5SriniNessuna valutazione finora

- HT Mod 3 and 4 Solved ProbsDocumento46 pagineHT Mod 3 and 4 Solved ProbsVishnu Prada A RNessuna valutazione finora

- To UploadDocumento2 pagineTo Uploadsmg26thmayNessuna valutazione finora

- Final HMT AssignmentsDocumento7 pagineFinal HMT Assignments544 vishwavijay PatilNessuna valutazione finora

- Tutorial Example For Traction and DriveDocumento11 pagineTutorial Example For Traction and DriveRajiv Vyas100% (1)

- Test-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oDocumento2 pagineTest-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oKrishnaJaiswal0% (1)

- Sheet 4Documento3 pagineSheet 4Yasmin RedaNessuna valutazione finora

- ME6502Documento10 pagineME6502Thulasi RamNessuna valutazione finora

- HMT Unit 1Documento9 pagineHMT Unit 1rp0212Nessuna valutazione finora

- MIN-305 Heat & Mass Transfer Tutorial - 2Documento2 pagineMIN-305 Heat & Mass Transfer Tutorial - 2Ashutosh SinghNessuna valutazione finora

- HT Problems-1Documento25 pagineHT Problems-1abhiram pasupuletiNessuna valutazione finora

- Assignment Unsteady StateDocumento2 pagineAssignment Unsteady StateChirag JainNessuna valutazione finora

- Assignment 2Documento4 pagineAssignment 2Roshan ShanmughanNessuna valutazione finora

- Digital Assignment 1Documento2 pagineDigital Assignment 1Anantha ReddyNessuna valutazione finora

- Assignment 3Documento2 pagineAssignment 3nprashantshekharNessuna valutazione finora

- Pressure Safety Valve Sizing Calculation Rev.01Documento3 paginePressure Safety Valve Sizing Calculation Rev.01Alvin Smith100% (10)

- Steady-State 2D Axisymmetric Heat Transfer WithconductionDocumento8 pagineSteady-State 2D Axisymmetric Heat Transfer WithconductionAhmed Badr MabroukNessuna valutazione finora

- A Study On The Thermal Comfort in Sleeping Environments in The Subtropics-Developing A Thermal Comfort Model For Sleeping Environments PDFDocumento12 pagineA Study On The Thermal Comfort in Sleeping Environments in The Subtropics-Developing A Thermal Comfort Model For Sleeping Environments PDFWGT KENDARINessuna valutazione finora

- Alfacubic - Alfa LavalDocumento24 pagineAlfacubic - Alfa LavalHarmonia MSanchezNessuna valutazione finora

- A Comprehensive Comparison of Mixing Rules For Calculation of Phase Equilibria in Complex SystemsDocumento8 pagineA Comprehensive Comparison of Mixing Rules For Calculation of Phase Equilibria in Complex Systemsmurdanetap957Nessuna valutazione finora

- Process Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 4Documento21 pagineProcess Simulation With Aspen Plus - Lecture - Chemical Engineering Design Towler & Sinnott Chapter 4Wahab MaqboolNessuna valutazione finora

- HVAC SYSTEM Operation and MaintenanceDocumento3 pagineHVAC SYSTEM Operation and MaintenanceSeru ArenaNessuna valutazione finora

- Water-Lithium Bromide Vapor Absorption SystemDocumento15 pagineWater-Lithium Bromide Vapor Absorption SystemSagar MoreNessuna valutazione finora

- (Cont'd) Review of Baisc ConceptsDocumento60 pagine(Cont'd) Review of Baisc Conceptskevintjj35Nessuna valutazione finora

- Physical 10Documento2 paginePhysical 10Rodriguez RommelNessuna valutazione finora

- 1.C.1 Limitations On The Work That Can Be Supplied by A Heat EngineDocumento30 pagine1.C.1 Limitations On The Work That Can Be Supplied by A Heat EnginekamsNessuna valutazione finora

- Anti Sweat HeatersDocumento2 pagineAnti Sweat HeatersbreavmacNessuna valutazione finora

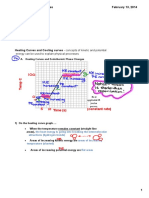

- Heating vs. Cooling Curve NotesDocumento5 pagineHeating vs. Cooling Curve NotesAlyssa ColeNessuna valutazione finora

- TD of Electrochemical Cells Lab ReportDocumento6 pagineTD of Electrochemical Cells Lab ReportDebalina Dass50% (2)

- Lapse Rate - Wikipedia, The Free EncyclopediaDocumento6 pagineLapse Rate - Wikipedia, The Free EncyclopediaambrofosNessuna valutazione finora

- Cooling Towers DesignDocumento8 pagineCooling Towers DesignMade PutraNessuna valutazione finora

- Steam Bench Apparatus ExperimentsDocumento4 pagineSteam Bench Apparatus Experimentsحسين عمريNessuna valutazione finora

- Process Simulation of Heat ExchangerDocumento5 pagineProcess Simulation of Heat ExchangersumitNessuna valutazione finora

- V G I S: On Variable-Primary FlowDocumento5 pagineV G I S: On Variable-Primary FlowSantiago J. ramos jrNessuna valutazione finora

- International StandardDocumento24 pagineInternational StandardOrlando MantillaNessuna valutazione finora

- Science 9 - Q4 - Week 5Documento17 pagineScience 9 - Q4 - Week 5Rhyan Zero-four BaluyutNessuna valutazione finora

- RDG 110Documento12 pagineRDG 110Ruben WalshNessuna valutazione finora

- MLZ18 24 PDFDocumento2 pagineMLZ18 24 PDFbabadapbadapNessuna valutazione finora

- EXPERIMENT CalorimeterDocumento15 pagineEXPERIMENT CalorimeterFath BondNessuna valutazione finora

- Cozy GWH18-24-28k Dreds Technical SpecificationsDocumento19 pagineCozy GWH18-24-28k Dreds Technical SpecificationsDuyNguyenNessuna valutazione finora

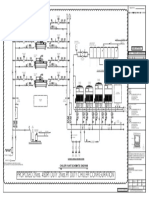

- Mep MTP Ac R SC 001 - Rev3Documento1 paginaMep MTP Ac R SC 001 - Rev3Hnin PwintNessuna valutazione finora

- Anexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPDocumento2 pagineAnexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPSicologo CimeNessuna valutazione finora

- Examples Steady Conduction in Slabs, Cylinders and Spheres Critical Thickness of InsulationDocumento22 pagineExamples Steady Conduction in Slabs, Cylinders and Spheres Critical Thickness of InsulationgazileNessuna valutazione finora

- Spare Parts Xarios 350 Container Frigo Cuisine PSODocumento65 pagineSpare Parts Xarios 350 Container Frigo Cuisine PSOVincent MarmandeNessuna valutazione finora

- BSC Part Two Updated20150915Documento58 pagineBSC Part Two Updated20150915Abhishek SinghNessuna valutazione finora