Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cad Cam Lab

Caricato da

Kashif HussainDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cad Cam Lab

Caricato da

Kashif HussainCopyright:

Formati disponibili

CAD/CAM LAB#02 15-02-2019

PART MODELING

Objective:

Introduction to Part Modeling in PRO-E software using Extrude, Round and Chamfer

features.

Software used:

PTC CREO ELEMENT PRO 5.0

Theory:

Part Modeling:

3D Parts and Assembly Modeling: 3D parts and assembly modeling is the CAD technique

through which the design intent of a part or assembly is accurately and unambiguously

described by a 3D virtual model, an almost tangible representation of physical reality.

Round Command:

The ROUND function rounds numbers to a specified level of precision. A round is an edge

treatment feature in which a radius or chord is added to one or more edges, an edge chain, or

the space between surfaces. Round works by rounding numbers 1-4 down, and rounding

numbers 5-9 up. It can round to the right or left of the decimal point.

Chamfer Command:

A bevel or chamfer can be defined by selecting two objects of the same or different object

types: lines, polylines, rays, and xlines. If the two selected objects are on the same layer, the

line defined is created on that layer. Otherwise, the line is created on the current layer. The

layer affects object properties including color and linetype. Chamfers are a type of feature

where an edge or corner is beveled. Surfaces can be solid model surfaces or

Kashif Hussain(16-011) Page 1

CAD/CAM LAB#02 15-02-2019

traditional Creo zero-thickness quilts and surfaces. You can create two types of chamfers:

corner chamfers and edge chamfers.

Extrude Command:

Extrude Command creates a 3D solid from an object that encloses an area, or a 3D surface

from an object with open ends. Objects can be extruded orthogonally from the plane of the

source object, in a specified direction, or along a selected path. An extrude feature is based

on a two-dimensional sketch. It linearly extrudes a sketch perpendicular to the sketching

plane to create or remove material. You can either select the sketch first then start the

Extrude tool, or you can start the Extrude tool and then select the sketch.

Kashif Hussain(16-011) Page 2

CAD/CAM LAB#02 15-02-2019

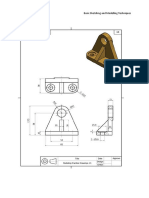

Task# 01:

Procedure:

First of all I created a new part file on creo screen.

I selected front panel.

Made a rectangle of 96 inch in length and 12 inch in width.

Made it hollow as shown in fig.

Then I made two holes of radius 10 inch on both sides as shown in fig.

Selected top panel I made a new rectangle of 10 inch in width and 30 inch in height.

Using round and chamfer tools I made its shape as shown in fig.

I successfully made the part according to the proper dimensions.

Kashif Hussain(16-011) Page 3

CAD/CAM LAB#02 15-02-2019

Task# 02:

Procedure:

First of all I created a new part file on Creo screen.

I selected front panel.

Made a rectangle of 100 inch.

Using chamfer I cut it.

Using 3 point circle tool I made half circles on both sides.

Made two holes at both ends.

I selected top panel.

Made hole at top of radius 60.

Made another hole of radius 47.

Cut this hole in middle on both sides by making a rectangle of 10 inches.

I successfully made the part according to the proper dimensions.

Kashif Hussain(16-011) Page 4

CAD/CAM LAB#02 15-02-2019

Task# 03:

Procedure:

First of all I created a new part file on Creo screen.

I selected front panel.

Made a rectangle of 80 inch.

At bottom side I made 2 another rectangles.

At end of these rectangles I made half circle of radius 40.

Made 2 holes of radius 16 at the distance of 25 inches from top.

Made a circle of 80 inch.

Made inner hole of radius 60.

Made another hole of radius 30.

I successfully made the part according to the proper dimensions.

Kashif Hussain(16-011) Page 5

CAD/CAM LAB#02 15-02-2019

Task# 04:

Procedure:

First of all I created a new part file on Creo screen.

I selected front panel.

Made a circle of radius 60.

Made inner hole of radius 40.

At left side of this circle made a rectangle of 60 inch in length and 60 in width.

At the end of this rectangle made a half circle of radius 25.

At the top side I made a rectangle as shown in fig.

At right side made a rectangle at distance of 15 inch from bottom.

Its length and width are 60 inch.

Made another rectangle of 60x45 as shown in fig.

Made 2 holes of radius 16.

Joined circle and boundary wall by a rectangle of 10 inch in width.

Kept care of dimensions.

I successfully made the part according to the proper dimensions.

Kashif Hussain(16-011) Page 6

Potrebbero piacerti anche

- Cad Lab 09Documento8 pagineCad Lab 09UsMan WarraichNessuna valutazione finora

- Autocad 2: The Joy of Mathematics, 204-5, Theoni Pappas 1989Documento4 pagineAutocad 2: The Joy of Mathematics, 204-5, Theoni Pappas 1989Farah RasheedNessuna valutazione finora

- QUESTION 1: Practicing Basic Commands of Pro/EDocumento24 pagineQUESTION 1: Practicing Basic Commands of Pro/ESubhradip SahaNessuna valutazione finora

- Proe TutorialDocumento15 pagineProe TutorialRajumhaveri HaveriNessuna valutazione finora

- 4inventor 201 Part 3Documento12 pagine4inventor 201 Part 3empty_shake5319Nessuna valutazione finora

- Learning Module MethodDocumento28 pagineLearning Module MethodakNessuna valutazione finora

- Chapter # 4Documento13 pagineChapter # 4M. RazaNessuna valutazione finora

- Autodesk Inventor Basic Sketching and Modelling TechniquesDocumento19 pagineAutodesk Inventor Basic Sketching and Modelling TechniquesSwanBellaNessuna valutazione finora

- Mel110 Lab SheetsDocumento16 pagineMel110 Lab SheetsVivek Verma100% (1)

- Exercise 2 - EN1740 2/8/2011: Linear ArrayDocumento5 pagineExercise 2 - EN1740 2/8/2011: Linear Arrayarturojimenez72100% (1)

- CIMCO CNC-Calc 2 Tutorial 4Documento12 pagineCIMCO CNC-Calc 2 Tutorial 4ing_pantovicNessuna valutazione finora

- Tutorial Cylinder Refined MeshDocumento9 pagineTutorial Cylinder Refined MeshShawn WaltzNessuna valutazione finora

- COM 215 Computer Packages II Practical BookDocumento18 pagineCOM 215 Computer Packages II Practical Bookabdulqudus abdulakeemNessuna valutazione finora

- Experiment No 3Documento10 pagineExperiment No 3pranja07Nessuna valutazione finora

- Session 13 Generate 2D Surface For 1D Line GeometryDocumento11 pagineSession 13 Generate 2D Surface For 1D Line Geometrykiranrnarik1998Nessuna valutazione finora

- Drawing Isometric Piping PDFDocumento6 pagineDrawing Isometric Piping PDFgamin0% (1)

- Braided Hose Tutorial by Leandro Fernandes Via GrabCadDocumento20 pagineBraided Hose Tutorial by Leandro Fernandes Via GrabCadDavid DickensNessuna valutazione finora

- Tutorial - How To Model Involute Gears in SolidWorks and Show Design Intent. - GrabCAD TutorialsDocumento74 pagineTutorial - How To Model Involute Gears in SolidWorks and Show Design Intent. - GrabCAD TutorialsEduNessuna valutazione finora

- Introduction To Part ModelDocumento11 pagineIntroduction To Part Modelsmg26thmayNessuna valutazione finora

- Part ModellingDocumento15 paginePart ModellingMaudi MasemolaNessuna valutazione finora

- Creating Arduino Board Case With Google SketchupDocumento27 pagineCreating Arduino Board Case With Google SketchupbelagioukNessuna valutazione finora

- Project #4 - Plate: Filename: PROJ-04.dwg Description: This Project Will Introduce You To The Use of The Arc ToolDocumento20 pagineProject #4 - Plate: Filename: PROJ-04.dwg Description: This Project Will Introduce You To The Use of The Arc ToolAgung vinel putra s. DepariNessuna valutazione finora

- Autocad Lab ReportDocumento9 pagineAutocad Lab ReportArsl RanaNessuna valutazione finora

- Numerical Modeling of An Octagonal Waveguide Applicator For High Power Microwave Heating Applications Using Ansoft's HFSSDocumento17 pagineNumerical Modeling of An Octagonal Waveguide Applicator For High Power Microwave Heating Applications Using Ansoft's HFSSbchaitanya55Nessuna valutazione finora

- In-Class Exam 2aDocumento3 pagineIn-Class Exam 2aRajib BaruaNessuna valutazione finora

- Google Sketchup Tutorial PacketDocumento11 pagineGoogle Sketchup Tutorial PacketJhon VelaNessuna valutazione finora

- Steps For Working With Draft Workbench in FreeCADDocumento3 pagineSteps For Working With Draft Workbench in FreeCADFaisal RehmanNessuna valutazione finora

- Autodesk Inventor Tutorial - Step 1: Installation and Setting UpDocumento16 pagineAutodesk Inventor Tutorial - Step 1: Installation and Setting UpavgpaulNessuna valutazione finora

- Tutorial 2: Steady Flow Past A Cylinder ISSIG 2015/2016Documento17 pagineTutorial 2: Steady Flow Past A Cylinder ISSIG 2015/2016Nader DallejNessuna valutazione finora

- Lab Manual: Cad 3DDocumento25 pagineLab Manual: Cad 3DnaveenNessuna valutazione finora

- Project 5: Modeling A Rocker Device (Using Sketch Curves) : PrerequisitesDocumento20 pagineProject 5: Modeling A Rocker Device (Using Sketch Curves) : PrerequisitessamihakhanNessuna valutazione finora

- 14-M&s-Shu - (S)Documento10 pagine14-M&s-Shu - (S)samiNessuna valutazione finora

- Drawing Dragster With SketchUp (Tutorial)Documento2 pagineDrawing Dragster With SketchUp (Tutorial)kmardock064100% (1)

- ANSYS Workbench 13 Tutorial - 2D Meshing With Prism Layers (Or Boundary Layers) On Wall BoundariesDocumento13 pagineANSYS Workbench 13 Tutorial - 2D Meshing With Prism Layers (Or Boundary Layers) On Wall BoundariesSyeilendra Pramuditya0% (1)

- CATPDG X Angle Bracket Detailed StepsDocumento13 pagineCATPDG X Angle Bracket Detailed StepsMuralidharan ShanmugamNessuna valutazione finora

- Adv. Laser Cutting Joinery Primer: The City University of New York Architectural Technology DeptDocumento10 pagineAdv. Laser Cutting Joinery Primer: The City University of New York Architectural Technology DeptramjoceNessuna valutazione finora

- Autocad EgDocumento7 pagineAutocad EgShelke Ms. Shreya Manish --Nessuna valutazione finora

- Create A CD Cover Design Using IllustratorDocumento142 pagineCreate A CD Cover Design Using IllustratorAbdellatif HarmaziNessuna valutazione finora

- Modul SW EnglishDocumento15 pagineModul SW EnglishrezaardNessuna valutazione finora

- Cad Cam FileDocumento29 pagineCad Cam FileLovely SainiNessuna valutazione finora

- Mechanical Engineering Department DJF41042 - CADCAM Practical Task 1 SESSION 2: 2022/2023Documento14 pagineMechanical Engineering Department DJF41042 - CADCAM Practical Task 1 SESSION 2: 2022/2023Amirun AminNessuna valutazione finora

- Drawing BasicsDocumento11 pagineDrawing Basicsapi-251224844Nessuna valutazione finora

- 2 Modeling and Assembly of Screw JackDocumento8 pagine2 Modeling and Assembly of Screw Jackselva_raj215414Nessuna valutazione finora

- CAD Lab ManualDocumento45 pagineCAD Lab ManualAmul KumarNessuna valutazione finora

- Cad Cam Practical Record BookDocumento125 pagineCad Cam Practical Record BookAKASHNessuna valutazione finora

- Essay of Engineering Design and Graphics With Solidworks 2016Documento4 pagineEssay of Engineering Design and Graphics With Solidworks 2016Manuel SanchezNessuna valutazione finora

- A Beginners GuideDocumento13 pagineA Beginners Guidesooner123456Nessuna valutazione finora

- Cad01 Activity 03 Group 04 Glorioso GuiaDocumento22 pagineCad01 Activity 03 Group 04 Glorioso GuiaGLORIOSO, Ken Erick O.Nessuna valutazione finora

- Date: Experiment No.:6: Sri. Y.SAGAR, Assistant Professor, Department of Mechanical Engineering, AITAMDocumento2 pagineDate: Experiment No.:6: Sri. Y.SAGAR, Assistant Professor, Department of Mechanical Engineering, AITAMN MAHESHNessuna valutazione finora

- INTRODUCTION TO Pro/E Wildfire 2.0: Unit IDocumento21 pagineINTRODUCTION TO Pro/E Wildfire 2.0: Unit IAjay CNessuna valutazione finora

- Electrical DRWDocumento12 pagineElectrical DRWbacktrxNessuna valutazione finora

- How To Create Footprints in OrCAD Layout HOA2003Documento4 pagineHow To Create Footprints in OrCAD Layout HOA2003danyNessuna valutazione finora

- MasterCAM - X5 - Mill Lesson #5Documento52 pagineMasterCAM - X5 - Mill Lesson #5Rafael DonadioNessuna valutazione finora

- Axial Fan (Solid Works Design)Documento14 pagineAxial Fan (Solid Works Design)ThanosNessuna valutazione finora

- Surface Lofts: Create Sketch1Documento10 pagineSurface Lofts: Create Sketch1bakri10101Nessuna valutazione finora

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)Da EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)Nessuna valutazione finora

- Csir Life Sciences Fresh Instant NotesDocumento4 pagineCsir Life Sciences Fresh Instant NotesAlps Ana33% (3)

- Trina 440W Vertex-S+ DatasheetDocumento2 pagineTrina 440W Vertex-S+ DatasheetBrad MannNessuna valutazione finora

- Noise and DB Calculations: Smart EDGE ECE Review SpecialistDocumento2 pagineNoise and DB Calculations: Smart EDGE ECE Review SpecialistLM BecinaNessuna valutazione finora

- Session 1Documento18 pagineSession 1Akash GuptaNessuna valutazione finora

- Alfa Week 1Documento13 pagineAlfa Week 1Cikgu kannaNessuna valutazione finora

- Dating Apps MDocumento2 pagineDating Apps Mtuanhmt040604Nessuna valutazione finora

- Alchemy of The HeartDocumento7 pagineAlchemy of The HeartAbdul RahimNessuna valutazione finora

- WWW Studocu Com in N 29646569 Sid 01682568219Documento1 paginaWWW Studocu Com in N 29646569 Sid 01682568219Nivetha SelvamuruganNessuna valutazione finora

- Create A Visual DopplerDocumento1 paginaCreate A Visual DopplerRahul GandhiNessuna valutazione finora

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocumento2 pagineLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahNessuna valutazione finora

- DIR-819 A1 Manual v1.02WW PDFDocumento172 pagineDIR-819 A1 Manual v1.02WW PDFSerginho Jaafa ReggaeNessuna valutazione finora

- Hare and Hyena: Mutugi KamundiDocumento18 pagineHare and Hyena: Mutugi KamundiAndresileNessuna valutazione finora

- Detail Design Drawings: OCTOBER., 2017 Date Span Carriage WayDocumento26 pagineDetail Design Drawings: OCTOBER., 2017 Date Span Carriage WayManvendra NigamNessuna valutazione finora

- Quotation of Suny PDFDocumento5 pagineQuotation of Suny PDFHaider KingNessuna valutazione finora

- Caring For Women Experiencing Breast Engorgement A Case ReportDocumento6 pagineCaring For Women Experiencing Breast Engorgement A Case ReportHENINessuna valutazione finora

- Pathogenic Escherichia Coli Associated With DiarrheaDocumento7 paginePathogenic Escherichia Coli Associated With DiarrheaSiti Fatimah RadNessuna valutazione finora

- Safety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536Documento4 pagineSafety Data Sheet SDS For CB-G PG Precision Grout and CB-G MG Multipurpose Grout Documentation ASSET DOC APPROVAL 0536BanyuNessuna valutazione finora

- RCA LCD26V6SY Service Manual 1.0 PDFDocumento33 pagineRCA LCD26V6SY Service Manual 1.0 PDFPocho Pochito100% (1)

- Pubb-0589-L-Rock-mass Hydrojacking Risk Related To Pressurized Water TunnelsDocumento10 paginePubb-0589-L-Rock-mass Hydrojacking Risk Related To Pressurized Water Tunnelsinge ocNessuna valutazione finora

- Invisible CitiesDocumento14 pagineInvisible Citiesvelveteeny0% (1)

- Unit 1 Module 3 Rep in PlantsDocumento26 pagineUnit 1 Module 3 Rep in Plantstamesh jodhanNessuna valutazione finora

- ST Arduino Labs CombinedDocumento80 pagineST Arduino Labs CombineddevProNessuna valutazione finora

- Iguard® LM SeriesDocumento82 pagineIguard® LM SeriesImran ShahidNessuna valutazione finora

- Math F112Documento3 pagineMath F112ritik12041998Nessuna valutazione finora

- Optimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsDocumento7 pagineOptimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsSheri ShahiNessuna valutazione finora

- Subject OrientationDocumento15 pagineSubject OrientationPearl OgayonNessuna valutazione finora

- Bcom (HNRS) Project Final Year University of Calcutta (2018)Documento50 pagineBcom (HNRS) Project Final Year University of Calcutta (2018)Balaji100% (1)

- KDE11SSDocumento2 pagineKDE11SSluisgomezpasion1Nessuna valutazione finora

- SubaruDocumento7 pagineSubaruclaude terizlaNessuna valutazione finora

- J.K. Brimacombe - Design of Continuous Casting MachinesDocumento13 pagineJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezNessuna valutazione finora