Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TCC Number 153 2 PDF

Caricato da

Omar VazquezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TCC Number 153 2 PDF

Caricato da

Omar VazquezCopyright:

Formati disponibili

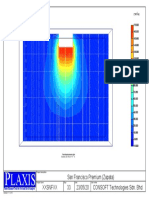

CURRENT IN AMPERES

100 000

10 000

20 000

30 000

40 000

50 000

60 000

70 000

80 000

90 000

1000

2000

3000

4000

5000

6000

7000

8000

9000

100

200

300

400

500

600

700

800

900

5 6 7 8 9 10 20 30 40 50 60 70 80 90

1000 1000

900 900

2-250E

2-300E

2-400E

200E

150E

175E

250E

300E

400E

100E

125E

800 800

10E

15E

25E

13E

20E

30E

40E

50E

65E

80E

700 700

3E

5E

7E

600 600

500 500

400 400

300 300

200 200

100 100

90 90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

9 9

8 8

7 7

6 6

5 5

TIME IN SECONDS

TIME IN SECONDS

4 4

3 3

2 2

1 1

.9 .9

.8 .8

.7 .7

.6 .6

.5 .5

.4 .4

.3 .3

.2 .2

.1 .1

.09 .09

.08 .08

.07 .07

.06 .06

.05 .05

.04 .04

.03 .03

.02 .02

.01 .01

1000

2000

3000

4000

5000

6000

7000

8000

9000

10 000

20 000

30 000

40 000

50 000

60 000

70 000

80 000

90 000

100 000

100

200

300

400

500

600

700

800

900

5 6 7 8 9 10 20 30 40 50 60 70 80 90

CURRENT IN AMPERES

MINIMUM MELTING TIME-CURRENT CHARACTERISTIC CURVES

SMU FUSE UNITS — S&C STANDARD SPEED

BASIS—These fuse units are tested in accordance with the proce Since fuse units having nickel-chrome or silver element con This narrow time band normally will provide the desired coordi

dures described in ANSI Standard C37.41-1981, and they are rated to struction are not subject to damage by aging or transient overcurrents, nation. If the selected S&C Standard Speed fuse unit does not meet

comply with ANSI Standard C37.46-1981. As required by these it is unnecessary to replace unblown fuse units of either of these the coordination requirements, check to see if the same ampere rating

standards, the minimum melting current is not less than 200% of constructions in single-phase or three-phase installations when one in the S&C Slow Speed or S&C Very Slow Speed will satisfy.

fuse-unit ampere rating, and the minimum melting curves are based or more fuse units have blown. Sometimes a selected ampere rating will fail to meet the coordina

on tests starting with the fuse unit at an ambient temperature of 25°C tion requirements in any available speed. In this case the selection of

and no initial load. COORDINATION—Any preloading reduces melting time. While this

phenomenon especially pronounced in other makes of fuses having another ampere rating for either the protecting or protected fuse usu

CONSTRUCTION—Fusible elements for fuse units rated 3E through minimum melting currents appreciably less then 200% of rating, the ally will satisfy all requirements.

7E amperes are nickel-chrome, under controlled tension; fusible effect of preloading must nonetheless be determined for the S&C fuse Do not assume that other fuses that do not employ S&C’s silver,

elements for fuse units rated 10E through 400E amperes are silver, units represented by these curves (see S&C Data Bulletin 240-195) helically coiled fusible element construction can better resolve a coor

helically coiled. All are of solderless construction. and adjustments to these curves must be made: dination impasse than the use of another ampere rating in one of the

1. When close coordination is required; S&C speed options. Such other fuses, including “time-lag” speeds,

TOLERANCES—Curves are plotted to minimum test points. Maximum

2. When, regardless of the preciseness of coordination, the fuse unit “super-slow” speeds, and “high-surge” speeds, require the use of

variations expressed in current values are:

is subjected to temporary overloads. “safety-zone” or setback allowances and, in addition, they have larger

Plus 10% for 10E through 400E ampere ratings. construction tolerances (plus 20% in current; plus 40% in terms

Plus 15% for 5E through 7E ampere ratings. There are cases where the coordination requirements may be very

exacting, for example, in coordinating a transformer primary fuse with of time). The application of these two factors will give a time interval

Plus 20% for 3E ampere rating. between the adjusted minimum melting curve and the total clearing

a secondary breaker and a source-side breaker. The time interval

APPLICATION—Like all high-voltage fuses, these fuse units are between the operating characteristics of the two breakers may be very curve greater than in the case of S&C speed options.

intended to accommodate overloads, not to interrupt them. Accord narrow. Under these circumstances there must be an extremely short

ingly, they feature fusible elements which are designed with a time interval between the minimum melting and the total clearing

minimum melting current of 200% of the fuse-unit ampere rating (for characteristics of the fuse.

fuse units rated 100 amperes or less) or 240% of the fuse-unit The fuse units represented by these curves possess this short

ampere rating (for fuse units rated over 100 amperes). As a result, time interval feature, since—having a nondamageable fusible

these fuse units have considerable peak-load capabilities; however,

FUSE UNITS AVAILABLE—

element of precise construction—they require: Type kV Nom. Ratings Ampere Ratings

they should never be exposed to loading in excess of the peak-load

1. As little as 10% total tolerance in melting current—compared to SMU-20®. . . . . . . . . . . . 14.4 through 34.5. . . . . . . 5E through 200E

capabilities listed in S&C Data Bulletin 240-190.

the 20% tolerance of many fuses (20% and 40% respectively in SMU-40®. . . . . . . . . . . . . . 4.8 through 25. . . . . . . . 3E through 400E

terms of time).

2. No “safety-zone” or setback allowances.

July 14, 2015

© S&C Electric Company 1972-2015, all rights reserved TCC Number 153-2

Potrebbero piacerti anche

- Regenerative Braking in Electric Vehicle 2Documento51 pagineRegenerative Braking in Electric Vehicle 2Subham Datta100% (1)

- (A) Wire Colour Identification (Iec 60204-1) : Prima Automation (I) Pvt. LTDDocumento2 pagine(A) Wire Colour Identification (Iec 60204-1) : Prima Automation (I) Pvt. LTDalkesh.engNessuna valutazione finora

- Handbook For Blast ResistantDocumento486 pagineHandbook For Blast Resistantvijaystructural100% (1)

- 2016CT Compressor Specs at GlanceDocumento4 pagine2016CT Compressor Specs at GlanceabsahkahNessuna valutazione finora

- Calculating heat energy radiated from a furnace flameDocumento5 pagineCalculating heat energy radiated from a furnace flameIvy Joy Ubina100% (1)

- Load Studies and Effects of Load VariationDocumento14 pagineLoad Studies and Effects of Load VariationAreeba Mushtaq AhmedNessuna valutazione finora

- Saudi Aramco Pre-Commissioning Form: Low Voltage Power Circuit BreakersDocumento3 pagineSaudi Aramco Pre-Commissioning Form: Low Voltage Power Circuit BreakersHaleem Ur Rashid BangashNessuna valutazione finora

- 2017CT CompressorSpecsAtAGlanceDocumento4 pagine2017CT CompressorSpecsAtAGlanceMadhana GopalNessuna valutazione finora

- Current in Amperes ChartDocumento1 paginaCurrent in Amperes ChartEddy UberguagaNessuna valutazione finora

- Total Clearing Time-Current Characteristic Curves: S&C Electric CompanyDocumento1 paginaTotal Clearing Time-Current Characteristic Curves: S&C Electric CompanyEddy UberguagaNessuna valutazione finora

- Minimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyDocumento1 paginaMinimum Tripping Time-Current Characteristic Curves: S&C Electric CompanyEddy UberguagaNessuna valutazione finora

- Current in Amperes - An Illustrated ChartDocumento1 paginaCurrent in Amperes - An Illustrated ChartRafaelo09Nessuna valutazione finora

- TCC Number 115 4Documento1 paginaTCC Number 115 4Dennis RimandoNessuna valutazione finora

- Long-time delay curve shift index for high ambient temperaturesDocumento1 paginaLong-time delay curve shift index for high ambient temperaturesBolivar MartinezNessuna valutazione finora

- Current Rating Multiples ChartDocumento1 paginaCurrent Rating Multiples ChartAmr AhmedNessuna valutazione finora

- GES-6121C: Multiples of Current RatingDocumento1 paginaGES-6121C: Multiples of Current RatingAdolfo Sotomayor BurgosNessuna valutazione finora

- GES-6122C: Multiples of Current RatingDocumento1 paginaGES-6122C: Multiples of Current RatingAdolfo Sotomayor BurgosNessuna valutazione finora

- Shift Index Temperature ChartDocumento1 paginaShift Index Temperature ChartBolivar MartinezNessuna valutazione finora

- Shift index curve for long-time overcurrent protectionDocumento1 paginaShift index curve for long-time overcurrent protectionPrathap KumarNessuna valutazione finora

- DES-095B: Approximately (0.784-Actual Pickup)Documento1 paginaDES-095B: Approximately (0.784-Actual Pickup)shrikanth5singhNessuna valutazione finora

- TCC Number 450 8 PDFDocumento1 paginaTCC Number 450 8 PDFjavier jimenez rodriguezNessuna valutazione finora

- Total Clearing Time-Current Characteristic Curves: Fault Tamer Fuse LimitersDocumento1 paginaTotal Clearing Time-Current Characteristic Curves: Fault Tamer Fuse LimitersStoner WddNessuna valutazione finora

- Comprehensive guide to circuit breaker ground trip element settingsDocumento2 pagineComprehensive guide to circuit breaker ground trip element settingsjurica_2006Nessuna valutazione finora

- Multiples of Ground Fault Pickup SettingDocumento1 paginaMultiples of Ground Fault Pickup SettingjosehenriquezsotoNessuna valutazione finora

- Multiples of Current Rating: Molded Case Circuit BreakersDocumento1 paginaMultiples of Current Rating: Molded Case Circuit BreakersAmr AhmedNessuna valutazione finora

- Long-time delay shift index chartDocumento1 paginaLong-time delay shift index chartMUSIC ELECNessuna valutazione finora

- Minimum Melting Time-Current Characteristic CurvesDocumento1 paginaMinimum Melting Time-Current Characteristic CurvesObed GarcíaNessuna valutazione finora

- Available Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Documento1 paginaAvailable Three-Phase Symmetrical Short-Circuit Current (Kiloamps)jurica_2006Nessuna valutazione finora

- Available Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Documento1 paginaAvailable Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Amr AhmedNessuna valutazione finora

- Des-095b - Long TimeDocumento1 paginaDes-095b - Long Timeshrikanth5singhNessuna valutazione finora

- Total Clearing Time-Current Characteristic Curves: Smu Fuse Units For Voltage-Transformer Applications-S&C Standard SpeedDocumento1 paginaTotal Clearing Time-Current Characteristic Curves: Smu Fuse Units For Voltage-Transformer Applications-S&C Standard SpeedObed GarcíaNessuna valutazione finora

- 165 6 PDFDocumento1 pagina165 6 PDFGonzalo Peñafiel CondoriNessuna valutazione finora

- DES-101B: Multiple of Trip Rating PlugDocumento1 paginaDES-101B: Multiple of Trip Rating Plugjurica_2006Nessuna valutazione finora

- Multiples of Current Rating: Molded Case Circuit Breakers Q LineDocumento1 paginaMultiples of Current Rating: Molded Case Circuit Breakers Q LineMUSIC ELECNessuna valutazione finora

- Catalogo ConductosDocumento8 pagineCatalogo ConductosCarlos ManriquezNessuna valutazione finora

- Model 9F54Dfc Series: Current in AmperesDocumento1 paginaModel 9F54Dfc Series: Current in AmperesPaulo H TavaresNessuna valutazione finora

- 165 6 2Documento1 pagina165 6 2Carlos A. Carpio CárdenasNessuna valutazione finora

- Vaccination Overview: Dekalb County Residents With at Least 1 DoseDocumento4 pagineVaccination Overview: Dekalb County Residents With at Least 1 DoseZachary HansenNessuna valutazione finora

- Curvas FusiblesDocumento2 pagineCurvas FusibleswilmerNessuna valutazione finora

- Previous Year SlidesDocumento276 paginePrevious Year Slidessalman siddiquiNessuna valutazione finora

- Gold - An Ideal Portfolio Diversifier: Retail Research 20 April, 2020Documento11 pagineGold - An Ideal Portfolio Diversifier: Retail Research 20 April, 2020Vivek TonapiNessuna valutazione finora

- Power Point UASDocumento1 paginaPower Point UASNurul KhatimahNessuna valutazione finora

- PLAXIS 3D Foundation Analysis Software TutorialDocumento1 paginaPLAXIS 3D Foundation Analysis Software TutorialJuan Guillermo Quitora RojasNessuna valutazione finora

- Struc TureDocumento1 paginaStruc TureAnh GiangNessuna valutazione finora

- PARAN3E ExerciseNo2 Layout1Documento1 paginaPARAN3E ExerciseNo2 Layout1Mickaela Kassandra ParanNessuna valutazione finora

- Daily COVID-19 cases, deaths and recoveries from June 24 to July 16, 2021Documento8 pagineDaily COVID-19 cases, deaths and recoveries from June 24 to July 16, 2021John Y FadrilanNessuna valutazione finora

- SMP 1 Weekly Overall Progress 20240113Documento262 pagineSMP 1 Weekly Overall Progress 20240113upickrahmanNessuna valutazione finora

- Situación Epidemiológica de Sarampión Rubeola y PFA Macro Oriente 14junio2021Documento40 pagineSituación Epidemiológica de Sarampión Rubeola y PFA Macro Oriente 14junio2021cdc.inmunopreveniblesNessuna valutazione finora

- MC 1 PDFDocumento1 paginaMC 1 PDFRoyal OtisNessuna valutazione finora

- Situación Epidemiológica de Sarampión Rubeola y PFA Macro Norte 17junio2021Documento49 pagineSituación Epidemiológica de Sarampión Rubeola y PFA Macro Norte 17junio2021cdc.inmunopreveniblesNessuna valutazione finora

- WSR WK27 20230703-0709 1Documento9 pagineWSR WK27 20230703-0709 1CHRISMAR ZALSOSNessuna valutazione finora

- Proposed Children'S Orphanage To Be Built at Kifaru Njia Panda-Moshi, KilimanjaroDocumento4 pagineProposed Children'S Orphanage To Be Built at Kifaru Njia Panda-Moshi, KilimanjaroChille Nchimunya BwalyaNessuna valutazione finora

- Web Analytics at Quality Alloys - Tanay - EPGP-10-156Documento11 pagineWeb Analytics at Quality Alloys - Tanay - EPGP-10-156Rohit Sharma100% (1)

- Site Plan + Luas - 230426 - 223115Documento1 paginaSite Plan + Luas - 230426 - 223115J.T HalohoNessuna valutazione finora

- Asignación de Persinal Y Curva "S"Documento2 pagineAsignación de Persinal Y Curva "S"RoberChavarríaCastañedaNessuna valutazione finora

- AT GRADE PLAN - PerfectDocumento1 paginaAT GRADE PLAN - PerfectnhaiNessuna valutazione finora

- OSHYIYEDocumento1 paginaOSHYIYENana BarimaNessuna valutazione finora

- ADA Index and Sample Output PDFDocumento8 pagineADA Index and Sample Output PDFKavita GohelNessuna valutazione finora

- Distribution LayoutDocumento1 paginaDistribution LayoutAndy ArenasNessuna valutazione finora

- Arabian Construction Company: 18,000 Civil& Buildings Cum. TotalDocumento3 pagineArabian Construction Company: 18,000 Civil& Buildings Cum. TotalJule LobresNessuna valutazione finora

- Daily COVID-19 UpdateDocumento3 pagineDaily COVID-19 UpdateFikri MaulanaNessuna valutazione finora

- C-Purlins/Cladding Layout Detail: Rehabilitation of Capangdan GymDocumento1 paginaC-Purlins/Cladding Layout Detail: Rehabilitation of Capangdan GymVictorino SantosNessuna valutazione finora

- GIORDANO HOUSE - 2120320 - DenahDocumento3 pagineGIORDANO HOUSE - 2120320 - DenahBintang Murnadi HanantoNessuna valutazione finora

- Hipot Test VT Reading Sample For GisDocumento1 paginaHipot Test VT Reading Sample For GisNOWFALNessuna valutazione finora

- Dr. Gigih Udi Atmo - Overview of Electric Vehicles Development in APECDocumento23 pagineDr. Gigih Udi Atmo - Overview of Electric Vehicles Development in APECArfie IkhsanNessuna valutazione finora

- Visualizing The 3 Scopes of Greenhouse Gas EmmisionsDocumento3 pagineVisualizing The 3 Scopes of Greenhouse Gas EmmisionsKonstantinos NikolopoulosNessuna valutazione finora

- 2007 03 08 EUCI - Nuclear RenaissanceDocumento44 pagine2007 03 08 EUCI - Nuclear RenaissanceEdward KeeNessuna valutazione finora

- VEHICLE FUEL ECONOMY IN MAJOR MARKETS 2005-2019Documento195 pagineVEHICLE FUEL ECONOMY IN MAJOR MARKETS 2005-2019Berl MNessuna valutazione finora

- Solar Air Conditioner: Jijin K Janan S8, Me B4ENME9425Documento21 pagineSolar Air Conditioner: Jijin K Janan S8, Me B4ENME9425Rahul RokssNessuna valutazione finora

- ICE Energy Efficiency, Inputoutput Flow and Emissions ControlDocumento22 pagineICE Energy Efficiency, Inputoutput Flow and Emissions ControlAhmed MohamedNessuna valutazione finora

- Chapter - 2 General InformaionsDocumento6 pagineChapter - 2 General InformaionsJahangir AlamNessuna valutazione finora

- 9 Inverters LowDocumento29 pagine9 Inverters LowteslanNessuna valutazione finora

- GreenVision Xceed - Product DatasheetDocumento3 pagineGreenVision Xceed - Product DatasheetJerson Bastidas AragonNessuna valutazione finora

- MSC Physics - Part-I - Part-IIDocumento16 pagineMSC Physics - Part-I - Part-IIRahul Kumar SharmaNessuna valutazione finora

- Types of Boilers ExplainedDocumento1 paginaTypes of Boilers Explainedrafique08Nessuna valutazione finora

- Flame Detection System RelayDocumento2 pagineFlame Detection System RelayqaedmahmoodNessuna valutazione finora

- Semester II Courses at a GlanceDocumento12 pagineSemester II Courses at a GlanceAnmol SahuNessuna valutazione finora

- Incubadora Ref 3990ltDocumento2 pagineIncubadora Ref 3990ltKarynaHernandezMonarrezNessuna valutazione finora

- Bioenergy Conversion FactorsDocumento4 pagineBioenergy Conversion FactorsAhmet SeçenNessuna valutazione finora

- CHAPTER 2 Lecture Notes EPS115Documento3 pagineCHAPTER 2 Lecture Notes EPS115NGEH SAMUEL SHUNessuna valutazione finora

- Compact NSX Compact Ins/Inv Masterpact NW DC - DC PV: Pact SeriesDocumento302 pagineCompact NSX Compact Ins/Inv Masterpact NW DC - DC PV: Pact SeriesThắng CòiNessuna valutazione finora

- 2012 Ewg Microgrids-Formatted PDFDocumento102 pagine2012 Ewg Microgrids-Formatted PDFเทสโก้ เอ็นเนอร์ยี่Nessuna valutazione finora

- Flex2power FOWTDocumento9 pagineFlex2power FOWTGiuseppe Di SienaNessuna valutazione finora

- Case Study - Rugby Borough Council John Barford Car ParkDocumento2 pagineCase Study - Rugby Borough Council John Barford Car Parkapi-250994550Nessuna valutazione finora

- Literature Review of BLDCDocumento6 pagineLiterature Review of BLDCsushil63666Nessuna valutazione finora

- 1503 NZM1-4 Molded Case Circuit-breakers-SEA - MCCBDocumento105 pagine1503 NZM1-4 Molded Case Circuit-breakers-SEA - MCCBAngga D SantosoNessuna valutazione finora

- 4991 Checklist 1905451Documento4 pagine4991 Checklist 1905451alaae5917Nessuna valutazione finora