Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stelex Pro

Caricato da

Rafael TellezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stelex Pro

Caricato da

Rafael TellezCopyright:

Formati disponibili

May, 10

STELEX* PrO

Ceramic Foam Filters For Carbon & Low Alloy Steel Castings

Product STELEX PrO ceramic foam filters are comprised of a carbon-alumina-ceramic

Description matrix that possesses unique physical properties of low thermal mass, high

thermal shock resistance, high hot strength and high resistance to thermal creep.

STELEX PrO filters are also resistant to chemical attack by most common slags

and deoxidizers. This unique combination of physical properties is ideally suited

for carbon and low alloy steel castings poured through conventional gating

systems.

STELEX PrO filters smooth the flow of molten metal to the mold cavity while

removing non-metallic inclusions such as slag, refractory materials, molding sand,

and products of reoxidation and deoxidation from the metal stream. They prime

over the full range of pouring temperatures for carbon and low alloy steel

minimizing the need for superheating. STELEX PrO filters are intended for use

with all common carbon and low alloy steel grades at pouring temperatures to

3050°F.

Filtration improves or maintains casting quality and can increase foundry

productivity and profitability. Proper use of STELEX PrO filters reduces internal

welding and cleaning costs, reduces the rate of casting returns, improves casting

machinability and cutting tool life, and reduces scrap. Filtration is one of the most

cost-effective and flexible means of satisfying the need for clean castings.

Product Filter Size Product Packaging Length / Frontal Thick-

Range (mm) Code (pcs/ctn) Width Area ness

(in) (in2) (in)

50 Diax20/10 PPI 133450 240 1.95 +/- .06 2.98 0.79

60 Diax20/10 PPI 141480 117 2.34 +/- .06 4.30 0.98

75 Diax25/10 PPI 312730 117 2.91 +/- .08 6.65 0.98

90 Diax25/10 PPI 654030 117 3.51 +/- .08 9.86 0.98

100 Diax25/10 PPI 420060 54 3.86 +/- .08 11.70 0.98

125 Diax30/10 PPI 594020 40 4.91 +/- .09 18.93 1.18

150 Diax30/10 PPI 707430 16 5.90 +/- .09 27.25 1.18

175 Diax35/10 PPI 107960 14 6.89 +/- 0.12 37.28 1.38

200 Diax35/10 PPI 408000 9 7.87 +/- .12 48.65 1.38

50x50x20/10 PPI 108070 240 1.95 +/- .05 3.80 0.79

55x55x25/10 PPI 111090 240 2.15 +/- .05 4.62 0.98

75x75x25/10 PPI 116090 117 2.95 +/- .08 8.70 0.98

100x100x25/10 PPI 120080 54 3.90 +/- .08 15.21 0.98

125x125x30/10 PPI 124570 40 4.91 +/- .09 24.11 1.18

150x150x30/10 PPI 130130 16 5.90 +/- .09 34.81 1.18

FOSECO, 20200 Sheldon Road, Brook Park, Ohio 44142-1360 USA

Telephone: 440-826-4548, Facsimile: 440-826-3434

Foseco is a division of Vesuvius USA Corporation, Illinois, USA

Product DEOXIDATION PRACTICE

Application The level of deoxidizers—particularly Al, Ti, and Zr—should be minimized.

“Clean” metal practices increase the filtration capacity of steel filters and reduce

filtration costs.

POURING TEMPERATURE

To ensure consistent filter priming and metal flow, metal should be poured at a

minimum of 75°F above its liquidus temperature. A typical minimum pouring

temperature for carbon steel and low alloy steels is 2830°F.

SUPERHEAT

The unique physical/thermal properties of STELEX PrO filters make it

unnecessary to superheat carbon and low alloy steels to minimize the risk of mis-

runs. Nevertheless, reasonable precautions should be taken to minimize pouring

temperature variations to ensure consistent filter performance.

FOUNDRY PRACTICE VARIATIONS

STELEX PrO filter performance can change significantly with variations in pouring

temperature, pouring rate from the ladle, metallostatic pressure, metal chemistry,

and filter placement in the gating system. Filter users are strongly encouraged to

conduct trials to determine obtainable flow rates and filtration capacities for each

filter size when using various foundry practices.

MANUAL DETERMINATION OF FILTER SIZE

Initial selection of filter size is a simple three-step process. Refer to Tables 1 & 2

for filter dimensions and performance characteristics.

Step 1

Flow rate requirements: A certain minimum filter area is required to achieve the

desired mold filling time. To determine the required minimum filter area, multiply

the gating system choke area by a suitable filter-to-choke ratio; typically between

4.5 : 1 and 6.0 : 1. The proper ratio will depend on metal cleanliness, ladle

practice and pouring temperature for the particular application. Referring to the

Usable Frontal Area column in Table 1, choose the STELEX PrO filter that

provides the required filter area.

Filter Area (in2) = Filter-to-Choke Ratio x Choke Area (in2)

Step 2

Filtration capacity requirements: Using the appropriate Filtration Capacity Range

column in Table 2, determine the filter that will pass a sufficient amount of steel

for the application.

Filtration Capacity (lbs) ≥ Poured Weight of the Casting (lbs)

Step 3

After determining the recommended filter size based on the flow rate and filtration

capacity requirements (Steps 1 & 2), the larger of the two filters should be used.

The user needs to confirm that the pouring ladle is capable of supplying metal to

the mold at the desired flow rate, as specified in the Nominal Flow Rate column of

Table 2, throughout the pour.

FOSECO, 20200 Sheldon Road, Brook Park, Ohio 44142-1360 USA

Telephone: 440-826-4548, Facsimile: 440-826-3434

Foseco is a division of Vesuvius USA Corporation, Illinois, USA

Product Table 2: Filtration Capacity and Maximum Flow Rate Values For STELEX PrO

Application Ceramic Foam Filters (average for all ladles)

(Con’t)

Maximum Filtration Capacity** Maximum Flow

Carbon and Low Alloy Steels Rate**

(Lbs) (lbs/sec)

High Level Low Level Carbon

Filter Size Deoxidation Deoxidation and

(mm) Products Products Low Alloy

“Dirty” Metal “Clean” Metal Steels

50 Diax20/10 PPI 98 147 8.4

60 Diax20/10 PPI 141 211 13.0

75 Diax25/10 PPI 220 330 23.0

90 Diax25/10 PPI 317 475 34.0

100 Diax25/10 PPI 391 586 46.0

125 Diax30/10 PPI 611 916 62.0

150 Diax30/10 PPI 880 1319 85.0

175 Diax35/10 PPI 1198 1795 109.0

200 Diax35/10 PPI 1564 2346 142.0

50x50x20/10 PPI 124 187 13.0

55x55x25/10 PPI 151 227 13.0

75x75x25/10 PPI 280 420 23.0

100x100x25/10 PPI 498 746 42.0

125x125x30/10 PPI 778 1166 63.0

150x150x30/10 PPI 1120 1680 87.0

** Flow Rate and capacity data was generated using Foseco’s METHODCALC* for steel filter application

software. The calculations for round filters assume a direct impingement application, 12-inch effective head

height, the filter as the choke, and a 2830oF pouring temperature from a lip pour ladle. The calculations for

square filters assume a FP1 filter print, 12-inch effective head height, the filter as the choke, and a 2830oF

pouring temperature from a lip pour ladle.

GATING DESIGN AND FILTER PLACEMENT

Optimal results are achieved using unpressurized gating systems. STELEX PrO

filters must be adequately supported to maintain integrity and to prevent metal

bypass. Please refer to the STELEX Filter Print Data Sheet for more details on

filter print design.

POURING PRACTICE

When pouring directly onto the face of the filter, minimize the height from which the

metal is poured. Maintain precise temperature control to minimize mis-runs.

Assure adequate metal delivery from the ladle to keep the sprue full during pouring

and prevent intermittent flow. The gating system should be designed to assure

rapid filling and be more than capable of accommodating the maximum delivery

rate from the ladle.

Patents STELEX PrO filters are covered by US patent # 7,138,084 Canadian patent # 2,413,496.

* Trademark of the Foseco Foundry Division of the Vesuvius Group, used under license.

CAUTION

FOSECO products are made from quality materials and are designed to serve with maximum efficiency and minimum risk. However, as with many substances used

in industry, health hazards may be present in the use of FOSECO products and, therefore, it is extremely important that the user familiarize himself with the warning

and handling instructions on the label and on the Occupational Safety and Health Data Sheet. Contact a FOSECO representative if further information is needed or

if the product is to be used in an unusual application.

Every effort is made to ensure the fitness of FOSECO products for their stated purpose, however, because FOSECO has no control over the use of its products, no

warranty can be made in regard to results attending their use or to possible adverse metallurgical consequences and side effects. You should read carefully the

Terms and Conditions of Sale which accompany the sale of any FOSECO product which you use.

FOSECO, 20200 Sheldon Road, Brook Park, Ohio 44142-1360 USA

Telephone: 440-826-4548, Facsimile: 440-826-3434

Foseco is a division of Vesuvius USA Corporation, Illinois, USA

FOSECO, 20200 Sheldon Road, Brook Park, Ohio 44142-1360 USA

Telephone: 440-826-4548, Facsimile: 440-826-3434

Foseco is a division of Vesuvius USA Corporation, Illinois, USA

Potrebbero piacerti anche

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDa EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNessuna valutazione finora

- STELEXDocumento1 paginaSTELEXbrazilfoundry1986Nessuna valutazione finora

- AMCOL - MCST - TR - HeviSand - Chromite - Double - Skin Defect - On - Heavy - Steel - Casting PDFDocumento12 pagineAMCOL - MCST - TR - HeviSand - Chromite - Double - Skin Defect - On - Heavy - Steel - Casting PDFSUNDRAMNAGANessuna valutazione finora

- Heat TreatmentDocumento179 pagineHeat TreatmentDebye101100% (1)

- Study On Retained AusteniteDocumento3 pagineStudy On Retained Austenitedwimukh360Nessuna valutazione finora

- Microsoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Documento81 pagineMicrosoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Damla Kaymakçı100% (1)

- Common Causes of Premature Failure of MN SteelDocumento3 pagineCommon Causes of Premature Failure of MN Steeldrackensohn100% (1)

- FP240Documento28 pagineFP240igorisakovNessuna valutazione finora

- Metal Identification Tests GuideDocumento24 pagineMetal Identification Tests GuideAnonymous dh6DITNessuna valutazione finora

- Alloying Elements and Their EffectsDocumento5 pagineAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Development of New Etchant For High Manganese Steel CastingDocumento9 pagineDevelopment of New Etchant For High Manganese Steel CastingShankhaPathakNessuna valutazione finora

- Steel CleanlinessDocumento22 pagineSteel CleanlinessfondershellNessuna valutazione finora

- Hadfields Manganese SteelDocumento3 pagineHadfields Manganese SteelndeminNessuna valutazione finora

- Effect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Documento7 pagineEffect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Uma KoduriNessuna valutazione finora

- Gray Iron Foundries Produce High-Strength CastingsDocumento20 pagineGray Iron Foundries Produce High-Strength Castingsbebe3838Nessuna valutazione finora

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocumento11 pagineCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNessuna valutazione finora

- MCM AllDocumento7 pagineMCM AllPalanisamy RajaNessuna valutazione finora

- Crystals 12 00978Documento9 pagineCrystals 12 00978irmaNessuna valutazione finora

- Desulfurization of SteelDocumento69 pagineDesulfurization of SteelPouria Homayoun100% (2)

- O HC HCDocumento101 pagineO HC HCIndustrial Infra Jobs100% (1)

- Analysis of Reasons Causing Riser Feeding FailureDocumento8 pagineAnalysis of Reasons Causing Riser Feeding Failuremarcotulio123Nessuna valutazione finora

- Characterizing Metallic Microstructure Cu-Based AlloysDocumento51 pagineCharacterizing Metallic Microstructure Cu-Based AlloysjuegyiNessuna valutazione finora

- The Structure and Magnetic Properties of Fe-Mn-C Alloy: Vera V. Kazantseva and Ludmila I. KveglisDocumento8 pagineThe Structure and Magnetic Properties of Fe-Mn-C Alloy: Vera V. Kazantseva and Ludmila I. KveglissushmaxNessuna valutazione finora

- ISO 7010 Safety Colours and - Safety SignsDocumento19 pagineISO 7010 Safety Colours and - Safety SignsKrishnaKumarNessuna valutazione finora

- HT Work Instruction Chart 23.03.2010 RevisedDocumento5 pagineHT Work Instruction Chart 23.03.2010 RevisedkvmoorthiNessuna valutazione finora

- Mechanism and Conditions for Obtaining Different Graphite Structures in Gray Cast IronDocumento21 pagineMechanism and Conditions for Obtaining Different Graphite Structures in Gray Cast IronArjyajyoti Goswami100% (1)

- Steel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofDocumento8 pagineSteel Processing in Energy Optimizing Furnace: 4.1 Preparation of EofRitesh KumarNessuna valutazione finora

- Carbon Dioxide Moulding ProcessDocumento17 pagineCarbon Dioxide Moulding ProcessqwertyuioNessuna valutazione finora

- Dictionary of Metal TerminologyDocumento59 pagineDictionary of Metal TerminologyyogeshNessuna valutazione finora

- Bar Basics and TerminologyDocumento24 pagineBar Basics and TerminologyEdwin MPNessuna valutazione finora

- Stainless Steel Technical PresentationDocumento23 pagineStainless Steel Technical PresentationRavi Teja100% (1)

- Metrode ER110S-G FillerDocumento6 pagineMetrode ER110S-G FillerBernie SimcsNessuna valutazione finora

- Nmd-Atm-2018r-00405 - Arghya Majumder - RinlDocumento18 pagineNmd-Atm-2018r-00405 - Arghya Majumder - RinlArghya MajumderNessuna valutazione finora

- ITT CCTdiagrams (M)Documento37 pagineITT CCTdiagrams (M)Michael Vincent MirafuentesNessuna valutazione finora

- Friction Coefficients of Some Common MaterialsDocumento2 pagineFriction Coefficients of Some Common MaterialsWanda Hafiz NurzamanNessuna valutazione finora

- Effect of Alloying Elements On Microstructure and Mechanical Properties of Ductile IronDocumento5 pagineEffect of Alloying Elements On Microstructure and Mechanical Properties of Ductile IronIjabiNessuna valutazione finora

- Effect of Alloying Elements On Steel PropertiesDocumento2 pagineEffect of Alloying Elements On Steel PropertiesKARTHIGEYAN.RNessuna valutazione finora

- Engineering Failure Analysis of Low Carbon Steels in Deep DrawingDocumento7 pagineEngineering Failure Analysis of Low Carbon Steels in Deep DrawingPaul RosiahNessuna valutazione finora

- Advances in The Metallurgy and Applications of ADIDocumento18 pagineAdvances in The Metallurgy and Applications of ADISEP-PublisherNessuna valutazione finora

- Reducing Gear Distortion with Simple FixtureDocumento7 pagineReducing Gear Distortion with Simple FixtureVireshVerma100% (1)

- Surface Graphite Degeneration in Ductile Iron CastDocumento8 pagineSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarNessuna valutazione finora

- Lead-Tin Phase EquilibirumDocumento19 pagineLead-Tin Phase Equilibirummenonharsh91% (11)

- Cast Iron SolidificationDocumento12 pagineCast Iron Solidificationkatchani123100% (1)

- Remanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingDocumento9 pagineRemanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingSujay NahaldeNessuna valutazione finora

- Casting and Fabrication of High-Damping Manganese-Copper AlloysDocumento28 pagineCasting and Fabrication of High-Damping Manganese-Copper Alloysbrad209Nessuna valutazione finora

- Effect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIDocumento6 pagineEffect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIgiokniessNessuna valutazione finora

- Basic Oxygen Furnace For Steel MakingDocumento3 pagineBasic Oxygen Furnace For Steel MakingRudrendu ShekharNessuna valutazione finora

- Control of SlagDocumento12 pagineControl of SlagVinay RajputNessuna valutazione finora

- High Chromium Irons ASTM A-532 CL. IIIADocumento1 paginaHigh Chromium Irons ASTM A-532 CL. IIIAAndre Sufadia SimorangkirNessuna valutazione finora

- The Current State of Worldwide Standards of Ductile IronDocumento8 pagineThe Current State of Worldwide Standards of Ductile IronN.PalaniappanNessuna valutazione finora

- Color Metallurgy of Cast IronDocumento13 pagineColor Metallurgy of Cast Ironmahmoud_allam3Nessuna valutazione finora

- Phosphorus Segregation in CR - Mo - V Cast Steel After Regenerative Heat TreatmentDocumento6 paginePhosphorus Segregation in CR - Mo - V Cast Steel After Regenerative Heat Treatmentsanketpavi21Nessuna valutazione finora

- 09 Cast IronDocumento34 pagine09 Cast IronyogeshmangulkarNessuna valutazione finora

- Tool Steels E28093 Molybdenum High Speed SteelsDocumento5 pagineTool Steels E28093 Molybdenum High Speed Steelswulfgang66Nessuna valutazione finora

- Cold Mounting EnglishpdfDocumento6 pagineCold Mounting EnglishpdfJorge BonillaNessuna valutazione finora

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- The Iron Puddler My life in the rolling mills and what came of itDa EverandThe Iron Puddler My life in the rolling mills and what came of itNessuna valutazione finora

- FT GeofoamDocumento2 pagineFT GeofoamMichael Angel0% (1)

- Stelex ZR PDFDocumento4 pagineStelex ZR PDFRafael TellezNessuna valutazione finora

- Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Documento1 paginaSpecification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Rafael TellezNessuna valutazione finora

- Match Capacity TableDocumento11 pagineMatch Capacity TableRafael TellezNessuna valutazione finora

- 16B5605 Rev.DDocumento1 pagina16B5605 Rev.DRafael TellezNessuna valutazione finora

- PSC 18 900 PSC 10 900 PDFDocumento1 paginaPSC 18 900 PSC 10 900 PDFRafael TellezNessuna valutazione finora

- Steel GalvanizedDocumento28 pagineSteel GalvanizedRafael TellezNessuna valutazione finora

- 33333Documento1 pagina33333Rafael TellezNessuna valutazione finora

- ForexDocumento83 pagineForexRafael TellezNessuna valutazione finora

- Specification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Documento1 paginaSpecification of Helical Compression Spring EN 15800:2010 Designed To EN 13906-1: 2002 Part No: 001 Issue No: 001Rafael TellezNessuna valutazione finora

- Type Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Documento1 paginaType Ø Nominal Class Ø PORT (In) Ø STEM (In) Pitch Lead Thrust (LB) Torque (LB-FT)Rafael TellezNessuna valutazione finora

- Port and Stem Specifications for Pressure Seal Gate ValveDocumento2 paginePort and Stem Specifications for Pressure Seal Gate ValveRafael TellezNessuna valutazione finora

- B132043 Seat Ring MachDocumento1 paginaB132043 Seat Ring MachRafael TellezNessuna valutazione finora

- Port Specifications for a Nominal 1500 PSC PropellerDocumento1 paginaPort Specifications for a Nominal 1500 PSC PropellerRafael TellezNessuna valutazione finora

- GT043C05MAA0095000Documento1 paginaGT043C05MAA0095000Rafael TellezNessuna valutazione finora

- GC243C05MAA0006350Documento1 paginaGC243C05MAA0006350Rafael TellezNessuna valutazione finora

- Lista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdDocumento6 pagineLista de Material: Lote Id: Nivel Base Id: Descripcion Qty - Per Fixed - Qty Scrap Perc Qty Hand Drawing - IdRafael TellezNessuna valutazione finora

- B132040 Steam MachDocumento1 paginaB132040 Steam MachRafael TellezNessuna valutazione finora

- GC243C05MAA0006350Documento1 paginaGC243C05MAA0006350Rafael TellezNessuna valutazione finora

- Lista de Material: Lote Id: Nivel Codigo Parte Descripcion Qty - Per Qty Hand Drawing - Id Base Id: WeightDocumento2 pagineLista de Material: Lote Id: Nivel Codigo Parte Descripcion Qty - Per Qty Hand Drawing - Id Base Id: WeightRafael TellezNessuna valutazione finora

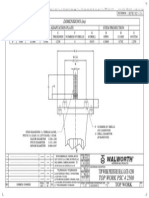

- Top Work 4 2500 PSCDocumento1 paginaTop Work 4 2500 PSCRafael TellezNessuna valutazione finora

- Calculo Torque A Presion EspecificaDocumento1 paginaCalculo Torque A Presion EspecificaRafael TellezNessuna valutazione finora

- Asme Sec. ViiiDocumento1 paginaAsme Sec. ViiiRafael TellezNessuna valutazione finora

- NPS 18" ANSI Class 1500 Pressure Seal Gate Valve Walworth DesignDocumento1 paginaNPS 18" ANSI Class 1500 Pressure Seal Gate Valve Walworth DesignRafael TellezNessuna valutazione finora

- Toc Analyzer PDFDocumento2 pagineToc Analyzer PDFPower PetroleumNessuna valutazione finora

- Brochure Steam AccumulatorDocumento2 pagineBrochure Steam AccumulatorFrank HuNessuna valutazione finora

- Practice Problems Set1 WithAnswersDocumento3 paginePractice Problems Set1 WithAnswersMukul ChandraNessuna valutazione finora

- Siemens Syngas Capable TurbinesDocumento8 pagineSiemens Syngas Capable TurbinesAlasdair McLeodNessuna valutazione finora

- B4A3Documento6 pagineB4A3ashokclineNessuna valutazione finora

- Building Design 2 Drainage NotesDocumento2 pagineBuilding Design 2 Drainage NotesLemis Sean VerasNessuna valutazione finora

- Cutback Asphalt (Rapid-Curing Type) : Standard Specification ForDocumento2 pagineCutback Asphalt (Rapid-Curing Type) : Standard Specification Fordong ganNessuna valutazione finora

- Tunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualDocumento398 pagineTunnel Operations, Maintenance, Inspection and Evaluation (Tomie) ManualGiuseppe Gentile100% (1)

- Load Calculation and Distribution for Amal Camp FacilitiesDocumento4 pagineLoad Calculation and Distribution for Amal Camp FacilitiesnikunjNessuna valutazione finora

- 2sc-Pco - Dual Solenoid Control ValveDocumento3 pagine2sc-Pco - Dual Solenoid Control Valveshan07011984Nessuna valutazione finora

- Study Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001Documento266 pagineStudy Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001ademaj08Nessuna valutazione finora

- Sludge ThickeningDocumento33 pagineSludge ThickeningKharisma Natalia100% (1)

- Moment ConnectionDocumento15 pagineMoment Connectionnitin400Nessuna valutazione finora

- CCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)Documento10 pagineCCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)ManafNessuna valutazione finora

- Numerical optimization of a transcritical CO2/propylene cascaded refrigeration-heat pump systemDocumento18 pagineNumerical optimization of a transcritical CO2/propylene cascaded refrigeration-heat pump systemzhyhhNessuna valutazione finora

- Correction of Service Manual Si-18 M-11011Documento18 pagineCorrection of Service Manual Si-18 M-11011Ahmed AzadNessuna valutazione finora

- Washing MCDocumento8 pagineWashing MCHatsune MikuNessuna valutazione finora

- BITS Pilani: Module 4: Design of Separation Systems Lecture-15Documento24 pagineBITS Pilani: Module 4: Design of Separation Systems Lecture-15sukhmaniNessuna valutazione finora

- Effective Width Flange Provisions For Composite Steel BridgesDocumento9 pagineEffective Width Flange Provisions For Composite Steel BridgesJorge PalominoNessuna valutazione finora

- Grinding Aid Admixtures Improve Cement ProductionDocumento3 pagineGrinding Aid Admixtures Improve Cement Productionjagrut100% (2)

- Operation Manual for Martin-Decker Record-O-Graph Part TW514Documento32 pagineOperation Manual for Martin-Decker Record-O-Graph Part TW514Rafael Charry AndradeNessuna valutazione finora

- Alarm ValveDocumento6 pagineAlarm ValveAnonymous ZPTCAz9Nessuna valutazione finora

- Anchored Brick Veneer Over Steel Studs PDFDocumento56 pagineAnchored Brick Veneer Over Steel Studs PDFaomareltayeb100% (1)

- Aniline Point & Diesel IndexDocumento1 paginaAniline Point & Diesel IndexSerena Serena0% (1)

- Condenser Bushings 25 KVDocumento8 pagineCondenser Bushings 25 KVOktafian PrabandaruNessuna valutazione finora

- As71164a CHECK LISTDocumento9 pagineAs71164a CHECK LISTJulio HernandezNessuna valutazione finora

- Power Contactor 1250 A - HubbellDocumento4 paginePower Contactor 1250 A - Hubbellmanuel99a2kNessuna valutazione finora

- Dlab Ms-H280-ProDocumento3 pagineDlab Ms-H280-ProAntoNessuna valutazione finora

- A Review On Surface Treatment For Concrete - Part 2 - Performance OkeDocumento10 pagineA Review On Surface Treatment For Concrete - Part 2 - Performance Okealdi sophianNessuna valutazione finora

- Dye Bath LubricantsDocumento6 pagineDye Bath Lubricantsthedevil666100% (1)