Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Investigation of AC Loss of Permanent Magnet of SPM Motor Considering Hysteresis and Eddy-Current Losses

Caricato da

Danny DurhamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Investigation of AC Loss of Permanent Magnet of SPM Motor Considering Hysteresis and Eddy-Current Losses

Caricato da

Danny DurhamCopyright:

Formati disponibili

Physics

Electricity & Magnetism fields

Okayama University Year 2004

Investigation of AC loss of permanent

magnet of SPM motor considering

hysteresis and eddy-current losses

A. Fukuma Susumu Kanazawa

Okayama University Okayama University

Daisuke Miyagi Norio Takahashi

Okayama University Okayama University

This paper is posted at eScholarship@OUDIR : Okayama University Digital Information

Repository.

http://escholarship.lib.okayama-u.ac.jp/electricity and magnetism/167

1964 IEEE TRANSACTIONS ON MAGNETICS, VOL. 41, NO. 5, MAY 2005

Investigation of AC Loss of Permanent Magnet

of SPM Motor Considering Hysteresis

and Eddy-Current Losses

A. Fukuma, S. Kanazawa, Daisuke Miyagi, and N. Takahashi, Fellow, IEEE

Department of Electrical and Electronic Engineering, Okayama University, Okayama 700-8530, Japan

NdFeB sintered magnets are widely used in rotating electrical machines. In order to develop an efficient rotating machine, it is impor-

tant to estimate ac loss of the permanent magnet of rotor precisely. In this paper, the ac losses of the permanent magnet of IEEJ model

(surface permanent-magnet motor model) are examined by using the three-dimensional finite-element method taking into account the

newly measured hysteresis losses of permanent magnet. The result shows that we should consider not only the eddy-current loss but also

the hysteresis loss, when the frequency of ac field due to a slot ripple is of the order of several hundred hertz.

Index Terms—Eddy-current loss, hysteresis loss, NdFeB magnet, SPM motor.

I. INTRODUCTION

R ECENTLY, NdFeB sintered magnets have been widely

used in rotating electrical machines. It is considered that

the major part of ac losses of the permanent magnet in motors

with NdFeB magnets are eddy-current losses due to a slot ripple,

inverter, etc. [1], as the conductivity of NdFeB magnet is fairly

high compared to that of a ferrite magnet. If a large ac loss is

produced in the NdFeB magnet, the temperature of magnet in-

creases and it may cause the thermal demagnetization. In order

to develop an efficient rotating machine, it is important to esti-

mate the ac loss correctly. But, the calculation of eddy-current

loss of permanent magnets in the rotor has not been verified by

experiments until now.

In this paper, the ac loss of NeFeB sintered magnet is mea-

sured by using a newly developed closed-type measuring equip-

ment, and compared to the calculated value. The behavior of

the hysteresis loss of permanent magnet is investigated, and it Fig. 1. Closed-type measuring equipment.

is found that the hysteresis loss is larger than the eddy-current

loss in the range of frequencies less than several hundreds hertz.

Then, the ac losses of the permanent magnet of rotor of SPM

motor model [2], which is proposed by IEE of Japan to inves-

tigate the estimation methods of iron losses, are examined con-

sidering the hysteresis and eddy-current losses.

II. MEASUREMENT OF AC LOSS OF PERMANENT MAGNETS

A. Measurement System and Conditions

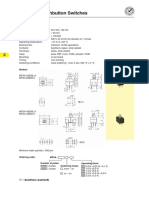

We measured ac loss of NdFeB magnets using the closed-type

measuring equipment shown in Fig. 1. The measured specimen

is an NdFeB magnet (NEOMAX-44H, NEOMAX Co. Ltd.) of

30 mm length, 10 mm width, and 10 mm thickness. The density

is 7500 kg/m and the conductivity is 6.9 10 S/m. We

measured the ac loss of a fully magnetized magnet. The ac loss

of NdFeB magnet is measured from 30 to 150 Hz and 0.01 to Fig. 2. Coaxial double coil.

0.1 T. The ac loss is obtained by the flux density measured

using the search coil and the magnetic field strength . is

measured using a coaxial double coil as shown in Fig. 2. This

coil detects the magnetic field strength on the surface of a spec-

imen by the difference of the inductive voltages of coil 1 and

Digital Object Identifier 10.1109/TMAG.2005.846282 coil 2.

0018-9464/$20.00 © 2005 IEEE

FUKUMA et al.: INVESTIGATION OF AC LOSS OF PERMANENT MAGNET OF SPM MOTOR 1965

Fig. 5. 3-D finite-element mesh (1/4 region).

Fig. 3. Hysteresis loss W and eddy-current loss W (fully magnetized,

50 Hz).

Fig. 6. Eddy-current distribution in magnet. (a) Distribution of eddy-current

vectors. (b) Distribution of eddy-current density.

sured by using a torque meter and by driving the permanent

magnet rotor by another motor.

IV. CALCULATION OF AC LOSS OF SPM MOTORS

Fig. 4. Analyzed model.

A. AC Loss of Permanent Magnets

1) Distribution of Flux and Eddy-Current Density in Perma-

B. Measured Results nent Magnet: We analyzed the flux and eddy-current distribu-

The ac loss was separated into the eddy-current loss tion in the magnets of the rotor by using the 3-D edge-based

and the hysteresis loss by using the two frequency method. hexahedral finite-element method [3]. Fig. 5 shows the region

The – curve at frequency Hz is shown in Fig. 3. analyzed (1/4 of the whole region). The number of elements is

In order to verify the validity of measurement, we analyzed the 247 696 and the number of nodes is 283 050. Eddy currents are

eddy-current loss of NdFeB magnet by using the 3-D FEM. The considered only in the magnets. Fig. 6(a) shows the eddy-cur-

relative permeability of magnet is considered 1.05 (fully mag- rent vector in the permanent magnet at the mechanical angle

netized). The calculated results are also shown in Fig. 3. The 30 . Fig. 6(b) shows the eddy-current density in the magnet. It

hysteresis loss is greater than the eddy-current loss. is 1/2 of the magnet. The eddy current shows small loops ac-

As the eddy-current loss is proportional to , is dom- cording to the slot ripple.

inant at high frequencies (for example, more than 1 kHz). How- The waveform of flux density ( , , ) at two points in

ever, the hysteresis loss cannot be neglected at low frequen- the permanent magnet of rotor is shown in Fig. 7. is the com-

cies. Therefore, the hysteresis loss may need to be considered in ponent which is parallel to the magnetization and is that per-

the analysis of the ac loss of widely used motors (normal speed pendicular to the magnetization. The flux density changes peri-

motor). odically due to the slot ripple at point a on the surface of magnet.

The flux density is almost constant at point b inside the magnet.

III. SPM MOTOR MODEL The fundamental frequency of flux waveform is 600 Hz.

2) Calculation of AC Loss: The eddy-current loss was

Fig. 4 shows a 4-pole SPM motor model [2]. The motor con- calculated directly by using the eddy-current density in the

sists of the rotor core, the permanent magnet, the stator core, permanent magnet obtained by using the 3-D FEM as follows:

and the aluminum case. The stator and rotor cores are made

of nonoriented silicon steel (grade: 50A1300). The core length

is 40 mm. The permanent magnet is Nd–Fe–B magnet and the (1)

magnetization is 1.26 T (parallel orientation). The rotor is ro-

tated at no excitation to investigate the iron loss of stator core

due to the flux produced by the permanent magnet of rotor. The where is the conductivity. is the volume of permanent

rotating speed is 1500 rpm. The iron loss of stator core is mea- magnet, and is a period.

1966 IEEE TRANSACTIONS ON MAGNETICS, VOL. 41, NO. 5, MAY 2005

Fig. 10. Loci of flux density vectors.

Fig. 7. Waveforms at each point of magnet. (a) Points in magnet. (b) Waveform

of flux density at point a. (c) Waveform of flux density at point b.

Fig. 11. W –B curve under rotating flux (50A1300, 50 Hz, measured).

slot, and also at the tip of teeth. In order to estimate the iron

loss precisely, it is necessary to take into account the iron loss

under rotating flux as shown in Fig. 10 [2]. The iron loss under

distorted elliptical rotating flux is estimated by using the iron

Fig. 8. Hysteresis loss of permanent magnet (600 Hz).

losses measured under elliptical rotating fluxes having various

axis ratios.

Fig. 11 shows iron losses under rotating flux of nonoriented

silicon steel (50A1300, 50 Hz) measured by using the 2-D SST

[4]. The axis ratio of the rotating flux of fundamental compo-

nent is defined as follows:

(2)

where and are the major and minor axes,

Fig. 9. W– f characteristics. (a) B = 0:01 T. (b) B = 0:1 T. respectively.

In the proposal estimation method, the iron loss under a

The hysteresis loss was calculated by using the approx- distorted rotating flux is represented as a summation of the loss

imated curve obtained from the measured values as shown in under an elliptical rotating flux of fundamental component

Fig. 8. In a first step, a – curve at 600 Hz was extrapolated and the iron loss under alternating flux of harmonic compo-

by using the measured at 150 Hz and 0.01–0.1 T shown in nents as follows:

Fig. 9 (The frequency and flux density are limited due to the ca-

pacity of power source). Next, the – curve is approximated

by assuming that the hysteresis loss is proportional to the square (3)

of flux density. The hysteresis loss was calculated by using

the approximated curve and by assuming that is the func- where denotes that the iron loss under rotating flux

tion of the maximum flux density at 600 Hz in each part of the is the function of axis ratio and the maximum flux density

permanent magnet. (major axis) . is the iron loss due to alternating flux

as a function of harmonic components .

B. AC Loss of Stator Core The calculation is performed by using the following proce-

Fig. 10 shows the loci of flux density vectors. Distorted el- dure: In a first step, the fundamental components in the and

liptical rotating flux can be observed at the back of teeth and components are obtained by using the harmonic analysis. Then,

FUKUMA et al.: INVESTIGATION OF AC LOSS OF PERMANENT MAGNET OF SPM MOTOR 1967

TABLE I

COMPARISON OF MEASURED AND CALCULATED RESULTS OF AC LOSS OF THE

IEEJ MODEL AT 1500 rpm

Fig. 13(a) and (b) shows the mechanical losses and iron

Fig. 12. Measuring equipment of torque.

losses measured.

Table I shows the comparison of the calculated and measured

ac losses of the IEEJ model. The hysteresis loss of magnets is

greater than twice the eddy-current loss at 1500 rpm. The results

show that we should consider not only the eddy-current loss but

also the hysteresis loss, when the frequency of ac field due to a

slot ripple is of the order of several hundred hertz (600 Hz for

the model in Fig. 4).

VI. CONCLUSION

The ac losses of the permanent magnet of IEEJ model (SPM

motor model) are examined by using the 3-D finite-element

method taking into account the newly measured hysteresis

losses of permanent magnet. Consequently, the hysteresis loss

of magnets is greater than twice the eddy-current losses at

1500 rpm. The results show that we should consider not only

the eddy-current loss but also the hysteresis loss in the analysis

of iron loss of SPM motor, when the frequency of ac field due

to a slot ripple is of the order of several hundred hertz.

ACKNOWLEDGMENT

This work was supported in part by Grant-in Aid for Basic Re-

search (B, no. 14350146), the Ministry of Education, Culture,

Fig. 13. Measured losses of IEEJ model. (a) Mechanical loss. (b) Iron loss. Sports, Science and Technology, Japan. The authors warmly

thank Mr. Takabayashi of NEOMAX Co. Ltd., who supplied

the NdFeB magnet.

the iron loss under the rotating flux of fundamental compo-

nent at any axis ratios and flux density can be obtained

by performing interpolation of the – curve. The iron loss REFERENCES

due to harmonic component is obtained as a summation of the [1] K. Itoh, Y. Hashiba, K. Sakai, and T. Yagisawa, “The A.C. losses of the

iron loss at each harmonics by using the – curves at various rare-earth permanent magnets,” Trans. IEE Jpn., vol. 118-A, no. 2, pp.

182–187, 1998.

frequencies. [2] H. Domeki, Y. Ishihara, C. Kaido, Y. Kawase, S. Kitamura, T. Shimo-

mura, N. Takahashi, T. Yamada, and K. Yamazaki, “Investigation of

benchmark model for estimating iron loss in rotating machine,” IEEE

V. RESULTS AND DISCUSSION Trans. Magn., vol. 40, no. 2, pp. 794–797, Mar. 2004.

The torque of the SPM motor model (IEEJ model) shown [3] A. Kameari, “Calculation of transient 3-D eddy current using edge-ele-

ments,” IEEE Trans. Magn., vol. 26, no. 2, pp. 702–705, Mar. 1990.

in Fig. 4 is measured by a torque meter when the permanent [4] M. Nakano, H. Nishimoto, K. Fujiwara, and N. Takahashi, “Improve-

magnet rotor is driven by another motor, as shown in Fig. 12 [3]. ments of single sheet testers for measurement of 2-D magnetic prop-

The iron loss of the stator is obtained by subtracting the torque erties up to high flux density,” IEEE Trans. Magn., vol. 35, no. 5, pp.

3965–3967, Sep. 1999.

(corresponding to the mechanical loss) measured by rotating a

rotor having nonmagnetized permanent magnet from the torque

when the permanent-magnet rotor is driven by another motor. Manuscript received June 8, 2004; revised December 11, 2004.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- TiniJet Waterjet CuttingDocumento1 paginaTiniJet Waterjet CuttingDanny DurhamNessuna valutazione finora

- Rev Bai Et Al BHR 2006 Surface Prep DecontaminationDocumento9 pagineRev Bai Et Al BHR 2006 Surface Prep DecontaminationDanny DurhamNessuna valutazione finora

- Howard JohnsonDocumento6 pagineHoward JohnsonDanny DurhamNessuna valutazione finora

- Linear Motor For Linear CompressorDocumento7 pagineLinear Motor For Linear CompressorDanny DurhamNessuna valutazione finora

- A Stirling-Rankine Fuel-Fired Heat PumpDocumento9 pagineA Stirling-Rankine Fuel-Fired Heat PumpDanny DurhamNessuna valutazione finora

- Performance Characterization of Sunpower Free-Piston Stirling EnginesDocumento6 paginePerformance Characterization of Sunpower Free-Piston Stirling EnginesDanny DurhamNessuna valutazione finora

- Qnergy The PCK80 Brochure Spec SheetDocumento2 pagineQnergy The PCK80 Brochure Spec SheetDanny DurhamNessuna valutazione finora

- Miniature Pushbutton Switches: SpecificationsDocumento1 paginaMiniature Pushbutton Switches: SpecificationsDanny DurhamNessuna valutazione finora

- Photocatalytic Hydrogen Production Using Clinoptilolite-Supported, Eosin Y-Sensitized Tio FOR Water SplittingDocumento4 paginePhotocatalytic Hydrogen Production Using Clinoptilolite-Supported, Eosin Y-Sensitized Tio FOR Water SplittingDanny DurhamNessuna valutazione finora

- BK3251 BekenDocumento13 pagineBK3251 BekenDanny DurhamNessuna valutazione finora

- Series 1846 - Single-Pole Pushbutton Switches: Product Features On RequestDocumento3 pagineSeries 1846 - Single-Pole Pushbutton Switches: Product Features On RequestDanny DurhamNessuna valutazione finora

- Aluminium: Extruded Sections Square BarDocumento1 paginaAluminium: Extruded Sections Square BarDanny DurhamNessuna valutazione finora

- CIPCPub201353 01Documento45 pagineCIPCPub201353 01Danny DurhamNessuna valutazione finora

- Mazda cx5Documento9 pagineMazda cx5Danny DurhamNessuna valutazione finora

- FlexiLine PricelistDocumento15 pagineFlexiLine PricelistDanny DurhamNessuna valutazione finora

- Snaa 123Documento10 pagineSnaa 123Danny DurhamNessuna valutazione finora

- Key Linear Motion Design TaenDocumento9 pagineKey Linear Motion Design TaenDanny DurhamNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MisII Manual PageDocumento21 pagineMisII Manual PageMorgan PeemanNessuna valutazione finora

- 18F4520Documento5 pagine18F4520Bruno ViniciusNessuna valutazione finora

- GXT6000 230Documento29 pagineGXT6000 230Para MihaiNessuna valutazione finora

- Myth-II-Soulblighter Manual Win enDocumento81 pagineMyth-II-Soulblighter Manual Win enlupyen youngNessuna valutazione finora

- Power System Protection: Noornabi ShaikhDocumento10 paginePower System Protection: Noornabi ShaikhSadam MemonNessuna valutazione finora

- 3G RNP Principles Nokia NSNDocumento31 pagine3G RNP Principles Nokia NSNFahmi YasserNessuna valutazione finora

- Cedes: GLS 126 NT and GLS 151 NTDocumento2 pagineCedes: GLS 126 NT and GLS 151 NTLoloy NorybNessuna valutazione finora

- K To 12 ICT - Computer Systems Servicing (NC II) Curriculum Guide May 2016 LO - Learning Outcome ofDocumento2 pagineK To 12 ICT - Computer Systems Servicing (NC II) Curriculum Guide May 2016 LO - Learning Outcome ofFroz WorksNessuna valutazione finora

- AHB SlaveDocumento18 pagineAHB SlaveRam VutaNessuna valutazione finora

- Basic DC Power Supply 2Documento51 pagineBasic DC Power Supply 2Joshua RefeNessuna valutazione finora

- Buku Kerja Praktikal Ej501 PW1-PW3 - JUN 2014 StudentDocumento17 pagineBuku Kerja Praktikal Ej501 PW1-PW3 - JUN 2014 StudentAL HxqNessuna valutazione finora

- AQA AS Physics A Chapter 4 Textbook AnswersDocumento4 pagineAQA AS Physics A Chapter 4 Textbook AnswerscathylisterNessuna valutazione finora

- Evaluating Generator Circuit Breakers Short-Circuit Duty Using IEEE C37.010 and C37.013Documento7 pagineEvaluating Generator Circuit Breakers Short-Circuit Duty Using IEEE C37.010 and C37.013lacan021100% (1)

- Free Chlorine Analyser (Swan)Documento2 pagineFree Chlorine Analyser (Swan)Văn Tuấn NguyễnNessuna valutazione finora

- Solid-State LaserDocumento7 pagineSolid-State LaserAdel AbdallahNessuna valutazione finora

- Akai Dv-p4785kdsm DVD PlayerDocumento50 pagineAkai Dv-p4785kdsm DVD PlayerhussainArifNessuna valutazione finora

- Schneider NS MCCBDocumento42 pagineSchneider NS MCCBEnder Ali Leon Valero100% (1)

- Robox User Manual RBX 1Documento120 pagineRobox User Manual RBX 1JoezifNessuna valutazione finora

- stm32 Eval-Tools PortfolioDocumento23 paginestm32 Eval-Tools PortfolioPanchal HitenNessuna valutazione finora

- Design Software 1Documento2 pagineDesign Software 1anbarasuval84Nessuna valutazione finora

- USB 3.1 Specification Language Usage Guidelines From USB-IFDocumento2 pagineUSB 3.1 Specification Language Usage Guidelines From USB-IFsorin-it100% (1)

- Image Steganography Project Using PythonDocumento5 pagineImage Steganography Project Using PythonRajesh KumarNessuna valutazione finora

- Real Time SystemsDocumento26 pagineReal Time Systemssreehari143Nessuna valutazione finora

- GS1 DataBar Encoder Decoder Software User GuideDocumento4 pagineGS1 DataBar Encoder Decoder Software User GuidenegokenNessuna valutazione finora

- Bengkel Teknik Menjawab SPM 2016 PDFDocumento59 pagineBengkel Teknik Menjawab SPM 2016 PDFSuriyati Yusoff75% (4)

- Construction of A Fuel Less Generator: J.O Otulana, A.A Akinwunmi, J.A Awoyemi, M.B Adeleke, M.I Efunbote OrelajaDocumento5 pagineConstruction of A Fuel Less Generator: J.O Otulana, A.A Akinwunmi, J.A Awoyemi, M.B Adeleke, M.I Efunbote OrelajapallassiNessuna valutazione finora

- NP 1820,+NP 6221+ (115V) +Service+Manual,+NP 2020,+NP 2120+Parts+and+Service+ManualDocumento504 pagineNP 1820,+NP 6221+ (115V) +Service+Manual,+NP 2020,+NP 2120+Parts+and+Service+ManualVictor Hugo Martinez QuinteroNessuna valutazione finora

- HDS 5/11 U/UX Service Manual: English 5.906-487.0 Rev. 00 (04/10)Documento50 pagineHDS 5/11 U/UX Service Manual: English 5.906-487.0 Rev. 00 (04/10)Jose Maria Castro PazosNessuna valutazione finora

- BA45F6622 + BC2161 + BC68F2332: Wireless Doorbell Solution (PIR)Documento3 pagineBA45F6622 + BC2161 + BC68F2332: Wireless Doorbell Solution (PIR)Reginaldo souza santosNessuna valutazione finora

- 2N7002K, 2V7002K Small Signal MOSFETDocumento7 pagine2N7002K, 2V7002K Small Signal MOSFETsindhu adhiwijayaNessuna valutazione finora