Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thyseenkrup - Stainless Steel 1-4713

Caricato da

dantegimenezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thyseenkrup - Stainless Steel 1-4713

Caricato da

dantegimenezCopyright:

Formati disponibili

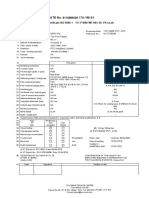

thyssenkrupp Materials (UK) Ltd

Stainless Steel 1.4713 Material Data Sheet

This data sheet applies to hot and cold rolled sheet and strip, semi-finished products, bars, rods and sections.

Application

For construction parts, which should be resistant to scaling up to about 800°C and extensively inured to the effects of sulphurous gases. The

inclination to carbonisation in reduced gases is very low.

Chemical Composition (heat analysis in %)

Product Form C Si Mn P S Cr Al

C, H, P ≤ 0.12 0.50 - 1.00 ≤ 1.00 ≤ 0.040 ≤ 0.015 6.00 - 8.00 0.50 - 1.00

C = cold-rolled strip H = hot-rolled strip P = hot rolled sheet L= semi-finished products, bars, rods and sections

Mechanical Properties (at room temperature in annealed condition)

Tensile

Proof Strength Elongation min. in %

Strength

Thickness a

Product Form or diameter d HB max. 1) 2) 3) Flat Products

mm Long Products

Rp0.2 N/mm2 Rp1.0 N/mm2 Rm N/mm2 3)

0.5 ≤ a/d < 3 3 ≤ a/d

C, H, P a ≤ 12

192 220 -

420 - 620 20 - 204) 155)

H d ≤ 25

1)

The maximum HB values may be raised by 100 units or the maximum tensile strength value may be raised by 200 N/mm2 and the minimum

elongation value be lowered to 20% for cold worked sections and bars of ≤ 35mm thickness.

2)

For guidance only.

3)

For rod, only the tensile values apply.

4)

Longitudinal test piece.

5)

Transverse test piece

Estimated average values about the long-term behaviour at elevated temperatures

1% Elongation1) for Rupture2) for

Temperature °C 1,000 h 10,000 h

N/mm2 N/mm2 1,000 h N/mm2 10,00 h N/mm2 100,000 h N/mm2

500 80 50 160 100 55

600 27.5 17.5 55 35 20

700 8.5 4.7 17 9.5 5

800 3.7 2.1 7.5 4.3 2.3

900 1.8 1.0 3.6 1.9 1.0

1)

Stress related to the output cross section, which leads after 1,000 or 10,000 h to a permanent elongation of 1%.

2)

Stress related to the output cross section, which leads after 1,000 or 10,000 or 100,000 h to breakage.

Page 1 Material Data Sheet 1.4713 06/2017

thyssenkrupp Materials (UK) Ltd

Stainless Steel 1.4713 Material Data Sheet

Reference data on some physical properties

Density at 20°C Thermal Conductivity W/m K at Specific Thermal Electrical

kg/dm3 20°C 500°C Capacity at 20°C J/kg K Resistivity at 20°C Ω mm2/m

7.7 23 25 450 0.7

Coefficient of linear thermal expansion 10-6 K-1 between 20°C and

200°C 400°C 600°C 800°C 1000°C

11.5 12.0 12.5 13.0 -

Guidelines on the temperature for hot forming and heat treatment

Hot Forming Heat Treatment +A (annealed), Microstructure

Temperature °C Type of Cooling Temperature °C Type of Cooling Microstructure

1100 - 750 Air 780 - 8401) Air, Water2) Ferrite

1)

If heat treatment is carried out in a continuous furnace , the upper part of the range specified is usually preferred or even exceed.

2)

In special cases, furnace cooling is also permitted.

Processing / Welding

Standard welding processes for this steel grade are:

▪▪ TIG-Welding

▪▪ MAG-Welding Solid Wire

▪▪ Arc Welding (E)

▪▪ Submerged Arc Welding (SAW)

Filler Metal

Process

Similar Higher Alloyed

TIG Thermanit X / 1.4370

MAG Solid Wire Thermanit 17 Thermanit X / 1.4370

Arc Welding (E) Thermanit 17 Thermanit X / 1.4370

Wire Powder Wire Powder

SAW Marathon 213

Thermanit 17 Thermanit X / 1.4370 Marathon 213

UA 600

Ferritic chrome steels are heat sensitive. Therefore the steel 1.4713 should be welded with lowest possible heat input by using thin electrode

diameter, low current intensity and stringer bead welding.

For wall thicknesses under 3mm, it is not necessary to preheat 1.4713. For thicker construction pars (>3mm) the preheating and interpass

temperatures 200 - 300°C should not be under respectively over run.

1.4713 can be processed with similar or higher alloyed filler metals. With sulphurous atmospheres a ferritic top layer should be laid on the media

side (Thermanit L 1.4820 - MAG and Arc Welding - Thermanit L, UP - Thermanit with Marathon 213).

Cold Forming

When cold forming 1.4713, certain preventative measures should be observed. Shees up to 3mm thickness can be cold bent if necessary

preheating with 200 - 300°C should be done.

Page 2 Material Data Sheet 1.4713 06/2017

thyssenkrupp Materials (UK) Ltd

Stainless Steel 1.4713 Material Data Sheet

Products with thicknesses > 3mm must be preheated up to 600 - 800°C, concerning machinability 1.4713 can be compared to low carbon steel.

Embrittlement

While heating 1.4713 over about 950 °C, embrittlement by grain growth occurs which can be removed any more.

Note

The material is magnetizable.

Editor

thyssenkrupp Materials (UK) Ltd

Cox’s Lane

Cradley Heath

West Midlands

B64 5QU

Important Note

Information given in this data sheet about the condition or usability of materials respectively products are no warranty for their properties, but act as

a description.

The information, we give on for advice, comply to the experiences of the manufacturer as well as our own. We cannot give warranty for the results

of processing and application of the products.

Page 3 Material Data Sheet 1.4713 06/2017

Potrebbero piacerti anche

- Dowelingjig Plans Cut TempDocumento9 pagineDowelingjig Plans Cut TempKeith WesleyNessuna valutazione finora

- Machining specifications for VG 4 150 discDocumento1 paginaMachining specifications for VG 4 150 disctauasi_1Nessuna valutazione finora

- JAM003MQN400 pulley specificationsDocumento1 paginaJAM003MQN400 pulley specificationsSebastian Davila hernandezNessuna valutazione finora

- Tug Fenders Form - Fill inDocumento2 pagineTug Fenders Form - Fill inaNessuna valutazione finora

- Jam003mqn400 409Documento1 paginaJam003mqn400 409Sebastian Davila hernandezNessuna valutazione finora

- ARKAN SHADES Welding Inspection & Paint InspectionDocumento2 pagineARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNessuna valutazione finora

- CES Business PresentationDocumento50 pagineCES Business PresentationGary David CrowhurstNessuna valutazione finora

- 43 - Hofmann - Portable Machine Tools Brochure - A4Documento2 pagine43 - Hofmann - Portable Machine Tools Brochure - A4Jorge VillalobosNessuna valutazione finora

- Carbon Arc Cutting PDFDocumento44 pagineCarbon Arc Cutting PDFMark InnesNessuna valutazione finora

- Modular Multi Cat 1205 Product SheetDocumento2 pagineModular Multi Cat 1205 Product SheetAnonymous hlPPOmxXB7Nessuna valutazione finora

- Astm MaterialsDocumento13 pagineAstm Materialssathish_iyengarNessuna valutazione finora

- Role of ContainersDocumento39 pagineRole of ContainersEliza PopaNessuna valutazione finora

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocumento10 pagineEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNessuna valutazione finora

- Engineering Specification for Seamless Coolant Hose PortDocumento5 pagineEngineering Specification for Seamless Coolant Hose Portjavier ortizNessuna valutazione finora

- 1 MTCDocumento2 pagine1 MTCRazvan CristeaNessuna valutazione finora

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocumento4 pagineDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNessuna valutazione finora

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocumento3 pagineMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNessuna valutazione finora

- Quality Plan for Air Preheater MaintenanceDocumento90 pagineQuality Plan for Air Preheater Maintenanceashis chatterjeeNessuna valutazione finora

- Thermal Insulation Application GuideDocumento7 pagineThermal Insulation Application GuideAbhishek KumarNessuna valutazione finora

- Tram Grooved Rails New Catalog January 2018Documento12 pagineTram Grooved Rails New Catalog January 2018Szabolcs Attila KöllőNessuna valutazione finora

- Difference between SS316 and SS316L Stainless Steel GradesDocumento1 paginaDifference between SS316 and SS316L Stainless Steel GradesSableen SinghNessuna valutazione finora

- Approved Itp-Dss - 28 Sep 2016Documento4 pagineApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNessuna valutazione finora

- Lloyds Approved MillsDocumento80 pagineLloyds Approved MillsJosip JurčićNessuna valutazione finora

- ASTM A778-01 Standard Specification For Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocumento5 pagineASTM A778-01 Standard Specification For Welded, Unannealed Austenitic Stainless Steel Tubular ProductsKok WaiNessuna valutazione finora

- Miter Gauge PDFDocumento8 pagineMiter Gauge PDFJesus MachadoNessuna valutazione finora

- DayeDocumento2 pagineDayeJosip JurčićNessuna valutazione finora

- ESR - Hazard AnalysisDocumento24 pagineESR - Hazard Analysisbmanojkumar16Nessuna valutazione finora

- ThyssenDocumento0 pagineThyssenAbbas RizviNessuna valutazione finora

- Boiler Materials: P.Sundaramoorthy BHEL, TiruchirappalliDocumento47 pagineBoiler Materials: P.Sundaramoorthy BHEL, Tiruchirappalliteddy tavaresNessuna valutazione finora

- KSR 1003 H e Side Mounted Magnetic Float SwitchesDocumento20 pagineKSR 1003 H e Side Mounted Magnetic Float SwitchesRoshan ShanmughanNessuna valutazione finora

- ASME 193 and 193MDocumento4 pagineASME 193 and 193MGauravNessuna valutazione finora

- JIS G4801 SUP10 Steel GuideDocumento2 pagineJIS G4801 SUP10 Steel GuideĐình Sỹ TTPNessuna valutazione finora

- Bsec Enterprises - CTG Dry DockDocumento5 pagineBsec Enterprises - CTG Dry DockTasnova Shahreen ChowdhuryNessuna valutazione finora

- Arcelormittal Pressure VesselDocumento10 pagineArcelormittal Pressure VesselkokopirokoNessuna valutazione finora

- Rules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire ProtectionDocumento444 pagineRules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire Protectionguichen wangNessuna valutazione finora

- Astm 1.05Documento3 pagineAstm 1.05asprclms durgapurNessuna valutazione finora

- Hyundai Electrode CATALOG - 7thDocumento134 pagineHyundai Electrode CATALOG - 7tharianaseri100% (1)

- Product Data: Hempadur Multi-Strength 35530Documento2 pagineProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNessuna valutazione finora

- OK Tigrod 12.64 TIG welding rod data sheetDocumento2 pagineOK Tigrod 12.64 TIG welding rod data sheetsoft4gsmNessuna valutazione finora

- ESAB Consumable PDFDocumento165 pagineESAB Consumable PDFbond8031Nessuna valutazione finora

- Abj Corporate Brochure - SmallsizeDocumento36 pagineAbj Corporate Brochure - Smallsizeumer shafiqueNessuna valutazione finora

- Seamless Steel Pipe for ShipbuildingDocumento2 pagineSeamless Steel Pipe for ShipbuildingshahjadaNessuna valutazione finora

- What TitleDocumento17 pagineWhat TitleBernathTurnipNessuna valutazione finora

- Catalog Tevi - Van Leeuwend-Slatina PDFDocumento62 pagineCatalog Tevi - Van Leeuwend-Slatina PDFBara SebastianNessuna valutazione finora

- Refinery InspectionDocumento44 pagineRefinery InspectiongamadiyaNessuna valutazione finora

- Sensitization of Inconel 625Documento9 pagineSensitization of Inconel 625nantha kumarNessuna valutazione finora

- Harmer Steel Rail DimenesionsDocumento3 pagineHarmer Steel Rail DimenesionsARTHURS316Nessuna valutazione finora

- Shipbuilding quality standard guideDocumento60 pagineShipbuilding quality standard guideMohamed HassanNessuna valutazione finora

- Nanotech PaintingDocumento16 pagineNanotech Paintingkr_abhijeet72356587Nessuna valutazione finora

- Kitz Butterfly Valve Catalog PDFDocumento28 pagineKitz Butterfly Valve Catalog PDFlyguyenquocduyNessuna valutazione finora

- 652-100-FINAL (ITP) Rev1Documento4 pagine652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENessuna valutazione finora

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocumento2 pagineCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNessuna valutazione finora

- INS P 035, Circularity Check - Cyl.sectionsDocumento10 pagineINS P 035, Circularity Check - Cyl.sectionsDeepakNessuna valutazione finora

- Sulphate Resisting Cement ManufactureDocumento3 pagineSulphate Resisting Cement ManufactureshaayashanmugaNessuna valutazione finora

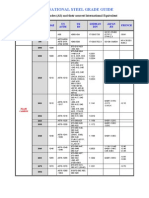

- Steel Grade GuideDocumento1 paginaSteel Grade Guidetoru101100% (1)

- Welder Certificate ISO 9606-1 QualificationDocumento1 paginaWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- Stainless Steel 1.4828 Material Data SheetDocumento3 pagineStainless Steel 1.4828 Material Data SheetAvn PrasadNessuna valutazione finora

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocumento3 pagineThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNessuna valutazione finora

- 1.4878 Eng PDFDocumento3 pagine1.4878 Eng PDFRoberto_PrrNessuna valutazione finora

- Lnm309h-Eng Stainless Steel Solid WireDocumento1 paginaLnm309h-Eng Stainless Steel Solid WiredantegimenezNessuna valutazione finora

- Degradation Machanism of Heat Resistant Steel at Elevated TemperaturesDocumento180 pagineDegradation Machanism of Heat Resistant Steel at Elevated TemperaturesdantegimenezNessuna valutazione finora

- Presentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVDocumento21 paginePresentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVdantegimenezNessuna valutazione finora

- 59997ESAB Duplex Paslanmaz Kaynagi - EN PDFDocumento8 pagine59997ESAB Duplex Paslanmaz Kaynagi - EN PDFtan boo siongNessuna valutazione finora

- Welding Consumables For The Hydro Power Industry - BohlerDocumento36 pagineWelding Consumables For The Hydro Power Industry - BohlerdantegimenezNessuna valutazione finora

- BW Pickling+Handbook EN 2017 GL 050 Preview PDFDocumento16 pagineBW Pickling+Handbook EN 2017 GL 050 Preview PDFjuan carlos alvarez gomezNessuna valutazione finora

- CAPILLA - Welding Consumables For Welding of Creep and Heat ResistantDocumento40 pagineCAPILLA - Welding Consumables For Welding of Creep and Heat ResistantdantegimenezNessuna valutazione finora

- EsabDocumento556 pagineEsabFábio MarquesNessuna valutazione finora

- RT Film IntepretationDocumento44 pagineRT Film Intepretationawong_911374100% (3)

- Magnetic Field IndicatorsDocumento2 pagineMagnetic Field IndicatorsdantegimenezNessuna valutazione finora

- 59997ESAB Duplex Paslanmaz Kaynagi - EN PDFDocumento8 pagine59997ESAB Duplex Paslanmaz Kaynagi - EN PDFtan boo siongNessuna valutazione finora

- Couplant Comparison and Specification ChartDocumento1 paginaCouplant Comparison and Specification ChartdantegimenezNessuna valutazione finora

- En 10228-2Documento7 pagineEn 10228-2Uthayan SPNessuna valutazione finora

- EsabDocumento556 pagineEsabFábio MarquesNessuna valutazione finora

- Fly Ash Particle Formation in Kraft Recovery Boilers: Pirita MikkanenDocumento71 pagineFly Ash Particle Formation in Kraft Recovery Boilers: Pirita MikkanendantegimenezNessuna valutazione finora

- UTP A 6222 MoDocumento1 paginaUTP A 6222 MoKara WhiteNessuna valutazione finora

- Corrosion Gauging With Dual Element TransducersDocumento8 pagineCorrosion Gauging With Dual Element TransducersdantegimenezNessuna valutazione finora

- ASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForDocumento9 pagineASTI - Boiler Tube Failure Investigation & Prevention - NACE - ForVinoth RajendraNessuna valutazione finora

- RT Film IntepretationDocumento44 pagineRT Film Intepretationawong_911374100% (3)

- Aga 9 2017Documento74 pagineAga 9 2017martin80% (5)

- Buying Firebrick - Tools of The TradeDocumento2 pagineBuying Firebrick - Tools of The TradedantegimenezNessuna valutazione finora

- A Guide To Etching Specialty Alloys For Microstructural EvaluationDocumento15 pagineA Guide To Etching Specialty Alloys For Microstructural EvaluationdantegimenezNessuna valutazione finora

- Tables - TechnicalProperties - EN 10088 PDFDocumento24 pagineTables - TechnicalProperties - EN 10088 PDFeugenio.gutenbertNessuna valutazione finora

- UTP 6222 MoDocumento1 paginaUTP 6222 ModantegimenezNessuna valutazione finora

- Stainless Steels G1e-001Documento31 pagineStainless Steels G1e-001DANIEL DIAZNessuna valutazione finora

- Disbonding: Industrial Solutions EnglishDocumento8 pagineDisbonding: Industrial Solutions EnglishdantegimenezNessuna valutazione finora

- Widmanstätten StructuresDocumento3 pagineWidmanstätten StructuresdantegimenezNessuna valutazione finora

- Intro To Basic UTDocumento41 pagineIntro To Basic UTgirish310100% (1)

- Attenuating Materials and TGC FunctionDocumento9 pagineAttenuating Materials and TGC FunctiondantegimenezNessuna valutazione finora

- VnDoc - Tải tài liệu, văn bản pháp luật, biểu mẫu miễn phíDocumento7 pagineVnDoc - Tải tài liệu, văn bản pháp luật, biểu mẫu miễn phíStranger NonameNessuna valutazione finora

- Karl Marx AssignmentDocumento1 paginaKarl Marx Assignmenthanunarabella1Nessuna valutazione finora

- Single Point Loading Working Model Specifications and Parts OverviewDocumento4 pagineSingle Point Loading Working Model Specifications and Parts OverviewAnonymous CYdagI100% (1)

- Rules of the Occult UndergroundDocumento247 pagineRules of the Occult UndergroundIsaak HillNessuna valutazione finora

- Corporate Presentation Codex International Fev 2022Documento9 pagineCorporate Presentation Codex International Fev 2022Stephane SeguierNessuna valutazione finora

- Katsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsDocumento33 pagineKatsina Polytechnic Lecture Notes on History and Philosophy of Science, Technology and MathematicsHamisu TafashiyaNessuna valutazione finora

- Planning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDocumento5 paginePlanning GPS Data Collection: Software Is Provided On The TEC7133 CD-ROM. You Can Also Download ThisDoniansyah Mai PutraNessuna valutazione finora

- Miners RuleDocumento2 pagineMiners Ruleபிரபாகரன் ஆறுமுகம்Nessuna valutazione finora

- Exp# 1c Exec System Call Aim: CS2257 Operating System LabDocumento3 pagineExp# 1c Exec System Call Aim: CS2257 Operating System LabAbuzar ShNessuna valutazione finora

- Aadhaar is proof of identity, not citizenshipDocumento1 paginaAadhaar is proof of identity, not citizenshipPARTAPNessuna valutazione finora

- Cylindrical Plug Gage DesignsDocumento3 pagineCylindrical Plug Gage DesignskkphadnisNessuna valutazione finora

- FlowTradersSOP PDFDocumento1 paginaFlowTradersSOP PDFAvinash IyerNessuna valutazione finora

- i-PROTECTOR SPPR Catalogue 1.0Documento2 paginei-PROTECTOR SPPR Catalogue 1.0Sureddi KumarNessuna valutazione finora

- Slippery? Contradictory? Sociologically Untenable? The Copenhagen School RepliesDocumento10 pagineSlippery? Contradictory? Sociologically Untenable? The Copenhagen School RepliesDaniel CorrenteNessuna valutazione finora

- Examining Oral Communication FunctionsDocumento5 pagineExamining Oral Communication FunctionsJoshua Lander Soquita CadayonaNessuna valutazione finora

- Port Ps PDFDocumento2 paginePort Ps PDFluisNessuna valutazione finora

- ButeDocumento89 pagineButeNassime AmnNessuna valutazione finora

- Paper 2 Answer SPMDocumento12 paginePaper 2 Answer SPMSylarkNessuna valutazione finora

- Create Login Application In Excel Macro Using Visual BasicDocumento16 pagineCreate Login Application In Excel Macro Using Visual Basicfranklaer-2Nessuna valutazione finora

- Bio Mini IA Design (HL)Documento7 pagineBio Mini IA Design (HL)Lorraine VictoriaNessuna valutazione finora

- Strategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFDocumento23 pagineStrategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFThomas Diwo0% (1)

- Fc6a Plus (MQTT)Documento44 pagineFc6a Plus (MQTT)black boxNessuna valutazione finora

- Unit 30 WorkDocumento2 pagineUnit 30 WorkThanh HàNessuna valutazione finora

- Automatic Helmet DetectDocumento4 pagineAutomatic Helmet Detectvasanth100% (1)

- Mapping of Significant Natural Resources: Category: Bodies of WaterDocumento3 pagineMapping of Significant Natural Resources: Category: Bodies of WaterDei HernandezNessuna valutazione finora

- Onward Journey Ticket Details E Ticket Advance ReservationDocumento1 paginaOnward Journey Ticket Details E Ticket Advance ReservationAnonymous yorzHjDBdNessuna valutazione finora

- 08 - Chapter 1 - Waveguide-Transmission Line - Microstrip LinesDocumento76 pagine08 - Chapter 1 - Waveguide-Transmission Line - Microstrip Linesgilberto araujoNessuna valutazione finora

- Plagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Documento7 paginePlagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Rostyslav SKLYAR, Dr. (Eng)Nessuna valutazione finora

- Department Electrical Engineering Management IV Assignment 1 Semester 1, 2020Documento2 pagineDepartment Electrical Engineering Management IV Assignment 1 Semester 1, 2020samuelNessuna valutazione finora

- Balino, Shedina D. Beed 2-CDocumento5 pagineBalino, Shedina D. Beed 2-CSHEDINA BALINONessuna valutazione finora