Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

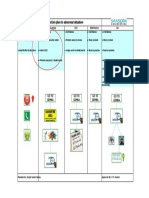

Equipment Initial Production Control System

Caricato da

srmohapatra50860 valutazioniIl 0% ha trovato utile questo documento (0 voti)

76 visualizzazioni1 paginaDM Pillar equipment INITIAL PRODUCTION CONTROL SYSTEM

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoDM Pillar equipment INITIAL PRODUCTION CONTROL SYSTEM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

76 visualizzazioni1 paginaEquipment Initial Production Control System

Caricato da

srmohapatra5086DM Pillar equipment INITIAL PRODUCTION CONTROL SYSTEM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Flow

Step Check Points Standard documents

Related depts Manufacturing depts Prod. Engg. Section

Policies •Initial flow control 1.Annual equipment plan

required/not required application

Prepare equipment •Purpose & necessity 2.Equipment plan study

Plan 2,3,4 Investment effects sheet

•Priority making 3.Equipment specification

1.Concept •Development deadline setting chart

Planning Study Equipment plan •Person Inchage 4.Equipment plan

checksheet

1st DR

•Budget & schedule 5.Equipment planning &

Plan •Countermeasures for budget table

Approved 5 anticipated problems 6.Process QA matrix

•Production capacity 7.4M analysis chart

Equipment Budget •Reliability 8.FMEA sheet(process)

plan •Flexibility 9.Reflection on equipmnt

•Operability design & action records

•Maintainability 10.Equipment design &

Requestt y •Safety manufacture specification

Request Buy

•Initial cost

2. Execution •Running cost

Planning •Required purchase lead

Approval

time

Equipment specification concept

•Equipment FMEA 11.Equipmet common

6,7,8,9,3,10 •Capacity specificaton

2nd DR •Reliability 12. FMEA sheet (

•Flexibility equipment)

•Operability 13.Basic design

•Maintainability checksheet (reflection on

quotation

•Safety equipment design &

•Economical efficiency action records)

request for order •Parts shapes, processing 14.Detailed design

placement 11 tolerances, materials, checksheet (reflection on

surface roughness, heat equipment design &

basic design treatment action records)

•selection of parts sold

12,9,13 on market

3. Design 3rd DR

detailed design

13,14,9 •Intermediate check 15. Attendance inspection

4th DR schedule,important check sheet

parts(assembly,processin (intermediate)

g accuracies)

Mfg drawings Mfg approval

drawings

•Equipment capacity, 15. Attendance inspection

4. process capacity check sheet (completion)

Manufacture Quotations •Function &

performance(operation,m

request for order aintenance,safety,

placement reliability)

•Correction schedule,

Manufacture 15 drawing revision

5. Attendance •Lay out & installation 16. Equipment

Test run 15 •Piping wiring installation check sheet

Attendance test

run

16

•Equipment capacity, 17.Initial flow control

MP meeting

Installation process capacity notice

•Problem 18.Initial flow control

6.Installation countermeasure chart

Test Run, •Designition & release of 19. Problem

adjustment initial flow control countermeasure records

•Operation records

•defect rates(Non-

Designate for initial flow control 17 defective rate)

7. Initial Flow •Failures, minor

Prepare full production 18 stoppages

control

•Safety

Full production operation 19 • Handling instruction

•Performance, availability

Release initial flow control 20

•Handling & Jishu Hozen 20. Operation manual

20,21,22,23 instruction 21. Periodical inspection

& repairing standard

8.Operation

Delivery 22. Jishu Hozen standrad

23. Work standards

VII-9 Example of equipment initial flow control system

Potrebbero piacerti anche

- Structured What If Technique A Complete Guide - 2020 EditionDa EverandStructured What If Technique A Complete Guide - 2020 EditionNessuna valutazione finora

- Basics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMDocumento314 pagineBasics To Corrosion at Petrochemical Plants: by Shahid Razzaq Inspection Unit - MMMuhammad Abdullah Khan100% (1)

- Application of Failure Mode Effect Analysis FMEA FDocumento17 pagineApplication of Failure Mode Effect Analysis FMEA FpradeepNessuna valutazione finora

- Design For MaintainabilityDocumento7 pagineDesign For MaintainabilityEmilian PopaNessuna valutazione finora

- Work Instruction For Vendor Development Procedure Ver1Documento46 pagineWork Instruction For Vendor Development Procedure Ver1Sanjay DeNessuna valutazione finora

- Cost of Carrying Out Company's Quality FunctionsDocumento15 pagineCost of Carrying Out Company's Quality FunctionsaamanwatkarNessuna valutazione finora

- SMT 1Documento12 pagineSMT 1scrt-mNessuna valutazione finora

- A FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationDocumento22 pagineA FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationLi NearNessuna valutazione finora

- Tds Nitric Acid HuchemsDocumento3 pagineTds Nitric Acid HuchemsB.R SinghNessuna valutazione finora

- Lesson LearnedDocumento1 paginaLesson LearnedR KumarNessuna valutazione finora

- Application of Fmea Method in A Manufacturing Organization Focused On QualityDocumento7 pagineApplication of Fmea Method in A Manufacturing Organization Focused On QualityRudra DasNessuna valutazione finora

- GM 1927 36 Quality System Basic Marzo 2009 Lpas PDFDocumento26 pagineGM 1927 36 Quality System Basic Marzo 2009 Lpas PDFmedi38Nessuna valutazione finora

- FMEA SampleDocumento94 pagineFMEA SampleKaran MalhiNessuna valutazione finora

- Nexteer Quality Alert: Response RequiredDocumento1 paginaNexteer Quality Alert: Response RequiredsimsonNessuna valutazione finora

- Part Name.:-Distribution Assy 3P386983-1Documento50 paginePart Name.:-Distribution Assy 3P386983-1Sameer SaxenaNessuna valutazione finora

- Fme (C) ADocumento4 pagineFme (C) AMurat IslamNessuna valutazione finora

- APQPDocumento85 pagineAPQProhitbaggaNessuna valutazione finora

- QMS Awareness ProgramDocumento9 pagineQMS Awareness ProgramshravandownloadNessuna valutazione finora

- Ten Rules of Good Manufacturing PracticeDocumento2 pagineTen Rules of Good Manufacturing PracticeGeorge MarkasNessuna valutazione finora

- SMP For Calibration of Gauges & TransmittersDocumento3 pagineSMP For Calibration of Gauges & Transmitterspradeep1987coolNessuna valutazione finora

- Apqp PQP Flow ChartDocumento1 paginaApqp PQP Flow ChartmjapmgNessuna valutazione finora

- Work Instruction For Operator (English)Documento1 paginaWork Instruction For Operator (English)PRAMODNessuna valutazione finora

- Process FMEA: Produce A Moulded Case As Per DrawingDocumento4 pagineProcess FMEA: Produce A Moulded Case As Per DrawingVikram PuriNessuna valutazione finora

- How To Implement An Effective Fmea ProcessDocumento31 pagineHow To Implement An Effective Fmea ProcessAmir KhakzadNessuna valutazione finora

- Capacity Verification Run at Rate IpaDocumento4 pagineCapacity Verification Run at Rate IpaBES100% (1)

- Toaz - Info Red Bin Analysis Procedure PRDocumento4 pagineToaz - Info Red Bin Analysis Procedure PRRohit QualityNessuna valutazione finora

- ENICOR 1441 Maint Process Activities Overview - Day 5Documento81 pagineENICOR 1441 Maint Process Activities Overview - Day 5modesto66100% (1)

- IATF Rules Dec2016Documento14 pagineIATF Rules Dec2016anthony dunnNessuna valutazione finora

- 4m Change & Ecn NoteDocumento1 pagina4m Change & Ecn NoteAnurag ChaudharyNessuna valutazione finora

- Etech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingDocumento4 pagineEtech Automation Mr. Varun Dev FMEA / 26221839 05.10.2012 Mr. Sethupathi Terminal BendingMadan PrakashNessuna valutazione finora

- Presentation On MSA by TS16949 Auditors From UL IndiaDocumento16 paginePresentation On MSA by TS16949 Auditors From UL Indiavish12321Nessuna valutazione finora

- Progress Report Phase Gate Status Review Template Excel Free Download - LlXioCX74CrSLyyDocumento4 pagineProgress Report Phase Gate Status Review Template Excel Free Download - LlXioCX74CrSLyyRafael HABNessuna valutazione finora

- Manufacturing Process of Piston IN Shriram Pistons & Rings LTDDocumento11 pagineManufacturing Process of Piston IN Shriram Pistons & Rings LTDVipul SinghalNessuna valutazione finora

- Fmea Overview and RoadmapDocumento47 pagineFmea Overview and RoadmapLake HouseNessuna valutazione finora

- SAMPLE - Process FlowDocumento2 pagineSAMPLE - Process Flowakav123Nessuna valutazione finora

- Customer Special CharacteristicsDocumento1 paginaCustomer Special Characteristicspundhir12898Nessuna valutazione finora

- 6000 Series PFMEA (English For Reference)Documento8 pagine6000 Series PFMEA (English For Reference)RonNessuna valutazione finora

- Layered Process Audit ChecksheetDocumento3 pagineLayered Process Audit ChecksheetKevin Poore100% (1)

- HSE Activities - FinalDocumento59 pagineHSE Activities - FinalRajanish BiswasNessuna valutazione finora

- Perception Sheet (Point of Change, Point of Modification, Point of Concern) DRBFM Extraction Matrix Worksheet 1/2Documento1 paginaPerception Sheet (Point of Change, Point of Modification, Point of Concern) DRBFM Extraction Matrix Worksheet 1/2Mau TauNessuna valutazione finora

- Methodology Tapping Methodology of WaterlineDocumento15 pagineMethodology Tapping Methodology of WaterlineBryNessuna valutazione finora

- Standard Reaction Plan To Abnormal Situation: Restart ProcessDocumento1 paginaStandard Reaction Plan To Abnormal Situation: Restart ProcessDeepak kumarNessuna valutazione finora

- Global Supplier Quality 15 Key ProcessesDocumento1 paginaGlobal Supplier Quality 15 Key ProcessesalexrferreiraNessuna valutazione finora

- Safe Handling of Petroleum ProductsDocumento12 pagineSafe Handling of Petroleum ProductsMwkthangkwr BrahmaNessuna valutazione finora

- FMEA BoilerDocumento2 pagineFMEA Boilersykin_fazilNessuna valutazione finora

- Supplier Controlled - Safe Launch PlanDocumento6 pagineSupplier Controlled - Safe Launch PlanMario RojasNessuna valutazione finora

- FIR-garments PDFDocumento4 pagineFIR-garments PDFTarun PariharNessuna valutazione finora

- Process Flow Diagram (PFD)Documento1 paginaProcess Flow Diagram (PFD)psathishthevanNessuna valutazione finora

- SPTR Rev Check ListDocumento5 pagineSPTR Rev Check ListSAKTHIVEL ANessuna valutazione finora

- The 8-D System: Awareness of Problem Choose/Verify Corrective ActionsDocumento3 pagineThe 8-D System: Awareness of Problem Choose/Verify Corrective ActionsAtul SharmaNessuna valutazione finora

- 8 - Project Quality ManagementDocumento18 pagine8 - Project Quality Managementatularvin231849168Nessuna valutazione finora

- Amendment SheetDocumento1 paginaAmendment SheetThaddeus MooreNessuna valutazione finora

- APQP Procedure From Elsmar - 2020-05Documento6 pagineAPQP Procedure From Elsmar - 2020-05khmortezaNessuna valutazione finora

- Potential Failure Mode Effect Analysis (Pfmea)Documento4 paginePotential Failure Mode Effect Analysis (Pfmea)manno200Nessuna valutazione finora

- Fmea (Failure Modes and Effects Analysis)Documento11 pagineFmea (Failure Modes and Effects Analysis)Oswaldo VallesNessuna valutazione finora

- Bheda, Maturity Grid and Cost of Quality QualityDocumento31 pagineBheda, Maturity Grid and Cost of Quality QualityArun KumarNessuna valutazione finora

- Inspectation Test PlanDocumento1 paginaInspectation Test Planazimr157Nessuna valutazione finora

- Cost of QualityDocumento15 pagineCost of QualitySachin MethreeNessuna valutazione finora

- Commissioning in DetailDocumento200 pagineCommissioning in DetailmohamedovicNessuna valutazione finora

- ABBCheiron CatalogueDocumento6 pagineABBCheiron Cataloguesrmohapatra5086Nessuna valutazione finora

- MNS-R System GuideDocumento17 pagineMNS-R System Guidesrmohapatra5086Nessuna valutazione finora

- Altivar 1200 - ATV1200A50006666Documento7 pagineAltivar 1200 - ATV1200A50006666srmohapatra5086Nessuna valutazione finora

- Power Distributor Box - JSPL - Sunil - Pattnaik PDFDocumento17 paginePower Distributor Box - JSPL - Sunil - Pattnaik PDFsrmohapatra5086Nessuna valutazione finora

- Installation of Current Limiting Reactors in Esp: - Monday, June 07, 2021Documento15 pagineInstallation of Current Limiting Reactors in Esp: - Monday, June 07, 2021srmohapatra5086Nessuna valutazione finora

- Abbcheiron Price ListDocumento2 pagineAbbcheiron Price Listsrmohapatra5086Nessuna valutazione finora

- Data Sheet 3VA2225-5JQ32-0AA0: ModelDocumento5 pagineData Sheet 3VA2225-5JQ32-0AA0: Modelsrmohapatra5086Nessuna valutazione finora

- Product Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)Documento7 pagineProduct Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)srmohapatra5086100% (1)

- IE2 IndustrialDocumento16 pagineIE2 Industrialsrmohapatra5086Nessuna valutazione finora

- Product Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)Documento7 pagineProduct Catalog - YEWS Screw Chiller - EN - PUBL7578 (0315)srmohapatra5086100% (1)

- Sinamics Perfect Harmony Gh180Documento338 pagineSinamics Perfect Harmony Gh180srmohapatra5086100% (2)

- 6SL3300-7TE38-4AA1 Datasheet en enDocumento1 pagina6SL3300-7TE38-4AA1 Datasheet en ensrmohapatra5086Nessuna valutazione finora

- Apex Series Ie2 Efficiency Ac MotorsDocumento4 pagineApex Series Ie2 Efficiency Ac Motorssrmohapatra5086Nessuna valutazione finora

- BJFL 30W Led I-Amaze-113009Documento1 paginaBJFL 30W Led I-Amaze-113009srmohapatra5086Nessuna valutazione finora

- 4 Port Modbustcp GatewayDocumento2 pagine4 Port Modbustcp Gatewaysrmohapatra5086Nessuna valutazione finora

- Kaizen Evaluation CriteriaDocumento1 paginaKaizen Evaluation Criteriasrmohapatra5086Nessuna valutazione finora

- Crompton - Retrofit Solutions LED Luminaires Lamps Catalogue 10032017Documento19 pagineCrompton - Retrofit Solutions LED Luminaires Lamps Catalogue 10032017srmohapatra5086Nessuna valutazione finora

- G740 - Control Unit & Terminal Unit - RevB1 PDFDocumento53 pagineG740 - Control Unit & Terminal Unit - RevB1 PDFsrmohapatra5086Nessuna valutazione finora

- S120 S150 List Manual LH1 0414 EngDocumento2.996 pagineS120 S150 List Manual LH1 0414 Engsrmohapatra5086Nessuna valutazione finora

- Latest DC BusDocumento72 pagineLatest DC Bussrmohapatra5086Nessuna valutazione finora

- Criteria For Correct Fuse SelectionDocumento4 pagineCriteria For Correct Fuse Selectionsrmohapatra5086Nessuna valutazione finora

- Newpricelist Havells 2017Documento40 pagineNewpricelist Havells 2017srmohapatra5086Nessuna valutazione finora

- Load Sharing in AC Drive PDFDocumento12 pagineLoad Sharing in AC Drive PDFsrmohapatra5086Nessuna valutazione finora

- BCG The Digital Marketing Revolution Has Only Just Begun May 2017 Tcm9 155449Documento20 pagineBCG The Digital Marketing Revolution Has Only Just Begun May 2017 Tcm9 155449Juan JesusNessuna valutazione finora

- BT Group - Wikipedia, The Free EncyclopediaDocumento14 pagineBT Group - Wikipedia, The Free Encyclopediabachtiar 119Nessuna valutazione finora

- Application For Leave of Absence - Issue 2Documento1 paginaApplication For Leave of Absence - Issue 2Azriel RhyienNessuna valutazione finora

- Key TermsDocumento10 pagineKey Termscuteserese roseNessuna valutazione finora

- Effective Financial Statement Analysis Requires An Understanding of A Firm SDocumento1 paginaEffective Financial Statement Analysis Requires An Understanding of A Firm SM Bilal SaleemNessuna valutazione finora

- Global Marketing Management: Chapter 7 Segmentation, Targeting and PositioningDocumento19 pagineGlobal Marketing Management: Chapter 7 Segmentation, Targeting and PositioningrameshmbaNessuna valutazione finora

- ANPQP Version 2.3 ChangesDocumento25 pagineANPQP Version 2.3 ChangesSerchecko Jauregui100% (1)

- Financial Management Module I: Introduction: Finance and Related DisciplinesDocumento4 pagineFinancial Management Module I: Introduction: Finance and Related DisciplinesKhushbu SaxenaNessuna valutazione finora

- Career Objective For A Fresher EngineerDocumento4 pagineCareer Objective For A Fresher Engineerlisa arifaniaNessuna valutazione finora

- Utb Programmes 2021-2022Documento3 pagineUtb Programmes 2021-2022labid.mccNessuna valutazione finora

- CUEGISDocumento2 pagineCUEGISAuryn Astrawita HendroSaputri100% (1)

- 900K Earnings in One Year WSO ReportDocumento14 pagine900K Earnings in One Year WSO ReportlacatrinaentrajineraNessuna valutazione finora

- The High Probability Trading Strategy SummaryDocumento2 pagineThe High Probability Trading Strategy SummaryJulius Mark Carinhay TolitolNessuna valutazione finora

- Adlabs Case StudyDocumento2 pagineAdlabs Case StudyjadeNessuna valutazione finora

- Checklist of Requirements For Cosmetic LTO Application PDFDocumento2 pagineChecklist of Requirements For Cosmetic LTO Application PDFBianca Camille YlingNessuna valutazione finora

- 2.2.1.essential Job VocabularyDocumento16 pagine2.2.1.essential Job VocabularyСофия ЗвиревичNessuna valutazione finora

- 3.1.1. Understanding Forex RolloverDocumento5 pagine3.1.1. Understanding Forex RolloverWishnu Okky Pranadi TirtaNessuna valutazione finora

- AftaDocumento6 pagineAftanurnoliNessuna valutazione finora

- Social Media Content Creation InstagramDocumento10 pagineSocial Media Content Creation InstagramtabilinNessuna valutazione finora

- SAP Intercompany Sales Process Flow & ConfiguationDocumento18 pagineSAP Intercompany Sales Process Flow & Configuationsurajit biswas67% (3)

- KVS Agra XII ACC QP & MS (Pre-Board) 23-24Documento21 pagineKVS Agra XII ACC QP & MS (Pre-Board) 23-24ragingcaverock696Nessuna valutazione finora

- Project - PPT 4 PlanningDocumento43 pagineProject - PPT 4 PlanningBirhanu AbrhaNessuna valutazione finora

- Chaikin Power Gauge Report GILD 29feb2012Documento4 pagineChaikin Power Gauge Report GILD 29feb2012Chaikin Analytics, LLCNessuna valutazione finora

- CAKPO T. Paul Luc Uriel: Cakpouriel@Documento2 pagineCAKPO T. Paul Luc Uriel: Cakpouriel@chancia angeNessuna valutazione finora

- To Generate Facility Plans, The Following Questions Must Be AnsweredDocumento30 pagineTo Generate Facility Plans, The Following Questions Must Be AnsweredPuneet GoelNessuna valutazione finora

- Ee16 Safety Management Prelim ExamDocumento15 pagineEe16 Safety Management Prelim Examjenixson tamondongNessuna valutazione finora

- Contract of BailmentDocumento10 pagineContract of BailmentPravah ShuklaNessuna valutazione finora

- Fifth Semester Commerce Costing (CBCS - 2017 Onwards) : Sub. Code 7BCO5C2Documento10 pagineFifth Semester Commerce Costing (CBCS - 2017 Onwards) : Sub. Code 7BCO5C2VELAVAN ARUNADEVINessuna valutazione finora

- Acreaty Ghana Executive SearchDocumento9 pagineAcreaty Ghana Executive SearchEugene EdiforNessuna valutazione finora

- Corporate Presentations PDFDocumento36 pagineCorporate Presentations PDFSamarendra JenaNessuna valutazione finora