Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

File 1583914519 PDF

Caricato da

Agam HanasichulaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

File 1583914519 PDF

Caricato da

Agam HanasichulaCopyright:

Formati disponibili

REDTAG

TECHNIQUES

A how to guide for Red Tag inventory efforts

with tips and tricks for maximum results.

100 Providence Pike Phone: 800-453-2727 www.nationalmarker.com

North Smithfield, RI 02896 Fax: 800-338-0309

Red Tag Techniques

Using the Red Tag Techniques create a Red Tag area, separate needed from unneeded items and discard the unneeded items as

follows:

The Red Tag technique is divided into three efforts. All efforts need a leader.

1. The first time effort: (Owner, President, etc.)

a. Identify a local area with one week storage capacity, and a holding area manager

b. The area must be highly visible and centrally located. This allows others to claim unneeded items

i. Have a RED TAG AREA Sign posted

ii. Set the boundaries of the area with Tape, Chain, etc

c. Clearly labeled with rules for use and disposition posted

i. Items in this area are available for all departments

ii. Do not remove items without permission from ___________________ ext.____

iii. These items will only remain in area for _____days. After that they will be disposed of

iv. Please do not remove tags

d. Let all know about the Red Tag area and rules through e-mail, intercom, postings on information boards, etc. Keep it

low cost

e. Example of a Red Tag:

General Information Action to Take

Date: Tagged By: Return to

Item Name: Discard

Location: Move to Red Tag Storage Area

Category Move to Storage Site

Equipment Raw Materials

Tools & Jigs Work-in-Process Other:

Finished Goods Stationary, etc.

Instruments Misc.

Consumable Materials Other

Machine Parts Additional Comments

Other:

Reason for Red Tag

Not Required Aged/Obsolete

Defect Other

Scrap

Other:

RPT177 Log No.

f. With the Red Tag area properly identified, decide on What is needed? What is not? Do the following:

i. Sort through all items in the work area (excess inventory, unneeded and defective items, Clutter, Wires, Tools,

Fixtures, Gauges, Garbage, Furniture, Wall and Ceiling hangings, unused equipment, storage of items from

other areas, paper work, supplies,etc) and ask:

1. Does it have a function in this area?

2. Is it needed? How often? By whom?

3. If we remove it, will it really matter?

4. Is it in the way? Does it take too much space?

ii. Look in cabinets with doors, under desks and tables, in drawers, shelves, in unlabeled boxes, around columns,

walls (outdated posters, slogans, notices, memos, boards) and ask:

1. Does it have a function in this area?

2. Is it needed? How often? By whom?

3. If we remove it, will it really matter?

4. Is it in the way? Does it take too much space?

g. Keep what is needed and discard what is not needed.

nationalmarker.com | P: 800.453.2727 F: 800.338.0309

© 2018 National Marker Company

Red Tag Techniques (...continued)

The following flow chart is a guideline for Inventory and/or Tolling:

Inventory

and/or

Tooling

Unneeded

Needed

(cannot be used)

Daily (Hourly)

Store at Point

of use Weekly

Store in area Discard all obsolete and

defective inventory right

away (now). Use red tag

Monthly area for tools, fixtures, etc.

Store in factory, Wait one week and than

but not in area discard unclaimed items.

Twice per Year or less

Store outside factory

h. Keep and properly store needed items.

i. Reduce the number of items needed to the quantity required at any given time.

j. Discard what is not needed by placing the items in the Red Tag area. Some items can be disposed of right away

without storage in the Red Tag area.

k. Some items will be claimed by other departments. Items that stay in area for more than a week (or predetermined

time), will be “disposed of items” on schedule.

l. Do not place items in red tag area that are not needed very often but cannot be disposed of. Instead store these

items away from work area. Retrieve only as needed.

2. The daily effort: (workers, supervisor)

a. Once the Red Tag techniques is applied for the first time the area will have only needed items. These conditions will

only last for about one week without daily maintenance.

b. Daily maintenance can be done by any worker.

c. Any item that is not needed should be red tagged and disposed of immediately.

3. The annual (or semiannual) effort: (5S Steering committee, Owner, President,

Director)

a. Even with daily maintenance all companies will need an annual (or semiannual) Red Tag effort.

b. This effort will require all workers in the area, supervisors, and outsiders. (Follow the guidelines for the first time

effort as it applies).

nationalmarker.com | P: 800.453.2727 F: 800.338.0309

© 2018 National Marker Company

Potrebbero piacerti anche

- Harman/kardon: Service ManualDocumento35 pagineHarman/kardon: Service ManualThai LamNessuna valutazione finora

- Lean Production at VolkswagenDocumento2 pagineLean Production at VolkswagenSumeth Daluwatta100% (1)

- 5S Implementation Manual Part 2Documento63 pagine5S Implementation Manual Part 2jgprasadNessuna valutazione finora

- AbsenteeismDocumento7 pagineAbsenteeismhenrydee100% (1)

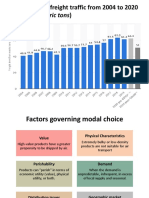

- Air CargoDocumento69 pagineAir CargoBleddyn 99100% (1)

- Ahmed Hassan Besheer CV - 1Documento6 pagineAhmed Hassan Besheer CV - 1Moud EzzNessuna valutazione finora

- Occupational Health & SafetyDocumento2 pagineOccupational Health & SafetyNitinNessuna valutazione finora

- Pinch Points V1110.1Documento1 paginaPinch Points V1110.1bob geldofNessuna valutazione finora

- LWMC Final HR ManualDocumento172 pagineLWMC Final HR ManualUsama QayyumNessuna valutazione finora

- Lean Kaizen Charter WorksheetDocumento9 pagineLean Kaizen Charter Worksheetdefreyn100% (1)

- 5 S Information and Training OutlineDocumento5 pagine5 S Information and Training Outlinekprasad_mlNessuna valutazione finora

- Powerful New Ideas: in Material Handling and MovementDocumento9 paginePowerful New Ideas: in Material Handling and MovementAmarjeet RaiNessuna valutazione finora

- Decision Tree For Incident ClassificationDocumento1 paginaDecision Tree For Incident ClassificationAdrian BagayanNessuna valutazione finora

- 8 Osha NoiseDocumento7 pagine8 Osha Noiseosama1928100% (1)

- 5S Training ManualDocumento26 pagine5S Training Manualmahendkakde100% (1)

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Documento15 pagine5S Basic Training: Whatis5Sandwhydowewanttodoit?Mahdi ZeynNessuna valutazione finora

- The Complete Guide For New ManagersDocumento28 pagineThe Complete Guide For New ManagersDahab Masr- YouTubeNessuna valutazione finora

- Toyota Executive SummaryDocumento16 pagineToyota Executive SummaryAmirahNessuna valutazione finora

- Mvrla 5s Ppt-SustenanceDocumento185 pagineMvrla 5s Ppt-SustenanceChethan Nagaraju KumbarNessuna valutazione finora

- HNG Corporate Presentation 1707replacedDocumento37 pagineHNG Corporate Presentation 1707replacedAvinash Ajit SinghNessuna valutazione finora

- Warehouse InductionDocumento47 pagineWarehouse InductionThrungNessuna valutazione finora

- Warehouse Safety Checklist Sample ReportDocumento14 pagineWarehouse Safety Checklist Sample ReportPIROM_C100% (1)

- Practical Approach To Practice 5SDocumento4 paginePractical Approach To Practice 5SNikola DjorovicNessuna valutazione finora

- 5S PrincipleDocumento53 pagine5S PrincipleAmir M. VillasNessuna valutazione finora

- Lesson 10 - Value Stream MappingDocumento21 pagineLesson 10 - Value Stream MappingHarishNessuna valutazione finora

- Chapter - 5 Implementation of 6S ConceptDocumento27 pagineChapter - 5 Implementation of 6S Conceptdevesh vermaNessuna valutazione finora

- How To Take Apart Emachines 250 NetbookDocumento16 pagineHow To Take Apart Emachines 250 Netbookmax30Nessuna valutazione finora

- 5S (Methodology) - WikipediaDocumento4 pagine5S (Methodology) - WikipediaBORRELNessuna valutazione finora

- 7 Equip Loss Def. by JIPMSDocumento5 pagine7 Equip Loss Def. by JIPMSRanjit BhandariNessuna valutazione finora

- Incident Management DashboardDocumento3 pagineIncident Management DashboardTOPdeskNessuna valutazione finora

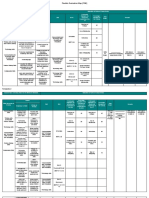

- Standardized Work SheetDocumento7 pagineStandardized Work Sheetbeenose100% (1)

- EHS Manager Manufacturing Mining in United States Resume Ken KempaDocumento3 pagineEHS Manager Manufacturing Mining in United States Resume Ken KempaKenKempaNessuna valutazione finora

- Poka Yoke ExamplesDocumento7 paginePoka Yoke ExamplesAkshay ZutshiNessuna valutazione finora

- 5S Presentation 2Documento38 pagine5S Presentation 2anbuskp100% (2)

- Lesson 1 - From Waste To Wealth - Session 2 WorksheetDocumento1 paginaLesson 1 - From Waste To Wealth - Session 2 WorksheetNicole Angela NavarroNessuna valutazione finora

- Safety Audit ManualsDocumento37 pagineSafety Audit ManualsAppal Raja100% (1)

- Lean Manufacturing PrinciplesDocumento14 pagineLean Manufacturing PrinciplesPavithraNessuna valutazione finora

- Cause Effect DiagramDocumento2 pagineCause Effect DiagramDhananjay SharmaNessuna valutazione finora

- 6S in HealthcareDocumento13 pagine6S in HealthcareChannel MedicalNessuna valutazione finora

- Chapter 8 Materials Handling ErgonomicsDocumento29 pagineChapter 8 Materials Handling ErgonomicsMít tờ KhánhNessuna valutazione finora

- Safety AttitudeDocumento15 pagineSafety AttitudeJhon SihalohoNessuna valutazione finora

- Ohs Procedure STDDocumento25 pagineOhs Procedure STDAli AkbarNessuna valutazione finora

- Ciencia Y Virtud: The 7SDocumento11 pagineCiencia Y Virtud: The 7SElle DyNessuna valutazione finora

- 5s Japanese MethodDocumento24 pagine5s Japanese MethodPraful E. PawarNessuna valutazione finora

- Job ProductionDocumento4 pagineJob ProductionTiana 'Chandie' ChandlerNessuna valutazione finora

- Visual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetyDocumento49 pagineVisual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetytrangnhNessuna valutazione finora

- Induction Training ProcessDocumento7 pagineInduction Training ProcessRanajit RoyNessuna valutazione finora

- Safety MaterialDocumento40 pagineSafety MaterialAzher AhmedNessuna valutazione finora

- Chapter 9. Failure Root Cause PreventionDocumento23 pagineChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNessuna valutazione finora

- WAAREE Energies PVT Ltd-LatestDocumento40 pagineWAAREE Energies PVT Ltd-LatestJp Gupta100% (2)

- Seven Basic Quality Tools: List / Use / InteractionDocumento56 pagineSeven Basic Quality Tools: List / Use / InteractionmangofaNessuna valutazione finora

- 09200-En-30 Process Facility Site Change ManagementDocumento6 pagine09200-En-30 Process Facility Site Change ManagementfernandoNessuna valutazione finora

- Effective Communication For Work Pre Employment Skills Lesson Element Communication Skills in The WorkplaceDocumento34 pagineEffective Communication For Work Pre Employment Skills Lesson Element Communication Skills in The WorkplaceNeha HittooNessuna valutazione finora

- The Functions of Visual ManagementDocumento18 pagineThe Functions of Visual ManagementAndreSantana100% (1)

- 1 S, 2 S & 3 S Audit Check Sheet For Miscellaneous ZonesDocumento10 pagine1 S, 2 S & 3 S Audit Check Sheet For Miscellaneous ZonesgcldesignNessuna valutazione finora

- Kaizen Structure Rev0Documento86 pagineKaizen Structure Rev0hiattolaNessuna valutazione finora

- Know The Meaning of Various Color Coding Used in Floor Marking!Documento12 pagineKnow The Meaning of Various Color Coding Used in Floor Marking!Aditya vatsyayanNessuna valutazione finora

- 5S PDFDocumento161 pagine5S PDFmadhuNessuna valutazione finora

- 2 Unit Two Sort ItemsDocumento11 pagine2 Unit Two Sort ItemsTagel BoruNessuna valutazione finora

- Poka-Yoke 5'S' Program On Zero Defects Manufacturing Work Place OrganizationDocumento30 paginePoka-Yoke 5'S' Program On Zero Defects Manufacturing Work Place Organizationjavedsh007Nessuna valutazione finora

- DR Chalapthi (5S)Documento39 pagineDR Chalapthi (5S)VIKAS GHATENessuna valutazione finora

- Chapter 02 and 03 and 04 PDFDocumento83 pagineChapter 02 and 03 and 04 PDFSalaarNessuna valutazione finora

- Aspen Plus Workshop For Reaction EngineeringDocumento44 pagineAspen Plus Workshop For Reaction EngineeringkotiNessuna valutazione finora

- Process Simulation of Hydrogen Production by Steam Reforming of Diluted Bioethanol Solutions: Effect of Operating Parameters On Electrical and Thermal Cogeneration by Using Fuel CellsDocumento19 pagineProcess Simulation of Hydrogen Production by Steam Reforming of Diluted Bioethanol Solutions: Effect of Operating Parameters On Electrical and Thermal Cogeneration by Using Fuel CellsAgam HanasichulaNessuna valutazione finora

- Sorry: Please Downloa DDocumento1 paginaSorry: Please Downloa DAgam HanasichulaNessuna valutazione finora

- CMN 2015 Submission 281Documento14 pagineCMN 2015 Submission 281Agam HanasichulaNessuna valutazione finora

- Simulation of Multi-Step Pressure Swing Adsorption Process For Production of Pure Hydrogen With High RecoveryDocumento6 pagineSimulation of Multi-Step Pressure Swing Adsorption Process For Production of Pure Hydrogen With High RecoveryAgam HanasichulaNessuna valutazione finora

- Catalytic Three-Phase Reactors: Gas, Liquid and Solid CatalystDocumento182 pagineCatalytic Three-Phase Reactors: Gas, Liquid and Solid CatalystAgam HanasichulaNessuna valutazione finora

- Matlab Guide BookDocumento26 pagineMatlab Guide BookKingchemNessuna valutazione finora

- Production and Operations ManagementDocumento284 pagineProduction and Operations Managementsnehal.deshmukh89% (28)

- Chemical Process Safety: Solutions Manual For Fundamentals With ApplicationsDocumento10 pagineChemical Process Safety: Solutions Manual For Fundamentals With ApplicationsAgam Hanasichula100% (2)

- Fatty Alcohol Production RouteDocumento10 pagineFatty Alcohol Production RouteAgam HanasichulaNessuna valutazione finora

- Internship Report - MJGOMES - 3476960Documento44 pagineInternship Report - MJGOMES - 3476960Agam HanasichulaNessuna valutazione finora

- Fundamentals of Hydrodynamics: Flow From A Tank Venturi Nozzle Jet ForcesDocumento1 paginaFundamentals of Hydrodynamics: Flow From A Tank Venturi Nozzle Jet ForcesAgam HanasichulaNessuna valutazione finora

- Thermolib UserManualDocumento334 pagineThermolib UserManualSarmad HussainNessuna valutazione finora

- Processtechnologyequipmentandsystemsbycharlese 191017161329Documento205 pagineProcesstechnologyequipmentandsystemsbycharlese 191017161329Agam HanasichulaNessuna valutazione finora

- Energies 12 03313 PDFDocumento15 pagineEnergies 12 03313 PDFAmeer AmbaniNessuna valutazione finora

- Module 1: Introduction and Thermochemistry: Objectives, Scope, Required Reading, & Assignment ScheduleDocumento18 pagineModule 1: Introduction and Thermochemistry: Objectives, Scope, Required Reading, & Assignment ScheduleAna Emily PrentissNessuna valutazione finora

- 4A.F.G.F.ads.S G. InterfaceDocumento88 pagine4A.F.G.F.ads.S G. InterfaceDewi AnatasyaNessuna valutazione finora

- Investigation of The Heat Efficiency of A Primary Reformer at An Ammonia Plant in IndonesiaDocumento47 pagineInvestigation of The Heat Efficiency of A Primary Reformer at An Ammonia Plant in IndonesiaKuldeep28883Nessuna valutazione finora

- Topsoe High Flux Steam Reform - AshxDocumento6 pagineTopsoe High Flux Steam Reform - AshxAgam HanasichulaNessuna valutazione finora

- Fractional Distillation Revision Questions: MinutesDocumento32 pagineFractional Distillation Revision Questions: MinutesAgam HanasichulaNessuna valutazione finora

- 6S TrainingDocumento40 pagine6S Trainingayaskant751001100% (2)

- Production and Operations ManagementDocumento284 pagineProduction and Operations Managementsnehal.deshmukh89% (28)

- 2 - Pipe Schedule & Inner Dia DimensionsDocumento1 pagina2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNessuna valutazione finora

- Ansi b36.10 Pipe SizeDocumento9 pagineAnsi b36.10 Pipe SizeSpoonful BurnsideNessuna valutazione finora

- Chemical Reaction Engineering O Levenspiel PDFDocumento89 pagineChemical Reaction Engineering O Levenspiel PDFAgam HanasichulaNessuna valutazione finora

- Chapter 7 SolutionsDocumento40 pagineChapter 7 SolutionsAgam HanasichulaNessuna valutazione finora

- Manualscilab RaoDocumento317 pagineManualscilab RaoMarcelo Antonucci CosNessuna valutazione finora

- Spec For Piping Design - Materials E1000713 - v1 PDFDocumento20 pagineSpec For Piping Design - Materials E1000713 - v1 PDFIlham AmirulNessuna valutazione finora

- Slides But2Documento181 pagineSlides But2Agam HanasichulaNessuna valutazione finora

- Dtec 2016 7731298Documento7 pagineDtec 2016 7731298BalajiNessuna valutazione finora

- Lsis MCCB Elcb (E)Documento316 pagineLsis MCCB Elcb (E)Bolivar MartinezNessuna valutazione finora

- Christine Jocson - EFAA1 - FEM - TemplateDocumento3 pagineChristine Jocson - EFAA1 - FEM - TemplateRomano Jocson100% (1)

- DWDM I Mid Objective QBDocumento7 pagineDWDM I Mid Objective QBkishore5783100% (1)

- Openway Centron Meter Spec Sheet PDFDocumento4 pagineOpenway Centron Meter Spec Sheet PDFmikeNessuna valutazione finora

- Blue and White Corporate Illustrated Blue Connections PresentationDocumento26 pagineBlue and White Corporate Illustrated Blue Connections PresentationveroNessuna valutazione finora

- Send and Fax GuideDocumento322 pagineSend and Fax GuideBhupendra SengarNessuna valutazione finora

- DBMS Practical FileDocumento18 pagineDBMS Practical FilevishwajeetNessuna valutazione finora

- Better Linux Disk Caching & Performance With VM - Dirty - RatioDocumento5 pagineBetter Linux Disk Caching & Performance With VM - Dirty - RatioSelçuk GÜLTEKİNNessuna valutazione finora

- Epsilon 140z DatasheetDocumento2 pagineEpsilon 140z DatasheetRiga RingsNessuna valutazione finora

- ITD Brochure InfromationDocumento5 pagineITD Brochure InfromationAfrican InstituteNessuna valutazione finora

- Chapter 10 AnswersDocumento6 pagineChapter 10 AnswersJohn HoltNessuna valutazione finora

- PDFDocumento22 paginePDFUmmeHaniAsifNessuna valutazione finora

- Module: The Oscilloscope's XY ModeDocumento6 pagineModule: The Oscilloscope's XY Moderumellemur59Nessuna valutazione finora

- Very GoodDocumento5 pagineVery GoodManjulya YeddiNessuna valutazione finora

- Ishu Worksheet 1Documento7 pagineIshu Worksheet 1Kertik SinghNessuna valutazione finora

- WG Next Generation FirewallsDocumento16 pagineWG Next Generation FirewallsVinod GuptaNessuna valutazione finora

- Ec2 Ug PDFDocumento1.001 pagineEc2 Ug PDFGisha RoyNessuna valutazione finora

- DIY Mobile Solar Power 2020Documento113 pagineDIY Mobile Solar Power 2020Silviu SerbanaNessuna valutazione finora

- Vss Cheat SheetDocumento1 paginaVss Cheat SheetPiyush BhateeNessuna valutazione finora

- RTV Servis HorvatDocumento24 pagineRTV Servis Horvatvedran54Nessuna valutazione finora

- Gatic Slotdrain PDFDocumento35 pagineGatic Slotdrain PDFshugd310850% (1)

- A Project Report On: RF Id Access Control SystemDocumento16 pagineA Project Report On: RF Id Access Control Systemharshraj086Nessuna valutazione finora

- Hannstar Product Specification: Model: Hsd101Pfw2Documento26 pagineHannstar Product Specification: Model: Hsd101Pfw2massipoedNessuna valutazione finora

- Thinking Design 01Documento6 pagineThinking Design 01ganeshs7577Nessuna valutazione finora

- Siddartha ResumeDocumento3 pagineSiddartha ResumeSasi KalaNessuna valutazione finora

- Ascii: Ask-Ee, ASCII Is A Code For Representing EnglishDocumento2 pagineAscii: Ask-Ee, ASCII Is A Code For Representing EnglishUbaid AbidNessuna valutazione finora

- 1.2.3.6 Packet Tracer - Troubleshooting Connectivty IssuesDocumento3 pagine1.2.3.6 Packet Tracer - Troubleshooting Connectivty IssuesDaniel CatalinNessuna valutazione finora