Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Afco - YS01 Series - Y Strainer

Caricato da

afie pio pioTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Afco - YS01 Series - Y Strainer

Caricato da

afie pio pioCopyright:

Formati disponibili

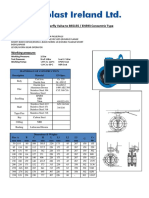

DATA SHEET

Y Strainer

General Connections

Flanged Ends

AFCO Y Strainer offers a compact and cost effective

solution for removal of debris or foreign material ANSI B16.1 Class 150

from the pipe lines. Typically use in pump system, EN1092-2 PN16

compressor, valve, or in similar application where

the amount of debris to be removed is small, and Grooved Ends

frequent cleaning is not required. Conforms to AWWA C606

The Y Strainer valves may be installed in horizontal Finish

pipe work or vertical pipe work. However, the

screening part shall be on the downside of the Fusion bond epoxy coated

strainer body, so the entrapped debris or foreign

Pressure-Temperature Performance

material can be collected for disposal.

See figure 1

Available in Flange-Flange, Flange-Groove and

Groove-Groove end connection. Flange drill is ANSI

Figure 1 Operating Pressure-Temperature chart

B16.1 Class 150 or PN 16 EN1092-2. Other Flange

end connection are available upon request.

Technical Data

Approval

UL Listed

Maximum Working pressure

300 PSI (20.87 bar)

Operating temperature

14°F (-10°C) to 230°F (110°C), for optimal

performance: refer to figure 1

Nominal Sizes

2” (DN50), 2 ½” (DN65), 3” (DN80), 4” (DN100), Components

5” (DN125), 6” (DN150), 8” (DN200), 10” (DN250)

See material list and figure 2

and 12” (DN300)

AFCO VALVES & CONTROLS | YS01 Series Page 1 of 5

Figure 2 Swing check valve components Table 1 Material list

No Description Material Specification

1 Body Ductile Iron ASTM A536 65-45-12

2 Screen Stainless Steel AISI 304 (Perforated)

3 Gasket EPDM Commercial

4 Cover Ductile Iron ASTM A536 65-45-12

5 Plug Carbon Steel ASTM A 197

Figure 3 Swing check valve dimensions

Flange-Flange Ends Flange-Groove Ends Groove-Groove Ends

Table 2 Standard screens

Size

Description Unit

2”-2 ½” 3”-4” 5” 6”-12”

inch 0.16 0.20 0.24 0.25

Hole Diameter

mm 4.06 5.08 6.10 6.35

Free Flow Area % 48 59 62 64

AFCO VALVES & CONTROLS | YS01 Series Page 2 of 5

Table 3 Dimensions

2” 2 ½” 3 4 5 6 8 10 12

SIZE Unit

50 65 80 100 125 150 200 250 300

Flange-Flange Ends

inch 7.99 10.00 10.24 12.13 15.67 18.58 21.65 25.75 30.00

L

mm 203 254 260 308 398 472 550 654 762

inch 5.20 6.22 6.89 7.99 11.42 13.15 15.39 18.11 23.23

H

mm 132 158 175 202 290 334 391 460 590

inch 7.68 9.45 10.63 12.60 16.73 19.49 22.44 27.56 33.07

H1

mm 195 240 270 320 425 495 570 700 840

Flange-Groove Ends

inch 7.99 10.00 10.24 12.13 15.67 18.58 21.65 25.75 30.00

L

mm 203 254 260 308 398 472 550 654 762

inch 5.12 6.22 6.89 7.99 11.42 13.15 15.39 18.11 23.23

H

mm 130 158 175 202 290 334 391 460 590

inch 7.68 9.45 10.63 12.60 16.73 19.49 22.44 27.56 33.07

H1

mm 195 240 270 320 425 495 570 700 840

inch 2.37 2.87 3.50 4.50 5.56 6.63 8.63 10.75 12.75

OD

mm 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273.0 323.9

Groove-Groove Ends

inch 9.03 10.00 10.71 12.13 15.67 18.58 21.65 25.75 30.00

L

mm 230 254 272.4 308 398 472 550 654 762

inch 5.12 6.22 6.89 7.99 11.42 13.15 15.39 18.11 23.23

H

mm 130 158 175 202 290 334 391 460 590

inch 7.68 9.45 10.63 12.60 16.73 19.49 22.44 27.56 33.07

H1

mm 195 240 270 320 425 495 570 700 840

inch 2.37 2.87 3.50 4.50 5.56 6.63 8.63 10.75 12.75

OD

mm 60.3 73.0 88.9 114.3 141.3 168.3 219.1 273.0 323.9

AFCO VALVES & CONTROLS | YS01 Series Page 3 of 5

Table 4 Part number and ordering information

Part Number

Nominal

Flange-Flange Flange-Flange Flange-Groove Flange-Groove

Sizes Groove-Groove

ANSI Class 150 EN1092-2 PN16 ANSI Class 150 EN1092-2 PN16

2”

YS01-300FF50 YS01-16FF50 YS01-300FG50 YS01-16FG50 YS01-GG50

(DN50)

2 ½”

YS01-300FF65 YS01-16FF65 YS01-300FG65 YS01-16FG65 YS01-GG65

(DN65)

3”

YS01-300FF80 YS01-16FF80 YS01-300FG80 YS01-16FG80 YS01-GG80

(DN80)

4”

YS01-300FF100 YS01-16FF100 YS01-300FG100 YS01-16FG100 YS01-GG100

(DN100)

5”

YS01-300FF125 YS01-16FF125 YS01-300FG125 YS01-16FG125 YS01-GG125

(DN125)

6”

YS01-300FF150 YS01-16FF150 YS01-300FG150 YS01-16FG150 YS01-GG150

(DN150)

8”

YS01-300FF200 YS01-16FF200 YS01-300FG200 YS01-16FG200 YS01-GG200

(DN200)

10”

YS01-300FF250 YS01-16FF250 YS01-300FG250 YS01-16FG250 YS01-GG250

(DN250)

12”

YS01-300FF300 YS01-16FF300 YS01-300FG300 YS01-16FG300 YS01-GG300

(DN300)

Installation 5. Visual inspection of the strainer should be

perform through the end ports to avoid

1. The strainer should be considered to be any dirt.

located in order to allow access for 6. Examine both flanges (valve and pipe) for

operation, adjustment and maintenance. correct gasket material, operating

2. Ensure the operating pressure of the pressure/temperature, contact face and

strainer accordance to the system surface finish.

pressure. 7. Strainers may be installed in horizontal

3. Strainer shall be installed on adequate pipe work or vertical pipe work. However,

support and all joining pipe work shall be the screening part shall be on the

supported to avoid the imposition of downside of the strainer body.

pipeline strains on the valve, which would 8. Fix all potential cause of leakage, prior to

decrease its performance or damage the final installation of the strainer.

strainer. Heavy strainer may needs

independent support or anchorage.

4. Handling strainer carefully, ensure the

environment temperature is in operating

temperature of the strainer.

AFCO VALVES & CONTROLS | YS01 Series Page 4 of 5

Maintenance

1. Strainer should be at zero pressure and

ambient temperature while performing

any maintenance.

2. In the event of gland leakage, each gland

nut should be tightened diametrically and

evenly until the leakage stops. Replace the

gland if it is required.

Copyright © 2017 AFCO American Fire Products Company

500 Delaware Ave, Ste 1 #1960 ▪ Wilmington, DE, US 19899

www.afcovalves.com

AFCO VALVES & CONTROLS | YS01 Series Page 5 of 5

Potrebbero piacerti anche

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocumento2 pagineWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNessuna valutazione finora

- Butterfly Valves EgeplastDocumento4 pagineButterfly Valves EgeplastdsyashankaNessuna valutazione finora

- Pipe SchedulesDocumento6 paginePipe SchedulesAnonymous 70lCzDJvNessuna valutazione finora

- Filtro WaterMistDocumento2 pagineFiltro WaterMisthuiryk goncalvesNessuna valutazione finora

- Ball Valve Weight For Nutech Control ValveDocumento11 pagineBall Valve Weight For Nutech Control Valveanandbhanushali1541991Nessuna valutazione finora

- Teknisk-2010 101 Butt Weld HubDocumento2 pagineTeknisk-2010 101 Butt Weld HubamitNessuna valutazione finora

- Catalog Profile Cu Pereti SubtiriDocumento52 pagineCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- En 10241 FittingsDocumento6 pagineEn 10241 FittingsDhavalNessuna valutazione finora

- RSERV21GTW400-Gateway J Valves S14 S15 ISODocumento11 pagineRSERV21GTW400-Gateway J Valves S14 S15 ISOgfdgdfgdfNessuna valutazione finora

- Keystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsDocumento4 pagineKeystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsteacgNessuna valutazione finora

- Válvula de Retención - Clase 600 - SCVDocumento2 pagineVálvula de Retención - Clase 600 - SCViMaJeniDeasNessuna valutazione finora

- KVC Ball ValvesDocumento1 paginaKVC Ball ValvesAlex VarHerNessuna valutazione finora

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocumento5 pagineDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNessuna valutazione finora

- Industry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsDocumento17 pagineIndustry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsAnthonyNessuna valutazione finora

- Cast Steel Y-Strainer Class: Figure No. ST1RCB St3RcbDocumento1 paginaCast Steel Y-Strainer Class: Figure No. ST1RCB St3RcbRoly AnggaraNessuna valutazione finora

- V-Cone Ficha TécnicaDocumento2 pagineV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- Valve - Gate - Osy - Nci 1Documento1 paginaValve - Gate - Osy - Nci 1Ahmed HassanNessuna valutazione finora

- Fire Valves PDFDocumento24 pagineFire Valves PDFSajjadNessuna valutazione finora

- 2212 Ca P0Documento1 pagina2212 Ca P0Oleg ShkolnikNessuna valutazione finora

- PVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListDocumento11 paginePVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListpauloNessuna valutazione finora

- MS Pipe Spec PDFDocumento1 paginaMS Pipe Spec PDFMahesh P MohanNessuna valutazione finora

- 26 HHW Katalog 2010 Eng UniversaleDocumento10 pagine26 HHW Katalog 2010 Eng Universalecos2012Nessuna valutazione finora

- Afco - CV01 Series - Swing Check ValveDocumento4 pagineAfco - CV01 Series - Swing Check Valveafie pio pioNessuna valutazione finora

- Blind Flanges - ANSI B16.5Documento7 pagineBlind Flanges - ANSI B16.5Paul SolorzanoNessuna valutazione finora

- PERHITUNGANtderi9xryx6 STR BAJADocumento110 paginePERHITUNGANtderi9xryx6 STR BAJAYasinta Rizka FNessuna valutazione finora

- 5600 Swing Flex Check ValveDocumento16 pagine5600 Swing Flex Check ValveMahmoud Abd ElnaeimNessuna valutazione finora

- Tables, Notes and Design MethodsDocumento3 pagineTables, Notes and Design MethodsSwaminathanNessuna valutazione finora

- Butterfly Valve DatasheetDocumento2 pagineButterfly Valve DatasheetKanthan DevanNessuna valutazione finora

- JIS ChannelsDocumento5 pagineJIS ChannelsRuri IswadiNessuna valutazione finora

- Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerDocumento1 paginaData Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerSteve NewmanNessuna valutazione finora

- 3" - 48" Ductile Iron Mechanical Joint Fittings ClassDocumento17 pagine3" - 48" Ductile Iron Mechanical Joint Fittings ClassNayan PatelNessuna valutazione finora

- Introduction To Vacuum GaugesDocumento11 pagineIntroduction To Vacuum GaugesNouroz BalochNessuna valutazione finora

- Butterfly Valve CatDocumento4 pagineButterfly Valve CatOleg ShkolnikNessuna valutazione finora

- Saravana EngineeringDocumento7 pagineSaravana EngineeringForesight SolutionsNessuna valutazione finora

- Valves 1234Documento13 pagineValves 1234Goutham KSNessuna valutazione finora

- 3"-48" Ductile Iron Mechanical Joint Fittings Class 350Documento11 pagine3"-48" Ductile Iron Mechanical Joint Fittings Class 350MIGUEL MIGUEL RIVAS SALCEDONessuna valutazione finora

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocumento2 pagine2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNessuna valutazione finora

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocumento3 pagineDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNessuna valutazione finora

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocumento3 pagineDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNessuna valutazione finora

- Butterfly ValvesDocumento4 pagineButterfly ValvesGopinath SekarNessuna valutazione finora

- RBL Precision Ansi RollerDocumento8 pagineRBL Precision Ansi RollerRingball_GusNessuna valutazione finora

- Data Sheet 30 - Fig TB705 Basket (Top Hat) StrainerDocumento1 paginaData Sheet 30 - Fig TB705 Basket (Top Hat) StrainerSteve NewmanNessuna valutazione finora

- Typo 1321 NDocumento1 paginaTypo 1321 NVikas PatelNessuna valutazione finora

- Strainer EN558 Serie1Documento1 paginaStrainer EN558 Serie1Jorge FerrerNessuna valutazione finora

- Confinement Check d0Documento15 pagineConfinement Check d0Srishti Project ConsultantsNessuna valutazione finora

- Kaysafe Engineering - Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerDocumento1 paginaKaysafe Engineering - Data Sheet 30 - Fig Tb705 Basket (Top Hat) StrainerSteve NewmanNessuna valutazione finora

- KVF-B16.48 Spectacle Blind BrochureDocumento26 pagineKVF-B16.48 Spectacle Blind Brochurepmech consultantNessuna valutazione finora

- ECON 3-Piece Firesafe Ball ValveDocumento6 pagineECON 3-Piece Firesafe Ball ValveKunming WangNessuna valutazione finora

- XC Flanged CouplingsDocumento6 pagineXC Flanged Couplingstexwan_Nessuna valutazione finora

- Type 01321 - Globe ValveDocumento1 paginaType 01321 - Globe ValveJoan ReigNessuna valutazione finora

- Isoflanges & Components DimensionDocumento12 pagineIsoflanges & Components DimensionJyoti Shankar MishraNessuna valutazione finora

- Jis Flanges PDFDocumento4 pagineJis Flanges PDFQuang ThanhNessuna valutazione finora

- PDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"Documento11 paginePDC High Performance Butterfly Valve Available in Sizes 2" Thru 24"pablopasqualini18Nessuna valutazione finora

- PVH Sight Glass Data SheetDocumento11 paginePVH Sight Glass Data SheetANIKET PATILNessuna valutazione finora

- Model 7041-A Flange-Ansi Class 125/150Documento2 pagineModel 7041-A Flange-Ansi Class 125/150Zaira LorenaNessuna valutazione finora

- Class 150 LBS Blind FlangeDocumento1 paginaClass 150 LBS Blind FlangeKarthi KeyanNessuna valutazione finora

- Drilling Fluids Processing HandbookDa EverandDrilling Fluids Processing HandbookValutazione: 4.5 su 5 stelle4.5/5 (4)

- Catalog Citifire Golden Bright PDFDocumento2 pagineCatalog Citifire Golden Bright PDFafie pio pioNessuna valutazione finora

- Progard H3Documento15 pagineProgard H3afie pio pioNessuna valutazione finora

- Citifire Fire HoseDocumento1 paginaCitifire Fire Hoseafie pio pioNessuna valutazione finora

- Citifire Fire ExtinguisherDocumento4 pagineCitifire Fire Extinguisherafie pio pioNessuna valutazione finora

- Brochure Siamesse ConnectionDocumento1 paginaBrochure Siamesse Connectionafie pio pioNessuna valutazione finora

- FM Approval Sprinkler VikingDocumento10 pagineFM Approval Sprinkler Vikingafie pio pioNessuna valutazione finora

- M85001-0535 - Riser Monitor Modules PDFDocumento4 pagineM85001-0535 - Riser Monitor Modules PDFafie pio pioNessuna valutazione finora

- M85001-0365 - Universal Input-Output Module MotherboardsDocumento4 pagineM85001-0365 - Universal Input-Output Module Motherboardsafie pio pioNessuna valutazione finora

- Quickfire IHB InsideDocumento1 paginaQuickfire IHB Insideafie pio pioNessuna valutazione finora

- Gsa UmDocumento6 pagineGsa Umafie pio pioNessuna valutazione finora

- M85006-0069 - Site Monitor SoftwareDocumento4 pagineM85006-0069 - Site Monitor Softwareafie pio pioNessuna valutazione finora

- Kabel 3x075 BrandsikkerDocumento2 pagineKabel 3x075 Brandsikkerafie pio pioNessuna valutazione finora

- GSA-M270 - M85001-0279 - Intelligent Manual Pull Stations PDFDocumento4 pagineGSA-M270 - M85001-0279 - Intelligent Manual Pull Stations PDFafie pio pioNessuna valutazione finora

- Afco - CV01 Series - Swing Check ValveDocumento4 pagineAfco - CV01 Series - Swing Check Valveafie pio pioNessuna valutazione finora

- Engineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure SwitchDocumento2 pagineEngineering Data Sheet: Manifold For Connecting 3/8" Hoses With Pressure Switchafie pio pioNessuna valutazione finora

- M85001 0297 Input ModulesDocumento4 pagineM85001 0297 Input Modulesafie pio pioNessuna valutazione finora

- RLCD C - M85005 0128 R Series Remote AnnunciatorsDocumento4 pagineRLCD C - M85005 0128 R Series Remote Annunciatorsafie pio pioNessuna valutazione finora

- Kabel 3x075 Brandsikker PDFDocumento1 paginaKabel 3x075 Brandsikker PDFafie pio pioNessuna valutazione finora

- Engineering Data Sheet: Pressure Relief CoverDocumento1 paginaEngineering Data Sheet: Pressure Relief Coverafie pio pioNessuna valutazione finora

- 0665 FFE Fireray 50 100 US Jan17 WEB PDFDocumento2 pagine0665 FFE Fireray 50 100 US Jan17 WEB PDFafie pio pioNessuna valutazione finora

- Cylinder 2.3.8Documento6 pagineCylinder 2.3.8afie pio pioNessuna valutazione finora

- Engineering Data Sheet: Cylinders W. INERGENDocumento2 pagineEngineering Data Sheet: Cylinders W. INERGENafie pio pioNessuna valutazione finora

- Brosure IEC MotorDocumento4 pagineBrosure IEC Motorafie pio pioNessuna valutazione finora

- GFY - Tornatech LiteDocumento4 pagineGFY - Tornatech Liteafie pio pioNessuna valutazione finora

- Waysmos Fm200 Agent Ma Ekm - BBKPN I 16 001 r0Documento8 pagineWaysmos Fm200 Agent Ma Ekm - BBKPN I 16 001 r0afie pio pioNessuna valutazione finora

- Ehase Flex - EH-600 - Flexible JointDocumento1 paginaEhase Flex - EH-600 - Flexible Jointafie pio pioNessuna valutazione finora

- Hose Rack CitifireDocumento1 paginaHose Rack Citifireafie pio pioNessuna valutazione finora

- Guidelines For Use of Pumps and Siphons For Emergency Reservoir DrawdownDocumento50 pagineGuidelines For Use of Pumps and Siphons For Emergency Reservoir DrawdownCharlie Chahua VicencioNessuna valutazione finora

- ABS Piping GroupsDocumento5 pagineABS Piping Groupsking852Nessuna valutazione finora

- Assignment 9Documento3 pagineAssignment 9HNessuna valutazione finora

- MsdsDocumento1 paginaMsdsAnissa PanlaquiNessuna valutazione finora

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocumento16 pagineHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNessuna valutazione finora

- Marcet Boiler: Thermodynamics LabDocumento5 pagineMarcet Boiler: Thermodynamics LabShiyas Basheer100% (1)

- Pitot Tube Exper.Documento4 paginePitot Tube Exper.AbdulrazzaqAL-Maliky100% (1)

- Fluid Lab 2 - Bernoulli ExpDocumento19 pagineFluid Lab 2 - Bernoulli ExpCik Tiem Ngagiman89% (65)

- Microtech: No Leakages For AgesDocumento20 pagineMicrotech: No Leakages For AgesManoj YadavNessuna valutazione finora

- Quiz 1 PDFDocumento7 pagineQuiz 1 PDFRuth MontebonNessuna valutazione finora

- A35758SDocumento112 pagineA35758SAldo Alonso GuemezNessuna valutazione finora

- Energy RatioDocumento2 pagineEnergy RatioVinay MPNessuna valutazione finora

- Axial-Flow Gas Turbine CompressorDocumento3 pagineAxial-Flow Gas Turbine CompressorDemostenes DeceoNessuna valutazione finora

- Gas Line Size-1Documento12 pagineGas Line Size-1svnaik14Nessuna valutazione finora

- Bonds Series 4100AR & 5100ARDocumento18 pagineBonds Series 4100AR & 5100ARGustavo FamaNessuna valutazione finora

- Ansi - Isa-75.01.01-2012 (60534-2-1 Mod)Documento70 pagineAnsi - Isa-75.01.01-2012 (60534-2-1 Mod)jleonos100% (4)

- Common Pool Inventory Sugar Yearwise - FinalDocumento66 pagineCommon Pool Inventory Sugar Yearwise - Finalmahesh goleNessuna valutazione finora

- Filter Oil Comressor BaruDocumento1 paginaFilter Oil Comressor BaruSyahrul SaputraNessuna valutazione finora

- ME200-Fluid Mechanics and MachineryDocumento3 pagineME200-Fluid Mechanics and Machinerynandan144Nessuna valutazione finora

- Hdpe Flow ChartDocumento3 pagineHdpe Flow ChartShaiju EbrahimNessuna valutazione finora

- Introduction To HEC - RAS Bridge HydraulicsDocumento70 pagineIntroduction To HEC - RAS Bridge HydraulicsPeter Jean-jacquesNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Flow Over Bodies: Drag and Lift: Solutions Manual For Fluid Mechanics: Fundamentals and Applications by Çengel & CimbalaDocumento65 pagineFlow Over Bodies: Drag and Lift: Solutions Manual For Fluid Mechanics: Fundamentals and Applications by Çengel & Cimbalaapi-19800460100% (8)

- Matc FileDocumento1.176 pagineMatc Filevineet57Nessuna valutazione finora

- Piping - WikipediaDocumento6 paginePiping - Wikipediaramthecharm_46098467Nessuna valutazione finora

- Testing of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedDocumento5 pagineTesting of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedKok WaiNessuna valutazione finora

- Flow ConditionerDocumento6 pagineFlow ConditionerIdehen KelvinNessuna valutazione finora

- M-30 Boiler Feed Water Piping Diagram PDFDocumento11 pagineM-30 Boiler Feed Water Piping Diagram PDFАндрей ХмелярчукNessuna valutazione finora

- 4 FlangesDocumento27 pagine4 Flangesvu ngocNessuna valutazione finora

- Dimensions of Spiral Wound Gaskets ASME B16Documento3 pagineDimensions of Spiral Wound Gaskets ASME B16Alma JakirovićNessuna valutazione finora