Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DMC Leap 1a 73 00 0023 01a 930a D - I 3 PDF

Caricato da

Panneer SelvamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DMC Leap 1a 73 00 0023 01a 930a D - I 3 PDF

Caricato da

Panneer SelvamCopyright:

Formati disponibili

LEAP-1A-73-00-0023-01A-930A-D

ENGINE FUEL AND CONTROL - PRESSURE SUB SYSTEM (73-21-45)

- PRESSURE SUB SYSTEM (PSS), PS3, AND P3B SENSING

SYSTEM HEATING, BLOWOUT AND VACUUM PROCEDURE

SERVICE BULLETIN

Table of contents

1. REVISION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

A. Revision reason . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

B. Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A. Reason . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. PLANNING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A. Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Concurrent requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. Reason . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

D. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

E. Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

F. Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

G.Manpower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

H. Weight and balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

I. Electrical load data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

J. Software accomplishment summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

K. Referenced documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

L. Documentation affected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

M.Industry support information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

N. Interchangeability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. MATERIAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5. ACCOMPLISHMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A.Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B.Get Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

C.General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

D.PS3 Sense Line Removal (Without Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

E.PS3 Hose Moisture Removal (Without Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

F.P3B Sense Line Removal (Without Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

G.P3B Sense Line Moisture Removal (Without Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

H.PS3 and P3B Sense Line Removal (With Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

to be continued ...

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 1/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

I.PS3 and P3B Hose Moisture Removal (With Optional Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

J.Job Closure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

K.Aircraft Back to Its Initial Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. ADDITIONAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

A. Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

List of tables

Table: Reasons for update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table: Support equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table: Consumables, materials and expendables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 1: Temperatures to set the Heat Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2: Temperatures to set the Heat Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3: Temperatures to Set the Heat Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4: Description of the Vacuum Pump Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 5: Description of the Heat Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6: Optional Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

List of figures

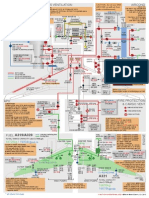

Figure 1 (Sheet 1/2): PS3 Sense Line, P3B Sense Line, and PSS Sensing Systems . . . . . . . . . . . . . 15

Figure 1 (Sheet 2/2): PS3 Sense Line, P3B Sense Line, and PSS Sensing Systems . . . . . . . . . . . . . 16

Figure 2 (Sheet 1/2): Connection of Vacuum Pump Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2 (Sheet 2/2): Connection of Vacuum Pump Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 3: Vacuum Gauge Corrections for Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 2/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

CFM PROPRIETARY INFORMATION

The information contained in this document is CFM proprietary information and is disclosed in confidence. It is the

property of CFM and shall not be used, disclosed to others or reproduced without the express written consent of CFM,

including, but without limitation, it is not to be used in the creation, manufacture, development, or derivation of any

repairs, modifications, spare parts, design, or configuration changes or to obtain FAA or any other government or

regulatory approval to do so. If consent is given for reproduction in whole or in part, this notice and the notice set forth

on each page of this document shall appear in any such reproduction in whole or in part. The information contained

in this document may also be controlled by U.S. export control laws. Unauthorized export or re-export is prohibited.

All technical documentation and information contained herein, with respect to assembly and disassembly,

cleaning, inspection methods and limits, repair methods and limits, operational limits, life limits and the like,

have been developed and approved for use with engines and parts that have been manufactured and/or

approved by CFM and that have been maintained in accordance with CFM technical documentation and

recommendations. CFM has no contractual or legal obligation for, nor knowledge of, non-CFM-approved

parts and repairs. Accordingly, this document is not intended to apply to non-CFM-approved parts and repair.

Reasons for update

Table: Reasons for update

To update paragraph 5., ACCOMPLISHMENT INSTRUCTIONS.

References

No References

Management information

Manufacturer recommendation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Recommended

Task type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Repair

Original issue date: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2018-01-30

1. REVISION INFORMATION

A. Revision reason

Issue Number Revision Reason

001 Baseline.

002 To update paragraphs 4., MATERIAL INFORMATION,

5., ACCOMPLISHMENT INSTRUCTIONS, and 6.,

ADDITIONAL INFORMATION.

003 To update paragraph 5., ACCOMPLISHMENT

INSTRUCTIONS.

B. Revision history

to be continued ...

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 3/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

Issue Number Issue Date

001 2018-01-30

002 2018-04-30

003 2018-10-22

2. SUMMARY

A. Reason

To improve reliability.

3. PLANNING INFORMATION

A. Applicability

LEAP-1A23, -1A24, -1A24E1, -1A26, -1A26E1, -1A30, -1A32, -1A33, -1A33B2, -1A35A

This Service Bulletin is applicable to all LEAP-1A engines with more than 1,500 flight hours time since new (TSN).

B. Concurrent requirements

None.

C. Reason

(1) Objective:

To improve reliability.

(2) Condition:

Over time and under certain operating conditions, water can accumulate inside the pressure sub system (PSS),

compressor discharge pressure (PS3) and compressor bleed pressure (P3B) sense lines. This accumulated

moisture can lead to a PS3 and/or P3B sense lines disagree faults and possible loss of thrust control.

(3) Cause:

Accumulation of moisture in the PSS, PS3 and P3B sense lines pressure sensing system.

(4) Improvement:

A new method is provided to remove the accumulated moisture from the PSS and PS3 and P3B sense lines

pressure sensing system. Heating, vacuuming, and blow out procedures will be used to remove accumulated

moisture.

(5) Substantiation:

Substantiation is by fleet experience.

D. Description

This Service Bulletin provides a procedure to remove accumulated moisture in the PSS unit and PS3 and

P3B sense lines.

E. Compliance

Category 2

CFM recommends that you do this Service Bulletin as soon as possible without effect on revenue service but

within 30 days of this Service Bulletin issue date and every 1,500 flight hours.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 4/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

Impact B

This recommendation is to address a condition that may result in an Increased Rate of In-Flight Shutdowns

(IFSD), Take-Off Aborts (TOA), Air Turn Backs (ATB) or Diversions (DIV).

NOTE: This Service Bulletin can be done on wing.

This Service Bulletin is offered to improve the reliability or performance of your CFM product, or to help prevent

the occurrence of the event or condition described in this Service Bulletin. If the operator elects not to participate

in the bulletin, that decision will be taken into consideration by CFM in evaluating future product performance

issues that may arise in the operator’s fleet.

F. Approval

The technical content of this Service Bulletin is approved by the FAA and under the Authority of DOA No.

EASA.21J.086.

G. Manpower

After you get access to the PSS, you will need approximately 1 man-hour for each engine or component.

H. Weight and balance

Weight and balance are not changed.

I. Electrical load data

Not Applicable.

J. Software accomplishment summary

Not Applicable.

K. Referenced documentation

Airbus A318/A319/A320/A321 Aircraft Maintenance Manual (AMM)

L. Documentation affected

Not Applicable.

M. Industry support information

None.

N. Interchangeability

Not Applicable.

4. MATERIAL INFORMATION

List of material sets

Not Applicable.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 5/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

List of support equipment

Support equipment

Unit $ Pkg

Name Tool Number Reference Qty MFR L/T

Price Qty

Standard Tools

TORQUE WRENCH -- Not Applicable 1 Quote 1 Qu-

ote

NOTE: Range to between 265 and 309 lb in. (29.9 and 34.9 Nm).

VACUUM PUMP KIT RC331931 Not Applicable 1 Quote 1 Qu-

ote

NOTE: Or equivalent as described in Table 4 in paragraph 6., ADDITIONAL INFORMATION.

NOTE: The vacuum pump kit is supplied by:

Rhinestahl Customer Tooling Solutions

7687 Innovation Way

Mason, OH 45040

U.S.A.

OR

Phone: (513) 229-5300

Fax: (513) 229-3165

E-mail: sales@rhinestahl.com

HEAT GUN -- Not Applicable 1 Quote 1 Qu-

ote

NOTE: Or equivalent as described in Table 5 in paragraph 6., ADDITIONAL INFORMATION.

NOTE: Replenishment Lead Time (L/T) in days.

NOTE: Prices are provided for planning purposes and are subject to change.

List of supplies

Consumables products, solutions and expendables parts

Name Supply Number Reference

Consumable Products

SAFETY WIRE 0.032 in. CP8002 LEAP-00-70-80-80-02A-077A-D

(0.8 mm) DIA

ENGINE OIL CP2442 LEAP-00-70-80-24-42A-077A-D

PIPETTE OR SYRINGE -- -

Specifications: polyethylene (or equivalent)

Capacity: 3 ml minimum Tip

Diameter: 5 mm maximum Tip

Length: 50 mm minimum

NOTE: Replenishment Lead Time (L/T) in days.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 6/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

List of spares

Not Applicable.

List of removed spares

Not Applicable.

5. ACCOMPLISHMENT INSTRUCTIONS

A. Safety Precautions

(1) On the center pedestal, on ENG panel 115VU, do as follows:

(a) Make sure that the ENG/MODE selector switch is in the NORM position.

(b) Make sure that the ENG/MASTER 1(2) control switch was in the OFF position not less than five minutes

before you do this procedure.

(c) Make sure that the WARNING NOTICE(S) are in position to tell persons not to operate:

1 The ENG/MODE selector switch.

2 The ENG/MASTER 1(2) control switch.

(2) On the ENG section of maintenance panel 50VU do as follows:

(a) Make sure that the ON legend of the FADEC GND PWR/1(2) pushbutton switch is off.

(b) Make sure that the WARNING NOTICE(S) is in position to tell persons not to energize the FADEC.

B. Get Access

(1) Make sure that the fan cowl doors are open. Refer to the Airbus A318/A319/A320/A321 AMM, 71-13-00,

MAINTENANCE PRACTICES, TASK 71-13-00-010-803-A and do as follows:

(a) For 4020KM1 (POWER PLANT-DEMOUNTABLE, ENGINE 1) 437AL, 438AR.

(b) For 4020KM2 (POWER PLANT-DEMOUNTABLE, ENGINE 2) 447AL, 448AR.

C. General

(1) If the ambient temperature is below 65 F (18.3 C) degrees, use a heat gun to heat the PS3 and P3B

pressure ports before you continue with the water removal.

(2) For the procedure without optional parts (Table 6), refer to steps 5.D. through 5.G.

(3) For the procedure with optional parts (Table 6), refer to steps 5.H. and 5.I.

NOTE: If you use optional parts (Table 6), the two PS3 and P3B pressure ports on the PSS (SIN: 65H02)

can be vacuumed together and the heat source must be applied to the PS3 and P3B pressure

ports.

D. PS3 Sense Line Removal (Without Optional Parts)

(1) Disconnect the PS3 sense line (SIN: 61005, Figure 1) from the PSS (SIN: 65H02) as follows:

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 7/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

WARNING: USE EYE PROTECTION WHEN YOU CUT MATERIAL OR PARTS. THE PARTICLES

CAN CAUSE DAMAGE TO YOUR EYES.

(a) Remove the safety wire (CP8002) from the PS3 sense line (SIN: 61005) B-nut.

CAUTION: KEEP THE PS3 SENSE LINE (SIN: 61005) AND OPEN PSS (SIN: 65H02) PORTS

AWAY FROM CONTAMINATION BECAUSE OF OUTSIDE PARTICLES AND SMALL

OBJECTS.

(b) Disconnect the PS3 sense line (SIN: 61005) B-nut from the pressure sense fittings on the PSS (SIN:

65H02).

E. PS3 Hose Moisture Removal (Without Optional Parts)

CAUTION: REMOVE AS MUCH STANDING WATER FROM THE PS3 PRESSURE PORT AS POSSIBLE

BEFORE YOU BEGIN THE VACUUM DRYING PROCEDURE. IF YOU DO NOT REMOVE

THE STANDING WATER, IT WILL DEGRADE THE CAPABILITY OF THE VACUUM PUMP

AND CAN DAMAGE EQUIPMENT.

(1) Do a PS3 transducer visual water removal:

(a) After you get access to the PS3 pressure port (Figure 2, CONFIGURATION 1) put a Pipette/Syringe

(--) into the opening of the PS3 transducer and withdraw the visible standing water. Continue the water

extraction until you cannot extract additional water.

(2) Do a vacuum dry-out procedure as follows:

CAUTION: ALWAYS OBEY MANUFACTURER'S INSTRUCTIONS WHEN YOU OPERATE EQUIP-

MENT. DAMAGE TO EQUIPMENT CAN OCCUR.

CAUTION: MAKE SURE THAT YOU CHANGE THE OIL IN THE VACUUM PUMP AFTER 50

USES OR VACUUM PUMP EFFECTIVENESS CAN BE COMPROMISED.

(a) Connect the vacuum hose end adapter of the vacuum pump to the PS3 pressure port on the PSS (SIN:

65H02). Tighten the fitting to 270 to 300 lb in. (30.5 to 33.8 Nm).

CAUTION: IF A NON-VARIABLE HEAT GUN IS USED WHEN AMBIENT TEMPERATURE IS

BELOW 64 F (17.7 C) DEGREES, IT CAN RESULT IN AN INCOMPLETE DRY-OUT.

(b) If the ambient temperature is below 65 F (18.3 C) degrees, use a heat gun to heat the PS3 pressure

port and do as follows:

1 Set the heat gun temperature. Refer to the Table 1.

Table 1: Temperatures to set the Heat Gun

Ambient Temperature Maximum Heat Gun Setting

65 F to 50 F (18.3 C to 10.0 C) degrees 250 F (121.1 C) degrees

49 F to 32 F (9.4 C to 0.0 C) degrees 300 F (148.9 C) degrees

31 F to 14 F (-0.5 C to -10.0 C) degrees 400 F (204.4 C) degrees

13 F to -4 F (-10.5 C to -20.0 C) degrees 500 F (260.0 C) degrees

Below -4 F (-20.0 C) degrees Not recommended

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 8/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

2 Apply heat to the PS3 pressure port with the heat gun for 4 minutes before you start the vacuum

dry-out procedure and apply the heat gun until the procedure is completed. Refer to Area A in Figure

1.

(c) Do the vacuum procedure as follows:

1 Turn the vacuum relief valve and blank-off valve handles to the open position.

CAUTION: DO NOT LET DEBRIS BE INGESTED INTO THE VACUUM PUMP RELIEF PORT.

IF THE PRESSURE READING IS NOT BELOW THE SPECIFIED THRESHOLD,

THE PROCEDURE COULD NOT BE EFFECTIVE.

2 Start the vacuum pump and let the pump motor achieve operating speed.

CAUTION: DO NOT CLOSE THE BLANK-OFF VALVE WHILE YOU REMOVE MOISTURE

FROM THE PSS. IF THE BLANK-OFF VALVE IS CLOSED, MOISTURE WILL

NOT BE REMOVED.

3 Turn the valve handle of the vacuum relief valve to the horizontal position to close it.

4 Make sure that the vacuum reading is within the green arc (25 to 30 inch Hg) for altitudes less than

5,000 ft (1,524.0 m). For altitudes above 5,000 ft (1,524.0 m) and altitude corrections, refer to Figure

3.

5 Run the vacuum pump for a minimum of 20 minutes.

6 After 20 minutes of operation, open the vacuum relief valve to release the pressure.

7 Turn off the vacuum pump.

8 Remove the vacuum hose end adapter from the PS3 pressure port.

(3) Blow out the PS3 sense line (SIN: 61005, Figure 1) as follows:

(a) Blow clean, dry air or nitrogen [approximately 100 psi (689 kPa), not more than 200 psi (1,379 kPa)] for

a minimum of 3 minutes. Continue until no moisture comes out from the sense line weep hole located

at the 6:00 o'clock position in the aft location of the fan compartment.

(b) Make sure that the PS3 sense line (SIN: 61005) weep hole is not blocked because of ice formation,

damage, or contamination, and that there is a free flow of air from the PS3 sense line (SIN: 61005)

weep hole.

NOTE: For best results, compressed nitrogen is recommended.

F. P3B Sense Line Removal (Without Optional Parts)

(1) Disconnect the P3B sense line (SIN: 61003, Figure 1) from the PSS (SIN: 65H02) as follows:

(a) Remove the loop-hinged clamp (clamp) (SIN: 61083) from the assembly bracket (bracket) (SIN: 6101A)

as follows:

1 Remove the bolt double hexagon head (bolt) (SIN: 61025) from the bracket (SIN: 6101A).

2 Remove the clamp (SIN: 61083) from the P3B sense line (SIN: 61003).

WARNING: USE EYE PROTECTION WHEN YOU CUT MATERIAL OR PARTS. THE PARTICLES

CAN CAUSE DAMAGE TO YOUR EYES.

(b) Remove the safety wire (CP8002) from the P3B sense line (SIN: 61003) B-nut.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 9/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

CAUTION: KEEP THE P3B SENSE LINE (SIN: 61003) AND OPENED PSS (SIN: 65H02) PORTS

AWAY FROM CONTAMINATION BECAUSE OF OUTSIDE PARTICLES AND SMALL

OBJECTS.

(c) Disconnect the P3B sense line (SIN: 61003) B-nut from the pressure sense fittings on the PSS (SIN:

65H02).

G. P3B Sense Line Moisture Removal (Without Optional Parts)

CAUTION: REMOVE AS MUCH STANDING WATER FROM THE P3B PRESSURE PORT AS POSSIBLE

BEFORE YOU BEGIN THE VACUUM DRYING PROCEDURE. IF YOU DO NOT TO REMOVE

THE STANDING WATER, IT WILL DEGRADE THE CAPABILITY OF THE VACUUM PUMP,

WHICH COULD CAUSE DAMAGE TO THE EQUIPMENT.

(1) Do a P3B transducer visual water removal:

(a) After you get access to the P3B hose pressure port (Figure 2 , CONFIGURATION 1), put a Pipette/Sy-

ringe (--) into the opening of the P3B transducer and withdraw the visible standing water. Continue

the water extraction until you cannot extract additional water.

(2) Do a vacuum dry-out procedure as follows:

CAUTION: ALWAYS OBEY MANUFACTURER'S INSTRUCTIONS WHEN YOU OPERATE EQUIP-

MENT. DAMAGE TO EQUIPMENT CAN OCCUR.

CAUTION: MAKE SURE THAT YOU CHANGE THE OIL IN THE VACUUM PUMP AFTER 50

USES OR VACUUM PUMP EFFECTIVENESS CAN BE COMPROMISED.

(a) Connect the vacuum hose end adapter of the vacuum pump to the P3B pressure port on the PSS (SIN:

65H02). Torque the fitting to 270 to 300 lb in. (30.5 to 33.8 Nm).

CAUTION: IF A NON-VARIABLE HEAT GUN IS USED WHEN AMBIENT TEMPERATURE IS

BELOW 64 F (17.7 C) DEGREES, IT CAN RESULT IN AN INCOMPLETE DRY-OUT.

(b) If the ambient temperature is below 65 F (18.3 C) degrees, use a heat gun to heat the P3B pressure

port as follows:

1 Set the heat gun temperature. Refer to the Table 2.

Table 2: Temperatures to set the Heat Gun

Ambient Temperature Maximum Heat Gun Setting

65 F to 50 F (18.3 C to 10.0 C) degrees 250 F (121.1 C) degrees

49 F to 32 F (9.4 C to 0.0 C) degrees 300 F (148.9 C) degrees

31 F to 14 F (-0.5 C to -10.0 C) degrees 400 F (204.4 C) degrees

13 F to -4 F (-10.5 C to -20.0 C) degrees 500 F (260.0 C) degrees

Below -4 F (-20.0 C) degrees Not recommended

2 Apply heat to the P3B pressure port with the heat gun for 4 minutes before you start the vacuum

dry-out procedure and apply the heat gun until the procedure is completed. Refer to Area A in Figure

1.

(c) Do the vacuum procedure as follows:

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 10/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

1 Turn the vacuum relief valve and blank-off valve handles to the open position.

CAUTION: DO NOT LET DEBRIS BE INGESTED INTO THE VACUUM PUMP RELIEF PORT.

IF THE PRESSURE READING IS NOT BELOW THE SPECIFIED THRESHOLD,

THE PROCEDURE COULD NOT BE EFFECTIVE.

2 Start the vacuum pump and let the pump motor achieve operating speed.

CAUTION: DO NOT CLOSE THE BLANK-OFF VALVE WHILE YOU REMOVE MOISTURE

FROM THE PSS. IF THE BLANK-OFF VALVE IS CLOSED, MOISTURE WILL

NOT BE REMOVED.

3 Turn the valve handle of the vacuum relief valve to the horizontal position to close it.

4 Make sure that the vacuum reading is within the green arc (25 to 30 inch Hg) for altitudes less than

5,000 ft (1,524.0 m). For altitudes above 5,000 ft (1,524.0 m) and altitude corrections, refer to Figure

3.

5 Run the vacuum pump for a minimum of 20 minutes.

6 After 20 minutes of operation, open the vacuum relief valve to release the pressure.

7 Turn off the vacuum pump.

8 Remove the vacuum hose end adapter from the P3B pressure port.

(3) Blow out the P3B sense line (SIN: 61003, Figure 1) as follows:

(a) Blow clean, dry air or nitrogen [approximately 100 psi (689 kPa), not more than 200 psi (1,379 kPa)] for

a minimum of 3 minutes. Continue until no moisture comes out from the sense line weep hole located

at the 6:00 o'clock position in the aft location of the fan compartment.

(b) Make sure that the P3B sense line (SIN: 61003) weep hole is not blocked because of ice formation,

damage, or contamination, and that there is a free flow of air from the P3B sense line (SIN: 61003)

weep hole.

NOTE: For best results, compressed nitrogen is recommended.

H. PS3 and P3B Sense Line Removal (With Optional Parts)

(1) Disconnect the PS3 sense line (SIN: 61005, Figure 1) and P3B sense line (SIN: 61003) from the PSS

(SIN: 65H02) as follows:

WARNING: USE EYE PROTECTION WHEN YOU CUT MATERIAL OR PARTS. THE PARTICLES

CAN CAUSE DAMAGE TO YOUR EYES.

(a) Remove the safety wire (CP8002) from the PS3 sense line (SIN: 61005) and P3B sense line (SIN:

61003) B-nuts.

CAUTION: KEEP THE PS3 SENSE LINE (SIN: 61005) AND P3B SENSE LINE (SIN: 61003) AND

OPENED PSS (SIN: 65H02) PORTS AWAY FROM CONTAMINATION BECAUSE OF

OUTSIDE PARTICLES AND SMALL OBJECTS OR DAMAGE TO THE HARDWARE

CAN OCCUR.

(b) Disconnect the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) B-nuts from the pressure

sense fittings on the PSS (SIN: 65H02).

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 11/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

I. PS3 and P3B Hose Moisture Removal (With Optional Parts)

CAUTION: REMOVE AS MUCH STANDING WATER FROM THE PS3 AND P3B PRESSURE PORTS AS

POSSIBLE BEFORE YOU START THE VACUUM DRYING PROCEDURE. IF YOU DO NOT

REMOVE THE STANDING WATER, IT WILL DEGRADE THE CAPABILITY OF THE VACUUM

PUMP AND CAN DAMAGE THE EQUIPMENT.

(1) Do a PS3 and P3B transducer visual water removal:

(a) After you get access to the PS3 and P3B pressure ports (Figure 2, CONFIGURATION 2), put a

Pipette/Syringe (--) into the opening of the PS3 and P3B transducers and withdraw the visible

standing water. Continue the water extraction until you cannot extract additional water.

(2) Do a vacuum dry-out procedure (Figure 2, CONFIGURATION 2) as follows:

CAUTION: ALWAYS OBEY THE MANUFACTURER'S INSTRUCTIONS WHEN YOU OPERATE

THE EQUIPMENT. DAMAGE TO THE EQUIPMENT CAN OCCUR.

CAUTION: MAKE SURE THAT YOU CHANGE THE OIL IN THE VACUUM PUMP AFTER 50

USES OR VACUUM PUMP EFFECTIVENESS CAN BE COMPROMISED.

(a) Connect one Teflon-6 SST braided Teflon hose assembly P/N RC331931P21 to the P3B pressure port

on the PSS (SIN: 65H02).

(b) Connect one more Teflon-6 SST braided Teflon hose assembly P/N RC331931P21 to the PS3 pressure

port on the PSS (SIN: 65H02).

(c) Connect the other two loose ends of the Teflon-6 SST braided Teflon hose assemblies P/N

RC331931P21 to the two horizontal ports on the J6T union tee SS fitting P/N RC331931P22.

(d) Connect the vacuum hose to the T-end of the J6T union tee SS fitting P/N RC331931P22.

(e) Torque all fittings to 270 to 300 lb in. (30.5 to 33.8 Nm).

CAUTION: IF A NON-VARIABLE HEAT GUN IS USED WHEN AMBIENT TEMPERATURE IS

BELOW 65 F (18.3 C) DEGREES, IT CAN CAUSE AN INCOMPLETE DRY-OUT.

(f) If the ambient temperature is below 65 F (18.3 C) degrees, use a heat gun to heat the PS3 and P3B

pressure ports and do as follows:

1 Set the heat gun temperature. Refer to the Table 3.

Table 3: Temperatures to Set the Heat Gun

Ambient Temperature Maximum Heat Gun Setting

65 to 50 F (18.3 to 10.0 C) degrees 250 F (121.1 C) degrees

49 to 32 F (9.4 to 0.0 C) degrees 300 F (148.9 C) degrees

31 to 14 F (-0.5 to -10.0 C) degrees 400 F (204.4 C) degrees

13 to -4 F (-10.5 to -20.0 C) degrees 500 F (260.0 C) degrees

Below -4 F (-20.0 C) degrees Not recommended

2 Apply heat to the PS3 and P3B pressure ports with the heat gun for 4 minutes before you start the

vacuum dry-out procedure and apply the heat gun until the procedure is completed. Refer to Area

A in Figure 1.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 12/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

(g) Do the vacuum procedure as follows:

1 Turn the vacuum relief valve and blank-off valve handles to the open position.

CAUTION: DO NOT LET CONTAMINATION ENTER THE VACUUM PUMP RELIEF PORT. IF

THE PRESSURE READING IS NOT BELOW THE SPECIFIED THRESHOLD, THE

PROCEDURE COULD NOT BE EFFECTIVE.

2 Start the vacuum pump and let the pump motor get to operating speed.

CAUTION: DO NOT CLOSE THE BLANK-OFF VALVE WHILE YOU REMOVE MOISTURE

FROM THE PSS (SIN: 65H02). IF THE BLANK-OFF VALVE IS CLOSED,

MOISTURE WILL NOT BE REMOVED.

3 Turn the valve handle of the vacuum relief valve to the horizontal position to close it.

4 Make sure that the vacuum reading is within the green arc (25 to 30 inch Hg) for altitudes less than

5,000 ft (1,524.0 m). For altitudes above 5,000 ft (1,524.0 m) and altitude corrections, refer to Figure

3.

5 Run the vacuum pump for a minimum of 20 minutes.

6 After 20 minutes of operation, open the vacuum relief valve to release the pressure.

7 Turn off the vacuum pump.

8 Remove the vacuum hose end adapter from the PS3 and P3B pressure ports.

(3) Blow out the PS3 sense line (SIN: 61005, Figure 1) and P3B sense line (SIN: 61003) as follows:

(a) Blow clean, dry air or nitrogen [approximately 100 psi (689 kPa), not more than 200 psi (1,379 kPa)] for

a minimum of 3 minutes. Continue until no moisture comes out from the sense line weep hole located

at the 6:00 o'clock position in the aft location of the fan compartment.

(b) Make sure that the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) weep holes are not

blocked because of ice formation, damage, or contamination, and that there is a free flow of air from

the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) weep holes.

NOTE: For the best results, compressed nitrogen is recommended.

J. Job Closure

(1) Connect the PS3 sense line (SIN: 61005, Figure 1) and P3B sense line (SIN: 61003) to the PSS (SIN:

65H02) as follows:

(a) Make sure that the mating surfaces are clean and clear of unwanted materials.

WARNING: REFER TO THE PRODUCT LABEL AND THE MANUFACTURER’S (MATERIAL)

SAFETY DATA SHEET (SDS) FOR INSTRUCTIONS ON THE HAZARDS, STORAGE,

SAFE HANDLING AND PROPER USE OF THIS PRODUCT.

1 Lubricate the threads of the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) coupling

nuts with engine oil (CP2442).

(b) Connect the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) coupling nuts with your

hand to the PSS (SIN: 65H02).

(c) Use a torque wrench to torque the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003)

coupling nuts to 265 to 309 lb in. (29.9 to 34.9 Nm).

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 13/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

(d) Install the clamp (SIN: 61083) on the bracket (SIN: 6101A) as follows:

1 Install the clamp (SIN: 61083) on the P3B sense line (SIN: 61003).

2 Attach the clamp (SIN: 61083) to the bracket (SIN: 6101A) with one bolt (SIN: 61025) and do as

follows:

a Torque the bolt (SIN: 61025) to 41.8 to 46.2 lb in. (4.7 to 5.2 Nm).

WARNING: USE EYE PROTECTION WHEN YOU CUT MATERIAL OR PARTS. THE PARTICLES

CAN CAUSE DAMAGE TO YOUR EYES.

(e) Safety the PS3 sense line (SIN: 61005) and P3B sense line (SIN: 61003) coupling nuts with safety

wire (CP8002).

K. Aircraft Back to Its Initial Configuration

(1) Put the Aircraft back to its initial configuration.

(2) Do an idle test. Refer to the Airbus A318/A319/A320/A321 AMM, 73-29-00, ADJUSMENT/TEST, TASK

73-29-00-740-803-A.

(3) Close the access as follows:

(a) Make sure that the work area is clean and clear of tools and other items.

(b) Close the fan cowl doors. Refer to the Airbus A318/A319/A320/A321 AMM, 71-13-00, MAINTENANCE

PRACTICES, TASK 71-13-00-410-803-A and do as follows:

1 For 4020KM1 (POWER PLANT-DEMOUNTABLE, ENGINE 1) 437AL, 438AR.

2 For 4020KM2 (POWER PLANT-DEMOUNTABLE, ENGINE 2) 447AL, 448AR.

(4) Remove the warning notice(s).

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 14/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

VIEW A

PSS

(SIN: 65H02)

FWD

P3B SENSE LINE

(SIN: 61003)

B

C

PS3 SENSE LINE

(SIN: 61005)

VIEW B

AREA A

FWD

ICN-LEAP-1A-73000023-B-07482-00001-A-002-01

PS3 Sense Line, P3B Sense Line, and PSS Sensing Systems

Figure 1 (Sheet 1 of 2)

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 15/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

VIEW C

BRACKET

(SIN: 6101A) BOLT

(SIN: 61025)

PS3 SENSE LINE

(SIN: 61005)

CLAMP

(SIN: 61083)

P3B SENSE

LINE

(SIN: 61003)

FWD

ICN-LEAP-1A-73000023-B-07482-00003-A-001-01

PS3 Sense Line, P3B Sense Line, and PSS Sensing Systems

Figure 1 (Sheet 2 of 2)

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 16/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

VIEW A

CONFIGURATION 1

FWD

PSS

(SIN: 65H02)

VACUUM RELIEF

VALVE

(SHOWN IN

OPEN POSITION)

PS3

P3B HOSE PRESSURE

PRESSURE PORT

PORT

VACUUM HOSE

VACUUM PUMP

BLANK-OFF VALVE

(SHOWN IN

OPEN POSITION)

ICN-LEAP-1A-73000023-B-07482-00002-A-002-01

Connection of Vacuum Pump Tool

Figure 2 (Sheet 1 of 2)

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 17/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

VIEW A

CONFIGURATION 2

(OPTIONAL)

PS3

J6T UNION PRESSURE

P3B HOSE

TEE SS PORT

PRESSURE

FITTING PORT PSS

(SIN: 65H02)

VACUUM HOSE TEFLON-6

(PRESENT) SST BRAIDED

TEFLON HOSE

ASSEMBLY

FWD

ICN-LEAP-1A-73000023-B-07482-00005-A-001-01

Connection of Vacuum Pump Tool

Figure 2 (Sheet 2 of 2)

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 18/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

ATMOSPHERIC

ALTITUDE PRESSURE

RANGE RANGE

(FT) (INCH HG)

BELOW 5,000 25 TO 30

5,001 TO 10,000 20 TO 25

10,001 TO 15,000 15 TO 20

ATMOSPHERIC PRESSURE (INCH HG) @59F

PRESSURE (INCH HG)

31.0

29.0

27.0

25.0

23.0

21.0

19.0

17.0

15.0

0 2,000 4,000 6,000 8,000 10,000 12,000 14,000 16,000

ALTITUDE (FT)

NOTES:

1. THE ATMOSPHERIC PRESSURE (INCH HG) DROPS

WITH THE INCREASE IN ALTITUDE (FT).

THE ATMOSPHERIC PRESSURE (INCH HG) CHANGE

FOR ALTITUDE (FT) IS SHOWN IN THE GRAPH.

2. FOR THIS PROCEDURE, THE PERMITTED VACUUM

INDICATOR GAUGE READING RANGE WITH

RESPECT TO THE ALTITUDE RANGE IS GIVEN

IN THE TABLE. ICN-LEAP-1A-73000023-B-07482-00004-A-002-01

Vacuum Gauge Corrections for Altitude

Figure 3

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 19/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

6. ADDITIONAL INFORMATION

A. Additional information

Table 4: Description of the Vacuum Pump Kit

System Operation Qty Description

Vacuum Pump 120V/60Hz. 1 Vacuum pump capable of 0.1 psia (6.8 mBar) or lower with built

in gauge to 0 to 30 in. (0 to 762 mm) of Mercury (Hg).

2-stage rotary vane super vac with gauge.

(1/4" and 3/8" male flare fitting supplied with pump).

Pump Oil. 1 Vacuum Oil (12 Qts.).

Start/Bleed Valve. 1 Ball Valve 3/8" sea male Fl. X female Fl.

Breather Vent. 1 Sintered metal filter 40 microns.

Female NPT to Female NPT 0.1 Brass coupler (package of 10) 3/8" female NPT to 3/8" female

Coupler. NPT.

Smoke Eliminator Filter. 1 Smoke eliminator filter for super evac pump.

Vacuum Hose. 1 Swagelok PTFE hose with fiber braid, 12' in length, Pump

connector is 3/8" Swagelok tube fitting, engine control

connector is 3/8" JIC (AN) fitting.

Pump Fitting. 1 Swagelok stainless steel tube fitting, male connector, 3/8 in.

Tube OD x 1/8 in. Male NPT. This fitting replaces the 1/4" SAE

fitting on the pump.

Table 5: Description of the Heat Gun

Item Description Specification Optional/Required

Accessories

Heat Gun. Steinel HG 2310 LCD Heat gun features LOC Two voltage versions, 120V

three-stage professional lockable override control™ USA and 230V Euro

heat gun or equivalent. of temperature and airflow

output settings. The LCD

display enables temperature

selection in increments of 10

F (12.2 C) degrees.

Table 6: Optional Parts

Part Number Nomenclature Qty

RC331931P21 Teflon-6 SST Braided Teflon Hose 2

Assembly (18 Inches W/FJIC E/E)

RC331931P22 J6T Union Tee SS Fitting 1

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

Page 20/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

LEAP-1A-73-00-0023-01A-930A-D

NOTE: If you use the optional tee fittings, the PS3 and P3B ports on the PSS (SIN: 65H02) can be vacuumed

together. The accomplishment instructions can be changed accordingly. A heat source must be alter-

nately applied to the PS3 and P3B pressure ports during the vacuum process.

Applicability: EngineRating - All LEAP-1A-73-00-0023-01A-930A-D

End of data module Page 21/21

© CFM PROPRIETARY INFORMATION: Subject to the restrictions on the media. Issue 003 - 2018-10-22

Potrebbero piacerti anche

- 71-0008 Issue 002Documento9 pagine71-0008 Issue 002Panneer Selvam0% (1)

- ATA 76 PW1100 - Rev. 0 (16-12-19)Documento38 pagineATA 76 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALNessuna valutazione finora

- B737NG CockpitDocumento1 paginaB737NG CockpitJair MouraNessuna valutazione finora

- Iae Engine: Oat Colder ThenDocumento1 paginaIae Engine: Oat Colder ThenBharat Bhushan100% (1)

- CFM Flight Ops Support A320Documento143 pagineCFM Flight Ops Support A320MarcinNessuna valutazione finora

- A330 PneumaticDocumento27 pagineA330 PneumaticTienek Lee100% (1)

- A318 Diffs B1 & 2 PT 1 of 2Documento216 pagineA318 Diffs B1 & 2 PT 1 of 2Mrityunjay Kumar JhaNessuna valutazione finora

- A318 Diffs B1 & 2 PT 2 of 2Documento364 pagineA318 Diffs B1 & 2 PT 2 of 2Mrityunjay Kumar JhaNessuna valutazione finora

- 04 A330 Ata 45Documento96 pagine04 A330 Ata 45OwenNessuna valutazione finora

- 27 BeamerDocumento226 pagine27 BeamerashufriendluckyNessuna valutazione finora

- 21 L3 Aug12 X PDFDocumento182 pagine21 L3 Aug12 X PDFHo Viet ThangNessuna valutazione finora

- 544-06 - Power ManagementDocumento32 pagine544-06 - Power ManagementHENIGUEDRINessuna valutazione finora

- A319/ A320/ A321 Technical Training ManualDocumento76 pagineA319/ A320/ A321 Technical Training ManualŞevval YalınNessuna valutazione finora

- The CFM56Documento4 pagineThe CFM56Okky Pangestoe WibowoNessuna valutazione finora

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Documento9 pagineEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNessuna valutazione finora

- 70 Power Plant CFM 56Documento152 pagine70 Power Plant CFM 56juan carlos balderas silvaNessuna valutazione finora

- A380-Level II&III - Ata 29 Hydraulic PowerDocumento56 pagineA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Nessuna valutazione finora

- 544-11 - Secondary AirDocumento42 pagine544-11 - Secondary AirHENIGUEDRINessuna valutazione finora

- Self Examination: 36 - PneumaticDocumento2 pagineSelf Examination: 36 - PneumaticAhmed Abdoul ZaherNessuna valutazione finora

- Training Manual A319 / A320 / A321: ATA 21 Air ConditioningDocumento44 pagineTraining Manual A319 / A320 / A321: ATA 21 Air ConditioningSomendra Brijesh PandeyNessuna valutazione finora

- Quick Reference Guide General Pneumatic: SR TechnicsDocumento2 pagineQuick Reference Guide General Pneumatic: SR TechnicsPanagiotis Diakidis0% (1)

- ATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyDocumento86 pagineATA 70 CFM56 B2: A318/19/20/21 Single Aisle FamilyZbor ZborNessuna valutazione finora

- 36 PneumaticDocumento60 pagine36 PneumaticQuynh Nguyen100% (1)

- Training Manual A319 / 320 / 321: ATA 22 AutoflightDocumento158 pagineTraining Manual A319 / 320 / 321: ATA 22 AutoflightŞevval YalınNessuna valutazione finora

- 757 PW2 CH 74 2004 SingleDocumento6 pagine757 PW2 CH 74 2004 SingleDiego Ruddy Arcaine ZegarrundoNessuna valutazione finora

- SR Technics: 22 Auto FlightDocumento210 pagineSR Technics: 22 Auto FlightTam HoNessuna valutazione finora

- A319 A320 A321 ATA 00 Abbreviation List eDocumento55 pagineA319 A320 A321 ATA 00 Abbreviation List eBogdanNessuna valutazione finora

- Braking and Steering System Trouble Shooting GuidelinesDocumento9 pagineBraking and Steering System Trouble Shooting GuidelinesSon NguyenNessuna valutazione finora

- 49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFDocumento24 pagine49 Honeywell 36-300 - Diff - L3 - Aug09 - X PDFHo Viet ThangNessuna valutazione finora

- Cf34-10e Colorization 011006Documento1 paginaCf34-10e Colorization 011006johala100% (1)

- Boeing 757 200/300 General FamiliarisationDocumento209 pagineBoeing 757 200/300 General FamiliarisationCatts Admin100% (1)

- LBM Day8Documento9 pagineLBM Day8Genaro RodriguezNessuna valutazione finora

- CFM56-7B Fan Blade Lubrication CESM-005Documento2 pagineCFM56-7B Fan Blade Lubrication CESM-005Keith Humphrey0% (2)

- B757 ATA 31-50 Indicating Recording L3Documento56 pagineB757 ATA 31-50 Indicating Recording L3anthonyNessuna valutazione finora

- TRENT 700 - N-TRENT-A330 - Chapter 54 PDFDocumento1.689 pagineTRENT 700 - N-TRENT-A330 - Chapter 54 PDF'Izzad Afif100% (2)

- 00 Engine Bleed Air SupplyDocumento14 pagine00 Engine Bleed Air SupplyAnas Abandeh100% (1)

- ATA 28 Fuel Level 3Documento128 pagineATA 28 Fuel Level 3miguel angel camargo chevel0% (1)

- A330 Ata 79-00-00Documento1 paginaA330 Ata 79-00-00essid zouhaierNessuna valutazione finora

- 70 Power Plant CFM 56Documento434 pagine70 Power Plant CFM 56Karthik Reddy100% (3)

- 544-09 - Heat MGMTDocumento22 pagine544-09 - Heat MGMTHENIGUEDRINessuna valutazione finora

- Ctc-214 Basic EngineDocumento365 pagineCtc-214 Basic Engineernesto rodriguezNessuna valutazione finora

- Ceo Neo DifferanceDocumento4 pagineCeo Neo Differancerustydfc100% (1)

- 49 Honeywell 131-9A Diff L3 Aug09 XDocumento36 pagine49 Honeywell 131-9A Diff L3 Aug09 XHo Viet Thang100% (1)

- CFM AMM ExtractsDocumento126 pagineCFM AMM ExtractsIsrael De Sousa Oliveira (LATAM)Nessuna valutazione finora

- Amm - 12 14 32 614 001 ADocumento3 pagineAmm - 12 14 32 614 001 Araiday84Nessuna valutazione finora

- TTM Single Aisle Line & Base Ata 49 ApicDocumento174 pagineTTM Single Aisle Line & Base Ata 49 Apic林至伟Nessuna valutazione finora

- Engine Variant: V2527-A5Documento12 pagineEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Ata 49 Apu Apic PDFDocumento174 pagineAta 49 Apu Apic PDFdavidNessuna valutazione finora

- CFMOilDebris PDFDocumento62 pagineCFMOilDebris PDFShreyas PingeNessuna valutazione finora

- Airbus T1+T2 CFM56 Tech Doc M8 - PP1Documento226 pagineAirbus T1+T2 CFM56 Tech Doc M8 - PP1doga dumanNessuna valutazione finora

- 70 Power Plant (V2500-A5)Documento296 pagine70 Power Plant (V2500-A5)Marcos Filho100% (1)

- CFM56Documento5 pagineCFM56Anonymous wkL8YVBENessuna valutazione finora

- A318 - ATA 38 - WATER & WASTE - Diff To A320 - L3Documento13 pagineA318 - ATA 38 - WATER & WASTE - Diff To A320 - L3super_jaizNessuna valutazione finora

- 544-14 - Starting IgnitionDocumento74 pagine544-14 - Starting IgnitionHENIGUEDRI100% (1)

- A320 49 Aps B1 e (1 CMP)Documento144 pagineA320 49 Aps B1 e (1 CMP)Sanju PhadkeNessuna valutazione finora

- Ajw gtcp331-500b Minipack SN p-1154Documento249 pagineAjw gtcp331-500b Minipack SN p-1154Okky Pangestoe WibowoNessuna valutazione finora

- FAA 2018 0855 0002 - Attachment - 2Documento15 pagineFAA 2018 0855 0002 - Attachment - 2Andrew OlsonNessuna valutazione finora

- Service Bulletin PowerplantDocumento15 pagineService Bulletin PowerplantAbdellah YazineNessuna valutazione finora

- DMC Leap 1a 72 00 0151 01a 930a D - 004 00 - SX UsDocumento14 pagineDMC Leap 1a 72 00 0151 01a 930a D - 004 00 - SX UsJason Lape100% (1)

- Engine Assembly - Core Module Assembly - (Right Side MTC Valve) (72-00-02) - Elimination of The Right Side MTC ValveDocumento64 pagineEngine Assembly - Core Module Assembly - (Right Side MTC Valve) (72-00-02) - Elimination of The Right Side MTC ValveMarcelo GasquesNessuna valutazione finora

- Figure 35-20-00-11200-00-SR (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 101-199 EMB SB 25-1876 For A/C 101-120Documento1 paginaFigure 35-20-00-11200-00-SR (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 101-199 EMB SB 25-1876 For A/C 101-120Panneer SelvamNessuna valutazione finora

- TRG A340 A320 31 03 Lru 01D PDFDocumento140 pagineTRG A340 A320 31 03 Lru 01D PDFPanneer SelvamNessuna valutazione finora

- 902 999Documento1 pagina902 999Panneer SelvamNessuna valutazione finora

- 901 901Documento1 pagina901 901Panneer SelvamNessuna valutazione finora

- Eo 001 099Documento1 paginaEo 001 099Panneer SelvamNessuna valutazione finora

- TRG A340 A320 31 06 Shop 01DDocumento32 pagineTRG A340 A320 31 06 Shop 01DPanneer SelvamNessuna valutazione finora

- Operator Requirements For Incorporation of Fuel Tank Flammability Reduction RequirementsDocumento24 pagineOperator Requirements For Incorporation of Fuel Tank Flammability Reduction RequirementsPanneer SelvamNessuna valutazione finora

- Figure 35-20-00-11200-00-KM (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 901-999Documento1 paginaFigure 35-20-00-11200-00-KM (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 901-999Panneer SelvamNessuna valutazione finora

- Figure 35-20-00-11200-00-SQ (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 201-250 EMB SB 25-1872 For A/C 201-204Documento1 paginaFigure 35-20-00-11200-00-SQ (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 201-250 EMB SB 25-1872 For A/C 201-204Panneer SelvamNessuna valutazione finora

- First-, Second-And Third-Party Testing - How and When: Position Paper No. 1/2000 May 2000Documento10 pagineFirst-, Second-And Third-Party Testing - How and When: Position Paper No. 1/2000 May 2000Panneer SelvamNessuna valutazione finora

- Avionics EquipmentDocumento4 pagineAvionics EquipmentPanneer SelvamNessuna valutazione finora

- 35-1088 R-00Documento22 pagine35-1088 R-00Panneer Selvam100% (1)

- L G A A: Figure 35-20-00-11200-00-WG (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 401-450Documento1 paginaL G A A: Figure 35-20-00-11200-00-WG (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 401-450Panneer SelvamNessuna valutazione finora

- Aerospace Vehicle Design Michael Selig - AE 442, Fall 2012 Steve D'Urso - AE 443, Spring 2013 The AirplaneDocumento18 pagineAerospace Vehicle Design Michael Selig - AE 442, Fall 2012 Steve D'Urso - AE 443, Spring 2013 The AirplanePanneer SelvamNessuna valutazione finora

- BD70CR30-017 Issue 0Documento14 pagineBD70CR30-017 Issue 0Panneer SelvamNessuna valutazione finora

- UOI vs. V.K. PuriDocumento15 pagineUOI vs. V.K. PuriPanneer SelvamNessuna valutazione finora

- Ca Form 19-10Documento128 pagineCa Form 19-10Panneer SelvamNessuna valutazione finora

- Appendix 2 - Aot A35n012-19Documento12 pagineAppendix 2 - Aot A35n012-19Panneer SelvamNessuna valutazione finora

- Sidoa320neo-0068 RevaDocumento12 pagineSidoa320neo-0068 RevaPanneer SelvamNessuna valutazione finora

- Ca Form 19-10 PDFDocumento4 pagineCa Form 19-10 PDFPanneer SelvamNessuna valutazione finora

- Faa Ad 74 08 09Documento4 pagineFaa Ad 74 08 09Panneer SelvamNessuna valutazione finora

- Aot A35n012 19 PDFDocumento4 pagineAot A35n012 19 PDFPanneer SelvamNessuna valutazione finora

- 53-1412 R-00Documento50 pagine53-1412 R-00Panneer Selvam100% (1)

- Ca Form 19-10Documento128 pagineCa Form 19-10Panneer SelvamNessuna valutazione finora

- 55-1055 R-00Documento25 pagine55-1055 R-00Panneer Selvam100% (2)

- Maintenance During Aircraft StorageDocumento4 pagineMaintenance During Aircraft StoragePanneer SelvamNessuna valutazione finora

- ProcedureDocumento4 pagineProcedurePanneer SelvamNessuna valutazione finora

- Part# Description Type Uom Qty Ar: P 1 OF 1 PagesDocumento1 paginaPart# Description Type Uom Qty Ar: P 1 OF 1 PagesPanneer SelvamNessuna valutazione finora

- GSE CockpitDocumento14 pagineGSE CockpitNimesh DelanNessuna valutazione finora

- Airbus A320: From CEO To NEO: DifferencesDocumento2 pagineAirbus A320: From CEO To NEO: DifferencesAjay KumarNessuna valutazione finora

- 25-20-26 Rev 5Documento11 pagine25-20-26 Rev 5huutri824849Nessuna valutazione finora

- 180° Turns On RunwayDocumento9 pagine180° Turns On RunwaybilelNessuna valutazione finora

- Aircraft Classifications - RfsDocumento69 pagineAircraft Classifications - RfsPaulo SouzaNessuna valutazione finora

- 51 StructureDocumento320 pagine51 StructureduythienddtNessuna valutazione finora

- Airbus Safety First Mag July 2012Documento26 pagineAirbus Safety First Mag July 2012Ou FeiNessuna valutazione finora

- Commercial Air Wars VIIIDocumento30 pagineCommercial Air Wars VIIIoussami2011.obNessuna valutazione finora

- A320 Air PDFDocumento1 paginaA320 Air PDFStephanie Johnson100% (1)

- A320-FCTM Vol2Documento748 pagineA320-FCTM Vol2lucasgoudardNessuna valutazione finora

- SP08B - Airbus - ADS-B in (ATSAW) PresentationDocumento31 pagineSP08B - Airbus - ADS-B in (ATSAW) PresentationvitorpeladoNessuna valutazione finora

- Notes CC GEO 4Documento10 pagineNotes CC GEO 4Delor FoyetNessuna valutazione finora

- A318/A319/A320/A321: Service BulletinDocumento62 pagineA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- A320 Slide Removal and InstallationDocumento7 pagineA320 Slide Removal and InstallationRameswar PradhanNessuna valutazione finora

- DFDR CVR RegulationsDocumento12 pagineDFDR CVR RegulationsAE100% (2)

- Getting Hands On Experience With Aerodynamic Deterioration PDFDocumento182 pagineGetting Hands On Experience With Aerodynamic Deterioration PDFVictor Borioli YancovitzNessuna valutazione finora

- 38 Water & WasteDocumento106 pagine38 Water & WasteduythienddtNessuna valutazione finora

- Primary Flight Control-A320Documento22 paginePrimary Flight Control-A320Zahid Zul50% (4)

- Wizz Air - CaptainDocumento3 pagineWizz Air - Captainpokemonbangkit02Nessuna valutazione finora

- A320NEO-B12-0009.2, NEO 36 Diffs, R4 170817Documento80 pagineA320NEO-B12-0009.2, NEO 36 Diffs, R4 170817simsimsom100% (2)

- Section 16 - TroubleshootingDocumento35 pagineSection 16 - Troubleshootingripan thakurNessuna valutazione finora

- Brochure Performance OpsDocumento2 pagineBrochure Performance OpsAIRBUS320Nessuna valutazione finora

- FCOM A320 (Flight Crew Operationg Manual A320) Iss 20190215 PDFDocumento3.654 pagineFCOM A320 (Flight Crew Operationg Manual A320) Iss 20190215 PDFIndra Jaya100% (3)

- BTK - A318 - A319 - A320 - A321 - IPC - 01-Aug-2019 - FIG. 79-21-10-01A - LUBRIFICATION UNIT INSTL Zone(s) 400 (Aug 01 - 19)Documento5 pagineBTK - A318 - A319 - A320 - A321 - IPC - 01-Aug-2019 - FIG. 79-21-10-01A - LUBRIFICATION UNIT INSTL Zone(s) 400 (Aug 01 - 19)Irfan05100% (1)

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Documento34 pagineWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Joao MeloNessuna valutazione finora

- A320 DownlockDocumento5 pagineA320 DownlockAshwani KumarNessuna valutazione finora

- PAL DMS Master Document List As of 02 November 2022Documento1 paginaPAL DMS Master Document List As of 02 November 2022MCC AdminNessuna valutazione finora

- Order 7360.1D Aircraft Type Designators FINAL PDFDocumento628 pagineOrder 7360.1D Aircraft Type Designators FINAL PDFJulio Cesar LibrerosNessuna valutazione finora

- Cold Weather MaintenanceDocumento5 pagineCold Weather MaintenancerameshneupaneNessuna valutazione finora

- AMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitDocumento10 pagineAMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitIrfan05100% (1)