Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

55-1055 R-00

Caricato da

Panneer SelvamCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

55-1055 R-00

Caricato da

Panneer SelvamCopyright:

Formati disponibili

@A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

AIRBUS

CUSTOMER SERVICES DIRECTORATE

1 Rond Point Maurice Bellonte

31707 BLAGNAC CEDEX

FRANCE

Tel : (33) 5 61 93 33 33

Telex : AIRBU 530526F

Fax : (33) 5 61 93 42 51

This summary is for information only and is not approved for modification of the aircraft.

ATA SYSTEM: 55

TITLE: STABILIZERS - VERTICAL STABILIZER - RUDDER Z STRUT CRACK

INSPECTION

**CONF ALL

MODIFICATIONS

None

REASON/DESCRIPTION/OPERATIONAL CONSEQUENCES

The rudder vertical support strut (Z strut) is located between the rear spar of the spar box and rudder

bearing No. 6 in the VTP. The design function of this strut is to keep the rudder in defined Z

position, to carry loads in hinge line direction and to prevent bending of the hinge arms. During routine

maintenance in the area, findings of longitudinal cracks combined with circumferential bulging at the

lower end of the rudder support Part Number R21924-2 were reported. Further investigations confirmed

that the crack was initiated by freezing water inside the strut tube.

This inspection Service Bulletin recommends a repetitive Detailed Inspection (DET) of the rudder

support strut P/N R21924-1, R21924-2 and R21924-2A and instructions depending on findings.

The embodiment of this Service Bulletin will permit early detection of cracks on rudder vertical support

struts.

NOTE: Accomplishment of the Service Bulletin No. A320-55-1058 (Production Modification No.

158335K18301 or Modification No. 160283K18302) cancels the requirements of this

Inspection Service Bulletin for the rudder support strut.

GENERAL EVALUATION

EVALUATION TABLE

COMPLIANCE RECOMMENDED (1) CANCELS INSPECTION SB NO

POTENTIAL AD NO A/C OPERATION AFFECTED NO

RELIABILITY AFFECTED NO PAX COMFORT AFFECTED NO

COST SAVING NO ETOPS AFFECTED NO

STRUCTURAL LIFE EXTN NO VENDOR SB INVOLVED NO

NOTE (1): Service Bulletin recommended to be accomplished to prevent significant operational

disruptions.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 1

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

MATERIAL PRICE INFORMATION

No Material

EFFECTIVITY

This Service Bulletin is applicable to this (these) operator(s) :

AIB AIC AIJ ALK ANA AVA AXM AZU CBJ CCA CDC CHB CSC

CSN CTV DLH EZY FFT GCR GOW HAL HKE IGO KZR LAN NKS

NVR ONE PGT RZO S2A SAS SBI TAM VIV VOI VRD VTI WOW

CONCURRENT REQUIREMENTS

None

REFERENCES / REPERCUSSIONS

TFU None

OEB None

AOT None

SIL None

ISI None

LINE MAINTENANCE AFFECTED No

LIFE LIMIT None

OTHER None

NATURE OF THE WORK

AIRCRAFT YES

EQUIPMENT NO

HARD NO

SOFT NO

OBRM NO

MANPOWER

Task 551055-832-848-001: Inspection

TOTAL MANHOURS 5.25

ELAPSED TIME (HOURS) 5.25

APPENDICES

None

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 2

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

**CONF ALL

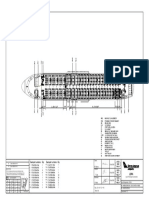

Z325

BR6

A B

PERFORM DETAILED

INSPECTION OF

THE Z STRUT

B

N_SB_551055_6_SAAA_01_00

Figure A-GSAAA - Sheet 01

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 3

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

This Page Intentionally Left Blank

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 4

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

AIRBUS

CUSTOMER SERVICES DIRECTORATE

1 Rond Point Maurice Bellonte

31707 BLAGNAC CEDEX

FRANCE

Tel : (33) 5 61 93 33 33

Telex : AIRBU 530526F

Fax : (33) 5 61 93 42 51

ATA SYSTEM: 55

TITLE: STABILIZERS - VERTICAL STABILIZER - RUDDER Z STRUT CRACK

INSPECTION

MODIFICATION No.: None

This document contains AIRBUS PROPRIETARY INFORMATION and shall at all times remain the

property of AIRBUS; no intellectual property right or licence is granted by AIRBUS in connection with

any information contained in it. It is delivered on the express condition that said document and the

information contained in it shall be treated as confidential, shall not be used for any purpose other than

that for which it is hereby delivered. It shall not be disclosed in whole or in part to third parties and shall

not be duplicated in any manner (except for the purposes of performing the tasks described hereunder

and provided that any recipient of such document shall comply with the conditions herein), without

AIRBUS prior written consent.

1. PLANNING INFORMATION

**CONF ALL

A. EFFECTIVITY

(1) Models

320-251N 320-271N 321-251N 321-253N 321-271N 321-272N

(2) Effectivity by MSN

6286 6419 6642 6720 6744 6772 6799 6801 6819 6829 6833 6849 6860 6864 6868

6904 6907 6914 6920 6946 6952 6967 6975 7001 7011 7033 7047 7051 7053 7060

7074 7078 7083 7094 7102-7103 7107 7124 7126 7129 7140-7141 7147 7150 7162

7172 7175 7181 7185-7186 7192 7195 7205 7209 7236 7249 7252 7269 7273 7277

7283 7290-7291 7309 7321 7323 7329-7331 7333-7334 7341 7343 7352 7354 7359

7367 7380 7386-7387 7391 7396 7399 7401 7409 7417 7429 7449 7459 7466 7470

7472 7475 7477 7480 7483-7484 7486 7489 7494-7495 7499 7504-7505 7507-7508

7510 7512 7514 7517 7521 7523 7526 7530 7533 7535 7538 7540 7544 7547-7548

7553-7555 7559-7560 7563 7565 7567-7568 7571 7576-7577 7579 7581 7587-7589

7591 7594 7598 7600 7602-7603 7606 7610 7612 7616 7618 7626 7629 7634

7638-7639 7642 7648-7649 7662-7663 7671 7676-7677 7682 7688 7694 7697-7698

7703 7705 7710 7719 7721 7723 7727 7731 7733 7735 7737 7744 7746 7751 7753

7755 7757 7764 7768 7770 7776 7778 7786 7788 7791 7794-7795 7799-7800

7802-7804 7807 7811-7813 7822 7824 7828 7834-7835 7837 7839 7841-7842 7844

7847-7851 7853-7854 7856 7858-7862 7864 7871 7875 7881 7887 7891-7892 7895

7897 7899 7912 7914 7917-7918 7920-7921 7925 7928 7930-7931 7936 7939

7941-7942 7944-7946 7949-7952 7959-7961 7965 7967-7968 7972 7979-7980

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 1

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

7983-7984 7986 8015 8038

(3) Effectivity by Operator

The Operator/MSN relationship is provided for information only and is correct at the time

of issue in accordance with the information available to AIRBUS. Any future changes

resulting from transfer of an aircraft from one operator to another will not be reflected in

this list unless the Service Bulletin is revised for another reason.

OPERATOR MSN

AIB 7480

AIC 7459 7475 7526 7559 7568 7616 7638 7662 7764 7776 7800 7930

7965

AIJ 7523 7576 7581 7939 7945 7986

ALK 7486 7535 7663 7697 7891

ANA 7401 7483 7554 7839 7881

AVA 7770 7822 7847 7887 7918 7928

AXM 6419 6642 7150 7195 7236 7309 7417 7508 7591 7612 7677 7719

7778 7794 7803 7837 7860 7921 7944 7949 7950 7984

AZU 7186 7283 7291 7354 7386 7409 7494 7521 7828 7960

CBJ 7875 7936 7952

CCA 7848 7899

CDC 7853

CHB 7795 7811 7849

CSC 7540 7579 7721 7744 7842 7895

CSN 6975 7129 7269 7343 7449 7470 7477 7530 7544 7548 7610 7920

7968 8015

CTV 7466 7505 7587 7603 7834

DLH 6801 6864 6920 7078 7103 7577 7588 7648 7710 7735

EZY 7649 7705 7802 7841

FFT 7141 7181 7249 7367 7387 7472 7538 7555 7600 7642 7727 7768

7824 7835 7925 7946 7967 7983

GCR 7333 7495 7533 7547 7751 7757 7788 7851 8038

GOW 7047 7074 7172 7205 7330 7507 7563 7571 7594 7737 7753 7813

7858 7859 7871

HAL 7917 7959

HKE 7209 7273 7512 7517 7598

IGO 6720 6744 6772 6799 6819 6829 6849 6860 6868 6904 6914 6946

6952 6967 7001 7033 7053 7083 7192 7252 7329 7331 7391 7396

7504 7510 7618 7892 7912 7914 7931 7961

KZR 7124 7567 7634

LAN 6286 7844 7864

NKS 6833 6907 7011 7094 7334

NVR 7746 7807

ONE 7175 7323 7484 7514 7698 7799 7854 7856

PGT 7140 7147 7162 7185 7321 7359 7380 7399 7429 7703 7786 7850

RZO 7972

S2A 7980

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 2

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

OPERATOR MSN

SAS 7277 7290 7341 7352 7489 7499 7565 7602 7676 7723 7755 7791

7897 7951 7979

SBI 7629 7671 7731 7812

TAM 7126

VIV 7060 7107

VOI 7051 7102 7553 7626 7688 7804 7862 7941

VRD 7589 7639 7861 7942

VTI 7606 7682 7733

WOW 7560 7694

(4) Configuration by MSN

MSN CONFIGURATION

6286 6419 6642 6720 6744 6772 6799 6801 6819 6829 6833 001

6849 6860 6864 6868 6904 6907 6914 6920 6946 6952 6967

6975 7001 7011 7033 7047 7051 7053 7060 7074 7078 7083

7094 7102 7103 7107 7124 7126 7129 7140 7141 7147 7150

7162 7172 7175 7181 7185 7186 7192 7195 7205 7209 7236

7249 7252 7269 7273 7277 7283 7290 7291 7309 7321 7323

7329 7330 7331 7333 7334 7341 7343 7352 7354 7359 7367

7380 7386 7387 7391 7396 7399 7401 7409 7417 7429 7449

7459 7466 7470 7472 7475 7477 7480 7483 7484 7486 7489

7494 7495 7499 7504 7505 7507 7508 7510 7512 7514 7517

7521 7523 7526 7530 7533 7535 7538 7540 7544 7547 7548

7553 7554 7555 7559 7560 7563 7565 7567 7568 7571 7576

7577 7579 7581 7587 7588 7589 7591 7594 7598 7600 7602

7603 7606 7610 7612 7616 7618 7626 7629 7634 7638 7639

7642 7648 7649 7662 7663 7671 7676 7677 7682 7688 7694

7697 7698 7703 7705 7710 7719 7721 7723 7727 7731 7733

7735 7737 7744 7746 7751 7753 7755 7757 7764 7768 7770

7776 7778 7786 7788 7791 7794 7795 7799 7800 7802 7803

7804 7807 7811 7812 7813 7822 7824 7828 7834 7835 7837

7839 7841 7842 7844 7847 7848 7849 7850 7851 7853 7854

7856 7858 7859 7860 7861 7862 7864 7871 7875 7881 7887

7891 7892 7895 7897 7899 7912 7914 7917 7918 7920 7921

7925 7928 7930 7931 7936 7939 7941 7942 7944 7945 7946

7949 7950 7951 7952 7959 7960 7961 7965 7967 7968 7972

7979 7980 7983 7984 7986 8015 8038

(5) Configuration definition

**CONF 001

Config. 001 is valid for all the aircraft given in the effectivity of this Service Bulletin as a

standard configuration.

(6) Material Effectivity

MATERIAL QTY PER A/C SEE NOTES

Consumable CMLD01 1

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 3

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

B. CONCURRENT REQUIREMENTS

None

C. REASON

(1) History

The rudder vertical support strut (Z strut) is located between the rear spar of the spar

box and rudder bearing No. 6 in the VTP. The design function of this strut is to keep the

rudder in defined Z position, to carry loads in hinge line direction and to prevent bending

of the hinge arms. During routine maintenance in the area, findings of longitudinal

cracks combined with circumferential bulging at the lower end of the rudder support Part

Number R21924-2 were reported. Further investigations confirmed that the crack was

initiated by freezing water inside the strut tube.

(2) Objective/Action

This inspection Service Bulletin recommends a repetitive Detailed Inspection (DET) of

the rudder support strut P/N R21924-1, R21924-2 and R21924-2A and instructions

depending on findings.

(3) Advantages

The embodiment of this Service Bulletin will permit early detection of cracks on rudder

vertical support struts.

NOTE: Accomplishment of the Service Bulletin No. A320-55-1058 (Production

Modification No. 158335K18301 or Modification No. 160283K18302)

cancels the requirements of this Inspection Service Bulletin for the rudder

support strut.

(4) Operational/Maintenance Consequences

None

D. DESCRIPTION

To accomplish this Service Bulletin it is necessary to :

Task 551055-832-848-001: Inspection

(1) Do a Detailed Inspection of the Rudder Support Strut

E. COMPLIANCE

(1) Classification

RECOMMENDED: Service Bulletin recommended to be accomplished to prevent

significant operational disruptions.

(2) Accomplishment Timescale

Accomplishment of this Service Bulletin is recommended, refer to Tables 1, 2 and 3.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 4

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

Table 1, Config. 001 - Identify the Z-Strut Part Number

Condition Action Compliance time (whichever comes Repetitive interval

first) (whichever comes

Threshold Grace period first)

All Aircraft Identify the Z-Strut None Within 24 months None

part number from ISB issuance

Z-Strut part Refer to Table 2

number is

R21924-1

Z-Strut part Refer to Table 3

number is

R21924-2 or

R21924-2A

Table 2 - Aircraft with Z-Strut Part Number R21924-1

Condition Action Compliance time (whichever comes Repetitive interval

first) (whichever comes

Threshold Grace period first)

Aircraft with Z-Strut Do a detailed None Within 24 months None

part number inspection of the from ISB issuance

R21924-1 Rudder Support

Strut, refer to

TASK

551055-832-848

001 Inspection

Corrosion, Contact AIRBUS Before next flight None None

scratches, dents, for further

cracks and/or guidance

bulging found

No findings Clear and clean Immediately after None None

strut drain holes inspection

Table 3- Aircraft with Z-Strut Part Number R21924-2 or R21924-2A

Condition Action Compliance time (whichever comes Repetitive interval

first) (whichever comes

Threshold Grace period first)

Aircraft with Z-Strut Do a detailed None Within 24 months None

part number inspection of the from ISB issuance

R21924-2 or Rudder Support

R21924-2A Strut, refer to

TASK

551055-832-848

001 Inspection

Aircraft is older Do MSB Before next flight None None

than 24 months A320-55-1058

Cracks and/or

bulging found

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 5

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

Aircraft is not older Do MSB None Within 24 months None

than 24 months A320-55-1058

Cracks and/or

bulging found

No findings Do a detailed None None Every 24 months

inspection of the

Rudder Support

Strut, refer to

TASK

551055-832-848

001 Inspection

OR

Do MSB Before next flight None None

A320-55-1058

F. APPROVAL

The technical content of this document is approved under the authority of Design

Organisation Approval No. EASA.21J.031.

If an aircraft listed in the effectivity has a modification or repair embodied that is not of

AIRBUS origin, and which affects the content of this Service Bulletin, the operator is

responsible for obtaining approval by its airworthiness authority for any adaptation necessary

before incorporation of the Service Bulletin.

G. MANPOWER

The manpower estimates given in this Service Bulletin are based on the direct labor cost to

do the work. These estimates assume that the work will be done by experienced personnel,

and may need to be revised upwards to suit operator’s circumstances. The estimates do not

include the time to prepare, plan or inspect the work. Manufacture and procurement of parts

and tools, drying times for paints, sealants, etc., and general administration work are also not

included.

Task 551055-832-848-001: Inspection

Get Access 3.00

On Aircraft

Do a Detailed Inspection of the Rudder Support Strut 0.25

Close-Up 2.00

TOTAL MANHOURS 5.25

ELAPSED TIME (HOURS) 5.25

H. WEIGHT AND BALANCE

Not Changed

I. ELECTRICAL LOAD DATA

Not Changed

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 6

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

J. REFERENCES

Aircraft Maintenance Manual (AMM) 06-20-00 06-41-55 12-34-24

20-16-00 55-36-48

Elec. Std. Practices Manual (ESPM) 20-55-00

K. PUBLICATION AFFECTED

None

L. INTERCHANGEABILITY/MIXABILITY

Not Applicable

M. SPARES

None

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 7

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

This Page Intentionally Left Blank

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 8

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

2. MATERIAL INFORMATION

**CONF ALL

A. MATERIAL - PRICE AND AVAILABILITY

No Material Set

B. INDUSTRY SUPPORT INFORMATION

AIRBUS will credit the man hours indicated in this Service Bulletin for inspections that are

performed on aircraft in warranty at the time of such inspection. Credit will be at the agreed

inhouse warranty labor rate. Claims for labor allowance should be received no later than 90

days after completion of the last affected warranted aircraft.

For those aircraft in warranty at the time of such inspection with findings further to inspection

as per this Service Bulletin, AIRBUS will share the costs of accomplishment of this Service

Bulletin by crediting the operator supplied AIRBUS parts for orders placed before Sep 01/20.

Claims for this allowance should be received no later than 90 days after completion of the last

affected aircraft of your fleet.

For those aircraft in warranty at the time of such inspection with findings further to

inspection as per this Service Bulletin, AIRBUS will credit the man hours indicated in this

Service Bulletin for corrections that are performed on aircraft in warranty at the time of

such correction. Credit will be at the agreed inhouse warranty labor rate. Claims for labor

allowance should be received no later than 90 days after completion of the last affected

warranted aircraft.

C. LIST OF COMPONENTS

No Kit

D. LIST OF MATERIALS - OPERATOR SUPPLIED

(1) Consumable Materials

Consumable CMLD01

ITEM DESCRIPTION REFERENCE TO CML QTY PER A/C SEE

MAT. No. NOTES

Non Aqueous Cleaner-General 08BAA9 As required

Textile-Lint Free Cotton 14SBA1 As required

(2) Components

None

(3) Equipment

None

E. PARTS TO BE RE-IDENTIFIED BY OPERATOR

None

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 9

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

F. TOOLING

None

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 10

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

3. ACCOMPLISHMENT INSTRUCTIONS

Task 551055-832-848-001 - Inspection

WARNING: MAKE SURE THAT YOU OBEY ALL THE WARNINGS AND ALL THE CAUTIONS

INCLUDED IN THE REFERENCED PROCEDURES.

CAUTION: ALWAYS OBEY THE PRECAUTIONS THAT FOLLOW TO KEEP

ELECTRICAL WIRING IN A SATISFACTORY CONDITION (ELECTRICALLY

AND MECHANICALLY SERVICEABLE). WHEN YOU DO MAINTENANCE

WORK, REPAIRS OR MODIFICATIONS, ALWAYS KEEP ELECTRICAL WIRING,

COMPONENTS AND THE WORK AREA AS CLEAN AS POSSIBLE. TO DO

THIS:

- PUT PROTECTION, SUCH AS PLASTIC SHEETING, CLOTHS, ETC., AS

NECESSARY ON WIRING AND COMPONENTS.

- REGULARLY REMOVE ALL SHAVINGS, UNWANTED MATERIAL AND

OTHER CONTAMINATION.

THESE PRECAUTIONS WILL DECREASE THE RISK OF CONTAMINATION

AND DAMAGE TO THE ELECTRICAL WIRING INSTALLATION.

IF THERE IS CONTAMINATION, REFER TO ESPM 20-55-00.

NOTE: The accomplishment instructions of this Service Bulletin include procedures given

in other documents or in other sections of the Service Bulletin. When the words

’refer to’ are used and the operator has a procedure accepted by the local authority

he belongs to, the accepted alternative procedure can be used. When the words ’in

accordance with’ are used then the given procedure must be followed.

NOTE: The access and close-up instructions, not comprising return to service tests, in this

Service Bulletin do not constitute or affect the technical intent of the Service

Bulletin. Operators can therefore, as deemed necessary, omit or add access and/or

close-up steps to add flexibility to their maintenance operations as long as the

technical intent of the Service Bulletin is met within the set parameters.

NOTE: Manual titles given in the accomplishment instructions are referred to by acronyms.

Refer to paragraph 1.J., References, for the definition of acronyms.

NOTE: This Service Bulletin contains the instructions for the on-aircraft maintenance

necessary to ensure the continued airworthiness of the aircraft.

For any deviations to the instructions contained herein, contact Airbus for further

instructions and approval.

NOTE: The purpose of flowcharts is to supplement the information given in the Procedure

and Compliance paragraphs and not to serve as the primary source for tasks or

compliance times given in this Service Bulletin.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 11

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

Task Associated Data

Zone

325

Access

Panel 325DL 325DR 325EL 325ER

Manpower

TOTAL MANHOURS 5.25

ELAPSED TIME (HOURS) 5.25

A. GENERAL

(1) Subtask 551055-910-201-001 - Standard Practices

Manpower Resources

Skills NON SPECIFIC

References

Aircraft Maintenance Manual (AMM) 06-20-00, Page Block 001

06-41-55, Page Block 001

Task 20-16-00-912-001

(a) For the identification of zones, refer to AMM 06-20-00, Page Block 001.

(b) For the identification of access panels, refer to AMM 06-41-55, Page Block 001.

(c) For circuit breaker safety practices, refer to AMM Task 20-16-00-912-001.

(2) Subtask 551055-839-201-001 - Administrative

Manpower Resources

Skills NON SPECIFIC

Write in the applicable aircraft records that you have done all the work given in this

Service Bulletin.

B. PREPARATION

(1) Subtask 551055-941-201-001 - Job Set-up

Work Zones and Access Panels

Zone Access/Work location

325 Access Panel 325DL, Panel 325DR, Panel 325EL, Panel

325ER

Manpower Resources

Skills AIRFRAME

References

Aircraft Maintenance Manual (AMM) Task 12-34-24-869-002

Task 55-36-48-000-001

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 12

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

NOTE: The items given in this note shall be considered as the basic Aircraft

configuration before you start a maintenance task:

- Aircraft on the ground resting on landing gear (the ground safety

locks and the wheel chocks are in position on the landing gear)

- Engine shut down, thrust reversers closed and locked

- Aircraft in clean configuration

- Parking brake applied

- Aircraft electrical network de-energized

- Hydraulic systems depressurized

- Access to the cockpit and cabin is available

- All circuit breakers are in closed position

- All controls in NORM, AUTO or OFF position.

(a) Make sure that the aircraft is electrically grounded, refer to AMM Task

12-34-24-869-002.

(b) Do the Job Set-up procedure as specified in the removal of the Rudder Support

Strut, refer to AMM Task 55-36-48-000-001.

C. PROCEDURE

(1) Subtask 551055-220-201-001 - Do a Detailed Inspection of the Rudder Support

Strut

Work Zones and Access Panels

Zone Access/Work location

325 Access Panel 325DL, Panel 325DR, Panel 325EL, Panel

325ER

Manpower Resources

Manhours 0.25

Minimum number of person 1

Subtask elapsed time 0.25

Skills AIRFRAME

Material necessary to do the job

Consumable CMLD01

ITEM DESCRIPTION REFERENCE TO QTY PER A/C SEE

CML MAT. No. NOTES

Non Aqueous Cleaner- 08BAA9 As required

General

Textile-Lint Free Cotton 14SBA1 As required

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 13

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

References

Fig. A-GBAAA Sheet 01

Detailed Inspection of the Rudder Sheet 02

Support Strut Sheet 03

Fig. A-GFAAA Sheet 01

Flowchart

(a) Inspect the Rudder Support Strut part number, refer to Fig. A-GBAAA Sheet 01.

1 If the part number is R21924-1:

a Do a detailed inspection of the Rudder Support Strut, part number

R21924-1, refer to Fig. A-GBAAA and Fig. A-GFAAA.

<1> If no damage was found, including damage from corrosion,

scratching, dents, cracks or bulging:

<a> Check the drain holes located on the strut body for clogging.

<b> Clear debris from the holes.

<c> Clean the hole openings with:

Textile-Lint Free 14SBA1 As required

Cotton

and

Non Aqueous 08BAA9 As required

Cleaner-General

<d> No further action is required.

<2> If damage was found:

<a> Contact AIRBUS before next flight and follow their instructions.

2 If the part number is R21924-2 or R21924-2A:

a Do a detailed inspection of the Rudder Support Strut, part number

R21924-2 or R21924-2A, refer to Fig. A-GBAAA and Fig. A-GFAAA.

<1> If neither crack(s) nor circumferential bulging was found:

<a> Accomplish Service Bulletin No. A320-55-1058 before the next

flight.

[1] No further action is required.

<b> Or do inspection again in accordance with Paragraph 1.E.(2).

[1] No further action is required.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 14

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

<2> If crack(s) and/or circumferential bulging was found:

<a> If the aircraft is older than 24 months:

[1] Accomplish Service Bulletin No. A320-55-1058 before the

next flight.

[2] No further action is required.

<b> If the aircraft is not older than 24 months:

[1] Accomplish Service Bulletin No. A320-55-1058 within 24

months.

[2] No further action is required.

D. TEST

None

E. CLOSE-UP

(1) Subtask 551055-942-201-001 - Close-up

Manpower Resources

Skills AIRFRAME

References

Aircraft Maintenance Manual (AMM) Task 55-36-48-400-001

NOTE: If you intend to accomplish an associated Repair Task during the same

layover period, the subsequent Close-up procedure is not necessary.

(a) Make sure that the work areas are clean and clear of tools and other items of

equipment.

(b) Do the Close-up procedure as specified in the installation of the Rudder Support

Strut, refer to AMM Task 55-36-48-400-001.

(c) Put the aircraft back to its initial configuration.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 15

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

**CONF ALL

Z325

BR6

A B

C D

RUDDER SUPPORT STRUT

B

N_SB_551055_6_BAAA_01_01

Figure A-GBAAA - Sheet 01

Detailed Inspection of the Rudder Support Strut

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 16

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

**CONF ALL

BULGING

CRACK

U C

P

N_SB_551055_6_BAAA_02_01

Figure A-GBAAA - Sheet 02

Detailed Inspection of the Rudder Support Strut

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 17

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

**CONF ALL

BULGING

N_SB_551055_6_BAAA_03_00

Figure A-GBAAA - Sheet 03

Detailed Inspection of the Rudder Support Strut

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 18

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

**CONF ALL

IDENTIFY Z−STRUT PART NUMBER:

R21924−1, R21924−2 OR R21924−2A

IS

THE PART PERFORM A DETAILED INSPECTION

NUMBER YES

OF RUDDER SUPPORT STRUT R21924−1

R21924−1?

NO

CORROSION,

SCRATCHES, DENTS,

PERFORM A DETAILED INSPECTION OF RUDDER CRACKS AND/OR NO

SUPPORT STRUT R21924−2 OR R21924−2A BULGING

FOUND?

CLEAR AND CLEAN

STRUT DRAIN HOLES

YES

CRACKS

AND/OR BULGING YES

FOUND?

CONTACT AIRBUS FOR

FURTHER GUIDANCE

NO A/C

OLDER THAN YES

24 MONTHS?

OR

DO MOD

REPEAT AS PER SB SB A320−55−1058

INSTRUCTIONS IN AS PER SB

PARAGRAPH 1.E.(2) INSTRUCTIONS IN

PARAGRAPH 1.E.(2)

NO

DO MOD

SB A320−55−1058

AS PER SB

INSTRUCTIONS IN

PARAGRAPH 1.E.(2) DO MOD

SB A320−55−1058

AS PER SB

INSTRUCTIONS IN

PARAGRAPH 1.E.(2)

NO FURTHER ACTION

NOTE:

THE PURPOSE OF FLOWCHARTS IS TO SUPPLEMENT

THE INFORMATION GIVEN IN THE PROCEDURE AND

COMPLIANCE PARAGRAPHS AND NOT TO SERVE AS

THE PRIMARY SOURCE FOR TASKS OR COMPLIANCE

TIMES GIVEN IN THE SERVICE BULLETIN.

N_SB_551055_6_FAAA_01_04

Figure A-GFAAA - Sheet 01

Flowchart

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 19

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

Service Bulletin REPORTING

TITLE: STABILIZERS - VERTICAL STABILIZER - RUDDER Z STRUT CRACK

INSPECTION

MODIFICATION No.: None

SB Reporting status

This Service Bulletin will only be incorporated into affected customized Maintenance and Flight

Operations Products if it is duly reported to Airbus.

General information

The SB Reporting policy is published in ISI 00.00.00135. This document provides information regarding:

the SB Reporting means and benefits, the update of customized Maintenance Products and customized

Flight Operations Products.

If this Service Bulletin has an operational impact, refer to paragraph "Flight Operations Products" for

further information on the update of affected Flight Operations Products.

SB Reporting procedure

Standard practice to report SB is to use the online reporting application on AirbusWorld.

Refer to ISI 00.00.00179:

- For complete information on reporting means to Airbus. Question 2 "What are the standard

practices for SB reporting?"

- If this SB requires previous or simultaneous accomplishment of other SBs, Question 3 "What about

the reporting of prerequisite Service Bulletin?"

NOTE: ISI 00.00.00179 covers all the frequently asked questions about SB Reporting. It is revised on a

regular basis.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 1

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

@A318/A319/A320/A321

SERVICE BULLETIN

QUALITY PERCEPTION FORM

Use this form to tell us what is your perception of the quality of this Service Bulletin. The reported data

that you provide us will be used to analyse areas of difficulties and to take corrective action to further

improve the quality of our Service Bulletins.

We thank you for the time you have taken in completing this form.

(Please rate on a scale of 1 to 4, with 4 being the highest score)

- Quality rating of this SB 4 3 2 1

- Quality rating of the Accomplishment Instructions 4 3 2 1

- Quality rating of the Illustrations 4 3 2 1

- Is this SB easy to understand ? Y/N

If you have had difficulties in the accomplishment of this SB please quote below the area(s) and give a

short description of the issue.

Planning Material Instructions

X Effectivity X Kit content X Preparation

X Reason X List of Materials Operator Supplied X Mod/Inspection

X Manpower X Industry support X Test

X References X Re-identification X Close-Up

X Publication X Tooling X Illustrations

Comments:

Operator: Date:

Name/Title:

Please return this form to:

AIRBUS

CUSTOMER SERVICES DIRECTORATE

1 Rond Point Maurice Bellonte

31707 BLAGNAC CEDEX FRANCE

Attn : SEM4 Service Bulletins Management

FAX : (33) 5 61 93 42 51

Or via your Resident Customer Support Office.

6 DATE: Aug 10/17 SERVICE BULLETIN No.: A320-55-1055

REVISION No.: 00 - Aug 10/17 Page: 1

Printed in FRANCE © AIRBUS S.A.S. 2007. All rights reserved.

Potrebbero piacerti anche

- Boeing 737-300 Transit CheckDocumento6 pagineBoeing 737-300 Transit CheckUmer JavedNessuna valutazione finora

- DMC Leap 1a 73 00 0023 01a 930a D - I 3 PDFDocumento21 pagineDMC Leap 1a 73 00 0023 01a 930a D - I 3 PDFPanneer Selvam100% (1)

- Appendix 2 - Aot A35n012-19Documento12 pagineAppendix 2 - Aot A35n012-19Panneer SelvamNessuna valutazione finora

- Pre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocumento5 paginePre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListLandy FebriansyahNessuna valutazione finora

- 1 Additional Lecture - Direct Maintenance Cost - Art or ScienceDocumento28 pagine1 Additional Lecture - Direct Maintenance Cost - Art or Scienceoliver_porras_3Nessuna valutazione finora

- SB 27-1242 r02Documento62 pagineSB 27-1242 r02ame7871Nessuna valutazione finora

- Aot A35n012 19 PDFDocumento4 pagineAot A35n012 19 PDFPanneer SelvamNessuna valutazione finora

- ProcedureDocumento4 pagineProcedurePanneer SelvamNessuna valutazione finora

- A320 Pedestal PanelDocumento1 paginaA320 Pedestal PanelnazzooNessuna valutazione finora

- SB 28-0093 r00Documento37 pagineSB 28-0093 r00Mohammad Faraz AkhterNessuna valutazione finora

- SB 71-1071.rev.1Documento45 pagineSB 71-1071.rev.1ArnauRodriguezVernetNessuna valutazione finora

- A318/A319/A320/A321: Service BulletinDocumento23 pagineA318/A319/A320/A321: Service BulletinPradeep K sNessuna valutazione finora

- 51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On AlDocumento4 pagine51-10-12 - General Procedure For The Detection of Heat Damage Using Eddy Current Conductivity Measurement On Alkien Duy PhanNessuna valutazione finora

- Flight Crew Operating Manual Preliminary Pages: Standard NomenclatureDocumento10 pagineFlight Crew Operating Manual Preliminary Pages: Standard NomenclatureTyoNessuna valutazione finora

- Maintenance Service Plan: Avionics & Mechanical Components - Pilatus OperatorsDocumento14 pagineMaintenance Service Plan: Avionics & Mechanical Components - Pilatus OperatorsDenisNessuna valutazione finora

- A318/A319/A320/A321: Service BulletinDocumento48 pagineA318/A319/A320/A321: Service BulletinPradeep K sNessuna valutazione finora

- Isi-00.00.00228 17jan2022Documento150 pagineIsi-00.00.00228 17jan2022Enikő PethőNessuna valutazione finora

- Als Part 1 A318a319a320a321Documento85 pagineAls Part 1 A318a319a320a321Muhammad Naqib Khan HARJAR MYDINNessuna valutazione finora

- A320 A321 P2F Mmel PTC R09 Dec 01 21 PDFDocumento170 pagineA320 A321 P2F Mmel PTC R09 Dec 01 21 PDFPiyush SinghalNessuna valutazione finora

- Quick Reference HandbookDocumento324 pagineQuick Reference HandbookJan kopáčekNessuna valutazione finora

- SB PolicyDocumento5 pagineSB PolicyEduardo MercadejasNessuna valutazione finora

- A320-Mel-Cdl-Cdd StatusDocumento18 pagineA320-Mel-Cdl-Cdd StatusvproNessuna valutazione finora

- v2500 Ts PDFDocumento18 paginev2500 Ts PDFGioVanni LorizioNessuna valutazione finora

- Fast24 PDFDocumento20 pagineFast24 PDFFrancisco Isaac LucenaNessuna valutazione finora

- Aircraft ManualsDocumento1 paginaAircraft ManualsAlyana Sophia CerdaNessuna valutazione finora

- Operators Information Transmission - Oit: Customer Services DirectorateDocumento3 pagineOperators Information Transmission - Oit: Customer Services DirectorateIbrahim KhalilNessuna valutazione finora

- AC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesDocumento12 pagineAC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesUjang SetiawanNessuna valutazione finora

- A320fam Ata05-20 Airplane GeneralDocumento119 pagineA320fam Ata05-20 Airplane GeneralSourab MukherjeeNessuna valutazione finora

- 08 Limitations PDFDocumento112 pagine08 Limitations PDFBharat BhushanNessuna valutazione finora

- A320 LopaDocumento1 paginaA320 LopaLiam SkrooNessuna valutazione finora

- Winsheld PDFDocumento34 pagineWinsheld PDFAnonymous FAa4A3akdNessuna valutazione finora

- Cs100.mmel TC (010) .BD500 3ab48 12703 00 PDFDocumento364 pagineCs100.mmel TC (010) .BD500 3ab48 12703 00 PDFbasem_androidNessuna valutazione finora

- EGLL - KJFK Flight PlanDocumento62 pagineEGLL - KJFK Flight PlanFLY XNessuna valutazione finora

- B Band FaultDocumento3 pagineB Band FaultJay R SVNessuna valutazione finora

- 21 20 DistributionDocumento22 pagine21 20 DistributionJay R SVNessuna valutazione finora

- Company Procedure Checpoint MNSDocumento7 pagineCompany Procedure Checpoint MNSمحمد هافيزيNessuna valutazione finora

- Als Part 1 Variation 7.2Documento5 pagineAls Part 1 Variation 7.2mnoorebsNessuna valutazione finora

- 2019 Amc MMC ProgramDocumento261 pagine2019 Amc MMC ProgramJivendra KumarNessuna valutazione finora

- EssaysDocumento5 pagineEssaysΓιάννης ΜούσουραςNessuna valutazione finora

- Neo-Stayover-Check R5 PDFDocumento11 pagineNeo-Stayover-Check R5 PDFLE THAI HONG VINHNessuna valutazione finora

- Goodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Documento16 pagineGoodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Muhammad Imran RosadinNessuna valutazione finora

- Part 145 Airworthiness Approved OrganisationsDocumento145 paginePart 145 Airworthiness Approved Organisationsflorin constantinNessuna valutazione finora

- A318 21 Diff L1 (1 CMP)Documento20 pagineA318 21 Diff L1 (1 CMP)Myplaylist Myplaylist100% (1)

- GVI Brake Units - 32-40-00-210-801-A PDFDocumento4 pagineGVI Brake Units - 32-40-00-210-801-A PDFpannNessuna valutazione finora

- A-330 Landing Gear Airworthiness Limitations SectionDocumento97 pagineA-330 Landing Gear Airworthiness Limitations SectionCHILLE GAMING100% (1)

- SB 32-1346 r09Documento681 pagineSB 32-1346 r09Marcin OstasziNessuna valutazione finora

- SVC A330Documento9 pagineSVC A330Maria Amparo Corredor TorresNessuna valutazione finora

- PRIM Software Load 80558481 - 003Documento2 paginePRIM Software Load 80558481 - 003A WongNessuna valutazione finora

- WLC 23aug2022 100342Documento286 pagineWLC 23aug2022 100342EssamNessuna valutazione finora

- Transit 737-400 19th September 2016Documento4 pagineTransit 737-400 19th September 2016Iftikhar JawedNessuna valutazione finora

- Readout Numerical Report: 4th Floor, Padmanabham, Technopark, Kariyavattom, Trivandrum-695 58, KeralaDocumento18 pagineReadout Numerical Report: 4th Floor, Padmanabham, Technopark, Kariyavattom, Trivandrum-695 58, KeralaSarath BabuNessuna valutazione finora

- A319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)Documento27 pagineA319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)A WongNessuna valutazione finora

- Wiring Instructions For Series It Itb and Its ConnectorsDocumento52 pagineWiring Instructions For Series It Itb and Its ConnectorsРоман ДяченкоNessuna valutazione finora

- Fast27 PDFDocumento32 pagineFast27 PDFsudarshan111990Nessuna valutazione finora

- A323 EA07 VN 00278197 Last Minutes R00 PDFDocumento12 pagineA323 EA07 VN 00278197 Last Minutes R00 PDFhợp trầnNessuna valutazione finora

- Found Fault: Form No: MNT-124Documento2 pagineFound Fault: Form No: MNT-124Teddy EshteNessuna valutazione finora

- DTA ALS Part 2 Variation 9.2Documento7 pagineDTA ALS Part 2 Variation 9.2Shealtiel UrsulumNessuna valutazione finora

- Safe Aircraft RefuellingDocumento6 pagineSafe Aircraft RefuellingRenzo Agurto PicardoNessuna valutazione finora

- LEAP Weekly Issue 01 Rev 03Documento22 pagineLEAP Weekly Issue 01 Rev 03Ankit KaushikNessuna valutazione finora

- A00010ADBFD9128Documento145 pagineA00010ADBFD9128Francisco100% (1)

- Job Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderDocumento7 pagineJob Card: 35-11-41-400-001-A - Installation of The Crew Oxygen-Storage CylinderKaushal VermaNessuna valutazione finora

- B 737 DraftDocumento98 pagineB 737 DraftAlrino Dwi PrasetyoNessuna valutazione finora

- FAA 2017 0713 0006 - Attachment - 8Documento112 pagineFAA 2017 0713 0006 - Attachment - 8Kevin PangilinanNessuna valutazione finora

- Mandatory Mandatory Mandatory: Printed in FRANCE © AIRBUS, 2006 All Rights ReservedDocumento21 pagineMandatory Mandatory Mandatory: Printed in FRANCE © AIRBUS, 2006 All Rights ReservedVero GAtelesisNessuna valutazione finora

- 35-1088 R-00Documento22 pagine35-1088 R-00Panneer Selvam100% (1)

- 902 999Documento1 pagina902 999Panneer SelvamNessuna valutazione finora

- Figure 35-20-00-11200-00-SR (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 101-199 EMB SB 25-1876 For A/C 101-120Documento1 paginaFigure 35-20-00-11200-00-SR (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 101-199 EMB SB 25-1876 For A/C 101-120Panneer SelvamNessuna valutazione finora

- TRG A340 A320 31 03 Lru 01D PDFDocumento140 pagineTRG A340 A320 31 03 Lru 01D PDFPanneer SelvamNessuna valutazione finora

- Avionics EquipmentDocumento4 pagineAvionics EquipmentPanneer SelvamNessuna valutazione finora

- Figure 35-20-00-11200-00-KM (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 901-999Documento1 paginaFigure 35-20-00-11200-00-KM (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 901-999Panneer SelvamNessuna valutazione finora

- TRG A340 A320 31 06 Shop 01DDocumento32 pagineTRG A340 A320 31 06 Shop 01DPanneer SelvamNessuna valutazione finora

- Figure 35-20-00-11200-00-SQ (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 201-250 EMB SB 25-1872 For A/C 201-204Documento1 paginaFigure 35-20-00-11200-00-SQ (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 201-250 EMB SB 25-1872 For A/C 201-204Panneer SelvamNessuna valutazione finora

- Ca Form 19-10 PDFDocumento4 pagineCa Form 19-10 PDFPanneer SelvamNessuna valutazione finora

- L G A A: Figure 35-20-00-11200-00-WG (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 401-450Documento1 paginaL G A A: Figure 35-20-00-11200-00-WG (SHEET 1) - Location of Emergency Oxygen Containers ON A/C FSN 401-450Panneer SelvamNessuna valutazione finora

- Ca Form 19-10Documento128 pagineCa Form 19-10Panneer SelvamNessuna valutazione finora

- Sidoa320neo-0068 RevaDocumento12 pagineSidoa320neo-0068 RevaPanneer SelvamNessuna valutazione finora

- Operator Requirements For Incorporation of Fuel Tank Flammability Reduction RequirementsDocumento24 pagineOperator Requirements For Incorporation of Fuel Tank Flammability Reduction RequirementsPanneer SelvamNessuna valutazione finora

- First-, Second-And Third-Party Testing - How and When: Position Paper No. 1/2000 May 2000Documento10 pagineFirst-, Second-And Third-Party Testing - How and When: Position Paper No. 1/2000 May 2000Panneer SelvamNessuna valutazione finora

- Aerospace Vehicle Design Michael Selig - AE 442, Fall 2012 Steve D'Urso - AE 443, Spring 2013 The AirplaneDocumento18 pagineAerospace Vehicle Design Michael Selig - AE 442, Fall 2012 Steve D'Urso - AE 443, Spring 2013 The AirplanePanneer SelvamNessuna valutazione finora

- 35-1088 R-00Documento22 pagine35-1088 R-00Panneer Selvam100% (1)

- 71-0008 Issue 002Documento9 pagine71-0008 Issue 002Panneer Selvam0% (1)

- Faa Ad 74 08 09Documento4 pagineFaa Ad 74 08 09Panneer SelvamNessuna valutazione finora

- Laboratory Assessment ChecklistDocumento28 pagineLaboratory Assessment ChecklistPanneer Selvam100% (2)

- BD70CR30-017 Issue 0Documento14 pagineBD70CR30-017 Issue 0Panneer SelvamNessuna valutazione finora

- SBDocumento4 pagineSBPanneer SelvamNessuna valutazione finora

- Covering Letter Powder Feeder X-Y ManipulatorDocumento1 paginaCovering Letter Powder Feeder X-Y ManipulatorPanneer SelvamNessuna valutazione finora

- Polygon NamesDocumento2 paginePolygon NamesPanneer SelvamNessuna valutazione finora

- Maintenance During Aircraft StorageDocumento4 pagineMaintenance During Aircraft StoragePanneer SelvamNessuna valutazione finora

- Part# Description Type Uom Qty Ar: P 1 OF 1 PagesDocumento1 paginaPart# Description Type Uom Qty Ar: P 1 OF 1 PagesPanneer SelvamNessuna valutazione finora

- E VG G F NI: Quality System ManualDocumento1 paginaE VG G F NI: Quality System ManualPanneer SelvamNessuna valutazione finora

- 33 11a 14 - 1121Documento55 pagine33 11a 14 - 1121Panneer SelvamNessuna valutazione finora

- Etops AirbusDocumento61 pagineEtops Airbusdarryl_baguio100% (4)

- Otp Oct2020Documento143 pagineOtp Oct2020Minh NguyenNessuna valutazione finora

- Removal of The Flame Arrestor and Flange AssemblyDocumento3 pagineRemoval of The Flame Arrestor and Flange AssemblySonny RaymundoNessuna valutazione finora

- A318/A319/A320/A321: Service BulletinDocumento59 pagineA318/A319/A320/A321: Service BulletinPradeep K sNessuna valutazione finora

- Level I - Ata 51 StructureDocumento10 pagineLevel I - Ata 51 StructurewagdiNessuna valutazione finora

- Airworthiness Directive: Airbus Industrie A320 AircraftDocumento2 pagineAirworthiness Directive: Airbus Industrie A320 AircraftlakshmimurugesanNessuna valutazione finora

- A350Documento46 pagineA350saudia686100% (4)

- PRNASC Presentation FinalDocumento35 paginePRNASC Presentation FinalLuisLoNessuna valutazione finora

- 2020 Airline Insights ReviewDocumento70 pagine2020 Airline Insights ReviewSatrio AditomoNessuna valutazione finora

- Aircraft Cabin Interiors MarketDocumento7 pagineAircraft Cabin Interiors MarketsajeshsimonNessuna valutazione finora

- Approved Training Organisations (ATO) in SwitzerlandDocumento17 pagineApproved Training Organisations (ATO) in SwitzerlandvonmanoNessuna valutazione finora

- Boeing Strategic ReportDocumento35 pagineBoeing Strategic ReportRick Png Jun Wei100% (1)

- Udyz HeshDocumento3 pagineUdyz HeshVahe VoskanyanNessuna valutazione finora

- Hydraulic Systems PDFDocumento6 pagineHydraulic Systems PDFnaziaNessuna valutazione finora

- 97 SenaraiGraduan Sidang14Documento15 pagine97 SenaraiGraduan Sidang14Putera HalimNessuna valutazione finora

- A320-232 Job Instruction Card (J.I.C.) : Card No.: - 242400-01-2 1 Mo OR 120 FH 1 Mo OR 120 FH OPH A320-232 SU-SKDocumento10 pagineA320-232 Job Instruction Card (J.I.C.) : Card No.: - 242400-01-2 1 Mo OR 120 FH 1 Mo OR 120 FH OPH A320-232 SU-SKmoamenNessuna valutazione finora

- List of Abbreviations: On A/C AllDocumento102 pagineList of Abbreviations: On A/C AllKaren NersisyanNessuna valutazione finora

- Manchester Airport Group - AeroTURN Case Study - 1112 PDFDocumento1 paginaManchester Airport Group - AeroTURN Case Study - 1112 PDFTransoft EMEANessuna valutazione finora

- Airlines IndustryDocumento45 pagineAirlines IndustrySahilNessuna valutazione finora

- Presentation Script (Beluga)Documento3 paginePresentation Script (Beluga)Khairun NasuhaNessuna valutazione finora

- VJC - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 32-41-00-210-002-A - Inspection - Check of The Wheels and TiresDocumento28 pagineVJC - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 32-41-00-210-002-A - Inspection - Check of The Wheels and TiresNam NguyenNessuna valutazione finora

- ON A/C FSN 101-150, 251-300: FIG. 28-11-85-26 - VALVE INSTL-CHECK LH Zone(s) : RH Zone(s) : Fape3 Unit P Er Ass YDocumento2 pagineON A/C FSN 101-150, 251-300: FIG. 28-11-85-26 - VALVE INSTL-CHECK LH Zone(s) : RH Zone(s) : Fape3 Unit P Er Ass YquynhNessuna valutazione finora

- Airbus Case StudyDocumento2 pagineAirbus Case StudyViren SharmaNessuna valutazione finora

- TSM SmokeDocumento2 pagineTSM SmokeSudin AmatyaNessuna valutazione finora

- Airbus A320 Touch & GoDocumento3 pagineAirbus A320 Touch & Goaedd eddaNessuna valutazione finora

- Trial SPM 2017 - Physics Paper 2Documento20 pagineTrial SPM 2017 - Physics Paper 2Cemerlang StudiNessuna valutazione finora

- AWS Welding Journal September 2012Documento134 pagineAWS Welding Journal September 2012ferrero68100% (1)

- Ata 21Documento32 pagineAta 21Nikolay RomadanovNessuna valutazione finora

- Metal Structure DesignerDocumento2 pagineMetal Structure DesignerWONNER156Nessuna valutazione finora