Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GE Discloses F412 Configuration Details: Single-Crystal Turbine Blades Tested

Caricato da

Rajesh Kumar Sahu0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaTitolo originale

1991 - 0980.PDF

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaGE Discloses F412 Configuration Details: Single-Crystal Turbine Blades Tested

Caricato da

Rajesh Kumar SahuCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

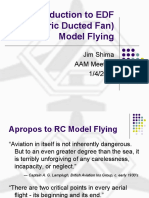

TECHNICAL: PROPULSION

GE discloses F412 configuration details

400, a three-stage low-pressure

BY GUY NORRIS (LP) compressor, a seven-stage General Electric F412

G eneral Electric has revealed

the configuration of the

F412 engine, designed for the

high-pressure (HP) compressor,

single-stage HP turbine and

two-stage LP turbine.

F412 fan scaled

from -400

Multi-hole

combuster shell

Redesigned

high-pressure turbine

cancelled A-12 US Navy attack Compared with the -400, the

aircraft, technology from which growth F404 would have a

is now being used to update its larger, increased airflow fan and

F404 powerplant proposed for "advanced core" derived from

the McDonnell Douglas F-18E/F the F412. As well as an in-

(Flight International, 3-9 April). creased airflow, the F412 fan

Details of the engine were was designed to have a lower

released as part of its bid to pressure ratio and an improved

p r o m o t e the g r o w t h F 4 0 4 , resistance to birds, foreign-

which will be offered in 90kN object damage and ice com-

Increased airflow Two-stage low-pressure

(20,0001b-thrust) and lOOkN pared with the F404. compressor turbine derived from F110

versions, compared with the The core, single-stage "ad-

71kN presently available. "The vanced low-pressure turbine"

point is that the millions the and the lengthened afterburner

Navy spent on developing the are derived from GE's variable- based on that used by the F110- for the F-18. The -402 uses

F412 were well spent — almost cycle F120 engine candidate for 129 would also be incorporated. monocrystal turbine materials,

all the t e c h n o l o g y for the the US Air Force's Advanced The growth engine would modified electrical-hydro-

growth F404 has already been Tactical Fighter. Variable-area also feature a 2,000h hot section mechanical control schedules

tried and tested in one form or and two-dimensional thrust- and turbine entry temperatures and improved materials in the

another," says GE. vectoring nozzles will be availa- up to 150°C higher than those afterburner to generate up to

The F412 is shown to have a ble as options. Full-authority currently produced. GE adds: 20% more power. Compared

large fan, scaled from the F404- digital engine control system "The growth F404 is not an with the F404-400, GE claims

F412 in disguise. The F412 is this will improve the F-18's

optimised for high subsonic time-to-climb/intercept perform-

cruise, with a larger fan and far ance at 50,000ft (15,100m) and

higher bypass ratio. It doesn't Mach 1.4 by 3 1 % and its maxi-

have an afterburner. As such, it m u m acceleration at around

fits neither the F-18E/F's mis- 35,000ft and M l . 6 by 27%.

sion profile, nor the airframe." The company adds that spe-

From 1992, GE is supplying cific excess power in a typical

the F404-402 enhanced per- combat manoeuvring situation

formance engine (EPE) as the at M0.9 and around 10,000ft

standard production powerplant will be boosted by 18%. •

Single-crystal turbine blades tested

S ingle-crystal turbine blades,

made by a new process, are

being tested in turbofan and

progressively upwards from a

water-cooled copper chill as the

mould is drawn down into a

turboshaft engines. water-cooled lower chamber.

The system, developed by In the new method the mould

Swiss-based Sulzer-MTU Cast- is integrally heated sequentially

ing Technology, has been to create the required unidirec-

adopted by two European foun- tional heat flow at the solidifica-

dries and is being developed tion front.

further by the European Com- Two European foundries, Th-

mission's Euram-Brite technol- yssen Guss of Germany and

ogy programme. Precicast of Switzerland, have

Sulzer-MTU says the method already c o n c l u d e d l i c e n s i n g

is easier to control and is more agreements. Direcuonally solidi-

economical than the traditional fied guide vanes and intermedi-

ROLLS-ROYCE TESTS TAY 727 INSTALLATION process, which involves pouring ate-pressure turbine blades for a

Testing of the Dee Howard-made Boeing 727-100 centre intake "S" duct molten metal into a ceramic turbofan, and complex-shaped

optimised for the Rolls-Royce Tay 650 engine is under way at the UK shell mould with up to ten vane segments and single-

company's Huchnall site. The tests are due to finish at the end of May blade cavities. The mould is crystal rotor blades from the

and will pave the way for engine installation, and eventual first heated by a resistance furnace to high-pressure turbine of a heli-

flight of the first Tay-powered 727 in April 1992 (Flight International, above the alloy melting point copter's turboshaft engine are

10-16 April). and the blades begin to solidify being used to test the process.

FLIGHT [INTERNATIONAL 17-23 April, 1991

Potrebbero piacerti anche

- British Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerDa EverandBritish Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerNessuna valutazione finora

- Master - TPE331 Turboprop EvolutionDocumento7 pagineMaster - TPE331 Turboprop Evolutionsandy100% (1)

- FI - Primeiro Kfir 1975 - 1254 PDFDocumento1 paginaFI - Primeiro Kfir 1975 - 1254 PDFguilhermeNessuna valutazione finora

- Recent Technology in Steam TurbineDocumento6 pagineRecent Technology in Steam TurbineIsmail RahimNessuna valutazione finora

- General Electric YF120 - WikipediaDocumento31 pagineGeneral Electric YF120 - WikipediacristianNessuna valutazione finora

- 1104C 44TAG2 Electropak PDFDocumento2 pagine1104C 44TAG2 Electropak PDFHayman AhmedNessuna valutazione finora

- GEAFOL Cast Resin Transformers in Protective Housings With An Air Water Cooling System enDocumento12 pagineGEAFOL Cast Resin Transformers in Protective Housings With An Air Water Cooling System enGabriel SantosNessuna valutazione finora

- KBL fire pump proposal for Amway projectDocumento5 pagineKBL fire pump proposal for Amway projectiotaautoNessuna valutazione finora

- F51 10 Advantages of VTF Pump PDFDocumento4 pagineF51 10 Advantages of VTF Pump PDFCarlos Fernando Roca AkamineNessuna valutazione finora

- 360KW Cummins Marine GensetDocumento3 pagine360KW Cummins Marine GensetChen CarolineNessuna valutazione finora

- Previous Page: 13-9. InsulationDocumento15 paginePrevious Page: 13-9. Insulationshady mohamedNessuna valutazione finora

- 601 - Helicopter Turboshaft EngineDocumento13 pagine601 - Helicopter Turboshaft EngineVishnu SankarNessuna valutazione finora

- Comparison of RR and GE Civil Turbofan Engines: Zhenyu SunDocumento9 pagineComparison of RR and GE Civil Turbofan Engines: Zhenyu SunVishnu RamNessuna valutazione finora

- 400kw Cummins Marine Generator SetDocumento3 pagine400kw Cummins Marine Generator SetChen CarolineNessuna valutazione finora

- A Transport Aft-Turbofan 59-GTP-20: B. E. Sells - W. R. DodgeDocumento9 pagineA Transport Aft-Turbofan 59-GTP-20: B. E. Sells - W. R. Dodge128mansouriNessuna valutazione finora

- The Two-Row Cyclone 14: Germany'S Big NineDocumento1 paginaThe Two-Row Cyclone 14: Germany'S Big Nineseafire47Nessuna valutazione finora

- H 010984Documento1 paginaH 010984Anonymous uKoNmLxkNessuna valutazione finora

- KWU Steam Turbine Module DesignDocumento14 pagineKWU Steam Turbine Module Designbhaskar100% (1)

- RB211-535 - Aircraft Commerce - Aug-Sep2013Documento7 pagineRB211-535 - Aircraft Commerce - Aug-Sep2013John100% (1)

- Vane Axial Flow Fans Performance CurvesDocumento40 pagineVane Axial Flow Fans Performance CurvesKim WongNessuna valutazione finora

- 250kw 50HZ Cummins Marine GeneratorDocumento3 pagine250kw 50HZ Cummins Marine GeneratorChen Caroline100% (1)

- Selection of Turbines and Power House DimesioningDocumento50 pagineSelection of Turbines and Power House DimesioningVinodh Kumar Yalla50% (2)

- Ae 1299 R5Documento16 pagineAe 1299 R5last730Nessuna valutazione finora

- TurbofanDocumento14 pagineTurbofanRasyid AtmodigdoNessuna valutazione finora

- Fan BOQDocumento16 pagineFan BOQpd statusNessuna valutazione finora

- SP1375 50HZ Perkins GeneratorDocumento4 pagineSP1375 50HZ Perkins GeneratorsunshinemachineryNessuna valutazione finora

- ZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsDocumento6 pagineZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsSiroos Yousefi100% (1)

- Tamd 63Documento2 pagineTamd 63Cristiano NunesNessuna valutazione finora

- Aero Engine PP DoneDocumento30 pagineAero Engine PP DoneHAMMAD AliNessuna valutazione finora

- RPF y Un50 02Documento4 pagineRPF y Un50 02DuskoNessuna valutazione finora

- Kfir—Israel's Mirage SuccessorDocumento1 paginaKfir—Israel's Mirage SuccessorLuiz AlvesNessuna valutazione finora

- CRC HBP 50 60Hz - MS0117A 0415 - NpyDocumento16 pagineCRC HBP 50 60Hz - MS0117A 0415 - NpyMARCOSNessuna valutazione finora

- 300kw Cummins Marine GeneratorDocumento3 pagine300kw Cummins Marine GeneratorChen CarolineNessuna valutazione finora

- Severe Surge Incidents at Process Air Compressor, Their After Effects and Problem ResolutionDocumento15 pagineSevere Surge Incidents at Process Air Compressor, Their After Effects and Problem ResolutionAbhimanyu SharmaNessuna valutazione finora

- 116 McKinley Climatic Laboratory 1944Documento8 pagine116 McKinley Climatic Laboratory 1944joaaoriicardoNessuna valutazione finora

- AERO ENGINES 1957 ... : FlightDocumento1 paginaAERO ENGINES 1957 ... : FlightRadu AndreiNessuna valutazione finora

- NAMV PaperDocumento8 pagineNAMV PaperenginvservNessuna valutazione finora

- SP1100 50HZ Perkins Generator STAMFORDDocumento4 pagineSP1100 50HZ Perkins Generator STAMFORDsunshinemachineryNessuna valutazione finora

- enDocumento2 pagineenZobeida RizoNessuna valutazione finora

- APMRDocumento28 pagineAPMRMahmoud Abdelghafar ElhussienyNessuna valutazione finora

- Turbocare Upgrade IP-HPDocumento11 pagineTurbocare Upgrade IP-HPduhaimNessuna valutazione finora

- Axial CompressorsDocumento6 pagineAxial CompressorsrubenNessuna valutazione finora

- SP1100 50HZ Perkins GeneratorDocumento4 pagineSP1100 50HZ Perkins GeneratorsunshinemachineryNessuna valutazione finora

- F 14A F 14B/D: F 14 Tf30 P 414 To F110 Ge 400 Engine Upgrade Technical ComparisonDocumento1 paginaF 14A F 14B/D: F 14 Tf30 P 414 To F110 Ge 400 Engine Upgrade Technical ComparisonNasr PooyaNessuna valutazione finora

- Lesson 13 TurbomachineryDocumento33 pagineLesson 13 TurbomachineryThomas ParentNessuna valutazione finora

- BSNA HVAC Line CardMISC6920819Documento2 pagineBSNA HVAC Line CardMISC6920819IMRANNessuna valutazione finora

- HVAC Product Line CardDocumento1 paginaHVAC Product Line Cardknotship.comNessuna valutazione finora

- CF680E Engine Ratings (Thrust)Documento5 pagineCF680E Engine Ratings (Thrust)Orlando PérezNessuna valutazione finora

- Supercritical Steam TurbinesDocumento18 pagineSupercritical Steam TurbinesAnonymous NUn6MESx100% (2)

- SP 1800 - 10311849 - enDocumento5 pagineSP 1800 - 10311849 - enShubham SinghNessuna valutazione finora

- TK-S Catalogue 001-2018Documento4 pagineTK-S Catalogue 001-2018DarrenkjcNessuna valutazione finora

- Powering P Powering Owering: The Lightning IIDocumento6 paginePowering P Powering Owering: The Lightning IIJOSEPH TinderNessuna valutazione finora

- 5-Design, maintenance and diagnostics of aircraft and gas turbines (АКІ)Documento21 pagine5-Design, maintenance and diagnostics of aircraft and gas turbines (АКІ)Juliana SatizabalNessuna valutazione finora

- Roller Bearing Gear Pumps and Motors (Bi-Rotational) : High Performance FeaturesDocumento19 pagineRoller Bearing Gear Pumps and Motors (Bi-Rotational) : High Performance FeaturesАлександр СимуковNessuna valutazione finora

- 1104C-44TG1 ElectropaK (PN1734 75th)Documento2 pagine1104C-44TG1 ElectropaK (PN1734 75th)OGNessuna valutazione finora

- Ae 1302 R4Documento12 pagineAe 1302 R4last730Nessuna valutazione finora

- Product Bulletin: Overhead Charge Air Pipes On 4012-46TAG ProductsDocumento2 pagineProduct Bulletin: Overhead Charge Air Pipes On 4012-46TAG ProductsMd ShNessuna valutazione finora

- Introduction To EDF Turbine AAM PresentationDocumento31 pagineIntroduction To EDF Turbine AAM PresentationMohammad ZolghadrNessuna valutazione finora

- Underground Geothermal HeatpumpsDocumento5 pagineUnderground Geothermal HeatpumpsSheryl MurchieNessuna valutazione finora

- Rolls-Royce Advanced Fighter Engine Demonstrator: G.M. LewisDocumento12 pagineRolls-Royce Advanced Fighter Engine Demonstrator: G.M. LewisJOSEPH TinderNessuna valutazione finora

- Essential QualificationsDocumento6 pagineEssential QualificationsRajesh Kumar SahuNessuna valutazione finora

- EASA-TCDS-E.050 (IM) Pratt and Whitney PW4000 - 94 Series Engines-01-19102012 PDFDocumento11 pagineEASA-TCDS-E.050 (IM) Pratt and Whitney PW4000 - 94 Series Engines-01-19102012 PDFWanda collinsNessuna valutazione finora

- Pushpak December 2017 PDFDocumento38 paginePushpak December 2017 PDFRajesh Kumar SahuNessuna valutazione finora

- 2014 0272 PaperDocumento8 pagine2014 0272 PaperRajesh Kumar SahuNessuna valutazione finora

- Gate 2020 IbDocumento98 pagineGate 2020 IbSarath ChandranNessuna valutazione finora

- Cfm56 7b Familiarization PrintDocumento86 pagineCfm56 7b Familiarization PrintRajesh Kumar Sahu100% (2)

- EASA-TCDS-E.050 (IM) Pratt and Whitney PW4000 - 94 Series Engines-01-19102012 PDFDocumento11 pagineEASA-TCDS-E.050 (IM) Pratt and Whitney PW4000 - 94 Series Engines-01-19102012 PDFWanda collinsNessuna valutazione finora

- Rolls-Royce Advanced Fighter Engine Demonstrator: G.M. LewisDocumento12 pagineRolls-Royce Advanced Fighter Engine Demonstrator: G.M. LewisJOSEPH TinderNessuna valutazione finora

- LEAP-1A A3 Modular Design Rev2.0Documento1 paginaLEAP-1A A3 Modular Design Rev2.0SatishReddy100% (4)

- Analysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionDocumento19 pagineAnalysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionJOSEPH TinderNessuna valutazione finora

- Analysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionDocumento19 pagineAnalysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionJOSEPH TinderNessuna valutazione finora

- Versatile Affordable Advanced Turbine Engines Provide Game Changing Capability With Superior Fuel EfficiencyDocumento11 pagineVersatile Affordable Advanced Turbine Engines Provide Game Changing Capability With Superior Fuel EfficiencyRajesh Kumar SahuNessuna valutazione finora

- Above, Rolls-Royce Cutaway of The RB.211-22 Three-Spool Advanced-Technology High-Bypass Turbofan. Initial Into-Service Versions Will DeliverDocumento1 paginaAbove, Rolls-Royce Cutaway of The RB.211-22 Three-Spool Advanced-Technology High-Bypass Turbofan. Initial Into-Service Versions Will DeliverRajesh Kumar SahuNessuna valutazione finora

- KManuscript66 RGDocumento10 pagineKManuscript66 RGRajesh Kumar SahuNessuna valutazione finora

- F135 Engine For F-35A Conventional Takeoff and Landing (Ctol)Documento2 pagineF135 Engine For F-35A Conventional Takeoff and Landing (Ctol)Rajesh Kumar SahuNessuna valutazione finora

- August 2018 Current Affairs Update PDFDocumento102 pagineAugust 2018 Current Affairs Update PDFpriyanka joshiNessuna valutazione finora

- New Horizons: Magazine From Uppsala UniversityDocumento40 pagineNew Horizons: Magazine From Uppsala UniversityRajesh Kumar SahuNessuna valutazione finora

- 1 ST Place Undergrad Engine DesignDocumento93 pagine1 ST Place Undergrad Engine DesignBob SmithNessuna valutazione finora

- October 2018 Current Affairs Update PDFDocumento46 pagineOctober 2018 Current Affairs Update PDFPragatiNessuna valutazione finora

- Adv EngertyuiopDocumento12 pagineAdv EngertyuiopRajesh Kumar SahuNessuna valutazione finora

- cmd16 Slideshow14032016 PDFDocumento128 paginecmd16 Slideshow14032016 PDFrsahu_36Nessuna valutazione finora

- How To Apply and Make PaymentDocumento4 pagineHow To Apply and Make PaymentRohit TyagiNessuna valutazione finora

- Mechanics of CuttingDocumento17 pagineMechanics of CuttingPercy RobertNessuna valutazione finora

- Gas Dynamics and Jet PropulsionDocumento12 pagineGas Dynamics and Jet Propulsionsiddigari vineerhNessuna valutazione finora

- Design & TolerancingDocumento9 pagineDesign & TolerancingJoseph RamosNessuna valutazione finora

- Lower PDFDocumento1 paginaLower PDFTepeRudeboyNessuna valutazione finora

- SSE 01 Sep S1 (Gate2016.info) PDFDocumento55 pagineSSE 01 Sep S1 (Gate2016.info) PDFharshitdwiveNessuna valutazione finora

- Multiviews and Visualization Auxiliary Views PDFDocumento30 pagineMultiviews and Visualization Auxiliary Views PDFcadcam01Nessuna valutazione finora

- European Vacancy and Recruitment Report 2012Documento200 pagineEuropean Vacancy and Recruitment Report 2012Joaquín Vicente Ramos RodríguezNessuna valutazione finora

- The Big Banana by Roberto QuesadaDocumento257 pagineThe Big Banana by Roberto QuesadaArte Público Press100% (2)

- Jamaica's Unemployment Aims, Causes and SolutionsDocumento23 pagineJamaica's Unemployment Aims, Causes and Solutionsnetzii300067% (3)

- Method Statement For Wall Panels InstallationDocumento11 pagineMethod Statement For Wall Panels InstallationChristos LoutrakisNessuna valutazione finora

- Global Finance - Introduction ADocumento268 pagineGlobal Finance - Introduction AfirebirdshockwaveNessuna valutazione finora

- 5.2.1 1539323575 2163Documento30 pagine5.2.1 1539323575 2163Brinda TNessuna valutazione finora

- Flotect Vane Operated Flow Switch: Magnetic Linkage, UL ApprovedDocumento1 paginaFlotect Vane Operated Flow Switch: Magnetic Linkage, UL ApprovedLuis GonzálezNessuna valutazione finora

- Nurses Assigned in Covid-19 Isolation Facilities. in This ConnectionDocumento4 pagineNurses Assigned in Covid-19 Isolation Facilities. in This ConnectionDan HizonNessuna valutazione finora

- Love in Plato's SymposiumDocumento31 pagineLove in Plato's Symposiumac12788100% (2)

- Initial Data Base (Narrative)Documento11 pagineInitial Data Base (Narrative)LEBADISOS KATE PRINCESSNessuna valutazione finora

- Management of Renal DiseasesDocumento57 pagineManagement of Renal DiseasesAyana KeikoNessuna valutazione finora

- Proceedings of The 2012 PNLG Forum: General AssemblyDocumento64 pagineProceedings of The 2012 PNLG Forum: General AssemblyPEMSEA (Partnerships in Environmental Management for the Seas of East Asia)Nessuna valutazione finora

- Minotaur Transformation by LionWarrior (Script)Documento7 pagineMinotaur Transformation by LionWarrior (Script)Arnt van HeldenNessuna valutazione finora

- 6 Holly Fashion Case StudyDocumento3 pagine6 Holly Fashion Case StudyCaramalau Mirela-Georgiana0% (1)

- A Study On Effectiveness of Ware Housing System in Flyton XpressDocumento23 pagineA Study On Effectiveness of Ware Housing System in Flyton XpressmaheshNessuna valutazione finora

- Dance Manual W. Learning Outcomes PDFDocumento8 pagineDance Manual W. Learning Outcomes PDFJoshua Quijano LamzonNessuna valutazione finora

- PersonalDevelopment Q1 Module 2Documento7 paginePersonalDevelopment Q1 Module 2Stephanie DilloNessuna valutazione finora

- Review Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningDocumento3 pagineReview Activity For The Final Test - 6 Level: 1. Match Phrasal Verbs and Match To The MeaningGabrielle CostaNessuna valutazione finora

- Standard Chartered BackgroundDocumento6 pagineStandard Chartered BackgroundAwesum Allen MukiNessuna valutazione finora

- Doña PerfectaDocumento317 pagineDoña PerfectadracbullNessuna valutazione finora

- Junior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDocumento13 pagineJunior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDrAjay Singh100% (1)

- MMS-TRG-OP-02F3 Narrative ReportDocumento14 pagineMMS-TRG-OP-02F3 Narrative ReportCh Ma100% (1)

- Lecture 9-EVENT BUDGETDocumento19 pagineLecture 9-EVENT BUDGETAlbina AbilkairNessuna valutazione finora

- Earth & Life Science Q1 Module 2 - DESIREE VICTORINODocumento22 pagineEarth & Life Science Q1 Module 2 - DESIREE VICTORINOJoshua A. Arabejo50% (4)

- 13 Years of Unremitting Tracking of Chinese Scientists To Find The Source of SARS Virus - NewsDocumento14 pagine13 Years of Unremitting Tracking of Chinese Scientists To Find The Source of SARS Virus - NewsWillSmathNessuna valutazione finora

- History of LotteryDocumento29 pagineHistory of LotteryBala G100% (2)

- Criminal Evidence Course OutlineDocumento3 pagineCriminal Evidence Course OutlineChivas Gocela Dulguime100% (1)

- Review For Development of Hydraulic Excavator Attachment: YANG Cheng Huang Kui LI Yinwu WANG Jingchun ZHOU MengDocumento5 pagineReview For Development of Hydraulic Excavator Attachment: YANG Cheng Huang Kui LI Yinwu WANG Jingchun ZHOU MengZuhaib ShaikhNessuna valutazione finora

- The Emergence of India's Pharmaceutical IndustryDocumento41 pagineThe Emergence of India's Pharmaceutical Industryvivekgupta2jNessuna valutazione finora

- Ko vs. Atty. Uy-LampasaDocumento1 paginaKo vs. Atty. Uy-LampasaMaria Janelle RosarioNessuna valutazione finora