Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ranger Fuel Charging and Controls - 3.2L

Caricato da

Eko SulistyoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ranger Fuel Charging and Controls - 3.2L

Caricato da

Eko SulistyoCopyright:

Formati disponibili

Fuel Charging and Controls — 3.

2L Duratorq-TDCi (148kW/200PS)

303-04C-1 - Puma 303-04C-1

.

SECTION 303-04C Fuel Charging and Controls — 3.2L

Duratorq-TDCi (148kW/200PS) - Puma

VEHICLE APPLICATION: 2011.50 Ranger

CONTENTS PAGE

DESCRIPTION AND OPERATION

Fuel Charging and Controls................................................................................................ 303-04C-2

Overview............................................................................................................................. 303-04C-2

General............................................................................................................................... 303-04C-2

Fuel pump........................................................................................................................... 303-04C-3

Fuel rail............................................................................................................................... 303-04C-3

Fuel injectors...................................................................................................................... 303-04C-4

GENERAL PROCEDURES

Fuel Injection Component Cleaning................................................................................... 303-04C-6

REMOVAL AND INSTALLATION

Fuel Pump.......................................................................................................................... 303-04C-8

Fuel Rail.............................................................................................................................. 303-04C-12

Fuel Injectors...................................................................................................................... 303-04C-14

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-2 - Puma 303-04C-2

DESCRIPTION AND OPERATION

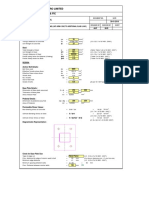

Fuel Charging and Controls

Overview

supplied to the fuel rail and fuel injector(s), in

Item Description

relation to the driving conditions.

1 Fuel rail The fuel is supplied at high-pressure to the fuel rail

2 Fuel injector(s) and to the fuel injectors ready for injection.

Depending on engine operating conditions, the fuel

3 Fuel pressure (FRP) sensor injection pressure varies between 230 bar and

4 Fuel metering valve 1600 bar.

5 Fuel temperature sensor Fuel system pressure is measured using an FRP

sensor located in the fuel rail. The FRP sensor

6 Fuel pump converts the fuel system pressure into a voltage

signal. This voltage signal acts as an input signal

to the powertrain control module (PCM) for

General calculation of the fuel injection quantity.

A common rail fuel injection system is used on the The power train control module (PCM) calculates

3.2L Duratorq-TDCi (Puma) diesel engine. the time of fuel injection and the fuel injection

quantity depending on various input variables. The

Within the fuel pump there is an integral fuel specified quantity of fuel is injected into the

transfer pump which draws the fuel from the fuel respective combustion chamber through the

tank to the fuel pump. solenoid actuated fuel injector(s). In doing so, a

A fuel metering valve is located in the supply port pre-injection and a main injection occur each time.

to the high-pressure chamber of the fuel pump. The excess fuel is returned to the fuel tank through

The fuel metering valve varies the quantity of fuel the fuel return line.

2011.50 Ranger G1272468en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-3 - Puma 303-04C-3

DESCRIPTION AND OPERATION

Fuel pump

Item Description The fuel pump is driven directly by the timing belt.

1 Fuel pump high-pressure outlet union The fuel pump has three pump elements, each

offset from each other by 120 degrees.

2 Fuel pump fuel return union

The fuel transfer pump is incorporated into the fuel

3 Fuel metering valve pump and is located on the drive flange. The fuel

4 Fuel temperature sensor transfer pump is a cycloid type pump.

5 Fuel pump O-ring seal The fuel metering valve is actuated by the PCM

using pulse width modulation.

6 Fuel pump input drive

7 Fuel pump fuel supply union

Fuel rail

2011.50 Ranger G1272468en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-4 - Puma 303-04C-4

DESCRIPTION AND OPERATION

Item Description Fuel injectors

1 Fuel rail to fuel injector number 1

high-pressure fuel supply line union

2 Fuel rail to fuel injector number 2

high-pressure fuel supply line union

3 Fuel rail to fuel injector number 3

high-pressure fuel supply line union

4 Fuel pump to fuel rail high-pressure fuel

supply line union

5 Fuel rail to fuel injector number 4

high-pressure fuel supply line union

6 Fuel rail to fuel injector number 5

high-pressure fuel supply line union

7 Fuel rail

8 FRP sensor

CAUTION: The FRP sensor must not be

detached or removed from the fuel rail.

The fuel rail is made from forged steel and is

retained by a support bracket located on the

camshaft carrier.

The fuel is delivered by one high-pressure fuel

supply line from the fuel pump to the fuel rail.

From the fuel rail, the fuel travels through the Item Description

high-pressure fuel supply line(s) to the fuel

injector(s). 1 Fuel injector electrical connector

2 Fuel injector fuel return line clip

3 Fuel injector

4 Fuel injector sealing washer

5 Fuel injector nozzle

6 Fuel injector high-pressure fuel supply line

union

The fuel injector(s) are located centrally on the

cylinder head upper section and are attached by

means of retaining clamps.

The fuel injector(s) are sealed from the combustion

chamber by means of a copper sealing washer

located between the fuel injector and the cylinder

head. A new sealing washer must always be

installed when carrying out installation work.

The fuel injectors are controlled directly by the

PCM.

The fuel return line(s) are attached to the top of

the fuel injector and are connected in series.

2011.50 Ranger G1272468en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-5 - Puma 303-04C-5

DESCRIPTION AND OPERATION

Item Description

1 Eight digit injector correction factor

(example only shown)

2 Eight digit serial code (For manufacturer

use only)

When installing new fuel injectors, the injector

correction factor from the new fuel injector(s) must

be recorded and uploaded using the Worldwide

Diagnostic System (WDS).

2011.50 Ranger G1272468en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-6 - Puma 303-04C-6

GENERAL PROCEDURES

Fuel Injection Component Cleaning

General Equipment components and connectors with lint-free

non-flocking material.

Pneumatic vacuum gun

1. For additional information, refer to: Solvents,

WARNINGS: Sealants and Adhesives (100-00 General

Information, Description and Operation)

Do not smoke or carry lighted tobacco or / Diesel Fuel System Health and Safety

open flame of any type when working on Precautions (100-00 General Information,

or near any fuel related components. Description and Operation).

Highly flammable mixtures are always

present and may ignite. Failure to follow 2.

these instructions may result in personal

injury.

Do not carry out any repairs to the fuel

injection system with the engine running.

The fuel pressure within the system can

be as high as 1600 bar. Failure to follow

this instruction may result in personal

injury.

Eye protection must be worn at all times

when working on or near any fuel related

components. Failure to follow this

instruction may result in personal injury.

CAUTIONS:

Make sure that the workshop area in which

the vehicle is being worked on is as clean

and dust-free as possible. Areas in which

work on clutches, brakes or where welding

or machining are carried out are not CAUTION: Use lint free cloth.

suitable in view of the risk of

contamination to the fuel system. 3. Using Brake Cleaner: 3U7J-2C410-AA

Make sure that clean non-plated tools are

used. Clean tools using a new brush that

will not lose its bristles and fresh suitable

evaporative cleaning agent, prior to

starting work on the vehicle.

Use a steel topped workbench and cover

it with clean, lint-free non-flocking material.

Make sure that all parts removed from the

vehicle are placed on the lint-free

non-flocking material.

Make sure that any protective clothing

worn is clean and made from lint-free

non-flocking material.

Make sure that any protective gloves worn

are new and are of the non-powdered latex

type.

Before using the suitable evaporative

cleaning agent, protect all electrical

2011.50 Ranger G37541en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-7 - Puma 303-04C-7

GENERAL PROCEDURES

4. Using a new brush that will not lose its

bristles, brush a suitable evaporative

cleaning agent onto the components being

removed and onto the surrounding area.

5. Using the pneumatic vacuum gun, remove

all traces of evaporative cleaning agent and

foreign material.

6. Dispose of any unused evaporative cleaning

agent and the brush after completing the

repair.

2011.50 Ranger G37541en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-8 - Puma 303-04C-8

REMOVAL AND INSTALLATION

Fuel Pump

Special Tool(s) / General Equipment

303-1317

Locking Tool, Fuel Injection

Pump Sprocket

303-679

Remover/Installer, Engine

Front Cover Inspection Plate

Ford approved diagnostic tool

Ford Diagnostic Equipment

Removal

1. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

WARNINGS:

Make sure that the engine is switched off.

Wait for a minimum of 1 minute after the

engine has stopped before commencing

any repair to the fuel injection system.

Make sure that the fuel pressure has

dropped to zero and that the fuel

temperature is at ambient temperature.

CAUTION: Extreme cleanliness must be

exercised when handling these

components.

2. General Equipment: Ford Diagnostic Equipment

2011.50 Ranger G1272469en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-9 - Puma 303-04C-9

REMOVAL AND INSTALLATION

3. Refer to: Battery Disconnect and Connect 9. Install the Special Tool(s): 303-1317

(414-01 Battery, Mounting and Cables,

General Procedures).

4. Refer to: Accessory Drive Belt - 2.2L

Duratorq-TDCi (88kW/120PS) - Puma/2.2L

Duratorq-TDCi (96kW/130PS) - Puma/2.2L

Duratorq-TDCi (110kW/150PS) - Puma/3.2L

Duratorq-TDCi (148kW/200PS) - Puma

(303-05 Accessory Drive - 2.2L Duratorq-TDCi

(88kW/120PS) - Puma/2.2L Duratorq-TDCi

(96kW/130PS) - Puma/2.2L Duratorq-TDCi

(110kW/150PS) - Puma/3.2L Duratorq-TDCi

(148kW/200PS) - Puma, Removal and

Installation).

10. CAUTION: Make sure that all openings

5. Refer to: Intake Manifold (303-01 Engine - 3.2L are sealed. Use new blanking caps.

Duratorq-TDCi (148kW/200PS) - Puma, Vacuum foreign material from the low-pressure

Removal and Installation). fuel supply line and fuel return line.

6. Refer to: Fuel Injection Component Cleaning Refer to: Fuel Injection Component Cleaning

(303-04 Fuel Charging and Controls - 3.2L (303-04 Fuel Charging and Controls - 3.2L

Duratorq-TDCi (148kW/200PS) - Puma, Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures). General Procedures).

7. Special Tool(s): 303-679

8. Torque: 64 Nm

2011.50 Ranger G1272469en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-10 - Puma 303-04C-10

REMOVAL AND INSTALLATION

11. Torque:

• Fuel rail high-pressure fuel supply line

unions

• Stage 1: 5 Nm

• Stage 2: 35 Nm

• Fuel rail high-pressure fuel supply line

bracket bolt 10 Nm

12. CAUTIONS:

Make sure that the fuel line remains in

contact at both ends until both unions

nuts have been unscrewed and the area

around the joints thoroughly cleaned.

Make sure that all openings are sealed. 13. Torque: 23 Nm

Use new blanking caps.

Vacuum foreign material from the high-pressure

fuel supply line, the fuel pump and the fuel rail.

Refer to: Fuel Injection Component Cleaning

(303-04 Fuel Charging and Controls - 3.2L

Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures).

2011.50 Ranger G1272469en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-11 - Puma 303-04C-11

REMOVAL AND INSTALLATION

14. Torque: 23 Nm

Installation

1. To install, reverse the removal procedure.

2. Carry out a Fuel System Leak Test using the

following menu options:

ToolBox/Powertrain/Service Functions

General Equipment: Ford approved diagnostic

tool

2011.50 Ranger G1272469en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-12 - Puma 303-04C-12

REMOVAL AND INSTALLATION

Fuel Rail

General Equipment

Ford Diagnostic Equipment

Removal

5.

1. WARNINGS:

Make sure that the engine is switched

off.

Make sure that the fuel pressure has

dropped to zero and that the fuel

temperature is at ambient temperature.

Wait at least 1 minute after the engine

has stopped before commencing any

repair to the fuel injection system.

CAUTION: Always carry out the cleaning

process before carrying out any repairs

to the fuel injection system components.

NOTE: Removal steps in this procedure may 6. CAUTIONS:

contain installation details. Make sure that the fuel line remains in

contact at both ends until both unions

2. Within the datalogger function, check that the nuts have been unscrewed and the area

fuel pressure has dropped to zero and that the around the joints thoroughly cleaned.

fuel temperature has either reached ambient Make sure that all openings are sealed.

temperature or is below 30ºC whichever is the Use new blanking caps.

greater.

Vacuum foreign material from the high-pressure

General Equipment: Ford Diagnostic Equipment fuel supply line, the fuel injector and the fuel rail.

3. Refer to: Battery Disconnect and Connect Refer to: Fuel Injection Component Cleaning

(414-01 Battery, Mounting and Cables, (303-04 Fuel Charging and Controls - 3.2L

General Procedures). Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures).

4. Torque:

• Stage 1: 22 Nm

• Stage 2: 25 Nm

2011.50 Ranger G1272470en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-13 - Puma 303-04C-13

REMOVAL AND INSTALLATION

7. CAUTION: Make sure that all openings Torque:

are sealed. Use new blanking caps. • Fuel rail high-pressure fuel supply line

Vacuum foreign material from the fuel rail fuel unions

return line quick release coupling. • Stage 1: 5 Nm

• Stage 2: 35 Nm

Refer to: Fuel Injection Component Cleaning • Fuel rail high-pressure fuel supply line

(303-04 Fuel Charging and Controls - 3.2L bracket bolt 10 Nm

Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures).

8. Refer to: Intake Manifold (303-01 Engine - 2.5L

Duratec-HE (122kW/165PS) - MI4, Removal

and Installation).

9. CAUTIONS: 10. Fuel rail bolts

Make sure that the fuel line remains in Torque:

contact at both ends until both unions • Stage 1: 6 Nm

nuts have been unscrewed and the area • Stage 2: 23 Nm

around the joints thoroughly cleaned.

Make sure that all openings are sealed.

Use new blanking caps.

Vacuum foreign material from the high-pressure

fuel supply line, the fuel pump and the fuel rail.

Refer to: Fuel Injection Component Cleaning

(303-04 Fuel Charging and Controls - 3.2L

Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures).

Installation

1. To install, reverse the removal procedure.

2011.50 Ranger G1272470en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-14 - Puma 303-04C-14

REMOVAL AND INSTALLATION

Fuel Injectors

General Equipment

Ford Diagnostic Equipment

Long Nose Pliers

Removal

1. WARNINGS: 3. Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

Make sure that the engine is switched

General Procedures).

off.

Make sure that the fuel pressure has 4.

dropped to zero and that the fuel

temperature is at ambient temperature.

Wait for a minimum of 1 minute after the

engine has stopped before commencing

any repair to the fuel injection system.

CAUTIONS:

Fuel injectors must not be dismantled

or the nozzles cleaned, not even with

ultrasonic equipment. Install new fuel

injectors if necessary.

Fuel injectors sharing a common fuel

injector clamp must be removed in 5.

pairs.

NOTE: Removal steps in this procedure may

contain installation details.

Refer to: Diesel Fuel System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Within the datalogger function of WDS, check

that the fuel pressure has dropped to zero and

that the fuel temperature has either reached

ambient temperature or is below 30ºC whichever

is the greater.

General Equipment: Ford Diagnostic Equipment

6. CAUTION: Make sure that all openings

are sealed. Use new blanking caps.

Vacuum foreign material from the fuel injector

and fuel return lines.

Refer to: Fuel Injection Component Cleaning

(303-04 Fuel Charging and Controls - 3.2L

Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures).

2011.50 Ranger G1272472en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-15 - Puma 303-04C-15

REMOVAL AND INSTALLATION

8.

7. CAUTIONS:

Make sure that the fuel line remains in

contact at both ends until both unions

nuts have been unscrewed and the area

around the joints thoroughly cleaned.

Make sure that all openings are sealed.

Use new blanking caps.

Vacuum foreign material from the high-pressure

fuel supply line, the fuel injector and the fuel rail.

Refer to: Fuel Injection Component Cleaning

(303-04 Fuel Charging and Controls - 3.2L

Duratorq-TDCi (148kW/200PS) - Puma,

General Procedures). 9. Torque:

Torque: • Stage 1: 5 Nm

• Stage 1: 22 Nm • Stage 2: 180°

• Stage 2: 25 Nm

2011.50 Ranger G1272472en

Fuel Charging and Controls — 3.2L Duratorq-TDCi (148kW/200PS)

303-04C-16 - Puma 303-04C-16

REMOVAL AND INSTALLATION

10. General Equipment: Long Nose Pliers

Installation

1. To install, reverse the removal procedure.

2. Record the new fuel injector correction factor

code.

3. Input the new Injector Correction Factors using

the following WDS menu options:

ToolBox/Powertrain/Service Functions

General Equipment: Ford Diagnostic Equipment

2011.50 Ranger G1272472en

Potrebbero piacerti anche

- Ford Ranger T6 Body Repair Manual 1Documento566 pagineFord Ranger T6 Body Repair Manual 1AngeloArayata67% (3)

- Holden Alloytec Camshaft TimingDocumento9 pagineHolden Alloytec Camshaft Timingducatiss900Nessuna valutazione finora

- Bravo Ranger Drifter RHD Electrical Wiring DiagramDocumento94 pagineBravo Ranger Drifter RHD Electrical Wiring Diagramscribcraft63% (8)

- Motor Ford Ranger PDFDocumento782 pagineMotor Ford Ranger PDFPedro Aguilera100% (1)

- Ford Ranger PX I & II / Mazda BT50 UP/UR: BCM and Lighting Circuits TroublesDocumento5 pagineFord Ranger PX I & II / Mazda BT50 UP/UR: BCM and Lighting Circuits TroublesAlli Yanti50% (2)

- Spill Control Valve InspectionDocumento1 paginaSpill Control Valve InspectionArdi AgusmanNessuna valutazione finora

- Ford Ranger PX MK II SpecificationsDocumento62 pagineFord Ranger PX MK II SpecificationsTulio MooreNessuna valutazione finora

- 2.2 Duratorque TimingDocumento9 pagine2.2 Duratorque TimingJam Bab100% (1)

- Workshop Manual Puma 2.2LDocumento152 pagineWorkshop Manual Puma 2.2LGaston Como100% (6)

- Torque Ford Ranger 3.2Documento3 pagineTorque Ford Ranger 3.2Jaime ForeroNessuna valutazione finora

- Service Bulletin: Fuel Injection PumpDocumento14 pagineService Bulletin: Fuel Injection PumpKrunoslavNessuna valutazione finora

- 2L, 2L-T, 3L, 5L Engine Sup. Rm582e PDFDocumento166 pagine2L, 2L-T, 3L, 5L Engine Sup. Rm582e PDFRojas José F100% (3)

- Ford Ranger T6 2011.50my Workshop Repair ManualDocumento11 pagineFord Ranger T6 2011.50my Workshop Repair ManualTetsunari Koda100% (2)

- 1hd Fte EngineDocumento43 pagine1hd Fte EngineAnonymous DYKEYoH92% (13)

- 1hd Fte EngineDocumento43 pagine1hd Fte EngineAzimuth Contracting60% (5)

- Fuel and Emission Control Systems (WL, WL Turbo, WL-3, WLT-3)Documento154 pagineFuel and Emission Control Systems (WL, WL Turbo, WL-3, WLT-3)pavel35100% (1)

- Sec5a4 Abs AsrDocumento94 pagineSec5a4 Abs AsrTadas PNessuna valutazione finora

- 04 Engine ProperDocumento5 pagine04 Engine Properwilliam_senati20057051Nessuna valutazione finora

- Ford 2.2L Duratorq TDCi 129kW 175PS Engine Service Manual Repair ManualDocumento865 pagineFord 2.2L Duratorq TDCi 129kW 175PS Engine Service Manual Repair ManualThiện Quang100% (1)

- 2AZ-FE FuelDocumento43 pagine2AZ-FE FuelAdedeji OluwatobilobaNessuna valutazione finora

- Engine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDocumento4 pagineEngine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDavid R PaucaraNessuna valutazione finora

- Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPMDocumento1 paginaScan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPMChamp Niwat100% (3)

- Isuzu N Series Elf Workshop Manual Section 0 General Information LGGEN WE 9991 PDFDocumento39 pagineIsuzu N Series Elf Workshop Manual Section 0 General Information LGGEN WE 9991 PDFRobert67% (3)

- Ford Ranger 2015 PDFDocumento25 pagineFord Ranger 2015 PDFDave GoSky60% (5)

- Ford Ranger PX MkII Workshop ManualDocumento6.849 pagineFord Ranger PX MkII Workshop Manualgusycaro100% (7)

- Engine: 1Kd-Ftv and 2Kd-Ftv EnginesDocumento46 pagineEngine: 1Kd-Ftv and 2Kd-Ftv EnginesJorge Luis Garcia ArevaloNessuna valutazione finora

- Sub Tank Fuel SystemDocumento5 pagineSub Tank Fuel SystemBen Dovers100% (6)

- FORD RANGER Workshop ManualDocumento1.427 pagineFORD RANGER Workshop ManualIvoo oo100% (11)

- Ford Ranger XLT Fault CodesDocumento6 pagineFord Ranger XLT Fault CodesDavisson9Nessuna valutazione finora

- EWD of Zace DR077W (VN)Documento41 pagineEWD of Zace DR077W (VN)Binh Binh100% (1)

- ENGINE Timing 4ZZ-FEDocumento31 pagineENGINE Timing 4ZZ-FEAriel100% (1)

- Engine 1KD 2KDDocumento72 pagineEngine 1KD 2KDJavier Espinosa100% (8)

- Smoother G LearningDocumento3 pagineSmoother G Learningdmitry esaulkovNessuna valutazione finora

- Em - Engine Mechanical PDFDocumento24 pagineEm - Engine Mechanical PDFMoaed Kanbar86% (21)

- 4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisDocumento91 pagine4Ja1-Tc & 4Jh1-Tc Engine: Engine Management System Operation & DiagnosisNguyễn ĐángNessuna valutazione finora

- 2L 3L 5L Engine Rm520e PDFDocumento328 pagine2L 3L 5L Engine Rm520e PDFJoãoPauloSouza89% (9)

- 2012.0 Ranger P375 Body Equipment Mounting Manual July 2014Documento86 pagine2012.0 Ranger P375 Body Equipment Mounting Manual July 2014Matthew Hutchins100% (1)

- Engine - 1VD-FTV EngineDocumento33 pagineEngine - 1VD-FTV EnginePablo Pérez100% (3)

- 303-01b Engine TD4Documento166 pagine303-01b Engine TD4Juraci Diniz100% (1)

- Hilux 1kd FTV Engine Repair Manual PDFDocumento5 pagineHilux 1kd FTV Engine Repair Manual PDFMichael100% (1)

- Ranger Drifter Repair Manual F161!10!99aDocumento676 pagineRanger Drifter Repair Manual F161!10!99aKatu201083% (6)

- Manual Ford Ranger 2010Documento287 pagineManual Ford Ranger 2010walroro50% (2)

- Patrol Zd30 Turbo Workshop ManualDocumento7 paginePatrol Zd30 Turbo Workshop ManualNarrogin HayNessuna valutazione finora

- 1 Hdfte - Servise Manual Denso+TestplanDocumento37 pagine1 Hdfte - Servise Manual Denso+Testplanleonid848100% (12)

- Isuzu D-Max Reset ProceduresDocumento1 paginaIsuzu D-Max Reset ProceduresMaster Xeoto88% (16)

- SISTEMA ELÉCTRICOS, Nissan Patrol GR, 2001, GasolinaDocumento278 pagineSISTEMA ELÉCTRICOS, Nissan Patrol GR, 2001, GasolinaAnonymous iaqwR2gZ28Nessuna valutazione finora

- Navara qr25deBCSDocumento20 pagineNavara qr25deBCSAhmedNessuna valutazione finora

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocumento3 pagineDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry DarmawanNessuna valutazione finora

- Ranger Drifter Overhaul Manual F161!20!99aDocumento118 pagineRanger Drifter Overhaul Manual F161!20!99aMrSmooth Smooth100% (3)

- Isuzu DPD EssayDocumento2 pagineIsuzu DPD EssaySteveNessuna valutazione finora

- S1-Yfce18g 2Documento605 pagineS1-Yfce18g 2Peter StanleyNessuna valutazione finora

- SM 33Documento68 pagineSM 33Enrique Arevalo LeyvaNessuna valutazione finora

- Fuel Charging and Controls - INGENIUM I4 2.0L PetrolDocumento274 pagineFuel Charging and Controls - INGENIUM I4 2.0L Petrolkhaledserag23Nessuna valutazione finora

- 623-08 - Fuel Distribution SystemDocumento38 pagine623-08 - Fuel Distribution SystemA ENGENHARIA DAS COISASNessuna valutazione finora

- Fuel System JTEC ChryslerDocumento56 pagineFuel System JTEC ChryslerkeiwerkasNessuna valutazione finora

- Jeep+2.5 TD PDFDocumento38 pagineJeep+2.5 TD PDFMiguel ChaconNessuna valutazione finora

- Fuel System Diagnosis: Section 6Documento7 pagineFuel System Diagnosis: Section 6sungjoo75Nessuna valutazione finora

- Theary of Operation - STC Fuel SystemDocumento5 pagineTheary of Operation - STC Fuel SystemMohamed MohamedNessuna valutazione finora

- Motor1 - 6l Engl PDFDocumento10 pagineMotor1 - 6l Engl PDFGeorge DraganNessuna valutazione finora

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDa EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineValutazione: 5 su 5 stelle5/5 (1)

- Logo Verification ReportDocumento1 paginaLogo Verification ReportDoğan ÇiğnaklıNessuna valutazione finora

- NSK Ball BearingDocumento42 pagineNSK Ball BearingJeya Vijaya Naveen VijayNessuna valutazione finora

- CDM 2 08 02 Release InfoDocumento9 pagineCDM 2 08 02 Release InforevolucionarioNessuna valutazione finora

- Kurikulum Car MaintenenDocumento1 paginaKurikulum Car MaintenenEko SulistyoNessuna valutazione finora

- 9 PDFDocumento1 pagina9 PDFEko SulistyoNessuna valutazione finora

- Ranger Electronic Engine Controls - 2.5LDocumento22 pagineRanger Electronic Engine Controls - 2.5LEko Sulistyo100% (1)

- 1994 System Wiring Diagrams Honda - AccordDocumento50 pagine1994 System Wiring Diagrams Honda - AccordFer Art Bioz Mikro100% (1)

- Ford Fiesta 1.25L PDFDocumento146 pagineFord Fiesta 1.25L PDFEko Sulistyo60% (5)

- 6+Engine+Cooling+1 25L PDFDocumento28 pagine6+Engine+Cooling+1 25L PDFEko SulistyoNessuna valutazione finora

- Cummins - QSB4.5 CM2350Documento18 pagineCummins - QSB4.5 CM2350bedoo54100% (2)

- Equipment Erection, Static and RotaryDocumento8 pagineEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- WindSeminar SlidessummaryDocumento36 pagineWindSeminar SlidessummaryM Refaat FathNessuna valutazione finora

- 2.F2097Inspection MaintCheckList10302013Documento66 pagine2.F2097Inspection MaintCheckList10302013ArisNessuna valutazione finora

- Axial Deformation On FramesDocumento31 pagineAxial Deformation On FramesAndy OretaNessuna valutazione finora

- Design of Base Plate LKP Arm 4-F-30.01.2018Documento5 pagineDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaNessuna valutazione finora

- Static Pitot Tube: Flow MeasurementDocumento23 pagineStatic Pitot Tube: Flow MeasurementMuthu KarthikNessuna valutazione finora

- PEH A2-A6 Process Controller Serv Man 0740801006Documento70 paginePEH A2-A6 Process Controller Serv Man 0740801006Mário Silva100% (1)

- Engine 4Hk1-Tc: Workshop ManualDocumento301 pagineEngine 4Hk1-Tc: Workshop ManualMauricio Gomez Gomez67% (3)

- EVO165DR GreenMech HäckslerDocumento54 pagineEVO165DR GreenMech HäckslerontoptreeworkerNessuna valutazione finora

- RCC & PSC Class Notes (Vivek Gupta) PDFDocumento329 pagineRCC & PSC Class Notes (Vivek Gupta) PDFSTARCAST ENTERTAINMENT100% (2)

- Flexible and Rigid PavementDocumento66 pagineFlexible and Rigid PavementArundhuti DasguptaNessuna valutazione finora

- Updated Mark PMDocumento10 pagineUpdated Mark PMRoy MokNessuna valutazione finora

- EG1109 Lectures 10-12Documento61 pagineEG1109 Lectures 10-12Steven KuaNessuna valutazione finora

- Baja Be 500 Owners ManualDocumento29 pagineBaja Be 500 Owners ManualDragos EnacheNessuna valutazione finora

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocumento15 pagineB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoNessuna valutazione finora

- 000.215.1257 - 05nov08 CarrilerasDocumento27 pagine000.215.1257 - 05nov08 CarrilerasAnonymous PEOSVpvaNessuna valutazione finora

- Flexible Grouted ClampDocumento14 pagineFlexible Grouted ClampMiroslav AleksicNessuna valutazione finora

- Exam PaperDocumento11 pagineExam PaperSi JampangNessuna valutazione finora

- Use of Fiber-Reinforced Soil For Blast ProtectionDocumento16 pagineUse of Fiber-Reinforced Soil For Blast ProtectionSameer ShashwatNessuna valutazione finora

- Project Report On Winter Internship IIT KharagpurDocumento39 pagineProject Report On Winter Internship IIT KharagpurTech broNessuna valutazione finora

- Sahara Regenerative Air DryersDocumento29 pagineSahara Regenerative Air DryersNaveen KumarNessuna valutazione finora

- Taheri-Degradation and Improvement of Mechanical Properties of Rock Under Triaxial Compressive Cyclic LoadingDocumento8 pagineTaheri-Degradation and Improvement of Mechanical Properties of Rock Under Triaxial Compressive Cyclic LoadingRichardson Chavez TaypeNessuna valutazione finora

- GuyhirnDocumento4 pagineGuyhirnTyburnNessuna valutazione finora

- Modelling Heat Transfer During Hot Rolling of Steel StripDocumento18 pagineModelling Heat Transfer During Hot Rolling of Steel Stripak123umtNessuna valutazione finora

- Xicoy Electronic Control Unit - V10 PDFDocumento20 pagineXicoy Electronic Control Unit - V10 PDFAurangzebNessuna valutazione finora

- MANUAL 08443-10A Rev 0 APPROVAL DOCUMENTS XL 110Documento79 pagineMANUAL 08443-10A Rev 0 APPROVAL DOCUMENTS XL 110Black ScorpionNessuna valutazione finora

- Ideal Gas LawDocumento21 pagineIdeal Gas Lawjervis GrajoNessuna valutazione finora

- AirsuspensionDocumento4 pagineAirsuspensionistvan szilard zoldNessuna valutazione finora

- Delo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemDocumento1 paginaDelo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemflyinzeskyNessuna valutazione finora