Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welder Certificate 2''

Caricato da

rajuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Welder Certificate 2''

Caricato da

rajuCopyright:

Formati disponibili

ANUGRAHA

Document Title

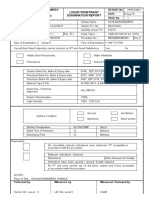

WELDER PERFORMANCE QUALIFICAION CERTIFICATE (WPQ)

(QW-301, Section IX, ASME Boiler and Pressure Vessel Code)

WELDER’S NAME:Mr. RAJ KISHOR IDENTICFICATION NO. : CPW-15

TEST POSITION: 6G DATE OF TEST: 26/10/2016

TEST DESCRIPTION

Identification of WPS followed: STE/WPS/008 √ Test Coupon Production weld

Specification and type/grade or UNS No/ thickness of base metal(s): A106 GR.B , 3.72mm

Testing Variables and Qualification Limits

Welding Variables(QW-350) Actual Values Range Qualified

Welding Process(es): GTAW GTAW

Type(i.e;manual,semi-automatic) used:

MANUAL MANUAL

Backing (with/without) WITH and WITHOUT for

WITHOUT for GTAW

GTAW

Plate √ Pipe (enter diameter if pipe or tube) 2’’ 1’’ and Above

Base metal P- No to P- No P1 P1 through P15 F

Filler metal or electrode specification(s) (SFA) (info. only) 5.18 5.18

Filler metal or electrode classification(s) (info. Only) ER70 S2 ER70 S2

Filler metal F- No(s) 6 1,2,3,&6

Consumable insert (GTAW or PAW) N/A N/A

Filler metal product Form (solid/metal or flux cored/powder) (GTAW or PAW) SOLID SOLID

Deposit thickness for each process

3.72mm(Min) 7.44mm(Max)

Process 1______GTAW ___ 3 Layers minimum YES √ NO

Process 1______ 3 Layers minimum YES NO NA NA

Position qualified (2G,6G,3F,etc) 6G ALL

Vertical progression (uphill or downhill) Uphill Uphill

Type of fuel gas (OFW) N/A N/A

Inert gas backing (GTAW,PAW,GMAW) N/A N/A

Transfer mode (spray/globular or pulse to short circuit- GMAW) N/A N/A

GTAW current type/polarity (AC.DCEP,DCEN) DCEN FOR GTAW DCEN FOR GTAW

RESULTS

Visual examination of completed weld (QW-302.4) - SATISFACTORY WQT NO:

X Transverse face and root bends [QW-462 . 3(a)] X Longitudinal bends [QW-462.3(b)] X Side bends [QW-462.2]

X Pipe Bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)]

X Plate bend specimen, corrosion – resistance weld metal overlay [QW-462.5(d)]

X Pipe specimen, macro test for fusion [QW-462.5(b)] X Plate specimen, macro test for fusion [QW-462.5(E)]

TYPE RESULT TYPE RESULT TYPE RESULT

N/A N/A N/A

Alternative Volumetric Examination Results [QW-191] _____SATISFACTORY________ RT √ or UT (Check one)

RT Report No:

Fillet weld –fracture test [QW-181.2] _____ N/A _________ Length and percent of defects _______ N/A _____________

X Fillet welds in plate [QW-462.4(b)] X Fillet welds in pipe [QW-462.4(c)]

Macro examination (QW-184): N/A Fillet size (in: N/A Concavity/Convexity (in): N/A

Film or Specimens evaluated by: Mr Company:.

Mechanical test conducted by: N/A Laboratory test no: N/A

Welding supervised by: SHAMJU Company:

ANUGRAHA OMPL

NAME:

SIGN:

DATE:

Potrebbero piacerti anche

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Format WPQDocumento2 pagineFormat WPQAkash Singh TomarNessuna valutazione finora

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocumento1 paginaPt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNessuna valutazione finora

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocumento3 pagineWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNessuna valutazione finora

- WPQ WeldCanada PDFDocumento1 paginaWPQ WeldCanada PDFAhmad DanielNessuna valutazione finora

- Manual Joints (QW - 402) : Page 1 of 12Documento12 pagineManual Joints (QW - 402) : Page 1 of 12miteshpatel191Nessuna valutazione finora

- Wps Mma PipeDocumento2 pagineWps Mma PipeDimitris NikouNessuna valutazione finora

- P-WPS 135 - MAG (GR 316)Documento9 pagineP-WPS 135 - MAG (GR 316)Tarun PatelNessuna valutazione finora

- Aws 001Documento1 paginaAws 001akshay sarfareNessuna valutazione finora

- P-WPS 135 - Mag (S355JR)Documento9 pagineP-WPS 135 - Mag (S355JR)Tarun PatelNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocumento3 pagineWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocumento3 pagineWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNessuna valutazione finora

- WPS 19Documento15 pagineWPS 19Avishek Gupta100% (1)

- WPSDocumento6 pagineWPSYASH BARDHAN SinghNessuna valutazione finora

- Welding Procedure Specification For GTAW & GMAWDocumento4 pagineWelding Procedure Specification For GTAW & GMAWanh thoNessuna valutazione finora

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 pagineWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Documento3 pagineWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNessuna valutazione finora

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Documento2 pagineWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNessuna valutazione finora

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 pagine(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Proposed Pwps For Our Jubail WorkDocumento2 pagineWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 pagineQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocumento1 paginaPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNessuna valutazione finora

- WPQ Process As Per ISO-9606-1 2013Documento4 pagineWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 pagineList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Procedure Specification According To EN ISO 15609, 2004Documento2 pagineWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNessuna valutazione finora

- Hardness Test Report: Test Details Machine DetailsDocumento1 paginaHardness Test Report: Test Details Machine DetailsESHWAR CHARYNessuna valutazione finora

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 paginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNessuna valutazione finora

- Proposed WPSDocumento2 pagineProposed WPSChisom Ikengwu100% (2)

- List of WPS (Jerp) PDFDocumento2 pagineList of WPS (Jerp) PDFAlam MD SazidNessuna valutazione finora

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Documento64 pagine1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianNessuna valutazione finora

- WPQ Sample PrintoutDocumento1 paginaWPQ Sample PrintoutKannan VelNessuna valutazione finora

- Wps For Aluminium WeldingDocumento8 pagineWps For Aluminium WeldingMohammed MusaNessuna valutazione finora

- PQR - PipeDocumento3 paginePQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Documento2 pagineWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNessuna valutazione finora

- WPS & WPQR (Asme Section IX)Documento7 pagineWPS & WPQR (Asme Section IX)Rizaldy PhoenksNessuna valutazione finora

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- WPS - 024Documento4 pagineWPS - 024MAT-LIONNessuna valutazione finora

- Wps Aws d1.1 NEWDocumento2 pagineWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- L.P.T Reports.Documento12 pagineL.P.T Reports.Shaikh AdilNessuna valutazione finora

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Documento2 paginePreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNessuna valutazione finora

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Documento3 pagineWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNessuna valutazione finora

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- Wps Is 2062 GR B Butt-OkDocumento2 pagineWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNessuna valutazione finora

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Documento2 pagineWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Val Caraig WPQTDocumento1 paginaVal Caraig WPQTMark Jason M. BrualNessuna valutazione finora

- PQR WPQ Witness Report LatestDocumento1 paginaPQR WPQ Witness Report LatestSatish KeskarNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocumento3 pagineVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNessuna valutazione finora

- Weld Test Checklist: Welder (S) DetailsDocumento2 pagineWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Flange 10 & 12 InchDocumento2 pagineFlange 10 & 12 InchreniNessuna valutazione finora

- WPQ Asme IxDocumento1 paginaWPQ Asme IxEDEN GONZALEZNessuna valutazione finora

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocumento1 paginaWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- 385 2 Internal Gtaw+SmawDocumento2 pagine385 2 Internal Gtaw+Smawsubash1688Nessuna valutazione finora

- Cert Piping W54.5Documento2 pagineCert Piping W54.5SANU0% (1)

- 0814 b090 DCCQ 001 Esp ManualDocumento9 pagine0814 b090 DCCQ 001 Esp ManualrajuNessuna valutazione finora

- 0814 B090 DCCQ 006电除尘器安装说明书封面(英文)Documento1 pagina0814 B090 DCCQ 006电除尘器安装说明书封面(英文)rajuNessuna valutazione finora

- Handling, Transportation and Storage Manual: MT Type EspDocumento1 paginaHandling, Transportation and Storage Manual: MT Type EsprajuNessuna valutazione finora

- (欣隆)MT电除尘器安装说明书(英文) (14 10 8)Documento36 pagine(欣隆)MT电除尘器安装说明书(英文) (14 10 8)raju100% (1)

- Operation Manual: MT MTC Type Electrodtatic PrecipitatorDocumento1 paginaOperation Manual: MT MTC Type Electrodtatic PrecipitatorrajuNessuna valutazione finora

- Handling, Transportation and Storage Manual: MT Type EspDocumento1 paginaHandling, Transportation and Storage Manual: MT Type EsprajuNessuna valutazione finora

- Model 02.11.2015Documento1 paginaModel 02.11.2015rajuNessuna valutazione finora

- WPS 7018+70S2Documento8 pagineWPS 7018+70S2rajuNessuna valutazione finora

- RFI FormatDocumento23 pagineRFI FormatrajuNessuna valutazione finora

- 07-3116 333 EC-33301 Iss - 0Documento5 pagine07-3116 333 EC-33301 Iss - 0rajuNessuna valutazione finora

- Format - Iii: Part-A (Annexure-C) Punch List Liquidated. Ready For FlushingDocumento1 paginaFormat - Iii: Part-A (Annexure-C) Punch List Liquidated. Ready For FlushingrajuNessuna valutazione finora

- MT Type Esp Installation Manual: 0814 B090 DCCQ 006 0 1/36Documento1 paginaMT Type Esp Installation Manual: 0814 B090 DCCQ 006 0 1/36rajuNessuna valutazione finora

- WPS 7018+70S2Documento5 pagineWPS 7018+70S2rajuNessuna valutazione finora

- Vivek Engineering Corporation Project: Pta Project Mangalore Client: M/S JBF Petrochemical Limited Unit: Osbl Radiography Offering RecordDocumento1 paginaVivek Engineering Corporation Project: Pta Project Mangalore Client: M/S JBF Petrochemical Limited Unit: Osbl Radiography Offering RecordrajuNessuna valutazione finora

- WPS 7018+70S2Documento8 pagineWPS 7018+70S2rajuNessuna valutazione finora

- Annexure - C To Format - Ii: Touch Painting of Weld Joints and Paint Damage Area To Be Carried OutDocumento1 paginaAnnexure - C To Format - Ii: Touch Painting of Weld Joints and Paint Damage Area To Be Carried OutrajuNessuna valutazione finora

- Format - IiDocumento116 pagineFormat - IirajuNessuna valutazione finora

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNessuna valutazione finora

- Mechanical: Department PR No. Indented by DateDocumento1 paginaMechanical: Department PR No. Indented by DaterajuNessuna valutazione finora

- Purchase Requisition: S. No Date Area PurposeDocumento2 paginePurchase Requisition: S. No Date Area PurposerajuNessuna valutazione finora

- Raju Mahadevan Resume - Quality Control EngineerDocumento4 pagineRaju Mahadevan Resume - Quality Control EngineerrajuNessuna valutazione finora

- Annexure To FORMAT - IDocumento3 pagineAnnexure To FORMAT - IrajuNessuna valutazione finora

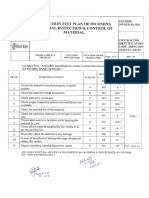

- ITP of Incoming Material Inspection & Control of MaterialDocumento1 paginaITP of Incoming Material Inspection & Control of MaterialrajuNessuna valutazione finora

- Exxonmobil Is The Largest Non-Government Owned Company in The Energy Industry andDocumento1 paginaExxonmobil Is The Largest Non-Government Owned Company in The Energy Industry andrajuNessuna valutazione finora

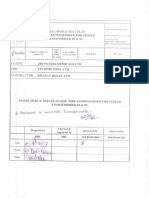

- ITP For Fire Extinguisher For Power Transformer - 01 & 02Documento5 pagineITP For Fire Extinguisher For Power Transformer - 01 & 02rajuNessuna valutazione finora

- HRSG WeldingDocumento20 pagineHRSG WeldingBhargav ChaudhariNessuna valutazione finora

- The Prediction of The Temperature Distribution and Weld Pool Geometry in The Gas Metal Arc Welding ProcessDocumento7 pagineThe Prediction of The Temperature Distribution and Weld Pool Geometry in The Gas Metal Arc Welding ProcessAlejandra HernandezNessuna valutazione finora

- wELDING MAIN PowerPoint PresentationDocumento159 paginewELDING MAIN PowerPoint PresentationsanjibkrjanaNessuna valutazione finora

- CSWIP 3.1 - Welding Inspector WIS5 (2017)Documento699 pagineCSWIP 3.1 - Welding Inspector WIS5 (2017)reezman96% (69)

- Titan Nasa PDFDocumento236 pagineTitan Nasa PDFMilan JavornikNessuna valutazione finora

- Datasheet Sandvik Saf 2205 en PDFDocumento12 pagineDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNessuna valutazione finora

- C8.100 Aluminum Welding GuideDocumento32 pagineC8.100 Aluminum Welding GuideIvan UriasNessuna valutazione finora

- CNRL Pipeline Welding Specifications 2009Documento5 pagineCNRL Pipeline Welding Specifications 2009ntrkulja@hotmail.comNessuna valutazione finora

- Welding 5 Course SyllabusDocumento5 pagineWelding 5 Course Syllabusapi-272067539Nessuna valutazione finora

- 3124 VR 7000cmt PDFDocumento55 pagine3124 VR 7000cmt PDFvladimirsoler01Nessuna valutazione finora

- General Knowledge - MIG Welding ConsumablesDocumento21 pagineGeneral Knowledge - MIG Welding ConsumablesPaul CadmanNessuna valutazione finora

- RT Interpretation-SignedDocumento7 pagineRT Interpretation-Signedhamdi hamdiNessuna valutazione finora

- Introduction To WeldingDocumento28 pagineIntroduction To WeldingMohammed Suleman0% (1)

- 01112015000000B - Boehler EMK 8 - Solid WireDocumento2 pagine01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNessuna valutazione finora

- Investigating of Tig Welding and Activated Tig WeldingDocumento21 pagineInvestigating of Tig Welding and Activated Tig WeldingVishnu TejaNessuna valutazione finora

- Integrated Design Project Proposal Defense Presentation: Automated Lawn MowerDocumento49 pagineIntegrated Design Project Proposal Defense Presentation: Automated Lawn MowerGwar VentureNessuna valutazione finora

- Project On Mig Welded JointsDocumento104 pagineProject On Mig Welded JointsOmer ali100% (1)

- Manual UTPDocumento478 pagineManual UTPjpinto69Nessuna valutazione finora

- Final Internship Report-1Documento21 pagineFinal Internship Report-1darshan aNessuna valutazione finora

- Surface & Coatings Technology: M.H. Amushahi, F. Ashra Fizadeh, M. ShamanianDocumento6 pagineSurface & Coatings Technology: M.H. Amushahi, F. Ashra Fizadeh, M. ShamanianCesar10TNessuna valutazione finora

- Welder Foundation Program Outline Apr 2020 HarmonizedDocumento126 pagineWelder Foundation Program Outline Apr 2020 HarmonizedBin QiNessuna valutazione finora

- Al WeldingDocumento70 pagineAl WeldingTuyen NguyenNessuna valutazione finora

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDocumento16 pagineGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanNessuna valutazione finora

- Welder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkDocumento1 paginaWelder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkMahendra singhNessuna valutazione finora

- Lean DuplexDocumento8 pagineLean DuplexAnonymous 6EmOaerug100% (1)

- Ch30 Fusion WeldingDocumento38 pagineCh30 Fusion WeldingSidd Sal100% (1)

- 15 Parts Catalog MillerDocumento100 pagine15 Parts Catalog MillereddyvegaNessuna valutazione finora

- E Book Student Guide DKM PsasdsdaDocumento31 pagineE Book Student Guide DKM PsasdsdazeroNessuna valutazione finora

- Revised Applicable Job Roles For PMKVY FY 2018-20Documento47 pagineRevised Applicable Job Roles For PMKVY FY 2018-20Brijesh PatelNessuna valutazione finora

- Tesda Circular: IssuedDocumento255 pagineTesda Circular: IssuedleonaNessuna valutazione finora