Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What Is The Index of An Unknown Lens?

Caricato da

Lê Xuân Nam0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaThis document discusses how to calculate the refractive index of an unknown lens. It provides the following key points:

1) You need three of the four variables (refractive index n, radius of curvature r, lens power F, and lens thickness) to calculate the unknown variable.

2) The equation (n - 1) * (F from focimeter) + 1 = Unknown index can be used to calculate the refractive index n if you know the lens measure reading, focimeter reading, and the calibrated refractive index.

3) This calculation assumes a thin lens and may only provide a rough estimate if the lens is actually thick. The thick lens equation is provided for calculating plus lens indices.

4

Descrizione originale:

carlton

Titolo originale

14carlton.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses how to calculate the refractive index of an unknown lens. It provides the following key points:

1) You need three of the four variables (refractive index n, radius of curvature r, lens power F, and lens thickness) to calculate the unknown variable.

2) The equation (n - 1) * (F from focimeter) + 1 = Unknown index can be used to calculate the refractive index n if you know the lens measure reading, focimeter reading, and the calibrated refractive index.

3) This calculation assumes a thin lens and may only provide a rough estimate if the lens is actually thick. The thick lens equation is provided for calculating plus lens indices.

4

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaWhat Is The Index of An Unknown Lens?

Caricato da

Lê Xuân NamThis document discusses how to calculate the refractive index of an unknown lens. It provides the following key points:

1) You need three of the four variables (refractive index n, radius of curvature r, lens power F, and lens thickness) to calculate the unknown variable.

2) The equation (n - 1) * (F from focimeter) + 1 = Unknown index can be used to calculate the refractive index n if you know the lens measure reading, focimeter reading, and the calibrated refractive index.

3) This calculation assumes a thin lens and may only provide a rough estimate if the lens is actually thick. The thick lens equation is provided for calculating plus lens indices.

4

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

looking at lenses

14

What is the index of

In our regular series on dispensing

calculations, Janet Carlton

explains how to calculate the

refractive index of a lens

an unknown lens?

What is the index of an unknown lens, and why do we You know three of the four variables:

need to know? Many of your myopic patients will be wearing a

higher index lens, and may want a new lens with the same index n - 1 = 0.523 (calibrated for crown)

as before. That’s fine if you originally supplied the lenses, but F left of equation = reading from lens measure (F1 + F2 =F’v)

with patients ‘shopping around’ you could easily be seeing a F right of equation = reading from the focimeter

patient who has no previous records with you. So:

Experienced practitioners may be able to identify some of the (0.523) x (F Actual from focimeter) + 1 = Unknown index

higher-index materials, for example the unique sound a polycar- F1+F2 from the lens measure

bonate lens makes when it is tapped. But as professionals you

need to demonstrate skill, not guesswork (Table 1). Do remember that by treating the lens as thin, the answer you

get will only be a rough answer, so if you get something like 1.787

Table 1 the index is probably 1.8.

-12.00 lens in a 50 eye frame If the current lens is spherical, then this calculation is simple,

1.6 lens Cost £40 t=1mm e=7.8mm but it is more likely that the lenses will be toric. Take both the lens

1.7 lens Cost £80 t=1mm e=6.7mm 1.1mm thinner than 1.6 measure reading and the focimeter readings along the highest (or

1.8 lens Cost £125 t=1mm e=5.4mm 1.3mm thinner than 1.7 lowest) power meridian.

(2.4mm thinner than 1.6) You should never need to worry about index when you have

Where t = centre thickness and e = edge thickness a hyperopic patient, as high-index materials make very little

noticeable difference in thickness. Should you need to calculate

the index of a plus lens you will need the ‘thick lens’ equation to

Imagine the scenario where a patient says that he is wearing a replace ‘F1 + F2 = F’v’ in the previous equation.

thinner lens, he remembers paying extra for it.

Your new patient is wearing a 1.7 index lens, but you had The thick lens equation is:

assumed that it was 1.6. Your patient would be happy that your

lenses were cheaper (half the price in the above data) but may F’v = F1 + F2 -dF1F2

decide that the lens was not as thin as the previous one, and insists 1 - dF2

that you remake them. Conversely if you assumed that the lenses

were 1.8 and dispensed that, the patient may think that you have where d = t/n, (t is measured with thickness callipers, in metres

over-charged him, and not appreciate the decrease in thickness. and n = 1.523)

Had you calculated the index and dispensed the same, the patient

would have been fairly charged, and received the thickness of lens Table 2

that he was expecting.

You should have in practice a lens measure; these are normally Some values for index (N), Abbé number (V) and density for

currently available lens materials

calibrated for crown glass (1.523) though some are now calibrated

for both crown and 1.7 index material. Remember to check the N V Density g/cm3

lens measure for accuracy against a known flat edge. A practice Plastics

mirror is ideal. If the reading on a plano surface is slightly out, you ADC ‘CR 39’ 1.498 58 1.32

will need to amend your final readings. For example, if the lens (Allyl diglycol carbonate monomer)

measure reads -0.25 rather than zero, all lens readings will be out PMMA 1.491 58 1.2

(Polymethyl methacrylate)

by -025.

Triology/Trivex 1.53 45 1.1

Now you can start to think about the maths. High-index lenses

Resin lenses 1.537 47 1.21

are normally minus lenses which can be treated as a ‘thin lens’. So 1.56 37.7 – 41 1.17 - 1.27

the calculations will be easy. Polycarbonate 1.586 30 1.2

So: Glass

F1 + F2 = F’v 1.523 58 2.55

F1 may well be plano, do check though. Just because it looks 1.6 42 2.65

flat doesn’t mean it is. Use the straight edge of your ruler for an

easy check system, if the edge sits well on the front surface with Table 2 shows some optical properties (including refractive

no gaps or rocking then assume it is a flat lens. If in doubt use index) for a range of lens materials.

the lens measure. We need to take care in using the index as the only criterion for

The only other equation you need to worry about is: providing the best lens for our patients. In our example above the

1.6 lens was 7.8mm thick, but a polycarbonate lens (1.589) almost

n - 1 = r identical in index is another millimetre thicker. That seems strange

F until you realise that the centre thickness of a polycarbonate lens

Where n = index, r = radius of curvature and F is the power of is greater, at 2mm. A higher-index lens is not always the answer,

that curve. especially with today’s fashion for small frames. Looking back to

our original data, where a 50mm diameter CR39 lens was 10.7mm

It will be unnecessary to actually calculate ‘r’, so a slight adapta- thick, were that glazed in a 44 eye the edge thickness would be

tion of this equation will give you: 7.8mm, the same as a 1.6 lens. Interesting!

n - 1 (From the lens measure) = n - 1 (Unknown index) ◆Janet Carlton is the dispensing clinic manager at City University

F F (From focimeter) Optometry Clinic

Optician January 12, 2007 No 6084 Vol 233 www.opticianonline.net

Potrebbero piacerti anche

- Practical Mechanical OpticsDocumento43 paginePractical Mechanical OpticsAdelle Katherine R. IntanNessuna valutazione finora

- The Lens: A Practical Guide for the Creative PhotographerDa EverandThe Lens: A Practical Guide for the Creative PhotographerValutazione: 4.5 su 5 stelle4.5/5 (5)

- 05 Aphakia and PseudophakiaDocumento15 pagine05 Aphakia and PseudophakiaMwanja Moses100% (1)

- Thick Lens:: Optics 1 - by Dr.H.Huang, Department of Applied Physics 1Documento16 pagineThick Lens:: Optics 1 - by Dr.H.Huang, Department of Applied Physics 1Shweta DixitNessuna valutazione finora

- Collimating a Newtonian Scientifically: Incorporating the Cave and Laser Telescope CollimatorsDa EverandCollimating a Newtonian Scientifically: Incorporating the Cave and Laser Telescope CollimatorsNessuna valutazione finora

- The Use of Bonding Agents For Portland Cement PlasteringDocumento3 pagineThe Use of Bonding Agents For Portland Cement PlasteringbatteekhNessuna valutazione finora

- Lens ThicknessDocumento5 pagineLens ThicknessJayakumar D SwamyNessuna valutazione finora

- Bone CementDocumento31 pagineBone CementSivaprasath Jaganathan100% (1)

- Dispensing in High Myopia and HypermetropiaDocumento29 pagineDispensing in High Myopia and Hypermetropiahenok biruk75% (4)

- Acrolon 890 EN 20130206Documento2 pagineAcrolon 890 EN 20130206hainguyenbkvhv0% (1)

- Optigal's Q & A for the NOCE: National Opticianry Certification Exam Questions - Basic CertificationDa EverandOptigal's Q & A for the NOCE: National Opticianry Certification Exam Questions - Basic CertificationNessuna valutazione finora

- A1 Polymer Physics (Polymer Solution) L1 N3 2012 (Student)Documento73 pagineA1 Polymer Physics (Polymer Solution) L1 N3 2012 (Student)洪意鈞Nessuna valutazione finora

- VISN1111 Geometrical and Physical Optics 2013 Tutorial-6Documento2 pagineVISN1111 Geometrical and Physical Optics 2013 Tutorial-6shadowosNessuna valutazione finora

- Kopp Any MagDocumento4 pagineKopp Any MagJulio SternNessuna valutazione finora

- Thin Lenses: Name: Naima M. Asolog Activity No.9Documento5 pagineThin Lenses: Name: Naima M. Asolog Activity No.9Gwendolyn CalatravaNessuna valutazione finora

- PHYS 202: Professor Stephen Thornton March 28, 2006Documento41 paginePHYS 202: Professor Stephen Thornton March 28, 2006SATYA NARAYAN SAHUNessuna valutazione finora

- Phy IpDocumento9 paginePhy IpCYBER KINGNessuna valutazione finora

- Design Realization: John Canny 11/25/03Documento38 pagineDesign Realization: John Canny 11/25/03Omar DoskyNessuna valutazione finora

- The Resolving Power: M & I T R PDocumento10 pagineThe Resolving Power: M & I T R PAbdulla AbdullahNessuna valutazione finora

- First 01Documento16 pagineFirst 01Khaled AltananyNessuna valutazione finora

- 2001 Optical MicrosDocumento6 pagine2001 Optical MicrosmaynaNessuna valutazione finora

- Class02 - 08 Schematic Eyes - IntroductionDocumento18 pagineClass02 - 08 Schematic Eyes - IntroductioncehborrotoNessuna valutazione finora

- Optics of The Eye: Distances Between Surfaces (MM)Documento24 pagineOptics of The Eye: Distances Between Surfaces (MM)Boussad CHAIBNessuna valutazione finora

- Exp7 Geometrical Optics - 6aXfLTJ PDFDocumento11 pagineExp7 Geometrical Optics - 6aXfLTJ PDFAnonymous TMIwZRYPgCNessuna valutazione finora

- Act 5 Thin LensesDocumento4 pagineAct 5 Thin LensesGwendolyn CalatravaNessuna valutazione finora

- Proyecotr XGADocumento37 pagineProyecotr XGAJesús OdremánNessuna valutazione finora

- 1.1 Frequency and Wavelength (Similar To One in The Book)Documento29 pagine1.1 Frequency and Wavelength (Similar To One in The Book)HarishNessuna valutazione finora

- A1 ThinLensDocumento5 pagineA1 ThinLensharry_11Nessuna valutazione finora

- Physics ActivitiesDocumento12 paginePhysics ActivitiesAnurag Verma 12th MedNessuna valutazione finora

- Physics InvestigatoryDocumento15 paginePhysics Investigatoryy m dNessuna valutazione finora

- Human EyeDocumento8 pagineHuman EyeJoe SinjlawiNessuna valutazione finora

- Table of ContentDocumento4 pagineTable of ContentPappu PriyaNessuna valutazione finora

- Magnifying GlassDocumento3 pagineMagnifying GlassMario ArielNessuna valutazione finora

- Lab #5: Geometric Optics Chi Shing Tsui 11/23/2009 Physics 4BLDocumento10 pagineLab #5: Geometric Optics Chi Shing Tsui 11/23/2009 Physics 4BLleontsui92130Nessuna valutazione finora

- General Science 1110L Lab Lab 7: Convex Lens: Ray Diagram For An Object Infinitely Far Away From The LensDocumento9 pagineGeneral Science 1110L Lab Lab 7: Convex Lens: Ray Diagram For An Object Infinitely Far Away From The LensMuhammad AzrinNessuna valutazione finora

- Hard Contact LensesDocumento46 pagineHard Contact LensesKapil BajajNessuna valutazione finora

- Test Your Basic Knowledge of OpticsDocumento3 pagineTest Your Basic Knowledge of Optics1978howeverNessuna valutazione finora

- Microscopy Lab AgendaDocumento2 pagineMicroscopy Lab AgendaSteve SullivanNessuna valutazione finora

- Hand Neutralisation and VertometryDocumento28 pagineHand Neutralisation and VertometryJúnior Alves100% (1)

- Newton's Ring Experiment - 1Documento6 pagineNewton's Ring Experiment - 1darshan100% (1)

- PH301 Merged 25-35Documento278 paginePH301 Merged 25-35Selvi RNessuna valutazione finora

- Experiment 6: The Following Website Should Be Accessed Before Coming To Class. Text Reference: pp189-196Documento5 pagineExperiment 6: The Following Website Should Be Accessed Before Coming To Class. Text Reference: pp189-196RupeshNessuna valutazione finora

- PHYS 2225 Lab 13 Dispersion and Geometric OpticsDocumento6 paginePHYS 2225 Lab 13 Dispersion and Geometric OpticsT. ArchulettaNessuna valutazione finora

- Lab 1 The MicroscopLab e F2014 - PDocumento21 pagineLab 1 The MicroscopLab e F2014 - PAnastasiaJabarovaNessuna valutazione finora

- Principles of Physics I (PHY111) Lab Experiment No: 7Documento17 paginePrinciples of Physics I (PHY111) Lab Experiment No: 7JU KomolNessuna valutazione finora

- Telescope Equations: Useful Formulas For Exploring The Night Sky Randy CulpDocumento97 pagineTelescope Equations: Useful Formulas For Exploring The Night Sky Randy CulparitmeticsNessuna valutazione finora

- Physics Investgatory ProjectDocumento14 paginePhysics Investgatory ProjectNidhish kannaNessuna valutazione finora

- Lumenlab DIY Projector Guide v2.0Documento41 pagineLumenlab DIY Projector Guide v2.0n.b.a oshan indrajith100% (1)

- Refractive Index of Liquids PDFDocumento7 pagineRefractive Index of Liquids PDFDevang TRIVEDINessuna valutazione finora

- 4 Quick and Easy Ways To Assess Optic Nerve Head SizeDocumento11 pagine4 Quick and Easy Ways To Assess Optic Nerve Head SizeTiffany FuentesNessuna valutazione finora

- Thin Lens Focus DistanceDocumento13 pagineThin Lens Focus DistanceselniNessuna valutazione finora

- Optics Assessment 2019 With AnswersDocumento10 pagineOptics Assessment 2019 With AnswersBenjamin NgNessuna valutazione finora

- Eye PiecesDocumento9 pagineEye PiecesYugandhar VeeramachaneniNessuna valutazione finora

- Tumbling e ChartDocumento21 pagineTumbling e ChartReka Vikaria AnggreliaNessuna valutazione finora

- Geometric and Wave Optics: Qilin XueDocumento5 pagineGeometric and Wave Optics: Qilin XueObama binladenNessuna valutazione finora

- Contact Lens Theory 1 Course 2 2013Documento67 pagineContact Lens Theory 1 Course 2 2013Danielle SangalangNessuna valutazione finora

- Physics ProjectDocumento16 paginePhysics ProjectsherineNessuna valutazione finora

- Barlow LensDocumento5 pagineBarlow Lenslm2kNessuna valutazione finora

- ph104 Exp08Documento18 pagineph104 Exp08mimiikebunnaNessuna valutazione finora

- Primary Eye Examination: A Comprehensive Guide to DiagnosisDa EverandPrimary Eye Examination: A Comprehensive Guide to DiagnosisJong-Soo LeeNessuna valutazione finora

- Viewing the Constellations with Binoculars: 250+ Wonderful Sky Objects to See and ExploreDa EverandViewing the Constellations with Binoculars: 250+ Wonderful Sky Objects to See and ExploreNessuna valutazione finora

- PLEXIGLAS LED® WhiteDocumento4 paginePLEXIGLAS LED® WhiteMisha SpiridonNessuna valutazione finora

- Jotun Siloxane Acrylic PrimerDocumento3 pagineJotun Siloxane Acrylic PrimerBiju_PottayilNessuna valutazione finora

- A Characterization of PMMA Bone CementDocumento13 pagineA Characterization of PMMA Bone CementSwanand KulkarniNessuna valutazione finora

- AkrylikaDocumento2 pagineAkrylikajimis73Nessuna valutazione finora

- Eudragit l100 55 PDFDocumento2 pagineEudragit l100 55 PDFJohnNessuna valutazione finora

- Identification of Plastics .Documento42 pagineIdentification of Plastics .Madhav RajpurohitNessuna valutazione finora

- Coatings With Solar Reflective Properties: - Nouryon Chemicals International B.VDocumento41 pagineCoatings With Solar Reflective Properties: - Nouryon Chemicals International B.VChris BothaNessuna valutazione finora

- A Review of The Properties and Applications of Poly (Methyl Methacrylate) (PMMA)Documento30 pagineA Review of The Properties and Applications of Poly (Methyl Methacrylate) (PMMA)Vlad KubinyeczNessuna valutazione finora

- Plastics - The - Facts 2019Documento42 paginePlastics - The - Facts 2019Manuel Jiménez Díaz100% (1)

- Kane Ace M-210 TDSDocumento1 paginaKane Ace M-210 TDSPhuoc Thinh Truong0% (1)

- TDS Concure 1315 IndiaDocumento4 pagineTDS Concure 1315 IndiaAjayNessuna valutazione finora

- Colored AcrylicsDocumento2 pagineColored AcrylicsConstruction materialNessuna valutazione finora

- Sandeep ChemistryDocumento21 pagineSandeep ChemistrySandeep Nandan MishraNessuna valutazione finora

- Pani Pmma NanoDocumento4 paginePani Pmma NanoRanjana SinghNessuna valutazione finora

- Resin and Cross-Linker Chemistry For Powder CoatingsDocumento36 pagineResin and Cross-Linker Chemistry For Powder CoatingsRashad SarwarNessuna valutazione finora

- Measurement of Optical Characteristic of Plastic by UH4150 SpectrophotometerDocumento3 pagineMeasurement of Optical Characteristic of Plastic by UH4150 Spectrophotometerborg borgNessuna valutazione finora

- Tle Nail Care9 Q4 Module 2Documento20 pagineTle Nail Care9 Q4 Module 2Pete Cruz100% (1)

- Technical Data Sheet: For Further Information Regarding This Product Please Refer To: Tel: +49 6108 919 394Documento1 paginaTechnical Data Sheet: For Further Information Regarding This Product Please Refer To: Tel: +49 6108 919 394sarhan yasmenNessuna valutazione finora

- Acrylic DrillingDocumento5 pagineAcrylic DrillingBui Hoang DucNessuna valutazione finora

- Dental Polymers Applied AspectsDocumento29 pagineDental Polymers Applied AspectsRajat DabholkarNessuna valutazione finora

- Roostaei Et Al 2023 Hollow Nip Znin2s4 Heterojunction For Simultaneous Hydrogen and Pyruvic Acid Production From LacticDocumento9 pagineRoostaei Et Al 2023 Hollow Nip Znin2s4 Heterojunction For Simultaneous Hydrogen and Pyruvic Acid Production From Lactictayeberoosta95Nessuna valutazione finora

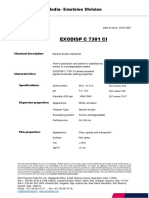

- Eoc Pipl - Exodisp C 7301 Ci - TdsDocumento2 pagineEoc Pipl - Exodisp C 7301 Ci - Tdssantosh mhetreNessuna valutazione finora

- Overviews On PMMADocumento44 pagineOverviews On PMMANathawat PleumsamranNessuna valutazione finora

- PDS CST820 CO enDocumento2 paginePDS CST820 CO enm.onderolaganNessuna valutazione finora

- Conchem Chapter 19Documento4 pagineConchem Chapter 19Mary Carmel HubahibNessuna valutazione finora

- Polylite TDSDocumento3 paginePolylite TDSRAZA MEHDINessuna valutazione finora