Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F804a Issue 8 Checklist (English) - 21-8-18

Caricato da

DavidHernandezCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F804a Issue 8 Checklist (English) - 21-8-18

Caricato da

DavidHernandezCopyright:

Formati disponibili

A Manufacturers Guide to the BRC Global Standard for Storage and

Distribution

1. Background

The Standard was developed to compliment the BRC Food Safety Standard for

manufacturing sites and enable certification of product safety and quality management

through the supply chain from the manufacturer to the retailer or food service customer.

BRC Certified manufacturers put considerable effort into ensuring that products are

manufactured in good hygienic conditions to meet exacting customer quality specifications.

This should enable customers to buy products in peak condition and therefore encourage

repeat purchases. The Storage and Distribution network is key to ensuring that the product

retains its quality and safety before it arrives at the customer.

Supply chains are often complex particularly where products are shipped over long

distances, however mapping the distribution network and maintaining a handle on

traceability is becoming more essential for retailers and manufacturers.

2. Using the BRC Storage and Distribution Standard for your supply chain

The BRC Storage and Distribution Standard provides accredited certification for storage

facilities and Distributors based on

Management commitment

Risk assessment

A documented Quality System

Accepted best practice for storage, handling and distribution of products.

It includes requirement for both Storage and the Distribution network and vehicles. In

practice the typical distribution network consists of a number of fixed locations (storage

facilities) with the distribution between locations carried out either by a company’s own

transport or very often by subcontracted vehicles. Distributors range from major distribution

groups to single driver operator businesses.

Whilst the Standard can be adopted by smaller vehicle operators, the requirements of the

Standard are designed such that the controls at the storage facility - loading and unloading

and the contractual controls on distributors they employ, provides effective management of

the supply chain.

3. Which Storage facilities are already covered by the Food Standard?

The storage facilities at the manufacturing site are included within the Food Safety Standard

audit. Where a manufacturer also has their own additional storage facilities near to the

manufacturing site (within 50 Km) these may be included within the Food Safety Standard

audit or specifically excluded from scope. This will be indicated on the audit report and

certificate.

All other Storage facilities should be certificated against the Storage and Distribution

Standard.

SD026 issue 1 A Manufacturers Guide to the BRC Global Standard for

Storage and Distribution

5/9/2013 Page 1

4. Scope

Although primarily used for packed food products the Standard also covers packaging and

consumer products.

5. What is included within the Standard?

The main Standard is in 8 sections

1.Management Measures to demonstrate that senior management are

commitment committed to achieving high standards of product safety and

quality and looking for continuous improvement

2. Hazard and risk analysis Using similar principles to HACCP to identify hazards which

may affect product safety or quality and ensure controls are

in place to reduce or eliminate the risks

3. Quality Management This requires a documented system of working and effective

System management of purchasing and customer contracts. The

section also sets out requirements for product traceability,

complaint handling and the management of non conforming

products, product recalls/withdrawals and business

continuity.

4. Site and building This covers the conditions and layout of the Storage

standards Warehouses and also looks at elements such as security.

5. Vehicle operating Sets requirements for the actual vehicles and includes

standards temperature controls, vehicle security and the physical

condition of the vehicles.

6. Facility Management This requires management of the facilities both storage and

vehicles and includes cleaning, pest control, maintenance

and waste disposal.

7. Good Operating Sets requirements for the operation of the warehouse with

Practices sections on receipt of goods, product handling, stock rotation

and release procedures.

8. Personnel Training requirements and expectations on personal hygiene

In addition to the main Standard there are also additional modules which cover other specific

services which some Storage facilities also offer such as product inspection, contract

packing, quantity control checks, waste recovery and recycling. These modules are added

where applicable.

6. How does the Standard operate

The operating rules for the Standard follow the same principles as most of the other BRC

Global Standards.

SD026 issue 1 A Manufacturers Guide to the BRC Global Standard for

Storage and Distribution

5/9/2013 Page 2

Audits are carried out by accredited Certification Bodies which have been approved by the

BRC. The auditors are restricted to auditors that are familiar with the sector and have

successfully completed the BRC training course and examination on the Standard.

The audits are planned, announced audits and are carried out at all storage facilities on an

annual basis. The duration of the audit varies depending on the size of the site and

complexity but is typically 1.5 days.

Audit reports provide a summary of how the sites comply with the Standard and identify any

non- conformities together with the action taken to correct these. Certificates are issued

when all non- conformities are completed but no grade is given to certificated sites.

7. How can I check if my suppliers are already certificated?

All certificated sites are included on the BRC Directory www.brcdirectory.com ,unless they

have specifically requested not to be included. It is possible to use the search facility on the

website to check the status of specific sites or to search for certificated suppliers.

SD026 issue 1 A Manufacturers Guide to the BRC Global Standard for

Storage and Distribution

5/9/2013 Page 3

8. Getting started with Storage and Distribution Standard

Full details about the scheme are available on the BRC website

www.brcglobalstandards.com and are contained in the Standard which is available from

TSO or via the BRC website. The process of gaining certification can be summarised in the

following steps

Get a copy of the Standard and assess the compliance of your site to

its requirements. The BRC have published guidance documents on

best practice and on the use of standards for some sectors which

Preparation may also be of assistance.

To assist in the implementation of the BRC Global Standards, the

BRC has developed a wide range of practical training courses. See

www.brcacademy.com for further information.

Review your current systems and practices against the requirements

Self of the standard in order to identify areas which may need further work

before undertaking a full audit.

assessment This can be carried out by your own site, by a consultant familiar with

the BRC Standard or by asking a Certification Body to undertake a

P pre-assessment.

Select an accredited Certification Body to carry out the evaluation on

your site. Only Certification Bodies that are registered by the BRC

Select a can undertake audits. Certification Bodies can be selected by country

certification and standard from the Directory section of the BRC website.

body Certification Bodies will require details of your site and operation

before being able to provide a quotation. Typical audit durations are

indicated in the standards.

A plan for the audit should be provided by your certification body to

The ensure that you and your team are properly prepared. The audit may

Audit be extended if staff or documentation is not available at the audit so

preparation is essential. It is important that the site is in operation at

P the time of the audit otherwise a further audit will be required.

At the end of the audit the Certification Body should provide a written

list of any areas which need improvement in order to gain

Corrective certification, this will also be discussed at the closing meeting. Where

Actions non conformances have been identified, these must be addressed

and suitable evidence provided to the Certification Body for

P assessment within 28 days. In some circumstances it may be

necessary for the auditor to return to the site to check that

appropriate corrective action has been taken.

The Certification Body will review the audit report from the auditor

and corrective action documentation provided in order to make a

Report and certification decision. The audit report and certificate (if applicable)

Certification should be issued within 42 days of the original audit date to the

person who paid for the audit usually the site.

P A copy of the report is automatically sent to the BRC to allow quality

control checking of the Certification Bodies. Certified sites are listed

on the BRC Directory web site to advertise their achievements.

SD026 issue 1 A Manufacturers Guide to the BRC Global Standard for

Storage and Distribution

5/9/2013 Page 4

Potrebbero piacerti anche

- Establishing A CGMP Laboratory Audit System: A Practical GuideDa EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNessuna valutazione finora

- Whitepaper - BRC Issue8 - US - Letter PDFDocumento13 pagineWhitepaper - BRC Issue8 - US - Letter PDFVinod Sale100% (1)

- Handbook of Microbiological Criteria for FoodsDa EverandHandbook of Microbiological Criteria for FoodsNessuna valutazione finora

- BRC FOOD ISSUE 8 - Understanding The Requirements PDFDocumento13 pagineBRC FOOD ISSUE 8 - Understanding The Requirements PDFCarlos Rosete100% (1)

- FAM814 Module 14 Meeting Costco Requirements v3 24.10.2022Documento9 pagineFAM814 Module 14 Meeting Costco Requirements v3 24.10.2022Lutviana Ema100% (1)

- BRC Food v6Documento4 pagineBRC Food v6VanifsmsNessuna valutazione finora

- Culture Excellence: Food SafetyDocumento8 pagineCulture Excellence: Food SafetyFarmer BrownNessuna valutazione finora

- Iso Ts PRP Food Part 2Documento7 pagineIso Ts PRP Food Part 2Rizqi Ahsan NashrullahNessuna valutazione finora

- BRC Food Issue 7 Audit ChecklistDocumento4 pagineBRC Food Issue 7 Audit ChecklistGlobal Manager Group0% (1)

- Comparative BRC FSSC22000Documento14 pagineComparative BRC FSSC22000Tati BarbieroNessuna valutazione finora

- BRC Global Standard For Food Safety Issue 7 Voluntary Module 11 Meat Supply Chain Free PDFDocumento15 pagineBRC Global Standard For Food Safety Issue 7 Voluntary Module 11 Meat Supply Chain Free PDFMiguel Ernesto Lacayo ChávezNessuna valutazione finora

- EM Trainer Guide - 1 Day CourseDocumento10 pagineEM Trainer Guide - 1 Day CoursePercy Vara CelisNessuna valutazione finora

- BRC Issue 8 UpdateDocumento37 pagineBRC Issue 8 Updatelaurentiu29100% (1)

- FSSC 22000: Requirements and Regulations For Certification BodiesDocumento41 pagineFSSC 22000: Requirements and Regulations For Certification BodiesJose LopezNessuna valutazione finora

- BRC001 Senior Management Commitment ProcedureDocumento4 pagineBRC001 Senior Management Commitment ProcedureJayashri chitteNessuna valutazione finora

- FSSC 5 - Seminar Food - Compatibility ModeDocumento22 pagineFSSC 5 - Seminar Food - Compatibility ModeKANINTA YUDHANessuna valutazione finora

- (HACCP) System in A Meat PlantDocumento100 pagine(HACCP) System in A Meat PlantWinNessuna valutazione finora

- Food Processing Industry - CODEX Standards, FDI & DumpingDocumento38 pagineFood Processing Industry - CODEX Standards, FDI & DumpingNarender YadavNessuna valutazione finora

- FSSC Quick Start Guide PDFDocumento26 pagineFSSC Quick Start Guide PDFsiva k100% (1)

- 31 Validation, Verification and Improvement of The FSMSDocumento5 pagine31 Validation, Verification and Improvement of The FSMSVeera Venkatesh MareeduNessuna valutazione finora

- Food Safety and Compliance With High Performance Weighing and Inspection 1240364414Documento112 pagineFood Safety and Compliance With High Performance Weighing and Inspection 1240364414Luthfa Umi AzizahNessuna valutazione finora

- FSSC 22000 Ver 5.1 (Include ISO 22000: 2018) : Exercise WorkbookDocumento16 pagineFSSC 22000 Ver 5.1 (Include ISO 22000: 2018) : Exercise WorkbookRizal Abdul AzizNessuna valutazione finora

- What Is Food Safety Culture - Aug 2021Documento13 pagineWhat Is Food Safety Culture - Aug 2021Alberto AfonsoNessuna valutazione finora

- BRCGS Standard For Packaging and Packaging MaterialsDocumento6 pagineBRCGS Standard For Packaging and Packaging Materialshunain zafarNessuna valutazione finora

- Guidance Document Milk 14 03 2019 PDFDocumento97 pagineGuidance Document Milk 14 03 2019 PDFSameer DamleNessuna valutazione finora

- 4.1.2a Supplier Questionnaire Template PDFDocumento5 pagine4.1.2a Supplier Questionnaire Template PDFhunain zafarNessuna valutazione finora

- ISO 22000 Food Safety Management SystemDocumento14 pagineISO 22000 Food Safety Management SystemkatariamanojNessuna valutazione finora

- BRC Report 2014Documento66 pagineBRC Report 2014Keng PitipongNessuna valutazione finora

- Case Food Fraud PreventionDocumento17 pagineCase Food Fraud PreventionAulia AnnaNessuna valutazione finora

- Implementation Manual: Brcgs Culture Excellence Food Safety Culture ModuleDocumento14 pagineImplementation Manual: Brcgs Culture Excellence Food Safety Culture ModuleMariela YapuNessuna valutazione finora

- Iso 22000 - Oprps Vs HaccpDocumento47 pagineIso 22000 - Oprps Vs HaccpVina AfilianiNessuna valutazione finora

- BRC012 Food Safety Culture QuestionnaireDocumento4 pagineBRC012 Food Safety Culture QuestionnairebushraahmedNessuna valutazione finora

- Gso 1016 2015Documento26 pagineGso 1016 2015Anil Yadav100% (1)

- Position Statements: BRC Global Standard For Food Safety Issue 6Documento9 paginePosition Statements: BRC Global Standard For Food Safety Issue 6Isabella GonçalvesNessuna valutazione finora

- FSSC 22000 Version 6.0 Upgrade ProcessDocumento7 pagineFSSC 22000 Version 6.0 Upgrade ProcessKarim HandoyoNessuna valutazione finora

- Management: ProgramsDocumento10 pagineManagement: ProgramsMike SajaNessuna valutazione finora

- FSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFDocumento80 pagineFSSC 22000 Vers 5, Add Req, ISO 22000 2018 Shared PDFSyahrizal MuhammadNessuna valutazione finora

- Iso 22000Documento11 pagineIso 22000Harits As SiddiqNessuna valutazione finora

- Allergen Awareness Training Presentation 0107 PDFDocumento32 pagineAllergen Awareness Training Presentation 0107 PDFsoniaditia_chemist100% (1)

- Protocol For Validation of FSMS - FinalVersionDocumento25 pagineProtocol For Validation of FSMS - FinalVersionChel Zalamea Domingo100% (1)

- Validation of Control Measures in A Food Chain Using The FSO ConceptDocumento7 pagineValidation of Control Measures in A Food Chain Using The FSO Conceptcaraquena123Nessuna valutazione finora

- Lecture 9 ISO 22000Documento44 pagineLecture 9 ISO 22000ch videosNessuna valutazione finora

- FSSC 22000 Documents PDFDocumento9 pagineFSSC 22000 Documents PDFSanjiv KumarNessuna valutazione finora

- Aud Agile Eng m04 Pnotes Conducting An AuditDocumento24 pagineAud Agile Eng m04 Pnotes Conducting An AuditMohamed ElsawyNessuna valutazione finora

- Basics of HACCP and Prerequisite ProgramsDocumento22 pagineBasics of HACCP and Prerequisite ProgramsAnonymous A1G77Sw59Nessuna valutazione finora

- Food Safety Management ResponsibilityDocumento13 pagineFood Safety Management ResponsibilityANURADHA NAGARKOTI100% (2)

- PUB100454 - Preview Handbook Iso 22000Documento13 paginePUB100454 - Preview Handbook Iso 22000sercalsaNessuna valutazione finora

- GFCO Certification ManualDocumento72 pagineGFCO Certification Manualatila117Nessuna valutazione finora

- FSSC A GFSI RequirementDocumento28 pagineFSSC A GFSI RequirementAkhilesh Dhar Diwedi100% (1)

- AIB Standards of InspectionDocumento62 pagineAIB Standards of InspectionRekta DEPNessuna valutazione finora

- CCP and OprpDocumento5 pagineCCP and OprpGorack ShirsathNessuna valutazione finora

- Additives GSO PDFDocumento294 pagineAdditives GSO PDFAdeesha DeshanNessuna valutazione finora

- ISO 22000 Checklist Sample PDF ReportDocumento24 pagineISO 22000 Checklist Sample PDF ReportNayely GonzálezNessuna valutazione finora

- Critical Elements For EMPDocumento54 pagineCritical Elements For EMPGaganpreet KaurNessuna valutazione finora

- sfc2017 Environmental MonitoringDocumento74 paginesfc2017 Environmental MonitoringLuis Gutiérrez100% (2)

- BRCGS Pack6Module10 V.3Documento20 pagineBRCGS Pack6Module10 V.3Anonymous XfIF3HdNessuna valutazione finora

- Case Studies On HaccpDocumento28 pagineCase Studies On HaccpAnonymous OPix6Tyk5INessuna valutazione finora

- Guia Globap GAP ISO 22002-5Documento14 pagineGuia Globap GAP ISO 22002-5Miguel Lemus100% (1)

- Quality Assessment - ManualDocumento152 pagineQuality Assessment - ManualprinceejNessuna valutazione finora

- Haccp Manual: Hawaii International Seafood, IncDocumento70 pagineHaccp Manual: Hawaii International Seafood, IncCamelia Stremtan0% (1)

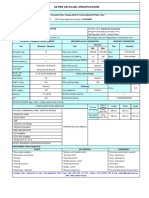

- Cons Is To MetroDocumento1 paginaCons Is To MetroDavidHernandezNessuna valutazione finora

- Ficha Tecnica AlmejasDocumento1 paginaFicha Tecnica AlmejasDavidHernandezNessuna valutazione finora

- SPEQ User Manual - DC Setup and Mapping (V1.5)Documento32 pagineSPEQ User Manual - DC Setup and Mapping (V1.5)DavidHernandez0% (1)

- Ficha Tecnica AlmejasDocumento1 paginaFicha Tecnica AlmejasDavidHernandezNessuna valutazione finora

- Ficha Tecnica Concha de Abanico Roe OffDocumento1 paginaFicha Tecnica Concha de Abanico Roe OffDavidHernandezNessuna valutazione finora

- Ficha Tecnica Concha de Abanico Roe Off-1Documento1 paginaFicha Tecnica Concha de Abanico Roe Off-1DavidHernandezNessuna valutazione finora

- Ficha Tecnica Concha de Abanico Roe On - 5Documento1 paginaFicha Tecnica Concha de Abanico Roe On - 5DavidHernandezNessuna valutazione finora

- Ficha Tecnica AlmejasDocumento1 paginaFicha Tecnica AlmejasDavidHernandezNessuna valutazione finora

- 1ficha Tecnica Calamar 10 - 15 - NewDocumento2 pagine1ficha Tecnica Calamar 10 - 15 - NewDavidHernandezNessuna valutazione finora

- 1ficha Tecnica Calamar 10 - 15 - NewDocumento2 pagine1ficha Tecnica Calamar 10 - 15 - NewDavidHernandezNessuna valutazione finora

- Ficha Tecnica Concha de Abanico Media Valva - 2Documento1 paginaFicha Tecnica Concha de Abanico Media Valva - 2DavidHernandezNessuna valutazione finora

- Ficha Tecnica Concha de Abanico Media Valva (1132411414020032)Documento1 paginaFicha Tecnica Concha de Abanico Media Valva (1132411414020032)DavidHernandezNessuna valutazione finora

- 1ficha Tecnica Calamar 10 - 15 - NewDocumento2 pagine1ficha Tecnica Calamar 10 - 15 - NewDavidHernandezNessuna valutazione finora

- 1ficha Tecnica Calamar 10 - 15 - NewDocumento2 pagine1ficha Tecnica Calamar 10 - 15 - NewDavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas 10% Glass (2313611414020102)Documento2 pagineFicha Tecnica Anillas 10% Glass (2313611414020102)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas (Mixtas)Documento1 paginaFicha Tecnica Anillas (Mixtas)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas - 10 11Documento2 pagineFicha Tecnica Anillas - 10 11DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas (Mixtas)Documento1 paginaFicha Tecnica Anillas (Mixtas)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas (Mixtas)Documento1 paginaFicha Tecnica Anillas (Mixtas)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas - 10 11Documento2 pagineFicha Tecnica Anillas - 10 11DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas - 10 11Documento2 pagineFicha Tecnica Anillas - 10 11DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas - 10 11Documento2 pagineFicha Tecnica Anillas - 10 11DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anillas - 10 11Documento2 pagineFicha Tecnica Anillas - 10 11DavidHernandezNessuna valutazione finora

- Ficha Tecnica AlmejasDocumento1 paginaFicha Tecnica AlmejasDavidHernandezNessuna valutazione finora

- Ficha Tecnica Aleta Cocida (2311202704010151)Documento2 pagineFicha Tecnica Aleta Cocida (2311202704010151)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Anchoveta HG X 10 KGDocumento1 paginaFicha Tecnica Anchoveta HG X 10 KGDavidHernandezNessuna valutazione finora

- Ficha Tecnica Aleta Cocida (2311202704010151)Documento2 pagineFicha Tecnica Aleta Cocida (2311202704010151)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Aleta (2311411414010152)Documento2 pagineFicha Tecnica Aleta (2311411414010152)DavidHernandezNessuna valutazione finora

- Ficha Tecnica Seafrost Filete PrecocidoDocumento1 paginaFicha Tecnica Seafrost Filete PrecocidoDavidHernandezNessuna valutazione finora

- CH 08Documento46 pagineCH 08isangNessuna valutazione finora

- Forum Discussion - ODDocumento5 pagineForum Discussion - ODHo Kok WengNessuna valutazione finora

- Top 20 SuppliersDocumento29 pagineTop 20 SupplierssachinNessuna valutazione finora

- Cargoconnect September 2022Documento100 pagineCargoconnect September 2022hello8434Nessuna valutazione finora

- Pharmacy Training ManualDocumento16 paginePharmacy Training Manualmaevalle.escNessuna valutazione finora

- Petrochemical, Oil & Gas Facilities: Very Early Warning Smoke DetectionDocumento42 paginePetrochemical, Oil & Gas Facilities: Very Early Warning Smoke DetectionnaveedfndNessuna valutazione finora

- Macdonald's Pakistan Supply ChainDocumento35 pagineMacdonald's Pakistan Supply ChainTaha Durrani0% (1)

- Category Management - A Pervasive, New Vertical/ Horizontal FormatDocumento5 pagineCategory Management - A Pervasive, New Vertical/ Horizontal FormatbooklandNessuna valutazione finora

- Warehouse OverviewDocumento18 pagineWarehouse OverviewpremNessuna valutazione finora

- PTP-Procure To PayDocumento21 paginePTP-Procure To PayGreg Pwol50% (2)

- Regogreen 427 Keithbarnesresume2Documento2 pagineRegogreen 427 Keithbarnesresume2api-29823189Nessuna valutazione finora

- Coles Group Limited: Business LogisticsDocumento11 pagineColes Group Limited: Business LogisticsRavi KumawatNessuna valutazione finora

- Plant LayoutDocumento66 paginePlant LayoutSanjay KumarNessuna valutazione finora

- BC2408 Project ProposalDocumento2 pagineBC2408 Project ProposalGdeNessuna valutazione finora

- Juan Antonio Pérez Duarte: Professional ExperienceDocumento2 pagineJuan Antonio Pérez Duarte: Professional ExperienceabeastinmeNessuna valutazione finora

- Volkswagen Case AnalysisDocumento2 pagineVolkswagen Case AnalysisVarun GokhaleNessuna valutazione finora

- Sop Warehouse DistributionsDocumento19 pagineSop Warehouse DistributionsAriel CarreroNessuna valutazione finora

- Coffee Distribution Business PlanDocumento41 pagineCoffee Distribution Business Planadmbad2100% (1)

- Oracle Warehouse Management Labs: Outbound Logistics Sales Orders Picking in WMS E-Business Suite R12.2.6Documento36 pagineOracle Warehouse Management Labs: Outbound Logistics Sales Orders Picking in WMS E-Business Suite R12.2.6manitenkasiNessuna valutazione finora

- Study of TESCO Supply Chain PDFDocumento17 pagineStudy of TESCO Supply Chain PDFAudrey UkeomaNessuna valutazione finora

- EtMusic Shop Business PlanDocumento9 pagineEtMusic Shop Business PlanAmanuel WorkuNessuna valutazione finora

- AUDA DP - Planning RegulationsDocumento93 pagineAUDA DP - Planning RegulationsManasviJindalNessuna valutazione finora

- Import Business in KenyaDocumento131 pagineImport Business in KenyaDj Backspin254Nessuna valutazione finora

- Supply Chain Management of Pizza HutDocumento48 pagineSupply Chain Management of Pizza Hutjahan73% (15)

- Auditing Theory Audit of The Inventory and Warehousing CycleDocumento15 pagineAuditing Theory Audit of The Inventory and Warehousing CycleMark Anthony Tibule100% (2)

- Guidance Document Flour Milling Sector 19-01-2018Documento87 pagineGuidance Document Flour Milling Sector 19-01-2018Maya SatoNessuna valutazione finora

- 备电48200使用说明书 1 14 translateDocumento25 pagine备电48200使用说明书 1 14 translateYe GyiiiNessuna valutazione finora

- Classification of CBW (Summarized)Documento3 pagineClassification of CBW (Summarized)VelNessuna valutazione finora

- Chanrobles Virtual Law Library: ChanroblesvirtualawlibraryDocumento4 pagineChanrobles Virtual Law Library: Chanroblesvirtualawlibraryzetski_17Nessuna valutazione finora

- New Microsoft Word DocumentDocumento3 pagineNew Microsoft Word DocumentImtiaz AhmadNessuna valutazione finora

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- A Complete Guide to Safety Officer Interview Questions and AnswersDa EverandA Complete Guide to Safety Officer Interview Questions and AnswersValutazione: 4 su 5 stelle4/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesDa EverandWorkbook to Accompany Maintenance & Reliability Best PracticesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Fire Fighting Pumping Systems at Industrial FacilitiesDa EverandFire Fighting Pumping Systems at Industrial FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (3)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityDa EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityValutazione: 5 su 5 stelle5/5 (2)

- Fundamentals of Risk Management for Process Industry EngineersDa EverandFundamentals of Risk Management for Process Industry EngineersNessuna valutazione finora

- Epidemiology and Demography in Public HealthDa EverandEpidemiology and Demography in Public HealthJaphet KillewoValutazione: 5 su 5 stelle5/5 (1)

- Culture, Health and Illness: An Introduction for Health ProfessionalsDa EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNessuna valutazione finora

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersDa EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersValutazione: 4 su 5 stelle4/5 (32)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDa EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNessuna valutazione finora

- Handbook of Hazardous Chemical PropertiesDa EverandHandbook of Hazardous Chemical PropertiesValutazione: 5 su 5 stelle5/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeDa EverandThe Invisible Rainbow: A History of Electricity and LifeValutazione: 4.5 su 5 stelle4.5/5 (21)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesDa EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (2)

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeDa EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNessuna valutazione finora

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDa EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsValutazione: 4 su 5 stelle4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesDa EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNessuna valutazione finora