Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Final Project Presentation SCM JSL 30.04.2019

Caricato da

PANKAJCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Final Project Presentation SCM JSL 30.04.2019

Caricato da

PANKAJCopyright:

Formati disponibili

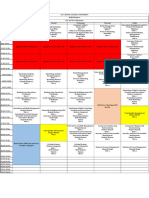

MBA-2018

Global

Inbound Change in Recomme

Supply Supply

Organizati & Value Typical Logistics ndations

Chain & Chain

on at a outbound Chain Issues of and for

major Detail of

glance Logistics mapping Logistics Transport Improvem

Infrastruc JSL

Details Strategy ent

ture

5

4

CONTROL

3 The Overall Cost of

IMPROVE Production by proper

The Supply Chain SCM and Logistics

2 Management

ANALYSE costs.

The Supply Chain Process and Logistics

1 MEASURE Management Cost

The Inbound- System viz.

DEFINE Outbound Logistics

The Objective: cost and total transit

time

Understanding the

Logistics & Supply Chain

Management of JSL

30.04.2019 JSL CASE STUDY Slide No.: 2

MBA-2018

JSL GLOBAL PRESENCE JSL FINANCIAL PERFORMANCE Point to Ponder:

JSL uses SCOR (Plan, Source,

Make, Deliver, Return(recycle)

Model in order to describe

supply chain activities from

suppliers to customers.

Largest stainless steel manufacturer in India. Logistics expenditures for Jindal Stainless Limited

Operates an integrated stainless steel plant at Jajpur, Odisha. Sl. No Logistics Spending FY’ 13-14 FY’ 14-15 FY’ 17-18

‘State-of-the-Art’ machinery and engineering from the best of European

suppliers, capable of producing globally competitive stainless steel products. 1 Inbound Logistics 976 1101 108

Well established distribution network with service centre access in both

Domestic and overseas market to optimize customer service and deliveries. 2 Outbound Logistics 592 676 547

3 Annual turnover in Crs. 11700 12401 12566

Point to Ponder:

JSL spends a minimum of average 14.16 % on logistics as

compared to international standards of 8%.

30.04.2019 JSL CASE STUDY Slide No.: 3

A.K.Jain & Brothers | Kolkata

A-1 Acid Pvt. Limited | Gujrat Bajaj Electricals | Bhubaneswar C&I Systems | Kota

123 Ply | New Delhi Bajrang Enterprise | Jodhpur CAD Studio | New Delhi

PT. Sif Makmur | Jakarta Balasore Alloys Limited | Balasore Caldery’s India Refractori | Nagpur

Dynamatic Technologies | New Delhi Aasix Nano Technologiees | Mohali Bearing Manufacturing | Mumbai Carbon Rotofluid | Ahmedabad

East Coast Magnets | Kolkata ABB India | Kolkata Bells Electrotech | Kolkata Carrier Airconditioning | Kolkata A.K.Jain & Brothers | Kolkata

Eastern Railways | Bhubaneswar ABR Enviro Systems | Indore Bevcon Wayors Pvt. Limited | Hyderabad Ceat Limited | Mumbai A.G.Electronics | Mumbai

Aerotech Systems | Hisar Bharat Aluminium Company | Faridabad Conserve Tech Systems | Pune A-1 Acid Pvt. Limited | Gujrat

Econship Tech Pvt. Ltd. | Navi Dee Kay Gears | Mumbai

Alfa Laval India Limited | Pune Bharat Electronics | Bangalore

Mumbai

Ambuja Cements Limited | Jaipur Bhushan Steel Limited | Raigad Delta Electricals | Ahmedabad A-One Industries | Haridwar

Electrogears India | Kolkata Ammonia Supply Company | Ranchi Blue Star Limited | Mumbai Diamond Saw Mills | Sirsa 123 Ply | New Delhi

Ellnbarrie Cryogenics | DKS Desiccants | Noida PT. Sif Makmur | Jakarta J.P Constructions | Hisar

Visakhapatnam Duex Industrial Systems | Mumbai

Jain Ferro Alloy | Mumbai

Emerson Process Management | Jainson Labs | Meerut

Chennai Jalan Refratech | Dhanbad

EPP Composites | New Delhi JDC Traders | New Delhi

Fairtech Engineers | Mumbai JCB India Limited | Pune

Jindal Automation | Roorkee

Fabco Universal | Dellhi Johnson Machineries | Nagpur

Ferrocare Machines | Pune Kaeser Compressors | Pune

Firpack Textile Mills | Jaipur Kirloskar Brothers Limited | Kolkata

Flowcon Engineers | Coimbatore KSB Pumps | Noida

Galaxy Motors | Gurgaon Larsen & Toubro | Mumbai

Gastek Engineering | New Delhi

Gear & Drives | Bangalore

General Electric | Mumbai

Global Engineering | Bhopal

HEG Limited | Noida

Hapag Lloyd India | New Delhi

HCL Infosystems | Noida

Hewlett Packard | Bangalore

Himadri Chemicals | Visakhapatnam

Hindalco Industries | Indore J.P Constructions | Hisar Industech Engineering Services | Bhubaneswar

IFM Electronic | Kolhapur Jain Ferro Alloy | Mumbai Lloyd Insulations India Limited | Kolkata

Indian Oil Corporation Limited | Karnal Jainson Labs | Meerut Jindal Steel & Power Limited | Raigarh

Indo Electricals | Vadodra Jalan Refratech | Dhanbad Caldery India Refractories | Nagpur

ITW India Limited | Medak JDC Traders | New Delhi Crane Control Equipments | New Delhi

Kaeser Compressors | Pune Essae Technology Pvt. Limited | Bangalore

Kirloskar Brothers Limited | Kolkata Lincoln Helios India Limited | Bangalore

KSB Pumps | Noida Rotamic Hydraulics Pvt. Limited | Kolkata

Larsen & Toubro | Mumbai Moog Motion Controls | Bangalore

International Combustion | Aurangabad

Elecktromag Methods | Mumbai Yesdee Electronics | Mumbai

Fairtech Engineers | Mumbai Tempsens Instruments India | Udaipur

Hitech Lubrication Systems | Faridabad Dell International Services | Bangalore

Sunbeam Industrial Products | Mumbai Premier Industrial Corporation | Kolkata

Plazma Technologies | Pune Shell India Markets Pvt. Limited | Angul

Indo Chemicals & Instruments | Cuttack Servo Controls & Hydraulics | Belgaum

Siemens Limited | Kolkata Thermax Limited | Vadodra

Symbiosis | Angul Yuken India Limited | Bangalore

Voltas Limited | Bhubaneswar Dee Kay Gears | Mumbai

Shalimar Paints | Cuttack Wika Instruments | Pune

Scientific Traders | Balasore Akers AB | Sweden Everest Analytics | Mumbai

Emerson Process Management | Chennai Sinosteel Equipment & Engineering | Beijing Lightkrafts | Kolkata

Rolex Industries | Mumbai Tenova Spa | Castellanza

Atlas Copco India Limited | Kolkata Thermocast Spa | Italy

Dantal Hydraulics Pvt. Limited | Gurgaon KTB Import-Export | Hamburg

Tractors India Pvt. Limited | Bhubaneswar Apex Fluidomatics Pvt. Limited | Naroda Primetals Tech Gmbh | Austria

C&I Systems | Kota Comac India Pvt. Limited | New Delhi AFS Sedan | France

CAD Studio | New Delhi Skytech Automation | Coimbatore Romani Srl | Italy

Caldery’s India Refractori | Nagpur Jindal Coke Limited | Jajpur Jiangsu Gongchang Roll Joint | China A.K.Jain & Brothers | Kolkata

Prama Instrumentation | Navi Mumbai

Carbon Rotofluid | Ahmedabad

Teisen Fire Control | Mumbai

Herberholz Gmbh | Ennerpetal A.G.Electronics | Mumbai

Carrier Airconditioning | Kolkata Lankhorst Engineered Products | Dublin

Ceat Limited | Mumbai Gauss Magnetics | Kolkata A-1 Acid Pvt. Limited | Gujrat

Toshniwal Industries Pvt. Limited | Ajmer

Conserve Tech Systems | Pune Kilner Vacuumation Limited | Sheffield A-One Industries | Haridwar

Piper Gmbh | Schwerte

Dee Kay Gears | Mumbai 123 Ply | New Delhi

30.04.2019 Slide No.: 4

Noritake Company Limited | Nagoya

Voith Turbo Gmbh | Crailsheim PT. Sif Makmur | Jakarta

Itipack SRL | Vicenza

Ship Containers Raw Material Handling

System Chrome pre-melter AOD Converter

Mines

Railway Wagon

Scrap Yard Electric Arc Furnace

Scrap

Vendors

warehouse

warehouse Bell Annealing Furnace

Packaging Unit

warehouse

Plant

Unpack and

Warehouse

Customer quality check

warehouse at End

customer

30.04.2019 JSL CASE STUDY Slide No.: 5

MBA-2018

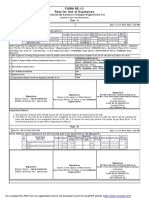

Sl. No Product Line Maximum width (MMs) Thickness (min-mm) Thickness (max-mm)

Product code Name of the items covered for inbound logistics

1 Slabs 1650 160 250

X Mild Steel Scrap, Nickel cathode, Ferro Nickel 2 Blooms 200 260 200

Low carbon Ferro chrome, Ferro silicon, Silicon manganese, 3 HR Coils 1650 2.0 12.7

Y

Molybdenum 4 HRAP Coils 1650 1.4 105

Z Dolomite lime, casting powder and chrome ore 5 CR Coils 1600 0.3 5.05

6 Plates 1650 12.7 80.15

Port Location

Plant

Product no. 1&6 Product no.2 Product no. 3&5 Product no.4

Product X Product Y Product Z

In Plant warehouse

Ferro Alloys & Fluxes

Scrap

Refractory’s

Quality Inspection Quality Quality

Container Yard SMTP route Railway siding

Fumigation Quality Inspection Inspection

Customs

Examination SMTP route Inspection Fumigation Fumigation Fumigation

Examination Lashing & Lashing Lashing Lashing

customs Customs Choking &Choking &Choking &Choking

Local Container Warehouse Warehouse Warehouse

Stuffing & cont.

Multimodal Route Freight Station

In plant siding CFS & Port CFS & Port CFS & Port

Customs

In plant siding area area area

Plant Warehouse Plant warehouse and

Plant Area gate in Vessel

Storage Area Origin Port

Storage Area Storage area

30.04.2019 Customer Warehouse Slide No.: 6

MBA-2018

Inbound value chain of JSL Outbound value chain of JSL

1-3 days 1-2 days 1-2 days 1-3 days 1-2 days 1-2 days

Supplier Ware

Shipping Lines Port Vessels Plant Shipping Lines Port Vessels

house

28-30 days 28-30 days

Plant Transport Customs Port Supplier

Transport Customs Port

warehouse

1-3 days 1-2 days 1-2days 1-3 days 1-2 days 1-2days

Timings Total Transit Time Timings Total Transit Time

Sl. no. Inbound Activities (No. of days) (in days) Sl. no. Outbound Activities (No. of days) (in days)

Loading at shippers warehouse (depending

1 upon the nature of cargo) 1 to 3 3 1 Packing and Lashing at Plant Warehouse 1 to 3 3

Shifting the cargo from warehouse to shipping Cargo gets handed over to agent of

2 line yard/truck/railway and warehouse agency 1 to 2 2 shipping/truck/railway company for advance

3 Loading into vessel/ truck/railway 1 to 2 2 2 boking 1 to 2 2

Voyage transit time to Indian Port/ state 3 Loading of cargo into vessel/truck/railway wagon. 1 to 2 2

4 boundaries etc. 28 to 30 30 4 Voyage time to destination port/state. 28 to 30 30

5 Documentation and customs clearances 1 to 2 2 5 Custom clearances and payment of taxes 1 to 2 2

Transportation of material from port to plant by

6 rail /road or through multimodal route yards. 1 to 2 2 6 Transportation of cargo to warehouses 1 to 2 2

Shifting of material from store to plant for

7 production 1 to 3 3 7 Shippers site and warehouses 1 to 3 3

The value chain mapping indicates the material flow starting from shipper‘s Outbound logistics of company A is very challenging since the products are

warehouse to the steel manufacturing plant in India. in different sizes in nature and required specific packing as per the

requirement of overseas customer.

30.04.2019 JSL CASE STUDY Slide No.: 7

MBA-2018

Information IT Capabilities

Interchange Suppliers

Material

Handling method

Materials Control Logistics Lack seaworthy

Handling Storage

Truck drivers Packing

Knowledge Trailers

Air/sea Packaging

Air Shipment Lack of Business Knowledge

Dispatches Loadability Trucks High Inventory

Water mode Loose Materials Low purchase

Arrivals

In transit theft In transit pilferages

Documentation Full vessel loadings Quality loss in transit

Bill Processing Value Added

Old Technology Payment Govt. Cost for

End user Products

used Regulation Plant Location handlings

Storage for prime

metals

Plant Scrap Yards

Poor Handling For lime &

Non-skilled labors Manual handling

LEGENDS

Issues pertaining to Logistics is found using SAP (Actor, Situation and Process) methodology

Result

SAP helped to understand the implications of the issues resulted out of situation, process Actor

or the acting agency as depicted in the above diagram. Situation

Inefficiency in any of these 3 elements paves way to increased logistics cost. Process

30.04.2019 JSL CASE STUDY Slide No.: 8

PREVIOUS

Creation of new service Centre facilities in Gurgaon, Mumbai, Vadodara and Chennai

SERVICE & for better last mile logistic and reduction of ware house cost due to economy of scale

WAREHOUSE in transportation.

LOCATIONS

Set up of warehouses in Hyderabad and Kolkata that look after the regional markets

and a retail outlet for off-the-shelf products has also been set up in Mumbai.

By incorporating new service centres the overall capacity of our processing lines i.e.

Slitting, Cut-to-Length and Polishing lines across the domestic network are 290,000,

160,000 & 10,000 tons per annum respectively.

The strategic location of all the service centres is catering to the scattered stainless-

steel requirement of India. JSSL’s distribution services meet specific requirements of

PRESENT

SERVICE & customers effectively and efficiently.

WAREHOUSE

LOCATIONS

Apart from this, the company also has a series of satellite marketing offices in all the

major cities of India.

30.04.2019 JSL CASE STUDY Slide No.: 9

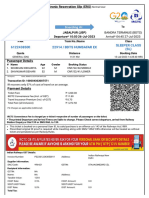

JSL depends on Vishakhapatnam port for containerized movement of both Imports and Exports which is at a distance of around

500km as container handling facilities do not exist at both ports Paradip and Dhamara closer to the Plant. So JSL should make joint

venture to create container handling facility either at Paradip, or Dhamara port. This will not only reduce logistics cost but also

turnaround time significantly for the company.

The 0.8mtpa plant is located in Odisha’s Jajpur district, which is well-connected with road and rail transportation and has proximity

to raw materials. But due to unavailability of trucks the inbound and outbound logistic is facing problem. So JSl should choose a

logistic vendor which can maintain 100% availability of trucks.

Spread over 800 acres, the plant is not constrained by space so JSL should develop raw material stock yard for easy and timely

unloading of containers and trucks for better transportation cost by avoiding detention charges.

Proper equipment should be available at plant and warehouses for material handling so that work can be completed within the

stipulated time in turn cost savings due to additional logistics can be avoided.

Paving and concreting of storage area can be carried out for the smooth bulk cargo handlings to avoid material handling losses.

Associate service provider Partner, port agency and National Highway authority should be given the freedom to implement

innovative ideas for material transport.

External factors like climatic condition, geographical and political factors of the region also to be taken into consideration pertaining

to Logistics & Supply Chain Management.

30.04.2019 JSL CASE STUDY Slide No.: 10

MBA-2018

Raw material HSM Vendor SMS Vendor CRM Vendor Logistics Process

Import Data_JSL Details Details Details Flow_JSL

SS JSL Corporate

Export-Domestic_JSL Presentation

Declaration: The data and datasheets presented in the PowerPoint presentation is used for Academic purpose only.

30.04.2019 JSL CASE STUDY Slide No.: 11

MBA-2018

30.04.2019 JSL CASE STUDY Slide No.: 11

Potrebbero piacerti anche

- Isuzu Trooper Workshop ManualDocumento3.573 pagineIsuzu Trooper Workshop Manualvit otio89% (19)

- ATJ 2A/85 (Pindaan 2019)Documento124 pagineATJ 2A/85 (Pindaan 2019)alBESTos100% (3)

- Wrong Answer SummaryDocumento4 pagineWrong Answer SummaryЕвгений Тимоновский0% (2)

- Wheel Alignment Theory Operation PDFDocumento5 pagineWheel Alignment Theory Operation PDFOskars ŠtālsNessuna valutazione finora

- GEP GameplanDocumento9 pagineGEP GameplanAkanksha TiwariNessuna valutazione finora

- Aircel Project On Market MappingDocumento40 pagineAircel Project On Market MappingAshish Kumar80% (5)

- SCM Maruti Suzuki Case Section B Group 7Documento20 pagineSCM Maruti Suzuki Case Section B Group 7ramcnarayanNessuna valutazione finora

- Mahindra Global StrategyDocumento11 pagineMahindra Global StrategyShivendra SinghNessuna valutazione finora

- Project Report On Tata SteelDocumento9 pagineProject Report On Tata SteelChander ShekharNessuna valutazione finora

- FS5A-EL 05 Transmission & TransaxleDocumento462 pagineFS5A-EL 05 Transmission & TransaxleShowdown H. Blood100% (4)

- NTTA List of Large Delinquent Toll AccountsDocumento710 pagineNTTA List of Large Delinquent Toll Accountsmlindenberger250% (2)

- JK Tyre Successful ProductDocumento15 pagineJK Tyre Successful ProductUday VoraNessuna valutazione finora

- Supply ChainDocumento13 pagineSupply ChainJobinSibyNessuna valutazione finora

- Logistics in India: Battle of Last Mile ConnectivityDocumento4 pagineLogistics in India: Battle of Last Mile ConnectivitysharmapoonamNessuna valutazione finora

- MahindraDocumento23 pagineMahindraPulkit GuptaNessuna valutazione finora

- Glass Industry in IndiaDocumento1 paginaGlass Industry in IndiaTANISHQ KATHOTIA0% (1)

- Titan IndustryDocumento13 pagineTitan IndustryVeera KumarNessuna valutazione finora

- Mahindra LogisticsDocumento21 pagineMahindra LogisticsSaksham SharmaNessuna valutazione finora

- 355 Tata Structura Brochure PDFDocumento13 pagine355 Tata Structura Brochure PDFAbhi JainNessuna valutazione finora

- Tata Steel Product, Process, SCM, HRM, InVENTORYDocumento35 pagineTata Steel Product, Process, SCM, HRM, InVENTORYvivid150% (2)

- M&M Case StudyDocumento24 pagineM&M Case StudyPrasanthviswanathanNessuna valutazione finora

- JK Tyre Sales Promotion (Repaired)Documento42 pagineJK Tyre Sales Promotion (Repaired)VinodDubeyNessuna valutazione finora

- JSW Steel - Investor Presentation - Feb 2017Documento44 pagineJSW Steel - Investor Presentation - Feb 2017Suraj SipaniNessuna valutazione finora

- Tata Consultancy ServicesDocumento5 pagineTata Consultancy ServicesNithin NallusamyNessuna valutazione finora

- Mahindra LogisticDocumento23 pagineMahindra LogisticJayant Vardhan100% (2)

- Company AnalysisDocumento9 pagineCompany AnalysisNaveen KumarNessuna valutazione finora

- Automotive Sector Trucks Business Caselet: Submitted By: Team Name: 4eggs Campus Name: IMT GhaziabadDocumento22 pagineAutomotive Sector Trucks Business Caselet: Submitted By: Team Name: 4eggs Campus Name: IMT GhaziabadRavi DhingraNessuna valutazione finora

- JSWSteel Limited ProjectDocumento16 pagineJSWSteel Limited ProjectSakshiNessuna valutazione finora

- Assignment On "AUTOMOBILE SECTOR OF ECONOMY"Documento7 pagineAssignment On "AUTOMOBILE SECTOR OF ECONOMY"salil12356Nessuna valutazione finora

- Tata Motors's AchivementsDocumento105 pagineTata Motors's AchivementsSunny SinghNessuna valutazione finora

- Iim Calcutta - Job Description Form: Name of The FirmDocumento2 pagineIim Calcutta - Job Description Form: Name of The FirmHimanshuNessuna valutazione finora

- Sagar Internship Report of Operation ExcellencyDocumento56 pagineSagar Internship Report of Operation ExcellencyJyoti Pathak FnEqfAISerNessuna valutazione finora

- Steel Industry in IndiaDocumento23 pagineSteel Industry in IndiaAnna KruglovaNessuna valutazione finora

- Sbra Full Risk PPT (Final)Documento20 pagineSbra Full Risk PPT (Final)Rishabh TyagiNessuna valutazione finora

- Logistic and SCM in MahindraDocumento59 pagineLogistic and SCM in MahindraKinjal KunjaNessuna valutazione finora

- Maruti Suzuki India Ltd. (MSIL) : History and LegacyDocumento27 pagineMaruti Suzuki India Ltd. (MSIL) : History and Legacykuldeep singhNessuna valutazione finora

- JSW Vs TSBSL - FinalDocumento22 pagineJSW Vs TSBSL - FinalAnita ChhawchariaNessuna valutazione finora

- COMPANY PROFILE Transport Corporation of India IsDocumento8 pagineCOMPANY PROFILE Transport Corporation of India Isuupriyam100% (1)

- Logistics India 2017Documento12 pagineLogistics India 2017Tosif MirNessuna valutazione finora

- Logistic D53Documento8 pagineLogistic D53Rahul SeleriNessuna valutazione finora

- Just in Time and Total Quality Management - Synergistic Processes - An OverviewDocumento19 pagineJust in Time and Total Quality Management - Synergistic Processes - An OverviewAmol ZarkarNessuna valutazione finora

- Manorama IndustriesDocumento35 pagineManorama IndustriesManas BaghNessuna valutazione finora

- Microeconomics Group ProjectDocumento5 pagineMicroeconomics Group ProjectNeel NarsinghaniNessuna valutazione finora

- Vedanta Resources Plc.Documento33 pagineVedanta Resources Plc.Abhay Pratap SinghNessuna valutazione finora

- Apollo Tyres PPT FinalDocumento17 pagineApollo Tyres PPT FinalGeena Mary GeorgeNessuna valutazione finora

- Vision Mission Values - Hindalco CSRDocumento5 pagineVision Mission Values - Hindalco CSRjojujohny100% (1)

- Industries in IndiaDocumento13 pagineIndustries in IndiaArvind RanganathanNessuna valutazione finora

- Tentative Ownership Cost Calculator (EV V/S ICE Vehicles) For Home ChargingDocumento4 pagineTentative Ownership Cost Calculator (EV V/S ICE Vehicles) For Home ChargingjitendraNessuna valutazione finora

- Supreme Corp Presentation May 2020Documento41 pagineSupreme Corp Presentation May 2020sherwinmitraNessuna valutazione finora

- Cox and KingsDocumento14 pagineCox and KingsSagar SawalkarNessuna valutazione finora

- SCM - MarutiDocumento20 pagineSCM - MarutiShorya Gupta50% (2)

- Supply Chain Management - MSILDocumento15 pagineSupply Chain Management - MSILGajananNessuna valutazione finora

- GEP GamEPlan2017 CaseDocumento6 pagineGEP GamEPlan2017 CaseVaibhavNessuna valutazione finora

- Key Players in IT IndustryDocumento6 pagineKey Players in IT IndustryprasannaNessuna valutazione finora

- Tyre Indusrty - 5 ForcesDocumento3 pagineTyre Indusrty - 5 ForcesRini RafiNessuna valutazione finora

- Jindal Steel ReportDocumento19 pagineJindal Steel ReportAshish AroraNessuna valutazione finora

- Yard Management System: Automation Division Tata Steel Ltd. CII Steel Summit, Delhi On 4 November, 2009Documento31 pagineYard Management System: Automation Division Tata Steel Ltd. CII Steel Summit, Delhi On 4 November, 2009Vinay KumarNessuna valutazione finora

- Supply Chain of HUL and Parle GDocumento20 pagineSupply Chain of HUL and Parle GMaitraya100% (1)

- Mis of Reliance IndustriesDocumento22 pagineMis of Reliance Industriessidhant sangle0% (1)

- MAHINDRA & MAHINDRA... FinalDocumento32 pagineMAHINDRA & MAHINDRA... FinalHIMANSHU RAWAT100% (1)

- P3 - InventoryControlDocumento43 pagineP3 - InventoryControlamirah khansaNessuna valutazione finora

- EtopDocumento7 pagineEtopAnilBahugunaNessuna valutazione finora

- Outline: Understanding The Supply ChainDocumento8 pagineOutline: Understanding The Supply ChainAditya PawarNessuna valutazione finora

- 2019 - Indian Logistics and Warehousing-Tracing The LifecycleDocumento27 pagine2019 - Indian Logistics and Warehousing-Tracing The LifecycleShikhar Srivastava100% (1)

- Supply Chain Management in Small and Medium-Sized EnterprisesDocumento7 pagineSupply Chain Management in Small and Medium-Sized EnterprisesOmiin Del la GeorgeNessuna valutazione finora

- Analyzing The Effect of Supply Chain Strategies and Collaboration On Performance Improvement Using MIMIC ModelDocumento10 pagineAnalyzing The Effect of Supply Chain Strategies and Collaboration On Performance Improvement Using MIMIC ModelSiwaporn KunnapapdeelertNessuna valutazione finora

- SBI PankajDocumento2 pagineSBI PankajPANKAJNessuna valutazione finora

- The Evolution of CIDocumento1 paginaThe Evolution of CIPANKAJNessuna valutazione finora

- Pooja PahwaUpdatedDocumento4 paginePooja PahwaUpdatedPANKAJNessuna valutazione finora

- Pooja PahwaUpdatedDocumento4 paginePooja PahwaUpdatedPANKAJNessuna valutazione finora

- Ethics Group - 3Documento13 pagineEthics Group - 3PANKAJNessuna valutazione finora

- Lean VSM CaseDocumento26 pagineLean VSM CasePANKAJNessuna valutazione finora

- Session 1Documento27 pagineSession 1PANKAJNessuna valutazione finora

- Assignment 2Documento13 pagineAssignment 2PANKAJNessuna valutazione finora

- Network Analysis by Group#12 (Comments) - MayankDocumento10 pagineNetwork Analysis by Group#12 (Comments) - MayankPANKAJNessuna valutazione finora

- Network Analysis by Group#12Documento9 pagineNetwork Analysis by Group#12PANKAJNessuna valutazione finora

- Pest & SwotDocumento7 paginePest & SwotPANKAJNessuna valutazione finora

- My Incomplete Transporttion ProblemDocumento3 pagineMy Incomplete Transporttion ProblemPANKAJNessuna valutazione finora

- Data AnalyticsDocumento10 pagineData AnalyticsPANKAJNessuna valutazione finora

- Learning Outcome From The Social Media Analytics Course: Detail DiscussionDocumento3 pagineLearning Outcome From The Social Media Analytics Course: Detail DiscussionPANKAJNessuna valutazione finora

- Digital Marketing Presentation - DraftDocumento24 pagineDigital Marketing Presentation - DraftPANKAJNessuna valutazione finora

- Group Project - Digital MarketingDocumento1 paginaGroup Project - Digital MarketingPANKAJNessuna valutazione finora

- Topic For Network Analysis: Green Crackers: 1.summary of Steps PerformedDocumento7 pagineTopic For Network Analysis: Green Crackers: 1.summary of Steps PerformedPANKAJNessuna valutazione finora

- Inventory MGMNT AccountsDocumento23 pagineInventory MGMNT AccountsTrinath OjhaNessuna valutazione finora

- My ERMDocumento22 pagineMy ERMPANKAJNessuna valutazione finora

- Group 3 - Morgan StanleyDocumento14 pagineGroup 3 - Morgan StanleyPANKAJNessuna valutazione finora

- Digital Marketing (Prof. Janardhan Krishna)Documento8 pagineDigital Marketing (Prof. Janardhan Krishna)Bahar RoyNessuna valutazione finora

- Internet of Things - Digital Marketing ReportDocumento7 pagineInternet of Things - Digital Marketing ReportPANKAJNessuna valutazione finora

- Additional Assignment - Digital MarketingDocumento1 paginaAdditional Assignment - Digital MarketingPANKAJNessuna valutazione finora

- Final Bidding Courses1234Documento1 paginaFinal Bidding Courses1234PANKAJNessuna valutazione finora

- CBS-Manual July 2019Documento8 pagineCBS-Manual July 2019PANKAJNessuna valutazione finora

- Data Analytics (Prof. Sumedha Chauhan)Documento6 pagineData Analytics (Prof. Sumedha Chauhan)PANKAJNessuna valutazione finora

- Elective Time Table (CR-54)Documento1 paginaElective Time Table (CR-54)PANKAJNessuna valutazione finora

- Elective Time Table (CR-66)Documento1 paginaElective Time Table (CR-66)PANKAJNessuna valutazione finora

- End Term Examination Schedule Fall 2019Documento8 pagineEnd Term Examination Schedule Fall 2019PANKAJNessuna valutazione finora

- Scope of Digital MarketingDocumento16 pagineScope of Digital MarketingPANKAJNessuna valutazione finora

- History of Skid RowDocumento17 pagineHistory of Skid RowkatherinetreesNessuna valutazione finora

- Worksheet Titanic Python PDFDocumento8 pagineWorksheet Titanic Python PDFrashmimehNessuna valutazione finora

- Traffic IslandsDocumento6 pagineTraffic IslandsQayes Al-Quqa100% (2)

- PESO Online Explosives-Returns SystemDocumento1 paginaPESO Online Explosives-Returns Systemgirinandini0% (1)

- Rigging and Slinging TechniquesDocumento15 pagineRigging and Slinging TechniquesShiraz Najat100% (2)

- Ata OxygenDocumento4 pagineAta OxygenGregor NettersheimNessuna valutazione finora

- Ballast Water Discharges in Denmark: Kristina Kern Frank Stuer-LauridsenDocumento48 pagineBallast Water Discharges in Denmark: Kristina Kern Frank Stuer-LauridsenChoirull RizalNessuna valutazione finora

- Oil and Gas IndustryDocumento6 pagineOil and Gas IndustryLuqman HadiNessuna valutazione finora

- Mtoe User GuideDocumento28 pagineMtoe User GuidepravinNessuna valutazione finora

- Korea Shooting Guide-EnglishDocumento54 pagineKorea Shooting Guide-EnglishFabiana Fabian100% (1)

- SAC8000T7原理图Documento72 pagineSAC8000T7原理图79wzmy5fpwNessuna valutazione finora

- Csir - Ugc Net Syllabus - Life Sciences (LS) : 1. Molecules and Their Interaction Relavent To BiologyDocumento8 pagineCsir - Ugc Net Syllabus - Life Sciences (LS) : 1. Molecules and Their Interaction Relavent To BiologyEr Purushottam PalNessuna valutazione finora

- 1961 1 EngDocumento15 pagine1961 1 EngTateNessuna valutazione finora

- Automatic Train Protection - Wikipedia, The Free EncyclopediaDocumento4 pagineAutomatic Train Protection - Wikipedia, The Free EncyclopediasaospieNessuna valutazione finora

- The Primary Advantages of Using Shipping Container PoolsDocumento2 pagineThe Primary Advantages of Using Shipping Container PoolsSeacon PoolsNessuna valutazione finora

- AP-T200-12 Bridge Design Guidelines For EQDocumento133 pagineAP-T200-12 Bridge Design Guidelines For EQRasiduzzaman RashidNessuna valutazione finora

- KingAir200 Cockpit LayoutDocumento1 paginaKingAir200 Cockpit LayoutRicardo Barros LeãoNessuna valutazione finora

- Maritime Logistics AND Documentation: Alagappa UniversityDocumento200 pagineMaritime Logistics AND Documentation: Alagappa UniversitySourav KollambiNessuna valutazione finora

- Can Love Happen TwiceDocumento4 pagineCan Love Happen TwiceDivya Sekhar60% (5)

- Pace Bus Schedule 422Documento2 paginePace Bus Schedule 422drjohnckim100% (1)

- Prathmesh PPT NewDocumento16 paginePrathmesh PPT NewPrathamesh GawliNessuna valutazione finora

- Manitou MLT 735 (EN)Documento20 pagineManitou MLT 735 (EN)ManitouNessuna valutazione finora

- Iit BombayDocumento3 pagineIit BombayAakanksha ParasharNessuna valutazione finora

- Apollo Experience Report Launch Escape Propulsion SubsystemDocumento29 pagineApollo Experience Report Launch Escape Propulsion SubsystemBob AndrepontNessuna valutazione finora